Growth by the μ-PD Method and Visible Laser Operation of a Single-Crystal Fiber of Pr3+:KY3F10

Abstract

:1. Introduction

2. Materials and Methods

2.1. Crystal Structure and Growth

2.2. Structural Characterization

2.3. Spectroscopy

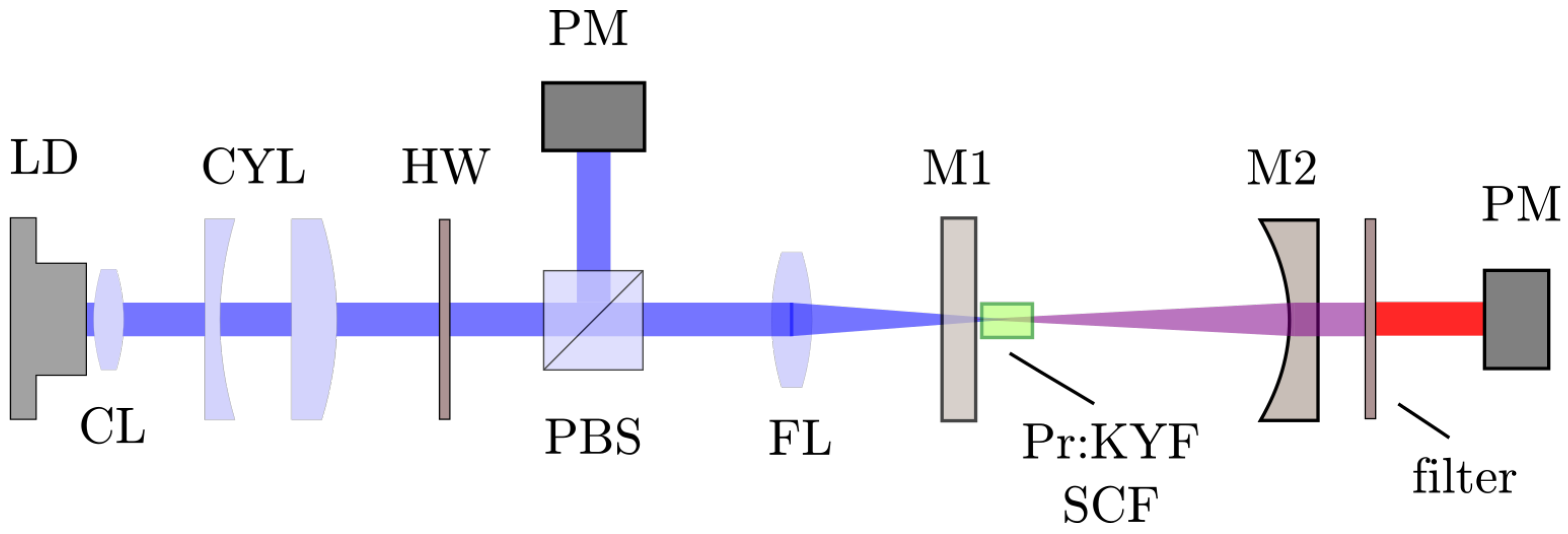

2.4. Laser

3. Results

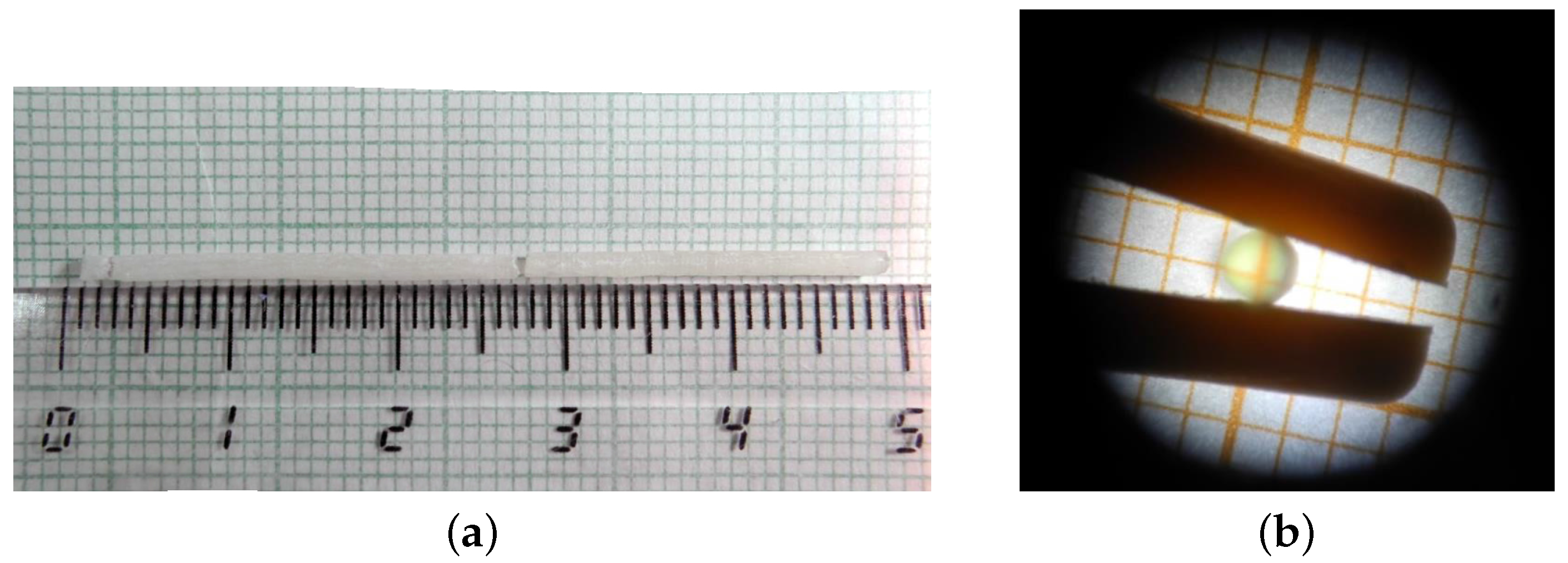

3.1. Structural Characterization

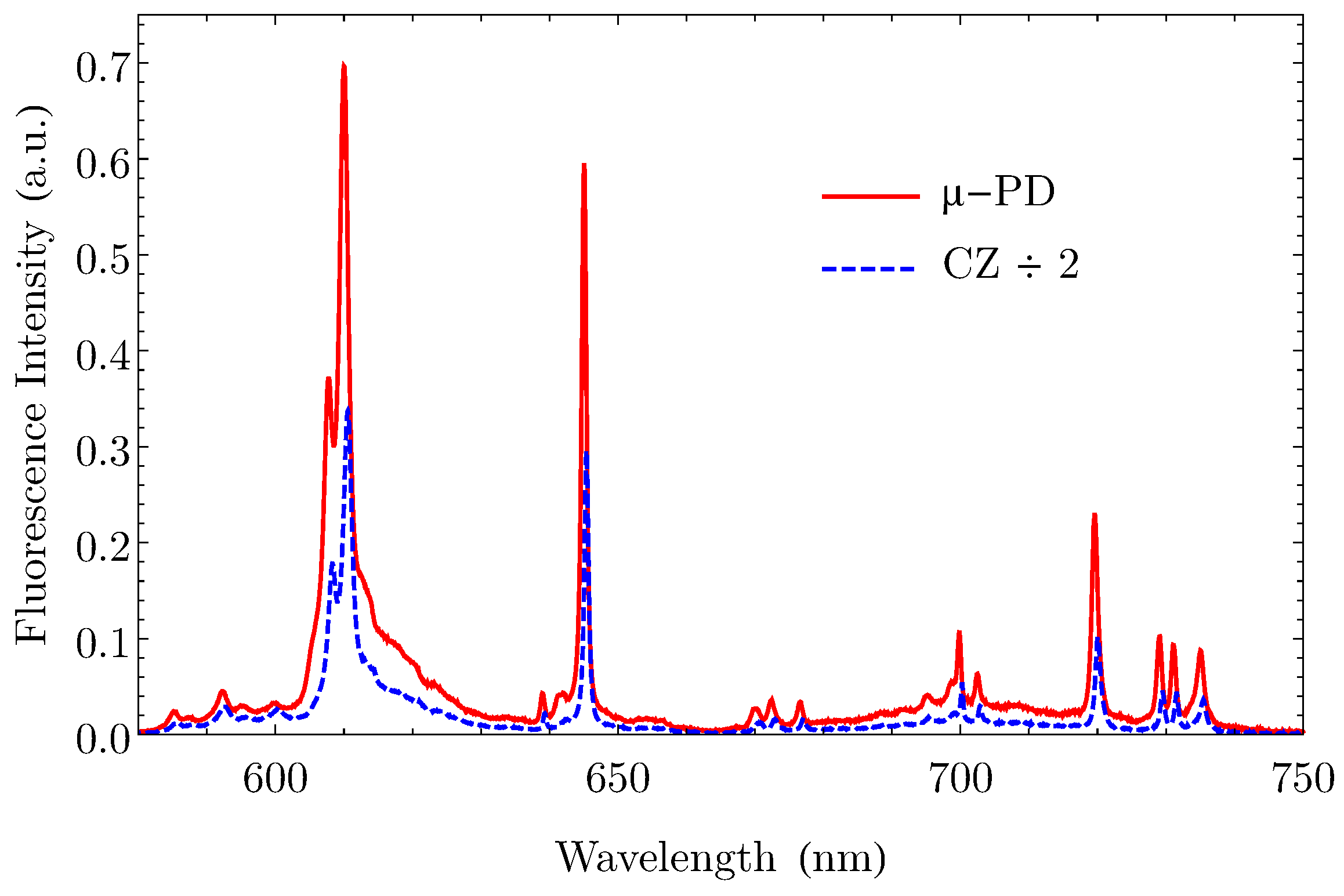

3.2. Spectroscopy

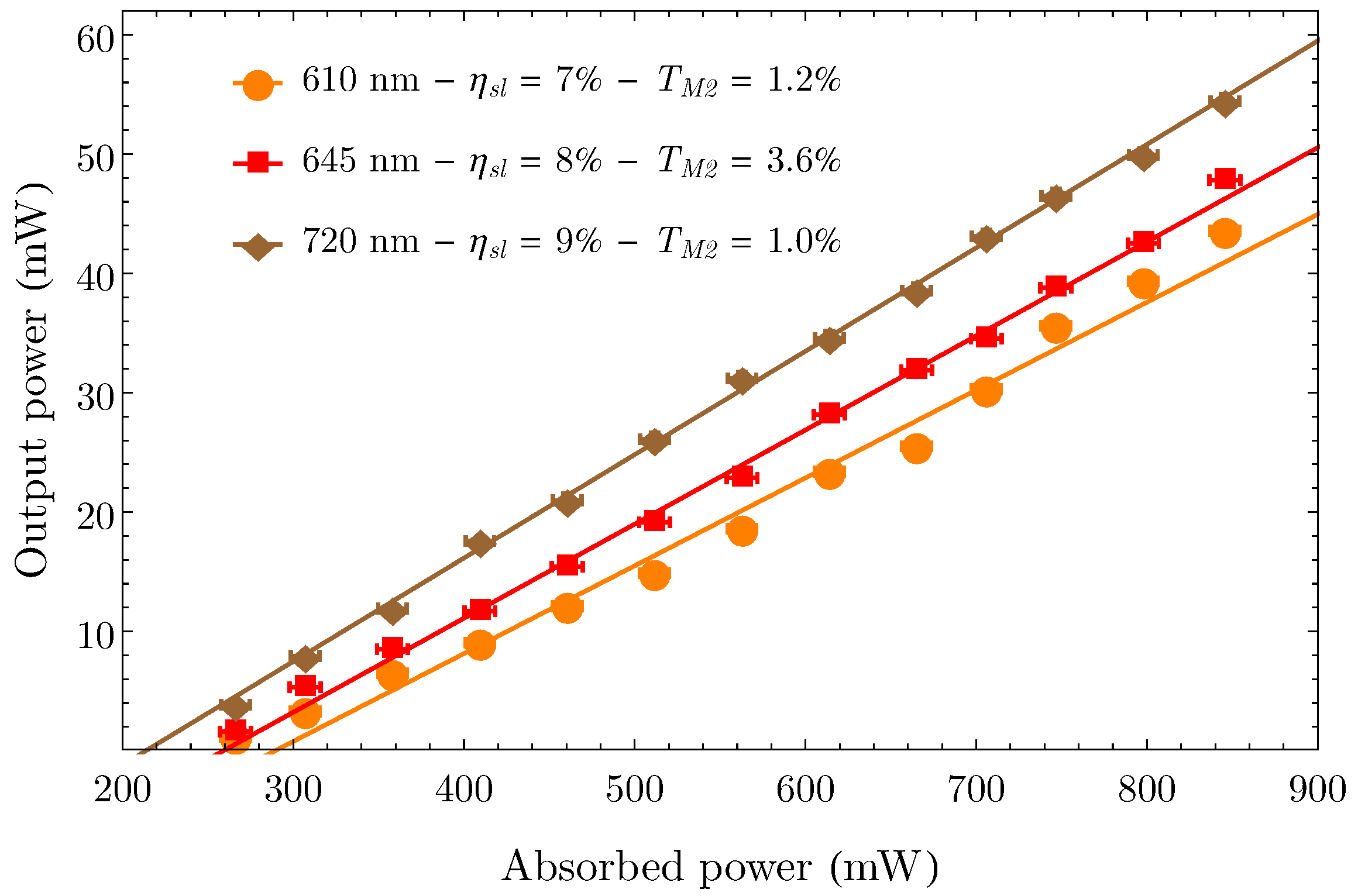

3.3. Laser Experiments

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| SCF | Single-crystal fiber |

| KYF | Potassium triyttrium decafluoride (KY3F10) |

| CZ | Czochralski |

| μ-PD | Micro-pulling-down |

| CW | Continuous-wave |

References

- Smart, R.; Carter, J.; Tropper, A.; Hanna, D.; Davey, S.; Carter, S.; Szebesta, D. CW room temperature operation of praseodymium-doped fluorozirconate glass fibre lasers in the blue-green, green and red spectral regions. Opt. Commun. 1991, 86, 333–340. [Google Scholar] [CrossRef]

- Sandrock, T.; Danger, T.; Heumann, E.; Huber, G.; Chai, B. Efficient continuous wave-laser emission of Pr3+-doped fluorides at room temperature. Appl. Phys. B 1994, 58, 149–151. [Google Scholar] [CrossRef]

- Kränkel, C.; Marzahl, D.T.; Moglia, F.; Huber, G.; Metz, P.W. Out of the blue: Semiconductor laser pumped visible rare-earth doped lasers. Laser Photon. Rev. 2016, 10, 548–568. [Google Scholar] [CrossRef]

- Sottile, A.; Damiano, E.; Tonelli, M. Diode-pumped laser operation of Pr3+:Ba(Y0.8Lu0.2)2F8 in the visible region. Opt. Lett. 2016, 41, 5555–5558. [Google Scholar] [CrossRef] [PubMed]

- Hegarty, J.; Huber, D.L.; Yen, W.M. Fluorescence quenching by cross relaxation in LaF3:Pr3+. Phys. Rev. B 1982, 25, 5638–5645. [Google Scholar] [CrossRef]

- Parisi, D.; Veronesi, S.; Tonelli, M. Method for Forming Bulk Crystals, in Particular Monocrystals of Fluorides Doped with Rare-Earth Ions. U.S. Patent 20120260846, 18 October 2012. [Google Scholar]

- Schellhorn, M.; Parisi, D.; Eichhorn, M.; Tonelli, M. Continuous-wave and Q-switched operation of a resonantly pumped Ho3+:KY3F10 laser. Opt. Lett. 2014, 39, 1193–1196. [Google Scholar] [CrossRef] [PubMed]

- Metz, P.W.; Müller, S.; Reichert, F.; Marzahl, D.T.; Moglia, F.; Kränkel, C.; Huber, G. Wide wavelength tunability and green laser operation of diode-pumped Pr3+:KY3F10. Opt. Express 2013, 21, 31274–31281. [Google Scholar] [CrossRef] [PubMed]

- Sottile, A.; Metz, P.W. Deep red diode-pumped Pr3+:KY3F10 continuous-wave laser. Opt. Lett. 2015, 40, 1992–1995. [Google Scholar] [CrossRef] [PubMed]

- Yoshikawa, A.; Chani, V. Growth of Optical Crystals by the Micro-Pulling-Down Method. MRS Bull. 2009, 34, 266–270. [Google Scholar] [CrossRef]

- Fukuda, T.; Chani, V. Shaped Crystals: Growth by Micro-Pulling-Down Technique; Advances in Materials Research; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Sottile, A.; Zhang, Z.; Veronesi, S.; Parisi, D.; Lieto, A.D.; Tonelli, M. Visible laser operation in a Pr3+:LiLuF4 monocrystalline fiber grown by the micro-pulling-down method. Opt. Mater. Express 2016, 6, 1964–1972. [Google Scholar] [CrossRef]

- Damiano, E.; Shu, J.; Sottile, A.; Tonelli, M. Spectroscopy and visible laser operations of a μ-PD grown Pr3+:LiYF4 single-crystal fiber. J. Phys. D Appl. Phys. 2017, 50, 135107. [Google Scholar] [CrossRef]

- McMillen, C.D.; Comer, S.; Fulle, K.; Sanjeewa, L.D.; Kolis, J.W. Crystal chemistry of hydrothermally grown ternary alkali rare earth fluorides. Acta Cryst. 2015, 71, 768–776. [Google Scholar] [CrossRef] [PubMed]

- Wells, J.P.R.; Yamaga, M.; Han, T.P.J.; Gallagher, H.G. Infrared absorption, laser excitation and crystal-field analyses of the C4v symmetry centre in KY3F10 doped with Pr3+. J. Phys. Condens. Matter 2000, 12, 5297. [Google Scholar] [CrossRef]

- Nehari, A.; Duffar, T.; Ghezal, E.; Lebbou, K. Chemical Segregation of Titanium in Sapphire Single Crystals Grown by Micro-Pulling-Down Technique: Analytical Model and Experiments. Cryst. Growth Des. 2014, 14, 6492–6496. [Google Scholar] [CrossRef]

- Veronesi, S.; Zhang, Y.; Tonelli, M.; Schellhorn, M. Efficient laser emission in Ho3+:LiLuF4 grown by micro-Pulling Down method. Opt. Express 2012, 20, 18723–18731. [Google Scholar] [CrossRef] [PubMed]

- Camy, P.; Doualan, J.L.; Moncorgé, R.; Bengoechea, J.; Weichmann, U. Diode-pumped Pr3+:KY3F10 red laser. Opt. Lett. 2007, 32, 1462–1464. [Google Scholar] [CrossRef] [PubMed]

- Findlay, D.; Clay, R.A. The measurement of internal losses in 4-level lasers. Phys. Lett. 1966, 20, 277–278. [Google Scholar] [CrossRef]

- Caird, J.A.; Payne, S.A.; Staber, P.R.; Ramponi, A.J.; Chase, L.L.; Krupke, W.F. Quantum electronic properties of the Na3Ga2Li3F12:Cr3+ laser. IEEE J. Quant. Electron. 1988, 24, 1077–1099. [Google Scholar] [CrossRef]

- Xu, B.; Camy, P.; Doualan, J.L.; Cai, Z.; Moncorgé, R. Visible laser operation of Pr3+-doped fluoride crystals pumped by a 469 nm blue laser. Opt. Express 2011, 19, 1191–1197. [Google Scholar] [CrossRef] [PubMed]

- Metz, P.W.; Calmano, T.; Marzahl, D.T.; Kraenkel, C.; Huber, G. Polarization Effects in Pr3+-Doped Cubic KY3F10 and Stable Dual Wavelength Lasing. In Advanced Solid State Lasers; Optical Society of America: Washington, DC, USA, 2015; p. ATu1A.3. [Google Scholar]

| T | P | P | ||

|---|---|---|---|---|

| 610 nm | 1.2% | 7% | 204 mW | 43 mW |

| 645 nm | 0.5% | 3% | 128 mW | 17 mW |

| 1.8% | 6% | 134 mW | 39 mW | |

| 3.6% | 8% | 171 mW | 47 mW | |

| 720 nm | 1.0% | 9% | 186 mW | 54 mW |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shu, J.; Damiano, E.; Sottile, A.; Zhang, Z.; Tonelli, M. Growth by the μ-PD Method and Visible Laser Operation of a Single-Crystal Fiber of Pr3+:KY3F10. Crystals 2017, 7, 200. https://doi.org/10.3390/cryst7070200

Shu J, Damiano E, Sottile A, Zhang Z, Tonelli M. Growth by the μ-PD Method and Visible Laser Operation of a Single-Crystal Fiber of Pr3+:KY3F10. Crystals. 2017; 7(7):200. https://doi.org/10.3390/cryst7070200

Chicago/Turabian StyleShu, Jun, Eugenio Damiano, Alberto Sottile, Zhonghan Zhang, and Mauro Tonelli. 2017. "Growth by the μ-PD Method and Visible Laser Operation of a Single-Crystal Fiber of Pr3+:KY3F10" Crystals 7, no. 7: 200. https://doi.org/10.3390/cryst7070200