Organization of Twisting Lamellar Crystals in Birefringent Banded Polymer Spherulites: A Mini-Review

Abstract

:1. Evidence of Lamellar Twisting in Banded Polymer Spherulites

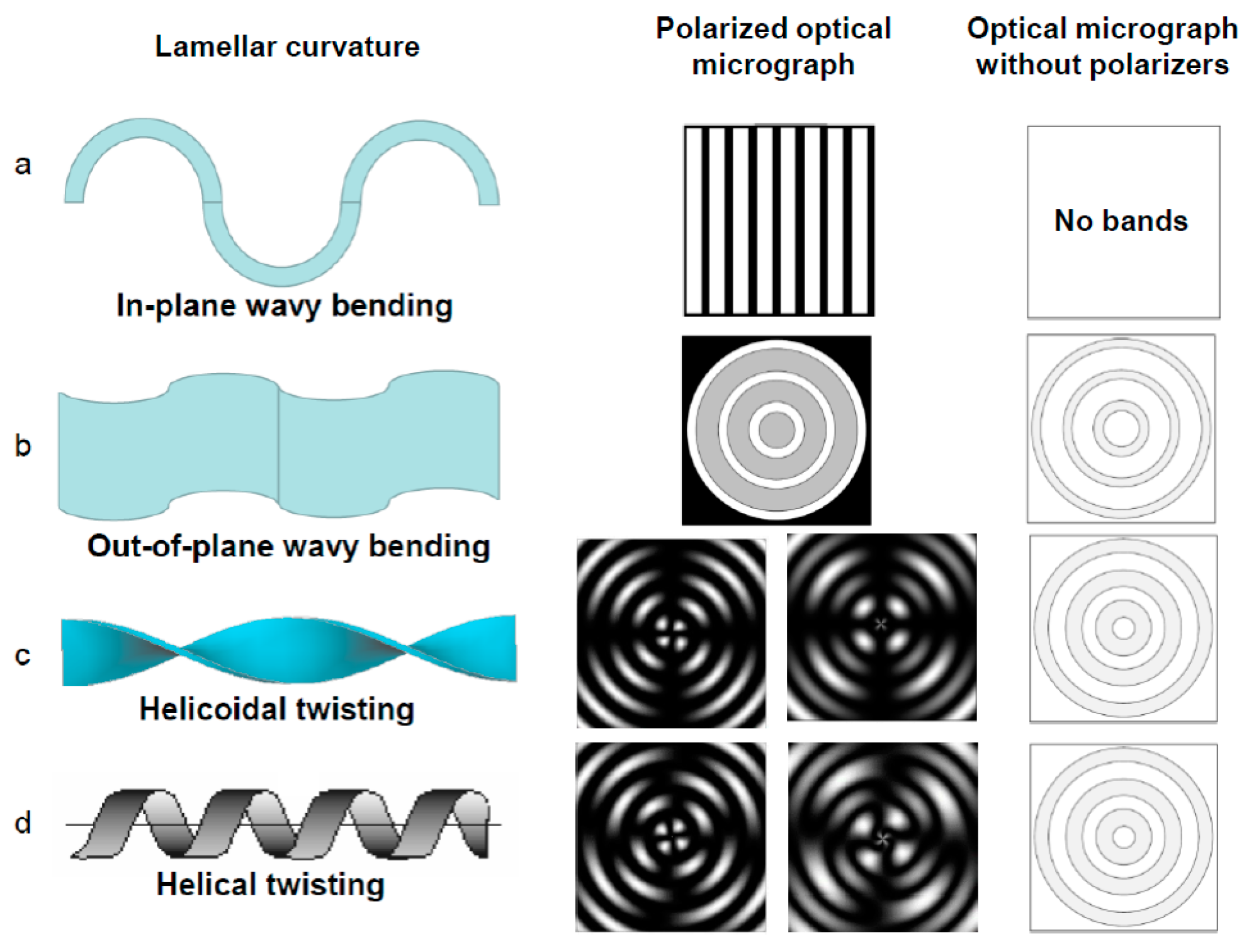

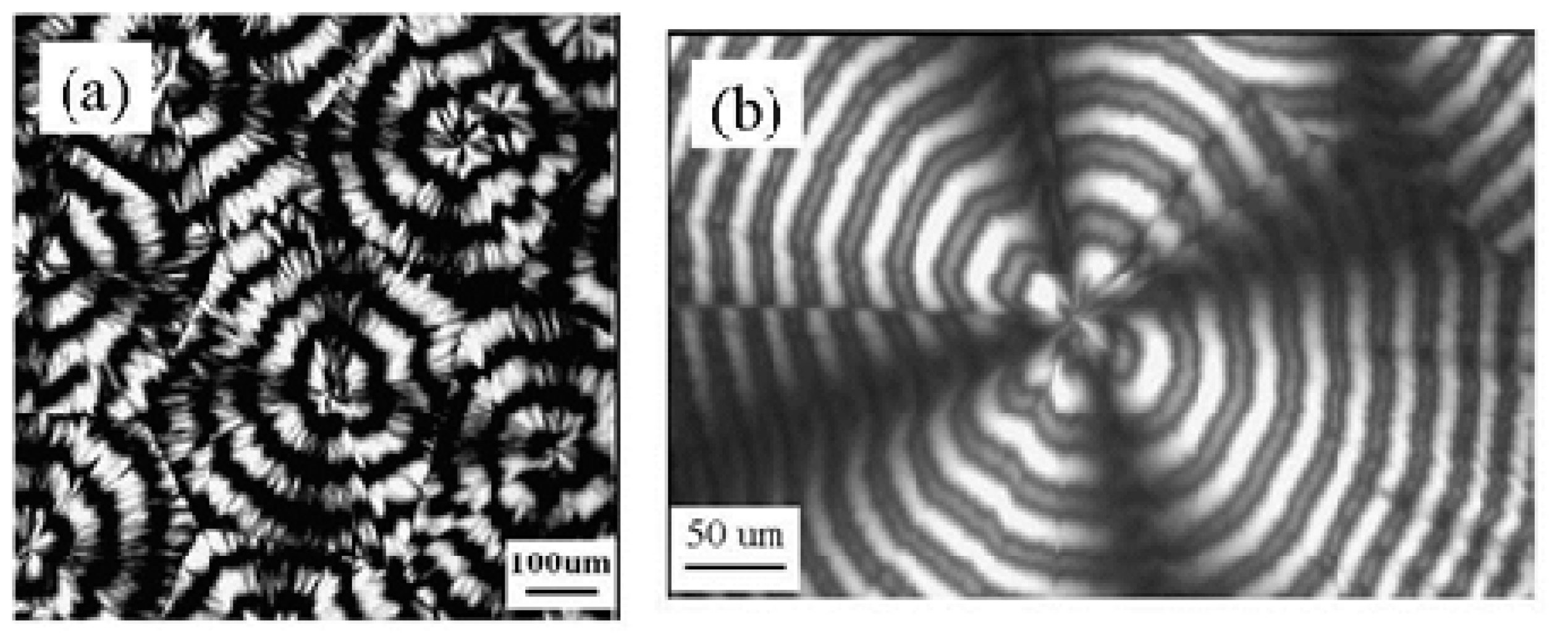

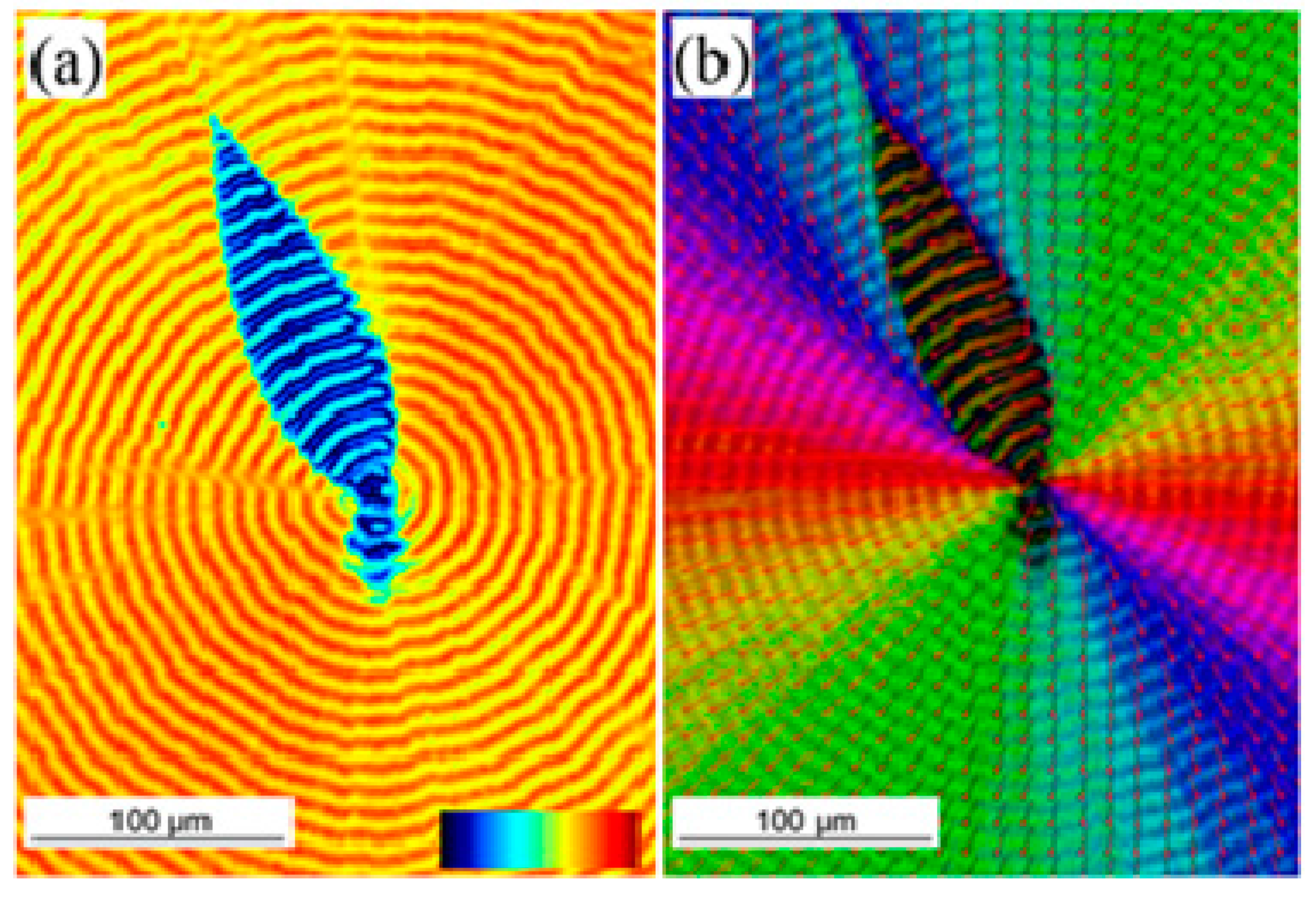

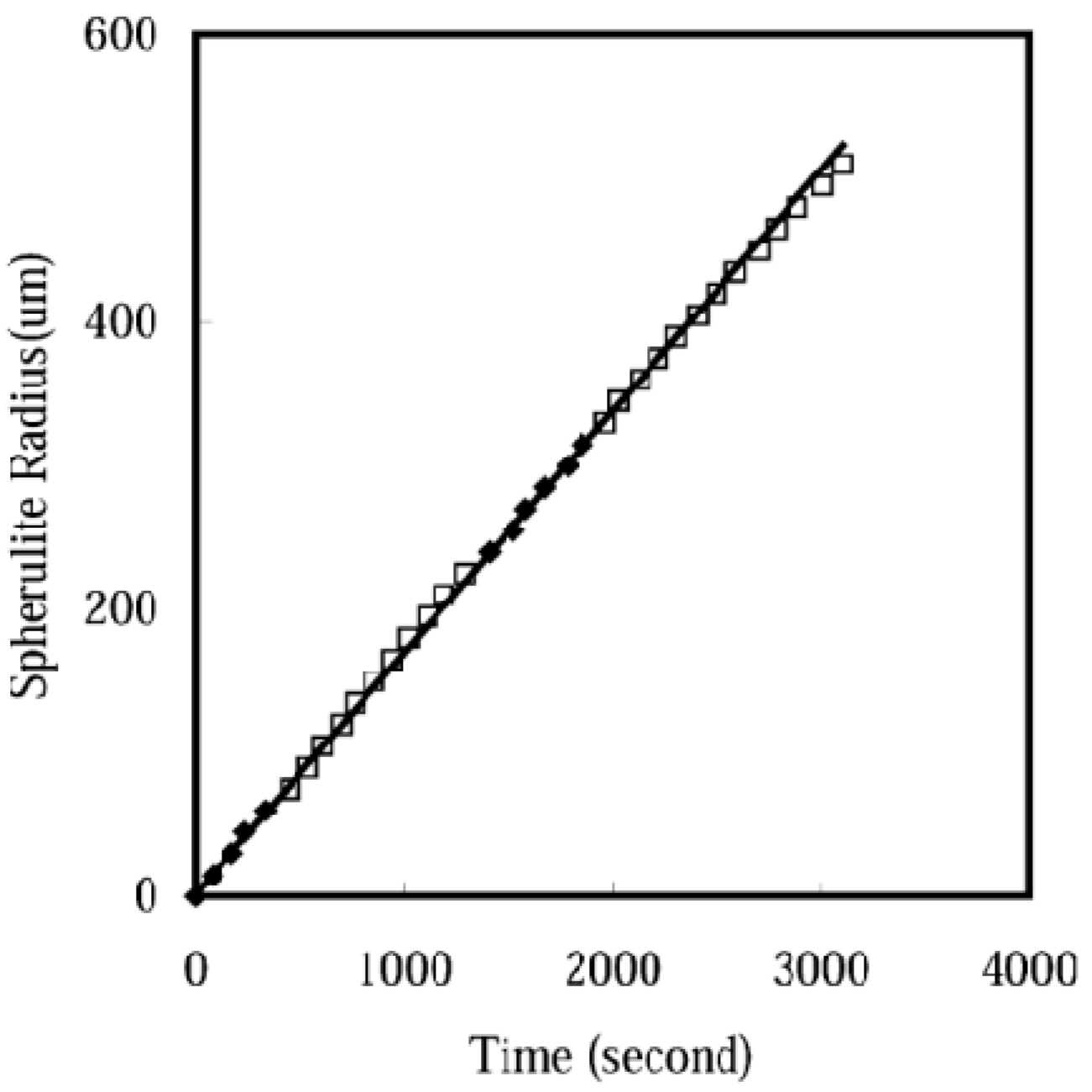

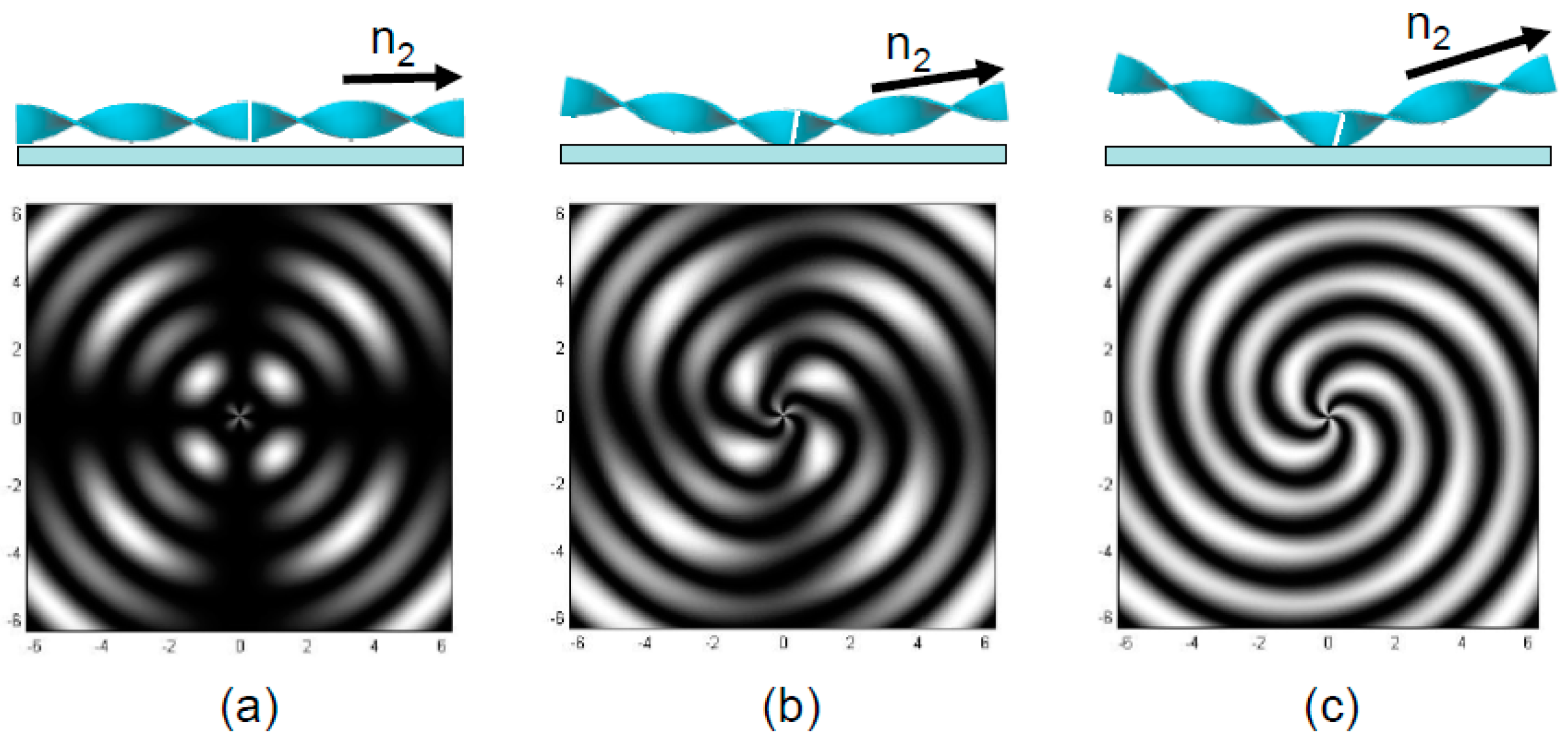

1.1. Observation of Banded Spherulites via Polarized Optical Microscopy

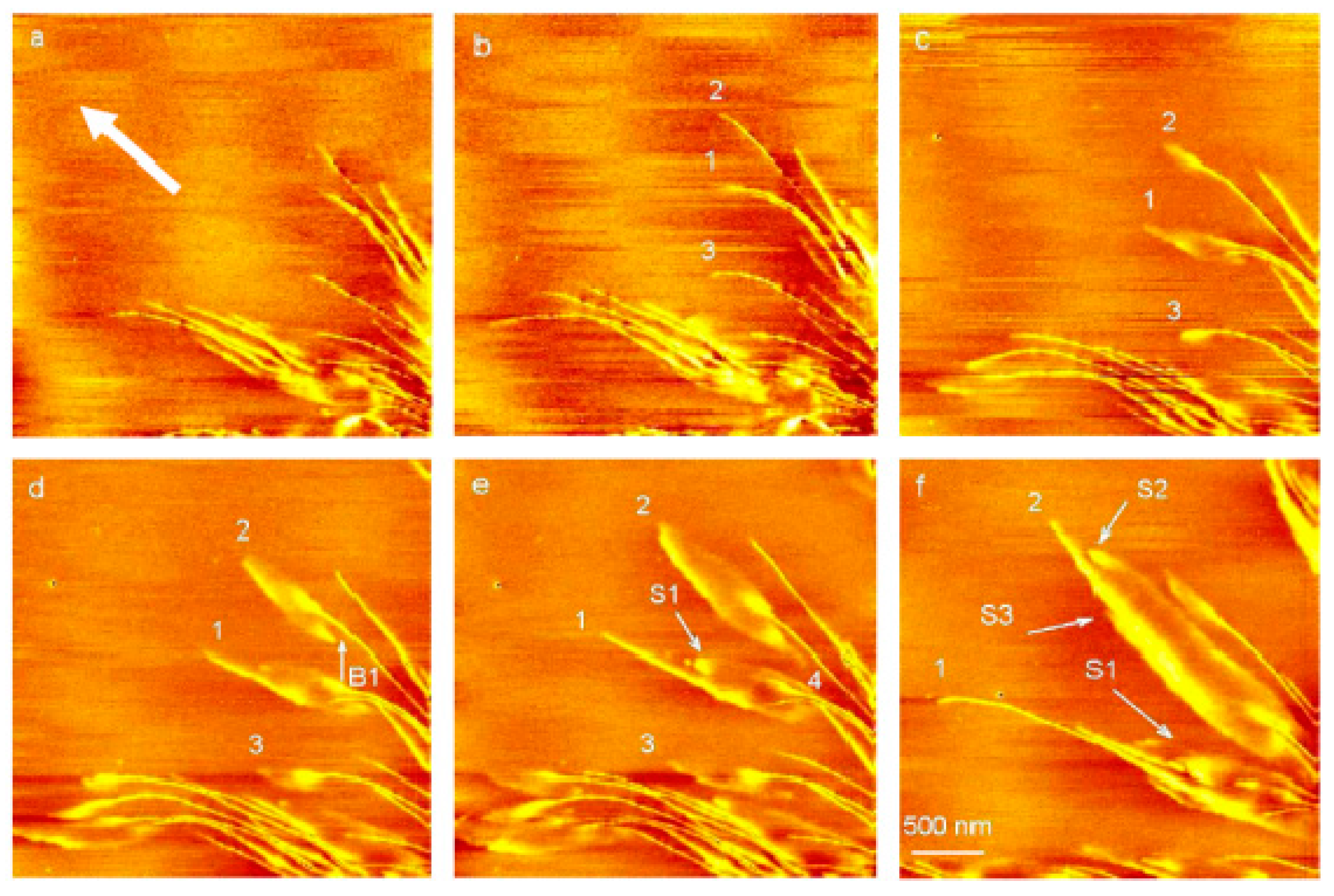

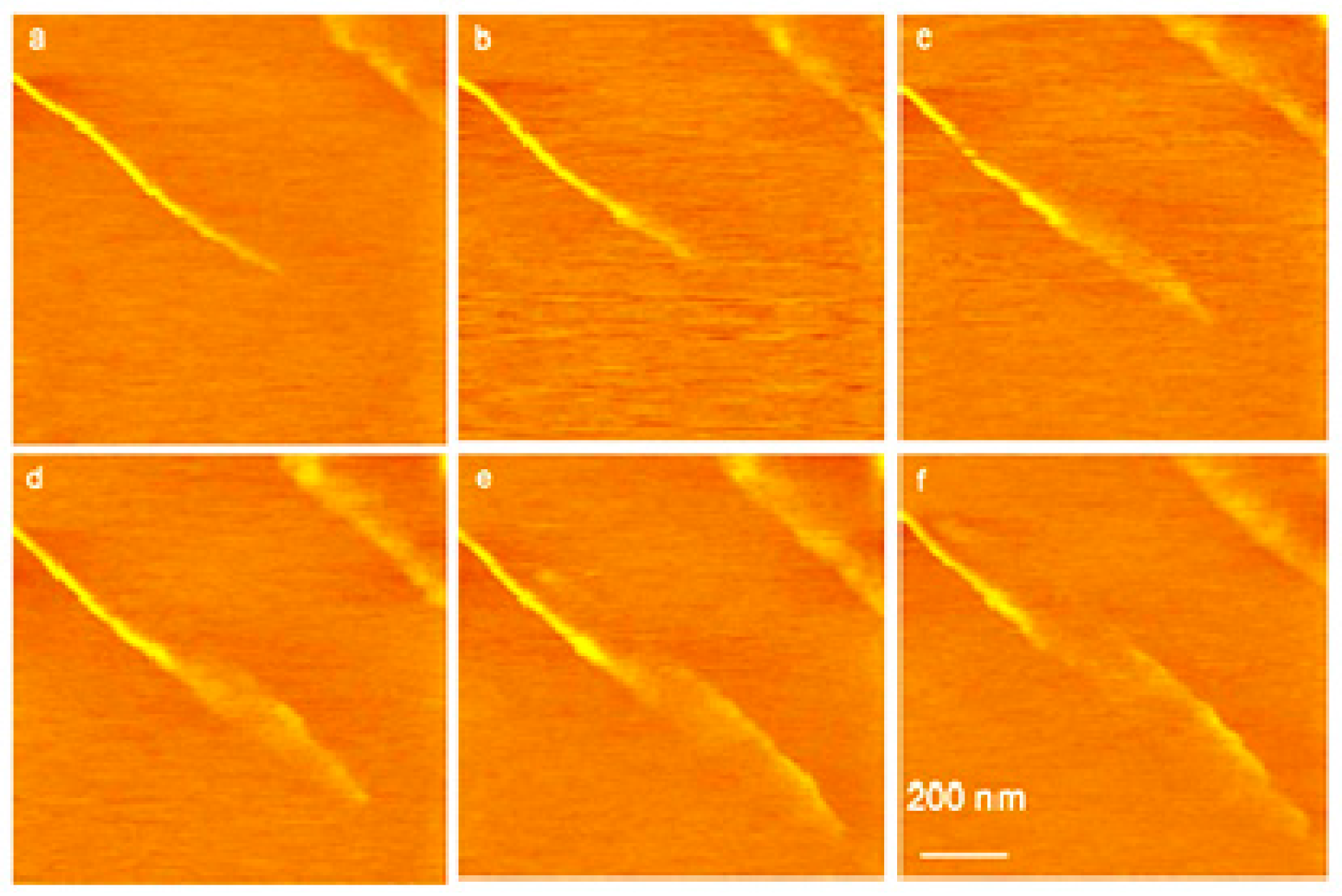

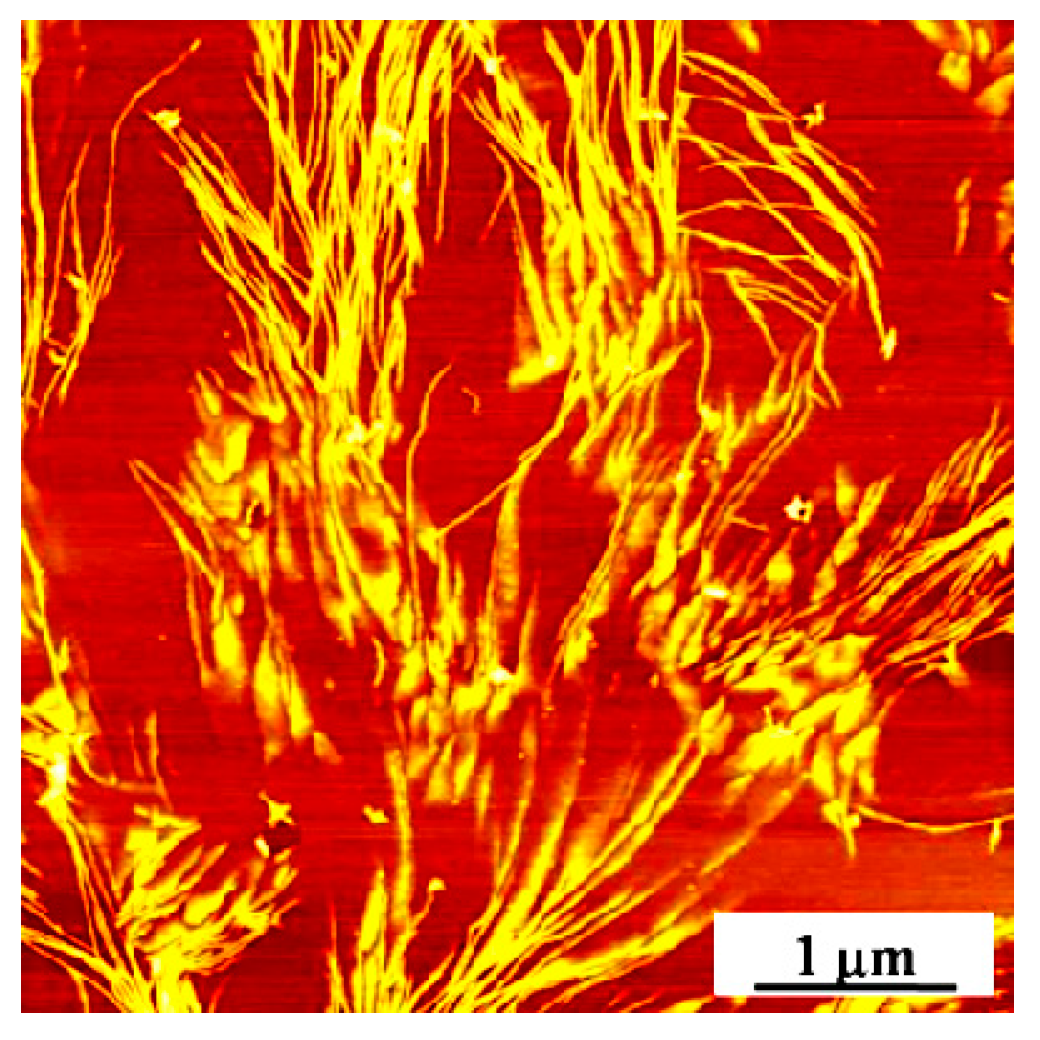

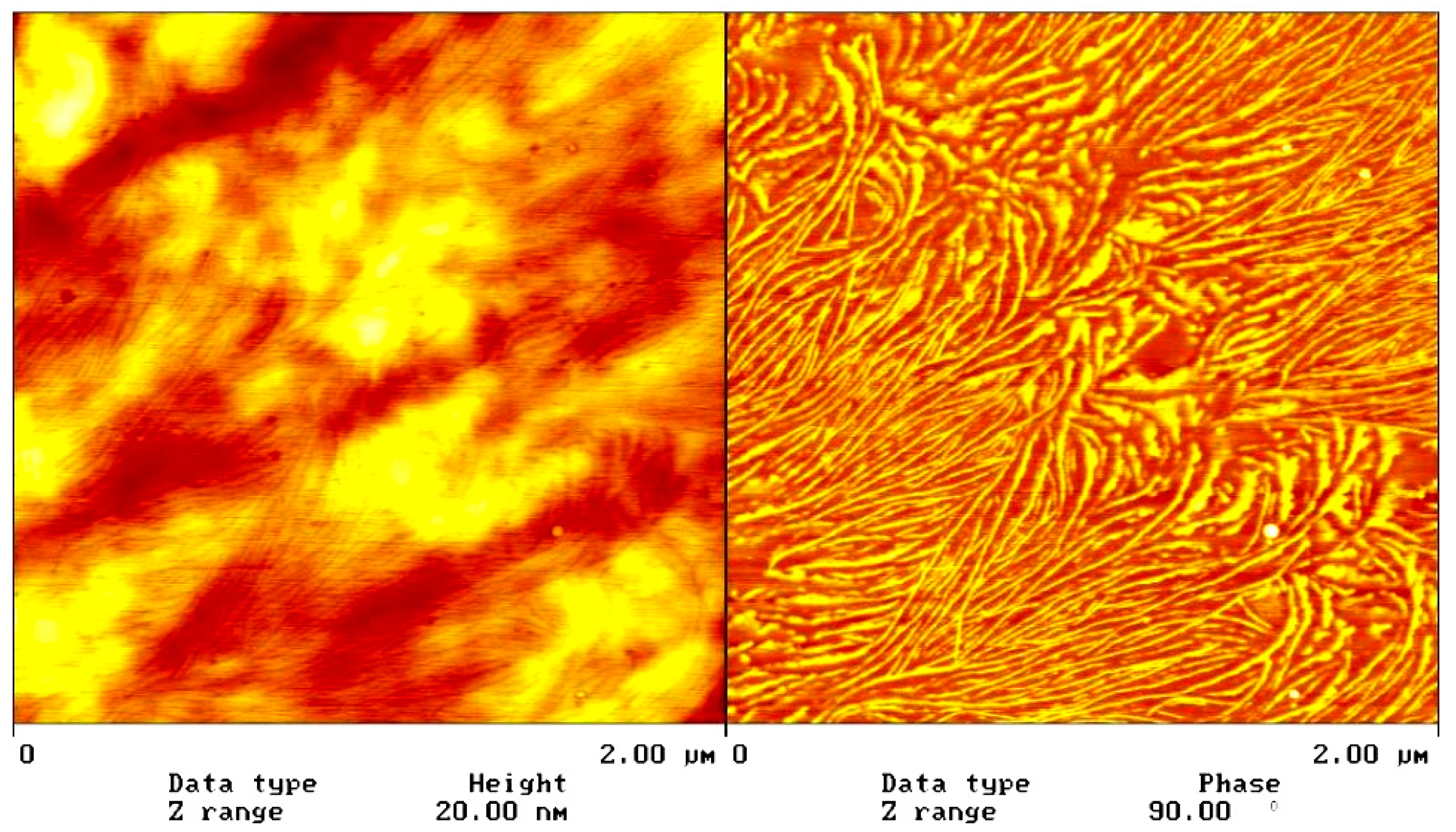

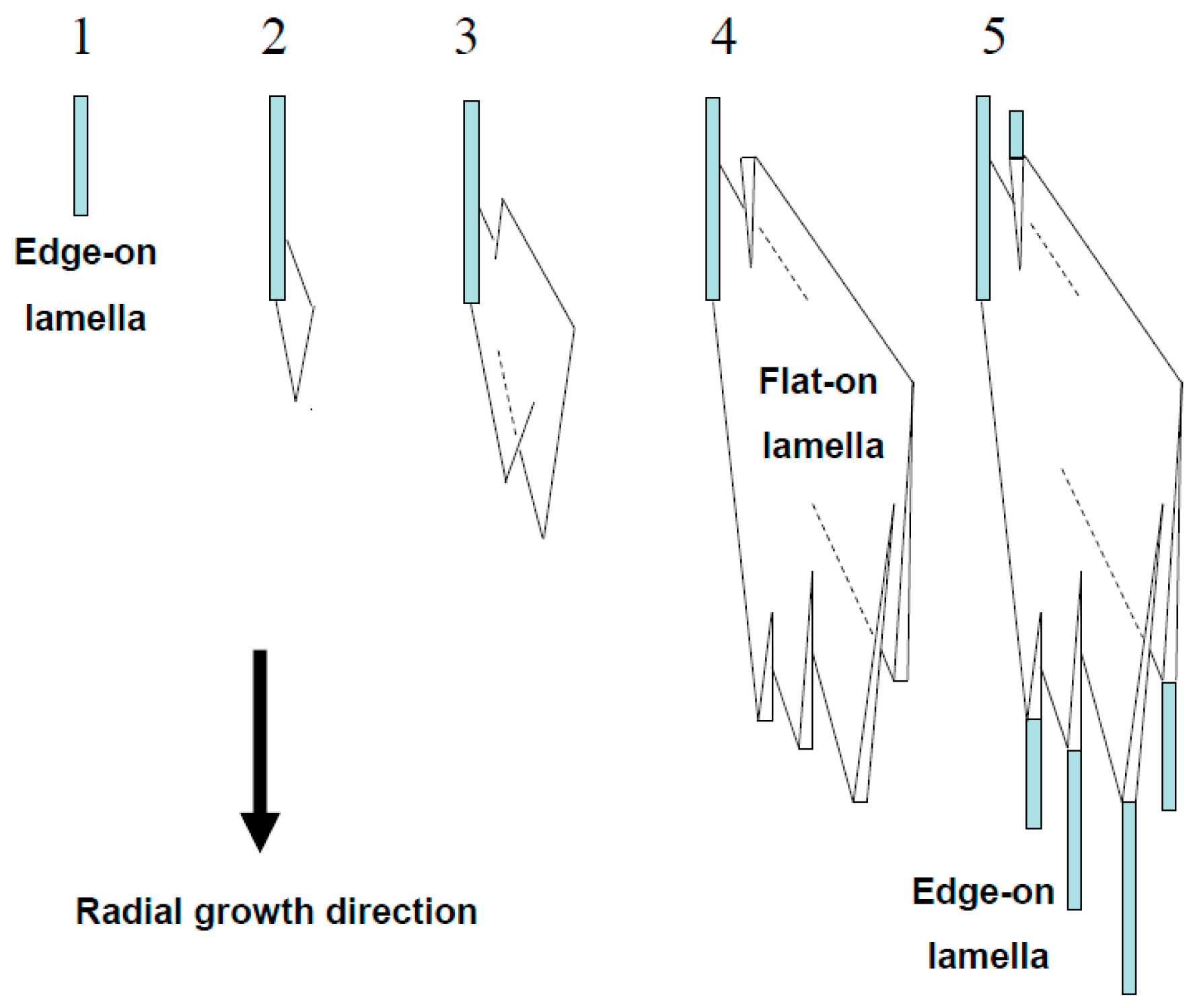

1.2. Real Time Atomic Force Microscopy (AFM) Observation Reveals Details of Lamellar Twisting

2. Organization of Twisted Lamellae in Banded Spherulites

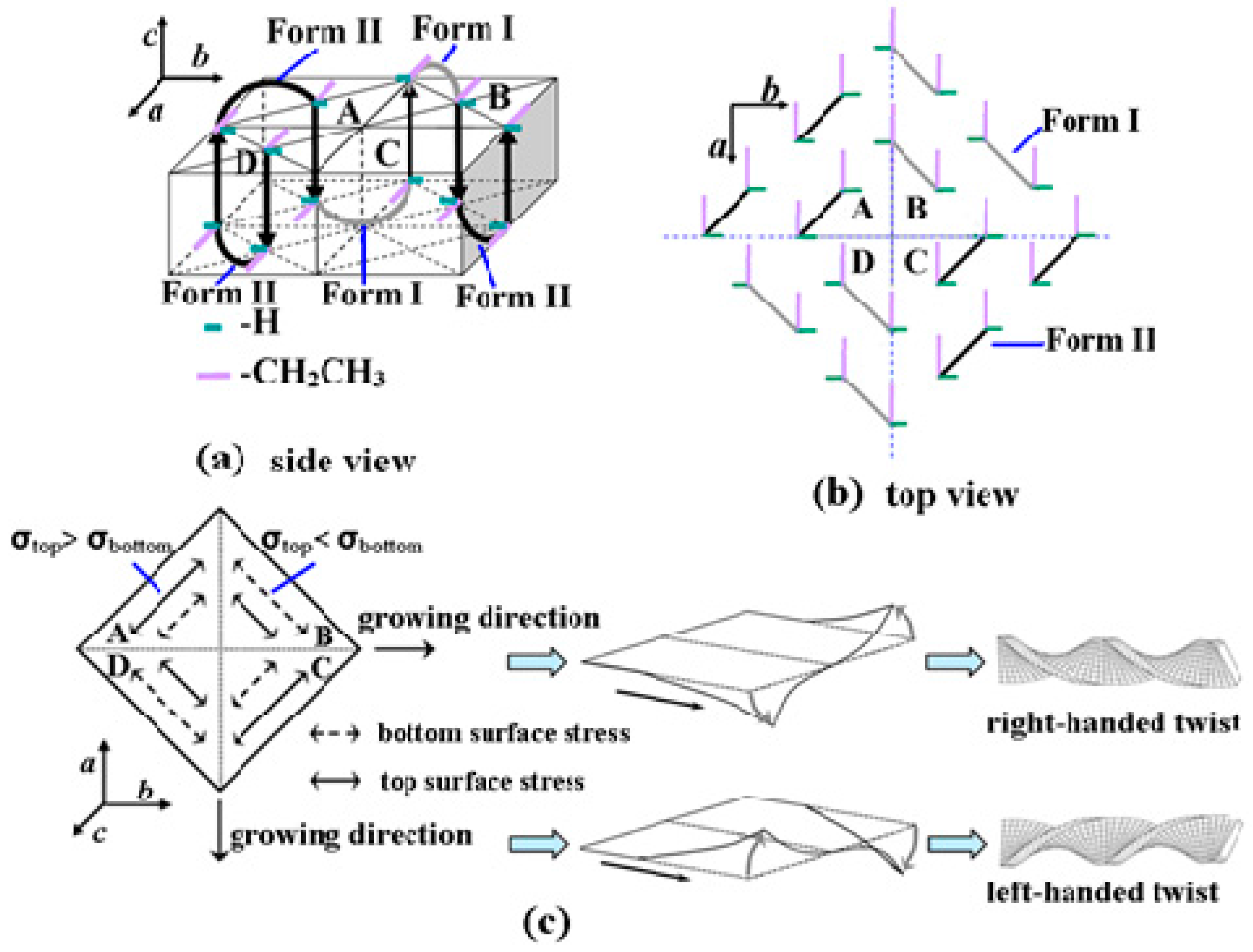

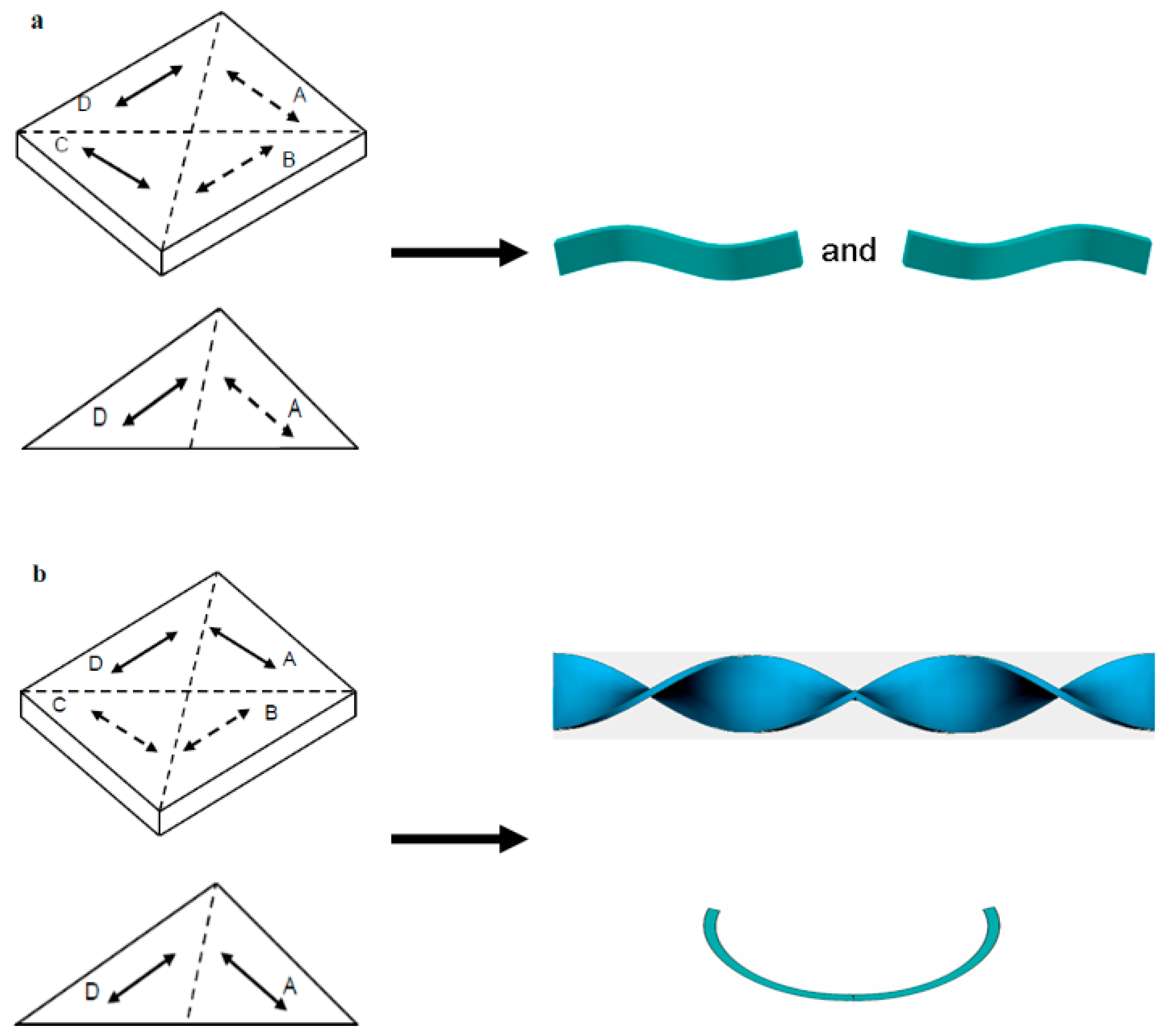

3. Driving Force for Lamellar Twisting in Banded Polymer Spherulites

4. Factors Affecting Band Spacing

5. Conclusions and Perspective

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Duan, Y.; Jiang, Y.; Jiang, S.; Li, L.; Yan, S.; Schultz, J.M. Depletion-induced nonbirefringent banding in thin isotactic polystyrene thin films. Macromolecules 2004, 37, 9283–9286. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, Z.; Chen, Y.; Gong, Y.; Huang, H.; He, T. Rhythmic growth-induced concentric ring-banded structures in poly(ε-caprolactone) solution-casting films obtained at the slow solvent evaporation rate. Macromolecules 2007, 40, 4381–4385. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; He, T. Morphological control of polymer spherulites via manipulating radial lamellar organization upon evaporative crystallization: A mini review. Crystals 2017, 7, 115. [Google Scholar] [CrossRef]

- Kwiatkowski, M.; Hinrichsen, G. A new banded texture in sheared thermotropic liquid crystalline polymers. J. Mater. Sci. 1990, 25, 1548–1550. [Google Scholar] [CrossRef]

- Ding, J.; Feng, J.; Yang, Y. Sinusoidal supermolecular structure of band textures in a presheared hydroxypropyl cellulose film. Polym. J. 1995, 27, 1132–1138. [Google Scholar] [CrossRef]

- Keith, H.D.; Padden, F.J. Twisting orientation and the role of transient states in polymer crystallization. Polymer 1984, 25, 28–42. [Google Scholar] [CrossRef]

- Lotz, B.; Cheng, S.Z.D. A critical assessment of unbalanced surface stresses as the mechanical origin of twisting and scrolling of polymer crystals. Polymer 2005, 46, 577–610. [Google Scholar] [CrossRef]

- Shtukenberg, A.G.; Punin, Y.O.; Gujral, A.; Kahr, B. Growth actuated bending and twisting of single crystals. Angew. Chem. Int. Ed. 2014, 53, 672–699. [Google Scholar] [CrossRef] [PubMed]

- Crist, B.; Schultz, J.M. Polymer spherulites: A critical review. Prog. Polym. Sci. 2016, 56, 1–63. [Google Scholar] [CrossRef]

- Bolotov, I.E.; Kolosov, V.Y.; Kozhyn, A.V. Electron microscope investigation of crystals based on bend-contour arrangement II. Bending phenomena of the crystal growth in an amorphous film. Phys. Status Sol. A 1982, 72, 645–654. [Google Scholar] [CrossRef]

- Keith, H.D.; Padden, F.J. The optical behavior of spherulites in crystalline polymers. Part I. Calculation of theoretical extinction patterns in spherulites with twisting crystalline orientation. J. Polym. Sci. 1959, 39, 101–102. [Google Scholar] [CrossRef]

- Price, F.P. On extinction patterns of polymer spherulites. J. Polym. Sci. 1959, 39, 139–150. [Google Scholar] [CrossRef]

- Keller, A. Investigations on banded spherulites. J. Polym. Sci. 1959, 39, 151–173. [Google Scholar] [CrossRef]

- Xu, J. Study on Tailor-Design of Polyhydroxyalkanoates and Crystallization Mechanism of Their Banded Spherulites. Ph.D. Thesis, Tsinghua University, Beijing, China, 2002. (In Chinese). [Google Scholar]

- Ye, H.M.; Wang, J.S.; Tang, S.; Xu, J.; Feng, X.Q.; Guo, B.H.; Xie, X.M.; Zhou, J.J.; Li, L.; Wu, Q.; et al. Surface stress effects on the bending direction and twisting chirality of lamellar crystals of chiral polymer. Macromolecules 2010, 43, 5762–5770. [Google Scholar] [CrossRef]

- Oldenbourg, R.; Mei, G. New polarized light microscope with precision universal compensator. J. Microsc. 1995, 180, 140–147. [Google Scholar] [CrossRef] [PubMed]

- Ye, H.M.; Xu, J.; Guo, B.H.; Iwata, T. Left- or right-handed lamellar twists in poly[(R)-3-hydroxyvalerate] banded spherulite: Dependence on growth axis. Macromolecules 2009, 42, 694–701. [Google Scholar] [CrossRef]

- Kahr, B.; Freudenthal, J.; Gunn, E. Crystals in light. Acc. Chem. Res. 2010, 43, 684–692. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Zeng, N.; He, H.; Liu, C.; Du, E.; He, Y.; Ma, H. Retardance of bilayer anisotropic samples consisting of well-aligned cylindrical scatterers and birefringent media. J. Biomed. Opt. 2016, 21, 055002. [Google Scholar] [CrossRef] [PubMed]

- Eppe, R.; Fischer, E.W.; Stuart, H.A. Morphologische strukturen in polyäthylenen, polyamiden und anderen kristallisierenden hochpolymeren. J. Polym. Sci. 1959, 34, 721–740. [Google Scholar] [CrossRef]

- Wang, Z.; An, L.; Jiang, W.; Jiang, B.; Wang, X. Ring-banded spherulite surface structure of poly(ε-caprolactone) in its miscible mixtures with poly(styrene-co-acrylonitrile). J. Polym. Sci. Part B Polym. Phys. 1999, 37, 2682–2691. [Google Scholar] [CrossRef]

- Ho, R.M.; Ke, K.Z.; Chen, M. Crystal structure and banded spherulite of poly(trimethylene terephthalate). Macromolecules 2000, 33, 7529–7537. [Google Scholar] [CrossRef]

- Vaughan, A.S. Etching and morphology of poly(vinylidene fluoride). J. Mater. Sci. 1993, 28, 1805–1813. [Google Scholar] [CrossRef]

- Cramer, K.; Lima, M.F.S.; Magonov, S.N.; Hellmann, E.H.; Jacobs, M.; Hellmann, G.P. Atomic force microscopy on tree-like crystals in polyvinylidene fluoride blends. J. Mater. Sci. 1998, 33, 2305–2312. [Google Scholar] [CrossRef]

- Hobbs, J.K.; McMaster, T.J.; Miles, M.J.; Barham, P.J. Direct observations of the growth of spherulites of poly(hydroxybutyrate-co-valerate) using atomic force microscopy. Polymer 1998, 39, 2437–2446. [Google Scholar] [CrossRef]

- Beekmans, L.G.M.; Hempenius, M.A.; Vancso, G.J. Morphological development of melt crystallized poly(propylene oxide) by in situ AFM: Formation of banded spherulites. Eur. Polym. J. 2004, 40, 893–903. [Google Scholar] [CrossRef]

- Xu, J.; Guo, B.H.; Zhang, Z.M.; Zhou, J.J.; Jiang, Y.; Yan, S.; Li, L.; Wu, Q.; Chen, G.Q.; Schultz, J.M. Direct AFM observation of crystal twisting and organization in banded spherulites of chiral poly(3-hydroxybutyrate-co-3-hydroxyhexanoate). Macromolecules 2004, 37, 4118–4123. [Google Scholar] [CrossRef]

- Fujiwara, Y. The superstructure of melt-crystallized polyethylene. I. Screwlike orientation of unit cell in polyethylene spherulites with periodic extinction rings. J. Appl. Polym. Sci. 1960, 4, 10–15. [Google Scholar] [CrossRef]

- Gazzano, M.; Focarete, M.L.; Riekel, C.; Scandola, M. Structural study of poly(L-lactic acid) spherulites. Biomacromolecules 2004, 5, 553–558. [Google Scholar] [CrossRef] [PubMed]

- Gazzano, M.; Focarete, M.L.; Riekel, C.; Ripamonti, A.; Scandola, M. Structural investigation of poly(3-hydroxybutyrate) spherulites by microfocus X-ray diffraction. Macromol. Chem. Phys. 2001, 202, 1405–1409. [Google Scholar] [CrossRef]

- Nozue, Y.; Hirano, S.; Kurita, R.; Kawasaki, N.; Ueno, S.; Iida, A.; Nishi, T.; Amemiya, Y. Co-existing handednesses of lamella twisting in one spherulite observed with scanning microbeam wide-angle X-ray scattering. Polymer 2004, 45, 8299–8302. [Google Scholar] [CrossRef]

- Hsieh, Y.T.; Ishige, R.; Higaki, Y.; Woo, E.M.; Takahara, A. Microscopy and microbeam X-ray analyses in poly(3-hydroxybutyrate-co-3-hydroxyvalerate) with amorphous poly(vinyl acetate). Polymer 2014, 55, 6906–6914. [Google Scholar] [CrossRef]

- Rosenthal, M.; Portale, G.; Burghammer, M.; Bar, G.; Samulski, E.T.; Ivanov, D.A. Exploring the origin of crystalline lamella twist in semi-rigid chain polymers: The model of Keith and Padden revisited. Macromolecules 2012, 45, 7454–7460. [Google Scholar] [CrossRef]

- Rosenthal, M.; Burghammer, M.; Bar, G.; Samulski, E.T.; Ivanov, D.A. Switching chirality of hybrid left–right crystalline helicoids built of achiral polymer chains: When right to left becomes left to right. Macromolecules 2014, 47, 8295–8304. [Google Scholar] [CrossRef]

- Hikima, Y.; Morikawa, J.; Hashimoto, T. Wavenumber dependence of FT-IR image of molecular orientation in banded spherulites of poly(3-hydroxybutyrate) and poly(l-lactic acid). Macromolecules 2013, 46, 1582–1590. [Google Scholar] [CrossRef]

- Jin, Y.; Wang, W.; Su, Z. Infrared imaging of ring-banded spherulites formed in poly(L-lactide)-poly(ethylene glycol) diblock copolymer: Segment distribution and orientation. Appl. Spectrosc. 2011, 65, 454–458. [Google Scholar] [CrossRef] [PubMed]

- Ellis, G.J.; Martin, M.C. Opportunities and challenges for polymer science using synchrotron-based infrared spectroscopy. Eur. Polym. J. 2016, 81, 505–531. [Google Scholar] [CrossRef]

- Sun, X.; Gao, N.; Li, Q.; Zhang, J.; Yang, X.; Ren, Z.; Yan, S. Crystal morphology of poly(3-hydroxybutyrate) on amorphous poly(vinylphenol) substrate. Langmuir 2016, 32, 3983–3994. [Google Scholar] [CrossRef] [PubMed]

- Enrique-Jimenez, P.; Vega, J.F.; Martínez-Salazar, J.; Ania, F.; Flores, A. Mapping the mechanical properties of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) banded spherulites by nanoindentation. Polymers 2016, 8, 358. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhou, J.J.; Li, L.; Xu, J.; Guo, B.H.; Zhang, Z.M.; Wu, Q.; Chen, G.Q.; Weng, L.T.; Cheung, Z.L.; et al. Surface properties of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) banded spherulites studied by atomic force microscopy and time-of-flight secondary ion mass spectrometry. Langmuir 2003, 19, 7417–7422. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Y.; Yang, J.; Gou, Q.; Wu, Y.; Wu, X.; Liu, P.; Gu, Q. Twisting of lamellar crystals in poly(3-hydroxybutyrate-co-3-hydroxyvalerate) ring-banded spherulites. Macromolecules 2010, 43, 4441–4444. [Google Scholar] [CrossRef]

- Xu, J.; Guo, B.H.; Zhou, J.J.; Li, L.; Wu, J.; Kowalczuk, M. Observation of banded spherulites in pure poly(L-lactide) and its miscible blends with amorphous polymers. Polymer 2005, 46, 9176–9185. [Google Scholar] [CrossRef]

- Oaki, Y.; Imai, H. Amplification of chirality from molecules into morphology of crystals through molecular recognition. J. Am. Chem. Soc. 2004, 126, 9271–9275. [Google Scholar] [CrossRef] [PubMed]

- Shtukenberg, A.G.; Gujral, A.; Rosseeva, E.; Cui, X.; Kahr, B. Mechanics of twisted hippuric acid crystals untwisting as they grow. CrystEngComm 2015, 17, 8817–8824. [Google Scholar] [CrossRef]

- Cui, X.; Rohl, A.L.; Shtukenberg, A.; Kahr, B. Twisted aspirin crystals. J. Am. Chem. Soc. 2013, 135, 3395–3398. [Google Scholar] [CrossRef] [PubMed]

- Frömsdorf, A.; Woo, E.M.; Lee, L.T.; Chen, Y.F.; Förster, S. Atomic force microscopy characterization and interpretation of thin-film poly(butylene adipate) spherulites with ring bands. Macromol. Rapid Commun. 2008, 29, 1322–1328. [Google Scholar] [CrossRef]

- Woo, E.M.; Lugito, G. Origins of periodic bands in polymer spherulites. Eur. Polym. J. 2015, 71, 27–60. [Google Scholar] [CrossRef]

- Lugito, G.; Woo, E.M.; Chuang, W.T. Interior lamellar assembly and optical birefringence in poly(trimethylene terephthalate) spherulites: Mechanisms from past to present. Crystals 2017, 7, 56. [Google Scholar] [CrossRef]

- Xu, J.; Guo, B.H.; Wu, Q.; Chen, J.C.; Chen, G.Q.; Zhou, J.J.; Jiang, Y.; Li, L. Organization process of the hierarchical structures in microbially synthesized polyhydroxyalkanoates. Curr. Appl. Phys. 2007, 7 (Suppl. 1), e41–e44. [Google Scholar] [CrossRef]

- Toda, A.; Arita, T.; Hikosaka, M. Three-dimensional morphology of PVDF single crystals forming banded spherulites. Polymer 2001, 42, 2223–2233. [Google Scholar] [CrossRef]

- Toda, A.; Okamuraa, M.; Hikosakaa, M.; Nakagawa, Y. AFM observation of polyethylene single crystals: Selective handedness of screw dislocations in a chair type. Polymer 2003, 44, 6135–6138. [Google Scholar] [CrossRef]

- Toda, A.; Okamura, M.; Taguchi, K.; Hikosaka, M.; Kajioka, H. Branching and higher order structure in banded polyethylene spherulites. Macromolecules 2008, 41, 2484–2493. [Google Scholar] [CrossRef]

- Barham, P.J.; Keller, A.; Otun, E.L.; Holmes, P.A. Crystallization and morphology of a bacterial thermoplastic: Poly-3-hydroxybutyrate. J. Mater. Sci. 1984, 19, 2781–2794. [Google Scholar] [CrossRef]

- Singfield, K.L.; Hobbs, J.K.; Keller, A. Correlation between main chain chirality and crystal “twist” direction in polymer spherulites. J. Cryst. Growth 1998, 183, 683–689. [Google Scholar] [CrossRef]

- Point, J.J. Structure fibreuse et phénomènes de cristallisation rayonnante dans les hauts polymères sphérolithiques. Bull. Acad. R. Belg. 1955, 41, 974–981. [Google Scholar]

- Lovinger, A.J.; Chua, J.O.; Gryte, C.C. Studies on the α and β forms of isotactic polypropylene by crystallization in a temperature gradient. J. Polym. Sci. Polym. Phys. Ed. 1977, 15, 641–656. [Google Scholar] [CrossRef]

- Kawashima, K.; Kawano, R.; Miyagi, T.; Umemoto, S.; Okui, N. Morphological changes in flat-on and edge-on lamellae of poly(ethylene succinate) crystallized from molten thin films. J. Macromol. Sci. Part B Phys. 2003, B42, 889–899. [Google Scholar] [CrossRef]

- Ding, M.; Yu, J.; He, J.; Zhang, J. An unusual spherulite morphology induced by nano-fillers from a concentrated cellulose/ionic liquid solution. RSC Adv. 2015, 5, 44648–44651. [Google Scholar] [CrossRef]

- Singfield, K.L.; Klass, J.M.; Brown, G.R. Optically active polyethers. 2. Atomic force microscopy of melt-crystallized poly(epichlorohydrin) enantiomers and their equimolar blend. Macromolecules 1995, 28, 8006–8015. [Google Scholar] [CrossRef]

- Rosenthal, M.; Hernandez, J.J.; Odarchenko, Y.I.; Soccio, M.; Lotti, N.; Di Cola, E.; Burghammer, M.; Ivanov, D.A. Non-radial growth of helical homopolymer crystals: Breaking the paradigm of the polymer spherulite microstructure. Macromol. Rapid Commun. 2013, 34, 1815–1819. [Google Scholar] [CrossRef] [PubMed]

- Hoffman, J.D.; Lauritzen, J.I., Jr. Crystallization of bulk polymers with chain folding: Theory of growth of lamellar spherulites. J. Res. Nat. Bur. Stand. 1961, 65A, 297. [Google Scholar] [CrossRef]

- Schultz, J.M.; Kinloch, D.R. Transverse screw dislocations: A source of twist in crystalline polymer ribbons. Polymer 1969, 10, 271–278. [Google Scholar] [CrossRef]

- Bassett, D.C.; Hodge, A.M. On the morphology of melt-crystallized polyethylene. III. Spherulitic organization. Proc. R. Soc. Lond. Ser. A 1981, 377, 61–71. [Google Scholar] [CrossRef]

- Schultz, J.M. Self-induced field model for crystal twisting in spherulites. Polymer 2003, 44, 433–441. [Google Scholar] [CrossRef]

- Keller, A.; Sawada, S. On the interior morphology of bulk polyethylene. Makromol. Chem. 1964, 74, 190–221. [Google Scholar] [CrossRef]

- Lotz, B.; Gonthier-Vassal, A.; Brack, A.; Magoshi, J. Twisted single crystals of Bombyx mori silk fibroin and related model polypeptides with β structure: A correlation with the twist of the β sheets in globular proteins. J. Mol. Biol. 1982, 156, 345–357. [Google Scholar] [CrossRef]

- Punin, Y.O. Growth of Crystals; Consultants Bureau: New York, NY, USA, 1983; Volume 14, pp. 121–131. [Google Scholar]

- Punin, Y.O. Structural and orientational instability of crystals during their growth. J. Struct. Chem. 1994, 35, 616–624. [Google Scholar] [CrossRef]

- Shtukenberg, A.G.; Freudenthal, J.; Kahr, B. Reversible twisting during helical hippuric acid crystal growth. J. Am. Chem. Soc. 2010, 132, 9341–9349. [Google Scholar] [CrossRef] [PubMed]

- Shtukenberg, A.G.; Punin, Y.O.; Gunn, E.; Kahr, B. Spherulites. Chem. Rev. 2012, 112, 1805–1838. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.S.; Ye, H.M.; Qin, Q.H.; Xu, J.; Feng, X.Q. Anisotropic surface effects on the formation of chiral morphologies of nanomaterials. Proc. R. Soc. A 2012, 468, 609–633. [Google Scholar] [CrossRef]

- Liu, J.; Ye, H.M.; Xu, J.; Guo, B.H. Formation of ring-banded spherulites of α and β modifications in poly(butylene adipate). Polymer 2011, 52, 4619–4630. [Google Scholar] [CrossRef]

- Ivanov, D.A.; Rosenthal, M. Microstructure of banded polymer spherulites: New insights from synchrotron nanofocus X-ray scattering. Adv. Polym. Sci. 2017, 277, 95–126. [Google Scholar]

- Huang, Y.; Luo, X.; Ma, D. Ringed spherulite morphology and compatibility in the binary blends of poly(ε-caprolactone) with ethyl cellulose. Eur. Polym. J. 2001, 37, 2153–2157. [Google Scholar]

- Schulze, K.; Kressler, J.; Kammer, H.W. Phase behaviour of poly(ε-caprolactone)/(polystyrene-ran-acrylonitrile) blends exhibiting both liquid-liquid unmixing and crystallization. Polymer 1993, 34, 3704–3709. [Google Scholar] [CrossRef]

- Keith, H.D.; Padden, F.J.; Russell, T.P. Morphological changes in polyesters and polyamides induced by blending with small concentrations of polymer diluents. Macromolecules 1989, 22, 666–675. [Google Scholar] [CrossRef]

- Ma, D.; Luo, X.; Zhang, R.; Nishi, T. Miscibility and spherulites in blends of poly(ε-caprolactone) with ethylene terephthalate-caprolactone copolyester. Polymer 1996, 37, 1575–1581. [Google Scholar]

- Wang, Z.; Wang, X.; Yu, D.; Jiang, B. The formation of ring-banded spherulites of poly(ε-caprolactone) in its miscible mixtures with poly(styrene-co-acrylonitrile). Polymer 1997, 38, 5897–5901. [Google Scholar] [CrossRef]

- Wen, T.; Shen, H.Y.; Wang, H.F.; Mao, Y.C.; Chuang, W.T.; Tsai, J.C.; Ho, R.M. Controlled handedness of twisted lamellae in banded spherulites of isotactic poly(2-vinylpyridine) as induced by chiral dopants. Angew. Chem. Int. Ed. 2015, 54, 14313–14316. [Google Scholar] [CrossRef] [PubMed]

- Cui, X.; Shtukenberg, A.G.; Freudenthal, J.; Nichols, S.; Kahr, B. Circular birefringence of banded spherulites. J. Am. Chem. Soc. 2014, 136, 5481–5490. [Google Scholar] [CrossRef] [PubMed]

- Li, M.C.; Wang, H.F.; Chiang, C.H.; Lee, Y.D.; Ho, R.M. Lamellar-twisting-induced circular dichroism of chromophore moieties in banded spherulites with evolution of homochirality. Angew. Chem. Int. Ed. 2014, 53, 4450–4455. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Bao, J.; Guo, B.H.; Ma, H.; Yun, T.L.; Gao, L.; Chen, G.Q.; Iwata, T. Imaging of nonlinear optical response in biopolyesters via second harmonic generation microscopy and its dependence on the crystalline structures. Polymer 2007, 48, 348–355. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Ye, H.; Zhang, S.; Guo, B. Organization of Twisting Lamellar Crystals in Birefringent Banded Polymer Spherulites: A Mini-Review. Crystals 2017, 7, 241. https://doi.org/10.3390/cryst7080241

Xu J, Ye H, Zhang S, Guo B. Organization of Twisting Lamellar Crystals in Birefringent Banded Polymer Spherulites: A Mini-Review. Crystals. 2017; 7(8):241. https://doi.org/10.3390/cryst7080241

Chicago/Turabian StyleXu, Jun, Haimu Ye, Shujing Zhang, and Baohua Guo. 2017. "Organization of Twisting Lamellar Crystals in Birefringent Banded Polymer Spherulites: A Mini-Review" Crystals 7, no. 8: 241. https://doi.org/10.3390/cryst7080241

APA StyleXu, J., Ye, H., Zhang, S., & Guo, B. (2017). Organization of Twisting Lamellar Crystals in Birefringent Banded Polymer Spherulites: A Mini-Review. Crystals, 7(8), 241. https://doi.org/10.3390/cryst7080241