Growth and Photocatalytic Properties of Gallium Oxide Films Using Chemical Bath Deposition

Abstract

:1. Introduction

2. Experimental

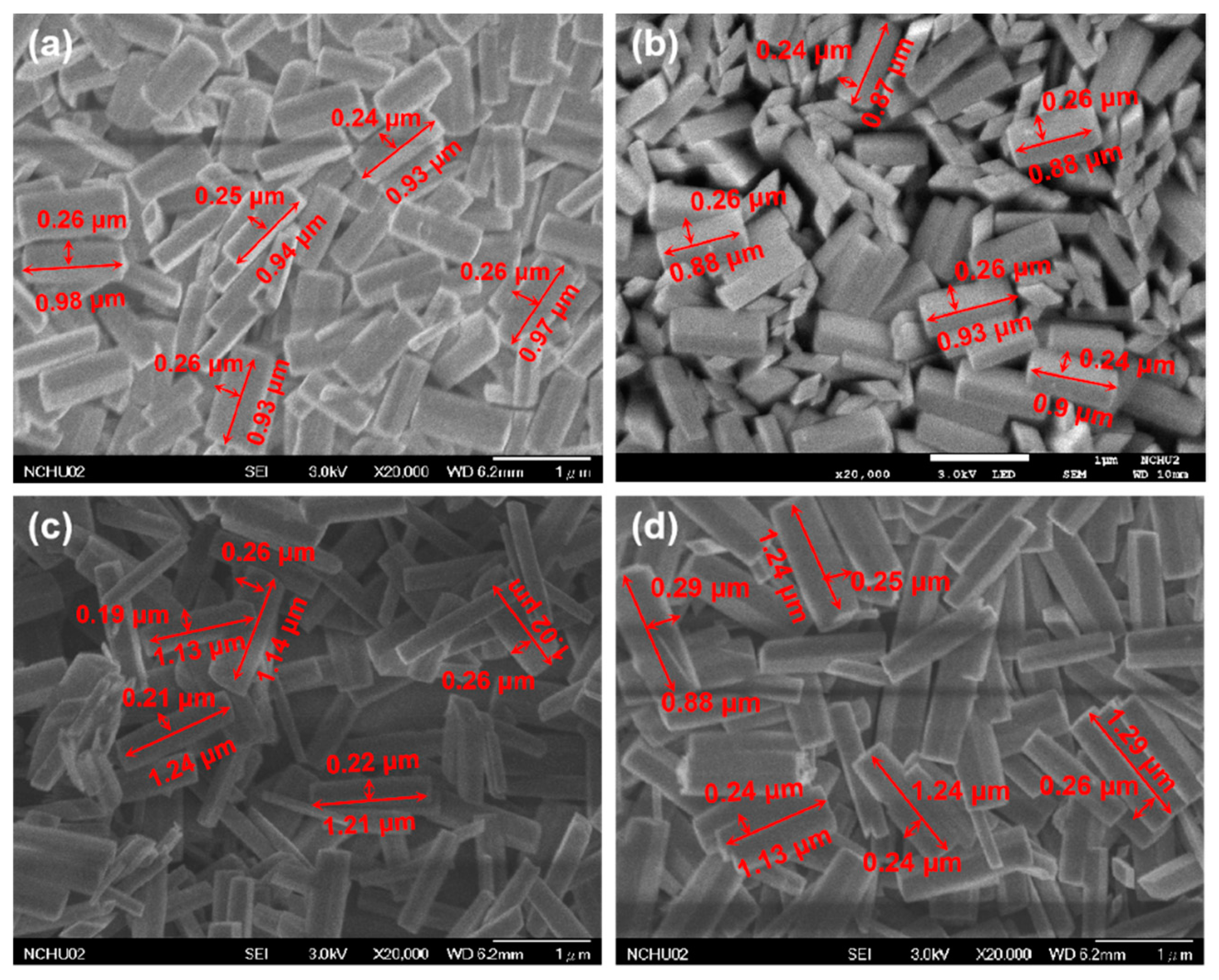

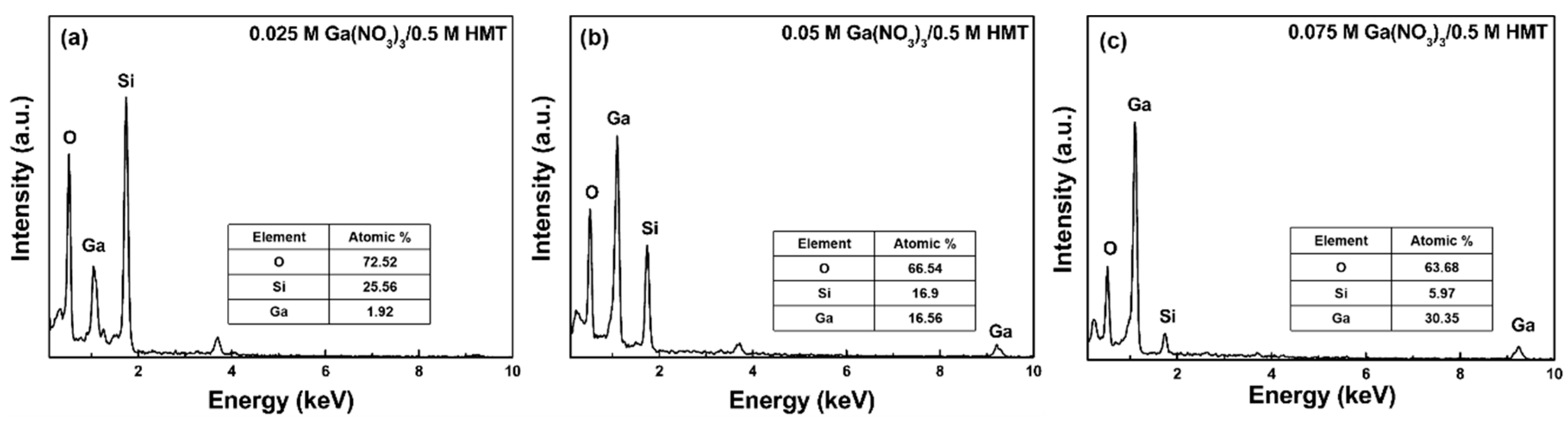

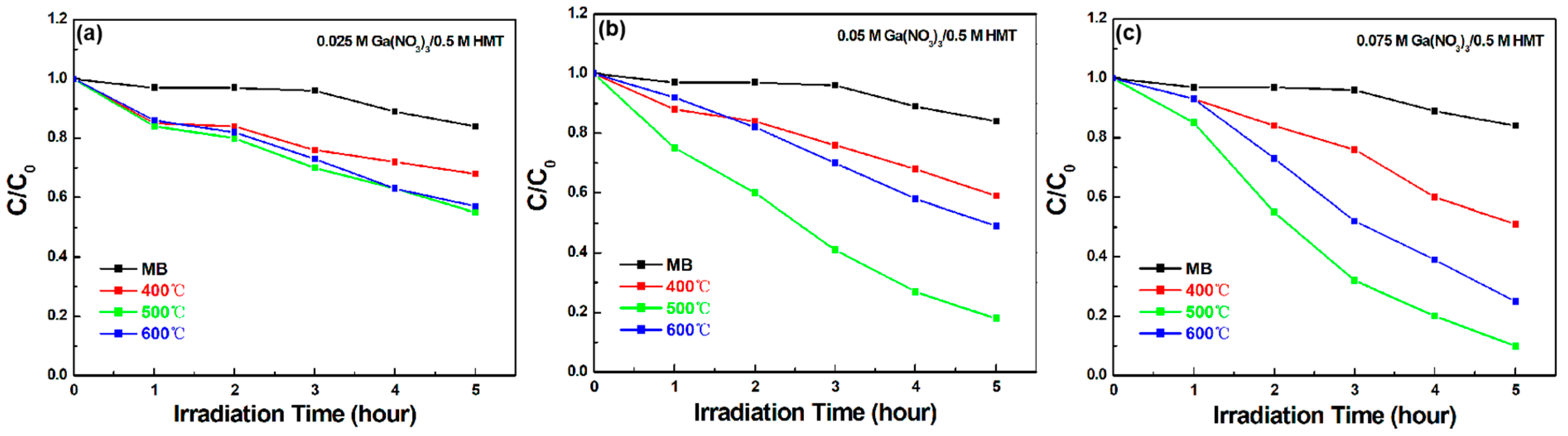

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fujishima, A.; Honda, K. Electrochemical Photolysis of Water at a Semiconductor Electrode. Nature 1972, 238, 37–38. [Google Scholar] [CrossRef] [PubMed]

- Fujishima, A. Hydrogen Production under Sunlight with an Electrochemical Photocell. J. Electrochem. Soc. 1975, 122, 1487. [Google Scholar] [CrossRef]

- Djurišić, A.B.; Leung, Y.H.; Ng, A.M.C. Strategies for improving the efficiency of semiconductor metal oxide photocatalysis. Mater. Horizons 2014, 1, 400. [Google Scholar] [CrossRef]

- Benjwal, P.; Kar, K.K. Simultaneous photocatalysis and adsorption based removal of inorganic and organic impurities from water by titania/activated carbon/carbonized eponocoxy namposite. J. Environ. Chem. Eng. 2015, 3, 2076–2083. [Google Scholar] [CrossRef]

- Houas, A. Photocatalytic degradation pathway of methylene blue in water. Appl. Catal. B Environ. 2001, 31, 145–157. [Google Scholar] [CrossRef]

- Lachheb, H.; Puzenat, E.; Houas, A.; Ksibi, M.; Elaloui, E.; Guillard, C.; Herrmann, J.-M. Photocatalytic degradation of various types of dyes (Alizarin S, Crocein Orange G, Methyl Red, Congo Red, Methylene Blue) in water by UV-irradiated titania. Appl. Catal. B Environ. 2002, 39, 75–90. [Google Scholar] [CrossRef]

- Tan, L.-L.; Ong, W.-J.; Chai, S.-P.; Goh, B.T.; Mohamed, A.R. Visible-light-active oxygen-rich TiO2 decorated 2D graphene oxide with enhanced photocatalytic activity toward carbon dioxide reduction. Appl. Catal. B Environ. 2015, 179, 160–170. [Google Scholar] [CrossRef]

- Liu, L.; Gao, F.; Zhao, H.; Li, Y. Tailoring Cu valence and oxygen vacancy in Cu/TiO2 catalysts for enhanced CO2 photoreduction efficiency. Appl. Catal. B Environ. 2013, 134, 349–358. [Google Scholar] [CrossRef]

- Núñez, J.; O’Shea, V.A.D.L.P.; Jana, P.; Coronado, J.M.; Serrano, D.P.; O’Shea, V.A.D.L.P. Effect of copper on the performance of ZnO and ZnO1−xNx oxides as CO2 photoreduction catalysts. Catal. Today 2013, 209, 21–27. [Google Scholar] [CrossRef]

- Pan, Y.-X.; Sun, Z.-Q.; Cong, H.-P.; Men, Y.-L.; Xin, S.; Song, J.; Yu, S.-H. Photocatalytic CO2 reduction highly enhanced by oxygen vacancies on Pt-nanoparticle-dispersed gallium oxide. Nano Res. 2016, 9, 1689–1700. [Google Scholar] [CrossRef]

- Reddy, L.S.; Ko, Y.H.; Yu, J.S. Hydrothermal Synthesis and Photocatalytic Property of β-Ga2O3 Nanorods. Nanoscale Res. Lett. 2015, 10, 364. [Google Scholar] [CrossRef] [PubMed]

- Roy, R.; Hill, V.G.; Osborn, E.F. Polymorphism of Ga2O3and the System Ga2O3—H2O. J. Am. Chem. Soc. 1952, 74, 719–722. [Google Scholar] [CrossRef]

- Stepanov, S.I.; Nikolaev, V.I.; Bougrov, V.E.; Romanov, A.E. Gallium oxide: Properties and applications-a review. Mater. Sci. 2016, 44, 63–86. [Google Scholar]

- Liu, X.; Qiu, G.; Zhao, Y.; Zhang, N.; Yi, R. Gallium oxide nanorods by the conversion of gallium oxide hydroxide nanorods. J. Alloys Compd. 2007, 439, 275–278. [Google Scholar] [CrossRef]

- Pilliadugula, R.; Krishnan, N. Gas sensing performance of GaOOH and β-Ga2O3 synthesized by hydrothermal method: A comparison. Mater. Res. Express 2019, 6, 025027. [Google Scholar] [CrossRef]

- Nakagawa, K.; Kajita, C.; Okumura, K.; Ikenaga, N.-O.; Nishitani-Gamo, M.; Ando, T.; Kobayashi, T.; Suzuki, T. Role of Carbon Dioxide in the Dehydrogenation of Ethane over Gallium-Loaded Catalysts. J. Catal. 2001, 203, 87–93. [Google Scholar] [CrossRef]

- Kuperberg, J.M.; Réti, F.; Miró, J.; Herndon, R.C.; Hajnal, Z.; Kiss, G.; Deák, P. Role of oxygen vacancy defect states in the n -type conduction of β-Ga2O3. J. Appl. Phys. 1999, 86, 3792–3796. [Google Scholar]

- Wu, X.; Song, W.; Huang, W.; Pu, M.; Zhao, B.; Sun, Y.; Du, J. Crystalline gallium oxide nanowires: Intensive blue light emitters. Chem. Phys. Lett. 2000, 328, 5–9. [Google Scholar] [CrossRef]

- Binet, L.; Gourier, D. ORIGIN OF THE BLUE LUMINESCENCE OF β-Ga2O3. J. Phys. Chem. Solids 1998, 59, 1241–1249. [Google Scholar] [CrossRef]

- Rodríguez, C.I.M.; Álvarez, M.; Ángel, L.; Rivera, J.D.J.F.; Arízaga, G.G.C.; Michel, C.R. α-Ga2O3 as a Photocatalyst in the Degradation of Malachite Green. ECS J. Solid State Sci. Technol. 2019, 8, Q3180–Q3186. [Google Scholar] [CrossRef]

- Zhao, B.X.; Li, X.; Yang, L.; Wang, F.; Li, J.C.; Xia, W.X.; Li, W.J.; Zhou, L.; Zhao, C.L. β-Ga2O3 nanorod synthesis with a one-step microwave irradiation hydrothermal method and its efficient photocatalytic degradation for perfluorooctanoic acid. Photochem. Photobiol. 2015, 91, 42–47. [Google Scholar] [CrossRef] [PubMed]

- Jin, S.; Lu, W.; Stanish, P.C.; Radovanovic, P.V. Compositional control of the photocatalytic activity of Ga2O3 nanocrystals enabled by defect-induced carrier trapping. Chem. Phys. Lett. 2018, 706, 509–514. [Google Scholar] [CrossRef]

- Wang, Y.; Li, N.; Duan, P.; Sun, X.; Chu, B.; He, Q. Properties and Photocatalytic Activity of β-Ga2O3 Nanorods under Simulated Solar Irradiation. J. Nanomater. 2015, 2015, 126. [Google Scholar]

- Minami, T. Oxide thin-film electroluminescent devices and materials. Solid-State Electron. 2003, 47, 2237–2243. [Google Scholar] [CrossRef]

- Ji, Z.; Du, J.; Fan, J.; Wang, W. Gallium oxide films for filter and solar-blind UV detector. Opt. Mater. 2006, 28, 415–417. [Google Scholar] [CrossRef]

- Oshima, Y.; Vίllora, E.G.; Shimamura, K. Quasi-heteroepitaxial growth of β-Ga2O3 on off-angled sapphire (0001) substrates by halide vapor phase epitaxy. J. Cryst. Growth 2015, 410, 53–58. [Google Scholar] [CrossRef]

- Pawar, S.; Pawar, B.; Kim, J.; Joo, O.-S.; Lokhande, C. Recent status of chemical bath deposited metal chalcogenide and metal oxide thin films. Curr. Appl. Phys. 2011, 11, 117–161. [Google Scholar] [CrossRef]

- Zainelabdin, A.; Zaman, S.; Amin, G.; Nur, O.; Willander, M. Deposition of well-aligned ZnO nanorods at 50 °C on metal, semiconducting polymer, and copper oxides substrates and their structural and optical properties. Cryst. Growth Des. 2010, 10, 3250–3256. [Google Scholar] [CrossRef]

- Errico, V.; Arrabito, G.; Plant, S.R.; Medaglia, P.G.; Palmer, R.E.; Falconi, C. Chromium inhibition and sizeselected Au nanocluster catalysis for the solution growth of lowdensity ZnO nanowires. Sci. Rep. 2015, 5, 12336. [Google Scholar] [CrossRef]

- Arrabitoa, G.; Erricoa, V.; Zhang, Z.M.; Han, W.H.; Falconia, C. Nanotransducers on printed circuit boards by rational design of highdensity, long, thin and untapered ZnO nanowires. Nano Energy 2018, 46, 54–62. [Google Scholar] [CrossRef]

- Zhao, Y.; Frost, R.L.; Yang, J.; Martens, W.N. Size and Morphology Control of Gallium Oxide Hydroxide GaO(OH), Nano- to Micro-Sized Particles by Soft-Chemistry Route without Surfactant. J. Phys. Chem. C 2008, 112, 3568–3579. [Google Scholar] [CrossRef]

- Huang, C.-C.; Yeh, C.-S.; Ho, C.-J. Laser Ablation Synthesis of Spindle-like Gallium Oxide Hydroxide Nanoparticles with the Presence of Cationic Cetyltrimethylammonium Bromide. J. Phys. Chem. B 2004, 108, 4940–4945. [Google Scholar] [CrossRef]

- Yao, J.; Wang, C. Decolorization of Methylene Blue with TiO2 Sol via UV Irradiation Photocatalytic Degradation. Int. J. Photoenergy 2010, 2010, 643182. [Google Scholar] [CrossRef]

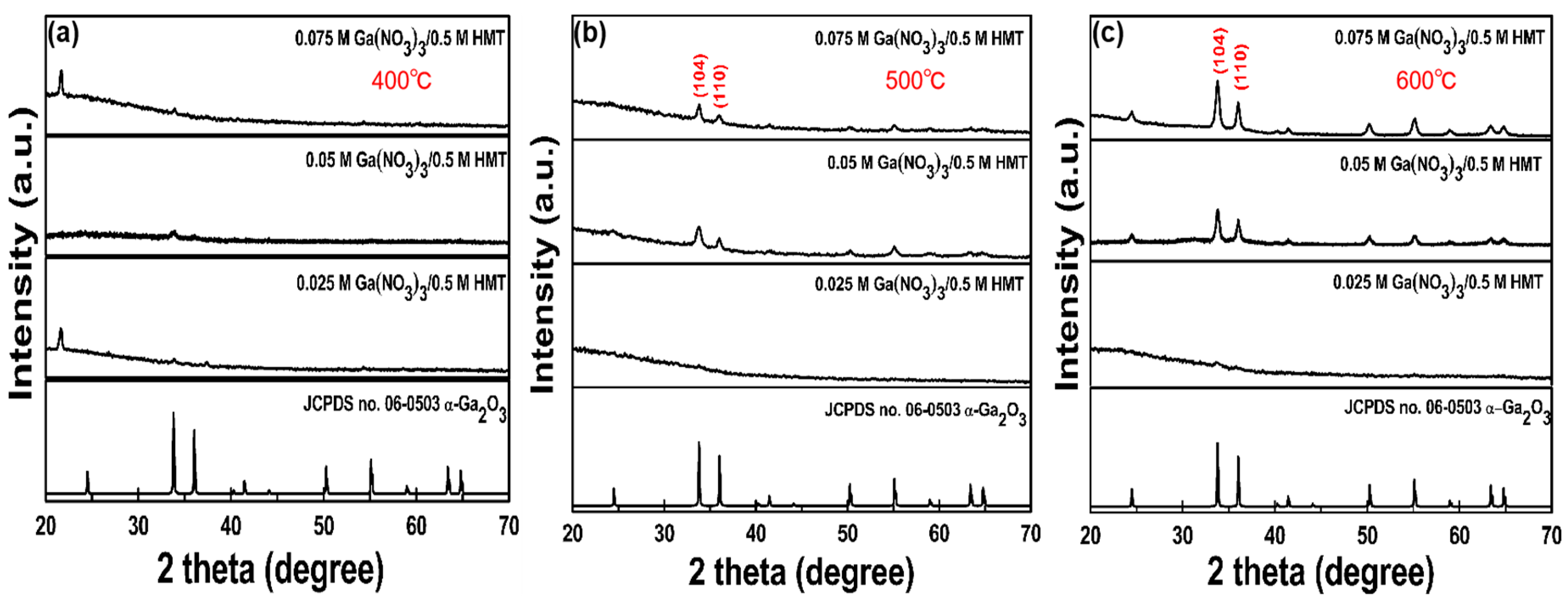

| Annealed Temperature | 0.05 M Ga(NO3)3 | 0.075 M Ga(NO3)3 |

|---|---|---|

| 500 °C | 2153.5 arcsec | 1567.4 arcsec |

| 600 °C | 1715 arcsec | 1700.6 arcsec |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yeh, C.-Y.; Zhao, Y.-M.; Li, H.; Yu, F.-P.; Zhang, S.; Wuu, D.-S. Growth and Photocatalytic Properties of Gallium Oxide Films Using Chemical Bath Deposition. Crystals 2019, 9, 564. https://doi.org/10.3390/cryst9110564

Yeh C-Y, Zhao Y-M, Li H, Yu F-P, Zhang S, Wuu D-S. Growth and Photocatalytic Properties of Gallium Oxide Films Using Chemical Bath Deposition. Crystals. 2019; 9(11):564. https://doi.org/10.3390/cryst9110564

Chicago/Turabian StyleYeh, Che-Yuan, Yi-Man Zhao, Hui Li, Fei-Peng Yu, Sam Zhang, and Dong-Sing Wuu. 2019. "Growth and Photocatalytic Properties of Gallium Oxide Films Using Chemical Bath Deposition" Crystals 9, no. 11: 564. https://doi.org/10.3390/cryst9110564