The Role of Superabsorbent Polymer on Strength and Microstructure Development in Cemented Dredged Clay with High Water Content

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Testing methods

2.3.1. Unconfined Compressive Strength

2.3.2. After-Curing Water Content

2.3.3. Microstructure

3. Results and Discussions

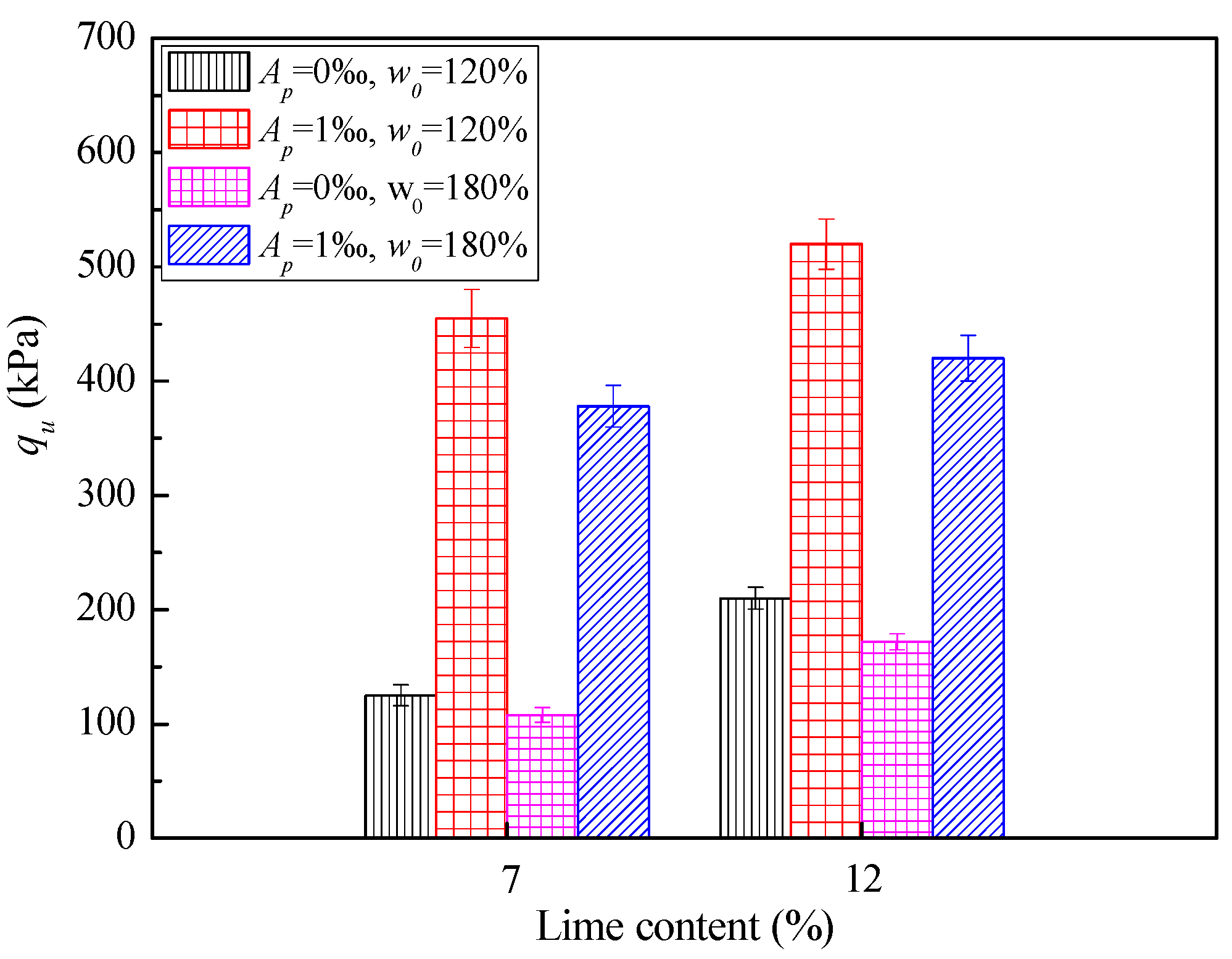

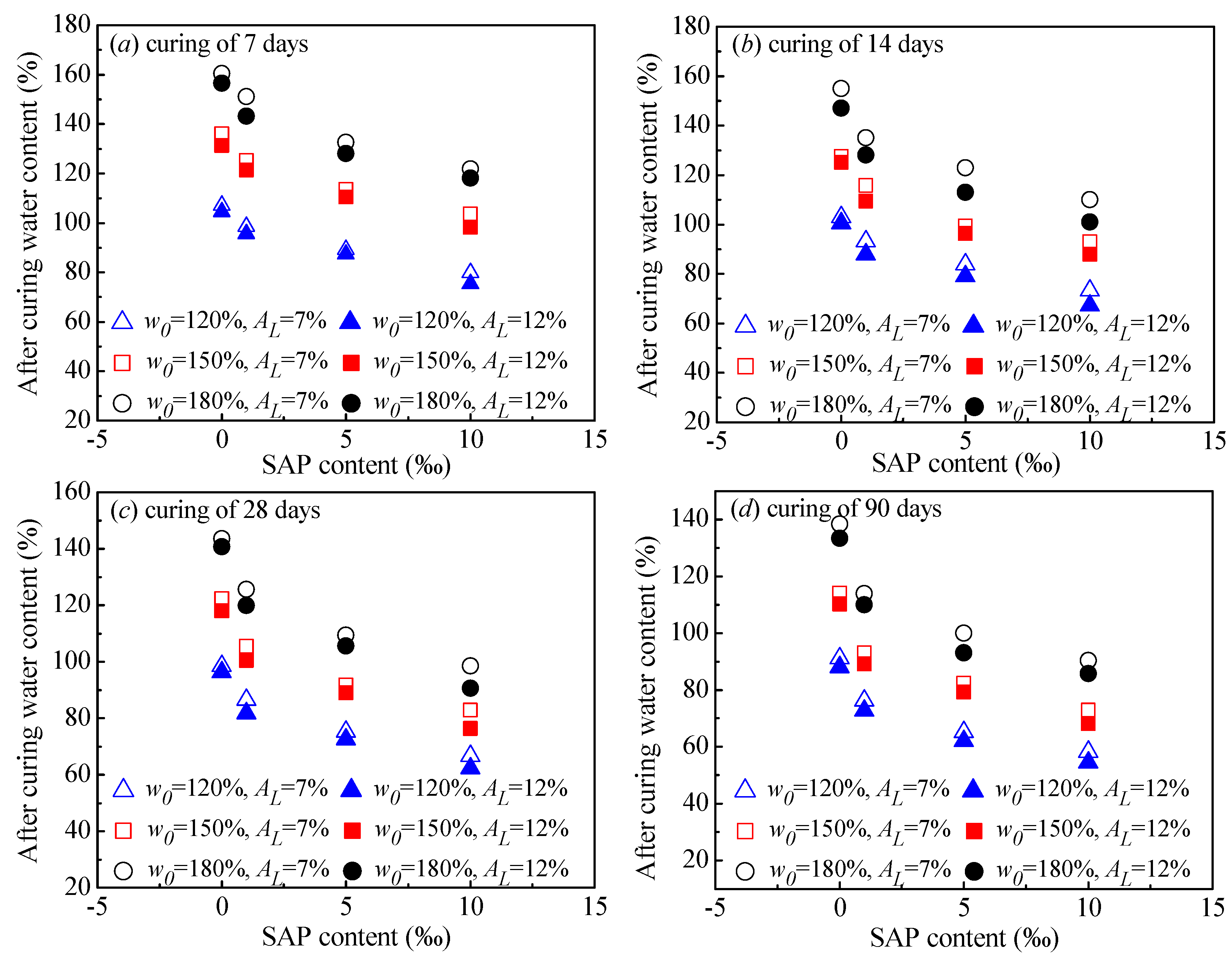

3.1. Unconfined Compressive Strength

3.2. Microstructure Analysis

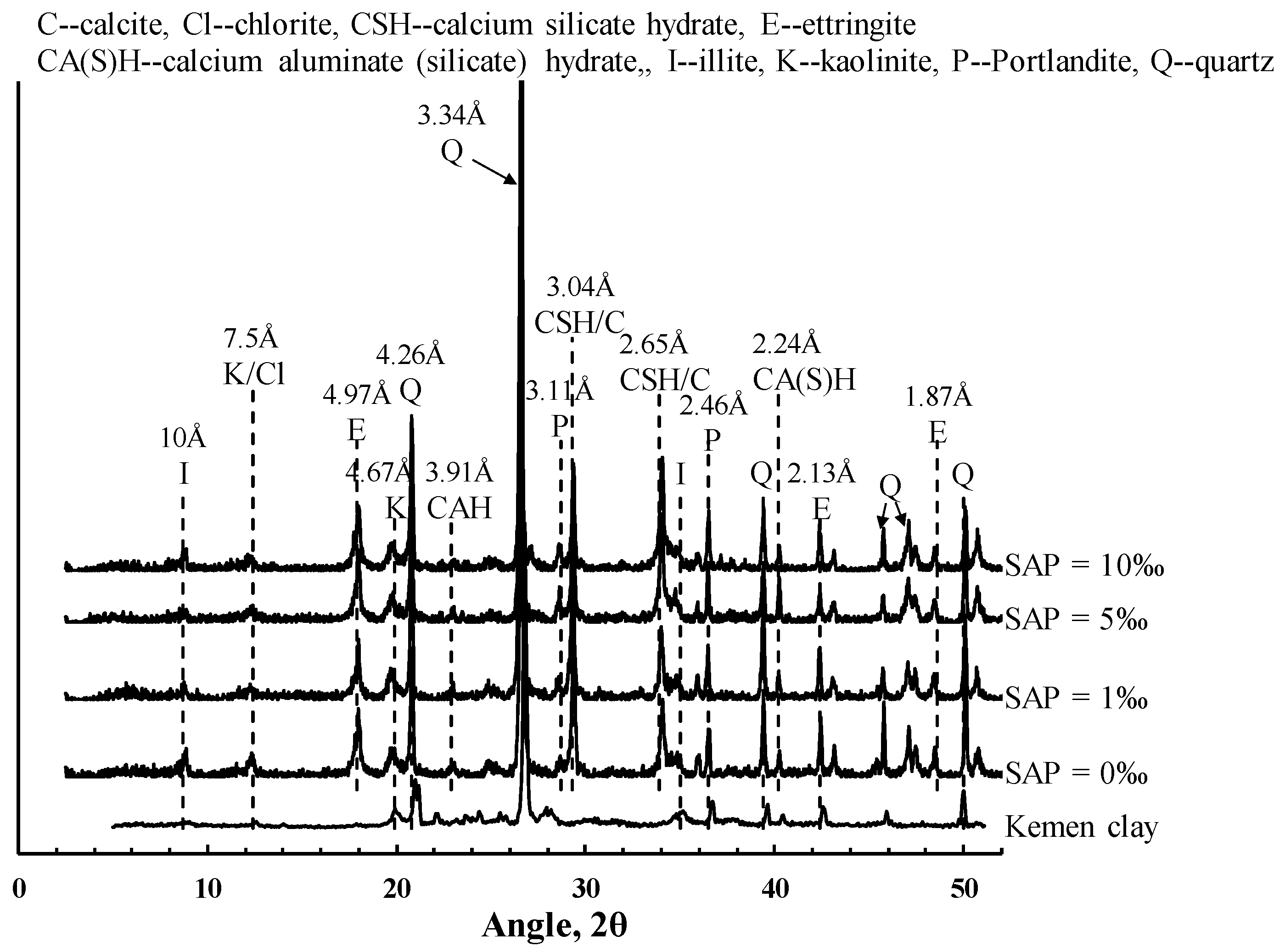

3.2.1. Results of XRD Tests

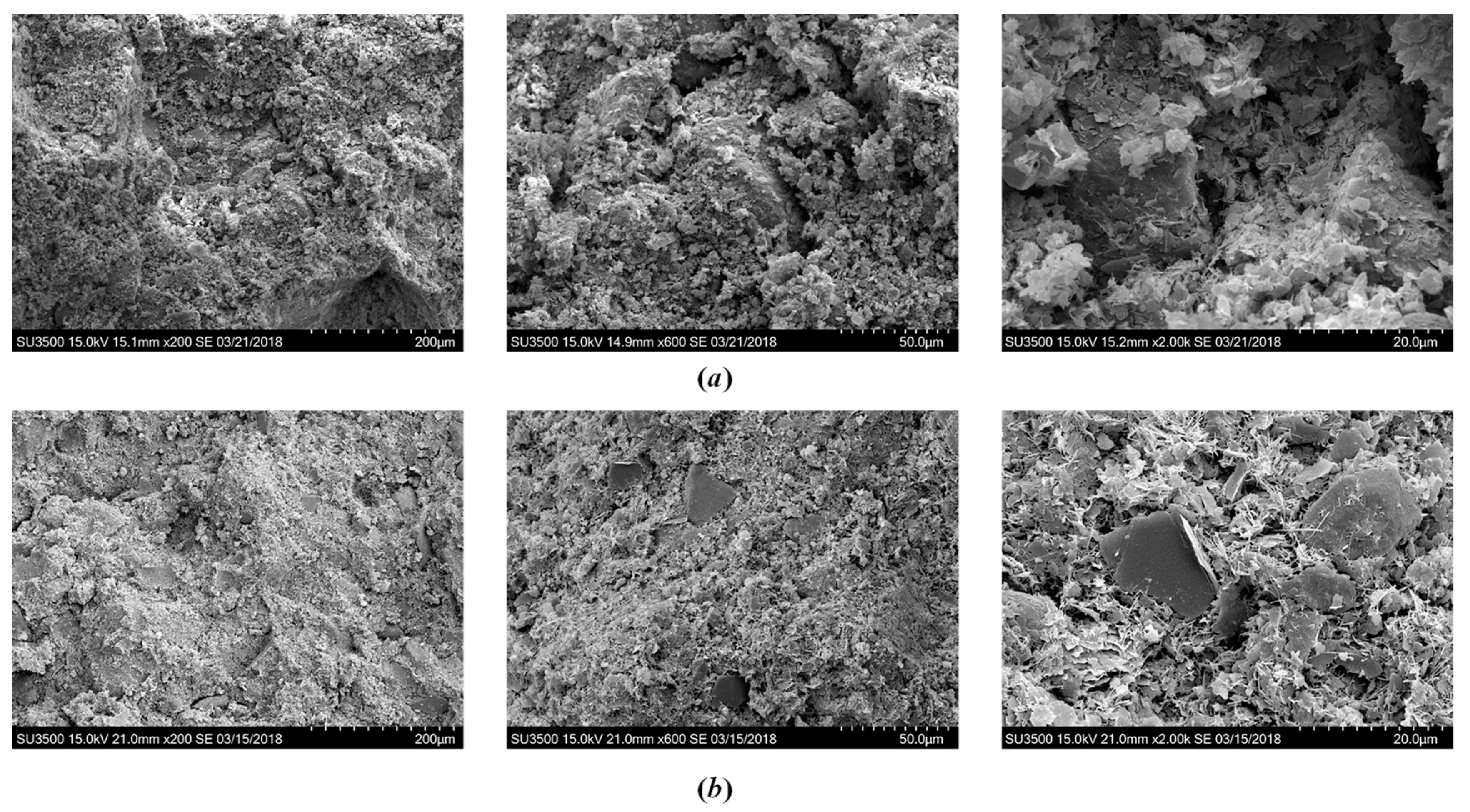

3.2.2. Effect of SAP

3.2.3. Effect of Lime Content

3.2.4. Effect of Initial Water Content

3.2.5. Effect of Curing Times

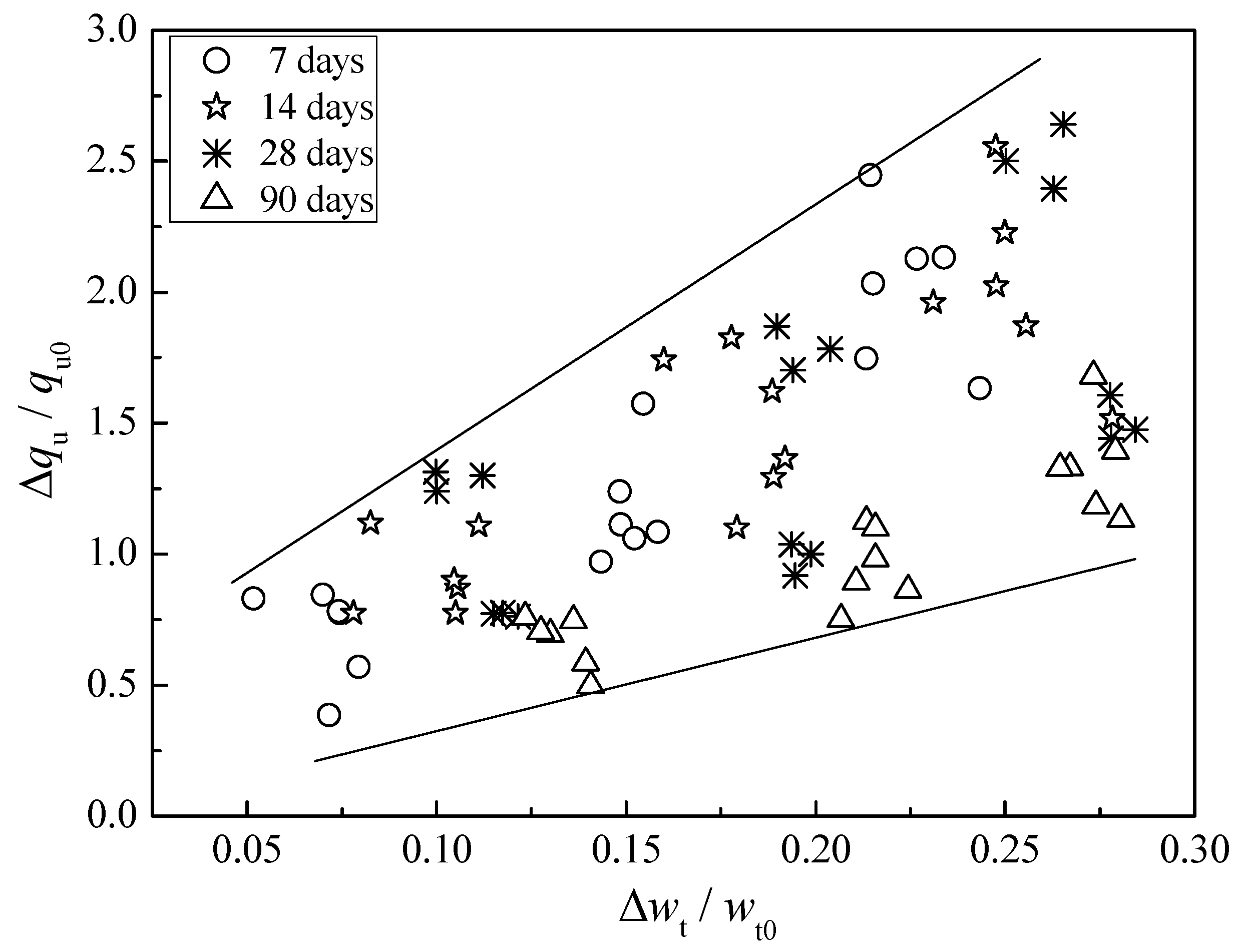

3.3. Mechanism of SAP on Strength Development

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Xu, G.Z. Grain Sorting Behavior of Dredged Slurries in Reclaimed Land and Its Effects on Engineering Properties. Ph.D. Thesis, Hohai University, Nanjing, China, 2013. [Google Scholar]

- Wang, D.X.; Abriak, N.E.; Zentar, R.; Xu, W.Y. Solidification/stabilization of dredged marine sediments for road construction. Environ. Technol. 2012, 33, 95–101. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.X.; Abriak, N.E.; Zentar, R. Strength and deformation properties of Dunkirk marine sediments solidified with cement. lime and fly ash. Eng. Geol. 2013, 166, 90–99. [Google Scholar] [CrossRef]

- Stronkhorst, J.A.F.; Van Hattum, B.; Postma, J.F.; De Kluijver, M.; Den Besten, P.J.; Vethaak, A.D. Environmental impact and recovery at two dumping sites for dredged material in the North Sea. Environ. Pollut. 2003, 124, 17–31. [Google Scholar] [CrossRef]

- Casado-Martinez, M.C.; Buceta, J.L.; Belzunce, M.J.; DelValls, T.A. Using sediment quality guidelines for dredged material management in commercial ports from Spain. Environ. Int. 2006, 32, 388–396. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Pang, S.D. Value-added utilization of marine clay as cement replacement for sustainable concrete production. J. Clean. Prod. 2018, 198, 867–873. [Google Scholar] [CrossRef]

- Tay, J.H.; Show, K.Y.; Hong, S.Y. Concrete aggregates made from sludge-marine clay mixes. J. Mater. Civ. Eng. 2002, 14, 392–398. [Google Scholar] [CrossRef]

- Kamruzzaman, A.H.M.; Chew, S.H.; Lee, F.H. Structuration and destructuration behavior of cement-treated Singapore marine clay. J. Geotech. Geoenviron. Eng. 2009, 135, 573–589. [Google Scholar] [CrossRef]

- Miura, N.; Horpibulsuk, S.; Nagaraj, T.S. Engineering behavior of cement stabilized clay at high water content. Soils Found. 2001, 41, 33–45. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Miura, N.; Nagaraj, T.S. Assessment of strength development in cement-admixed high water content clays with Abrams’ law as a basis. Géotechnique 2003, 53, 439–444. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Bergado, D.T.; Lorenzo, G.A. Compressibility of cement admixed clays at high water content. Géotechnique 2004, 54, 151–154. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Chinkulkijniwat, A.; Raksachon, Y.; Suddeepong, A. Analysis of strength development in cement-stabilized silty clay from microstructural considerations. Constr. Build. Mater. 2010, 24, 2011–2021. [Google Scholar] [CrossRef]

- Tsuchida, T.; Tang, Y.X. Estimation of compressive strength of cement-treated marine clays with different initial water contents. Soils Found. 2015, 55, 359–374. [Google Scholar] [CrossRef]

- Zeng, L.-L.; Hong, Z.-S.; Cui, Y.-J. On the volumetric strain–time curve patterns of dredged clays during primary consolidation. Géotechnique 2015, 65, 1023–1028. [Google Scholar] [CrossRef]

- Zeng, L.L.; Hong, Z.S.; Cui, Y.J. Determining the virgin compression lines of reconstituted clays at different initial water contents. Can. Geotech. J. 2015, 52, 1408–1415. [Google Scholar] [CrossRef]

- Zeng, L.-L.; Hong, Z.-S.; Cui, Y.-J. Time-dependent compression behaviour of dredged clays at high water contents in China. Appl. Clay Sci. 2016, 123, 320–328. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Raksachon, Y. Role of fly ash on strength and microstructure development in blended cement stabilized silty clay. Soils Found. 2009, 49, 85–98. [Google Scholar] [CrossRef]

- Yi, Y.; Gu, L.; Liu, S. Microstructural and mechanical properties of marine soft clay stabilized by lime-activated ground granulated blastfurnace slag. Appl. Clay Sci. 2015, 103, 71–76. [Google Scholar] [CrossRef]

- Deng, Y.F.; Yue, X.B.; Liu, S.Y.; Chen, Y.G.; Zhang, D.W. Hydraulic Conductivity of Cement-stabilized Marine Clay with Metakaolin and its correlation with Pore Size Distribution. Eng. Geol. 2015, 193, 46–152. [Google Scholar] [CrossRef]

- Wu, Z.; Deng, Y.; Liu, S.; Liu, Q.; Chen, Y.; Zha, F. Strength and micro-structure evolution of compacted soils modified by admixtures of cement and metakaolin. Appl. Clay Sci. 2016, 127, 44–51. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Bai, Y.; Song, Z.; Lu, Y.; Qian, W.; Kanungo, D.P. Evaluation of Strength Properties of Sand Modified with Organic Polymers. Polymers 2018, 10, 287. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Z.; Song, Z.; Bai, Y.; Qian, W.; Wei, J.; Kanungo, D.P. Tensile Behavior of Polyurethane Organic Polymer and Polypropylene Fiber-Reinforced Sand. Polymers 2018, 10, 499. [Google Scholar] [CrossRef]

- Liu, J.; Song, Z.; Lu, Y.; Wang, Q.; Kong, F.; Bu, F.; Kanungo, D.P.; Sun, S. Improvement Effect of Water-Based Organic Polymer on the Strength Properties of Fiber Glass Reinforced Sand. Polymers 2018, 10, 836. [Google Scholar] [CrossRef]

- Islam, M.R.; Hu, Y.G.; Mao, S.S.; Mao, J.Z.; Eneji, A.E.; Xue, X.Z. Effectiveness of a water-saving super-absorbent polymer in soil water conservation for corn (Zea mays L.) based on eco-physiological parameters. J. Sci. Food Agric. 2011, 91, 1998–2005. [Google Scholar] [CrossRef] [PubMed]

- Jensen, O.M.; Hansen, P.F. Water-entrained cement-based materials: II. Experimental observations. Cem. Concr. Res. 2002, 32, 973–978. [Google Scholar] [CrossRef]

- Justs, J.; Wyrzykowski, M.; Bajare, D.; Lura, P. Internal curing by superabsorbent polymers in ultra-high performance concrete. Cem. Concr. Res. 2015, 76, 82–90. [Google Scholar] [CrossRef]

- Shen, D.; Shi, H.; Tang, X.; Ji, Y.; Jiang, G. Effect of internal curing with super absorbent polymers on residual stress development and stress relaxation in restrained concrete ring specimens. Constr. Build. Mater. 2016, 120, 309–320. [Google Scholar] [CrossRef]

- Shen, D.; Wang, M.; Chen, Y.; Wang, W.; Zhang, J. Prediction of internal relative humidity in concrete modified with super absorbent polymers at early age. Constr. Build. Mater. 2017, 149, 543–552. [Google Scholar] [CrossRef]

- Dang, J.; Zhao, J.; Du, Z. Effect of superabsorbent polymer on the properties of concrete. Polymers 2017, 9, 672. [Google Scholar] [CrossRef]

- Bian, X.; Wang, Z.F.; Ding, G.Q.; Cao, Y.P. Compressibility of cemented dredged clay at high water content with super-absorbent polymer. Eng. Geol. 2016, 208, 198–205. [Google Scholar] [CrossRef]

- Bian, X.; Cao, Y.P.; Wang, Z.F.; Ding, G.Q.; Lei, G.H. Effect of super-absorbent polymer on the undrained shear behavior of cemented dredged clay with high water content. ASCE J. Mater. Civ. Eng. 2017, 29, 04017023. [Google Scholar] [CrossRef]

- Bian, X.; Ding, G.Q.; Wang, Z.F.; Cao, Y.P.; Ding, J.W. Compression and strength behavior of cement-lime-polymer solidified dredged material at high water content. Mar. Georesour. Geotechnol. 2017, 35, 840–846. [Google Scholar] [CrossRef]

- ASTM International. ASTM D2487. Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System); ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Hong, Z.S.; Bian, X.; Cui, Y.J.; Gao, Y.F.; Zeng, L.L. Effect of initial water content on undrained shear behavior of reconstituted clays. Géotechnique 2013, 63, 411–450. [Google Scholar] [CrossRef]

- ASTM International. ASTM D4219. Standard Test Method for Unconfined Compressive Strength Index of Chemical-Grouted Soils; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Lorenzo, G.A.; Bergado, D.T. Fundamental parameters of cement-admixed clay—New approach. J. Geotech. Geoenviron. Eng. 2004, 130, 1042–1050. [Google Scholar] [CrossRef]

- Delage, P.; Marcial, D.; Cui, Y.J.; Ruiz, X. Ageing effects in a compacted bentonite: A microstructure approach. Géotechnique 2006, 56, 291–304. [Google Scholar] [CrossRef]

- Zeng, L.L.; Cui, Y.J.; Conil, N.; Zghondi, J.; Armand, G.; Talandier, J. Experimental study on swelling behaviour and microstructure changes of natural stiff Teguline clays upon wetting. Can. Geotech. J. 2017, 54, 700–709. [Google Scholar] [CrossRef]

- Bian, X.; Cui, Y.J.; Li, X.Z. Voids effect on the swelling behaviour of compacted bentonite. Géotechnique 2018. [Google Scholar] [CrossRef]

- Bensted, J.; Barnes, P. Structure and Performance of Cements; Spon Press: New York, NY, USA, 2002. [Google Scholar]

- Du, Y.J.; Jiang, N.J.; Liu, S.Y.; Jin, F.; Singh, D.N.; Puppala, A.J. Engineering properties and microstructural characteristics of cement-stabilized zinc-contaminated kaolin. Can. Geotech. J. 2014, 51, 289–302. [Google Scholar] [CrossRef]

- Wang, Y.; Duc, M.; Cui, Y.J.; Tang, A.M.; Benahmed, N.; Sun, W.J.; Ye, W.M. Aggregate size effect on the development of cementitious compounds in a lime-treated soil during curing. Appl. Clay Sci. 2017, 136, 58–66. [Google Scholar] [CrossRef] [Green Version]

| Soils | Gs: Mg/m3 | Liquid Limit: % | Plastic Limit: % | Activity | Illite | Chlorite | Kaolinite | Smectite |

|---|---|---|---|---|---|---|---|---|

| Composition (%) | ||||||||

| Kemen Clay | 2.67 | 60.0 | 30.0 | 1.20 | 54 | 15 | 16 | 15 |

| Binders | CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | MgO | CO2 | Other |

|---|---|---|---|---|---|---|---|---|

| Cement | 59.3 | 22.41 | 4.24 | 3.46 | 4.11 | 3.48 | - | 3.0 |

| Lime | 95.3 | 0.06 | - | - | - | 2.13 | 0.33 | 2.18 |

| Particle Size (μm) | Water Absorption (g/g) | Water Desorption (%) |

|---|---|---|

| 120–150 | 85 | 3.8 |

| Initial Water Content (%) | Cement and Lime Content, AA = AC + AL (%) | SAP Content, Ap (‰) | UCT a | XRD | SEM |

|---|---|---|---|---|---|

| 120 | 15 | 0 | 7 D, 14 D, 28 D, 90 D b | 28 D | 7 D, 28 D, 90 D |

| 120 | 15 | 1 | 7 D, 14 D, 28 D, 90 D | - | - |

| 120 | 15 | 5 | 7 D, 14 D, 28 D, 90 D | - | - |

| 120 | 15 | 10 | 7 D, 14 D, 28 D, 90 D | 28 D | 7 D, 28 D, 90 D |

| 120 | 10 | 0 | 7 D, 14 D, 28 D, 90 D | - | - |

| 120 | 10 | 1 | 7 D, 14 D, 28 D, 90 D | - | - |

| 120 | 10 | 5 | 7 D, 14 D, 28 D, 90 D | - | - |

| 120 | 10 | 10 | 7 D, 14 D, 28 D, 90 D | 28 D | 28 D |

| 150 | 15 | 0 | 7 D, 14 D, 28 D, 90 D | - | - |

| 150 | 15 | 1 | 7 D, 14 D, 28 D, 90 D | - | - |

| 150 | 15 | 5 | 7 D, 14 D, 28 D, 90 D | - | - |

| 150 | 15 | 10 | 7 D, 14 D, 28 D, 90 D | - | - |

| 150 | 10 | 0 | 7 D, 14 D, 28 D, 90 D | - | - |

| 150 | 10 | 1 | 7 D, 14 D, 28 D, 90 D | - | - |

| 150 | 10 | 5 | 7 D, 14 D, 28 D, 90 D | - | - |

| 150 | 10 | 10 | 7 D, 14 D, 28 D, 90 D | - | - |

| 180 | 15 | 0 | 7 D, 14 D, 28 D, 90 D | - | - |

| 180 | 15 | 1 | 7 D, 14 D, 28 D, 90 D | - | - |

| 180 | 15 | 5 | 7 D, 14 D, 28 D, 90 D | - | - |

| 180 | 15 | 10 | 7 D, 14 D, 28 D, 90 D | 28 D | 28 D |

| 180 | 10 | 0 | 7 D, 14 D, 28 D, 90 D | - | - |

| 180 | 10 | 1 | 7 D, 14 D, 28 D, 90 D | - | - |

| 180 | 10 | 5 | 7 D, 14 D, 28 D, 90 D | - | - |

| 180 | 10 | 10 | 7 D, 14 D, 28 D, 90 D | - | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bian, X.; Zeng, L.; Deng, Y.; Li, X. The Role of Superabsorbent Polymer on Strength and Microstructure Development in Cemented Dredged Clay with High Water Content. Polymers 2018, 10, 1069. https://doi.org/10.3390/polym10101069

Bian X, Zeng L, Deng Y, Li X. The Role of Superabsorbent Polymer on Strength and Microstructure Development in Cemented Dredged Clay with High Water Content. Polymers. 2018; 10(10):1069. https://doi.org/10.3390/polym10101069

Chicago/Turabian StyleBian, Xia, Lingling Zeng, Yongfeng Deng, and Xiaozhao Li. 2018. "The Role of Superabsorbent Polymer on Strength and Microstructure Development in Cemented Dredged Clay with High Water Content" Polymers 10, no. 10: 1069. https://doi.org/10.3390/polym10101069