Preparation and Characterization of Hot Melt Copolyester (PBTI) Ultrafine Particles and Their Effect on the Anti-Pilling Performance of Polyester/Cotton Fabrics

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Processing

2.2.1. Preparation of Copolyester Particles

2.2.2. Anti-Pilling Finishing of Polyester/Cotton Woven Fabrics

2.3. Characterization

3. Results and Discussion

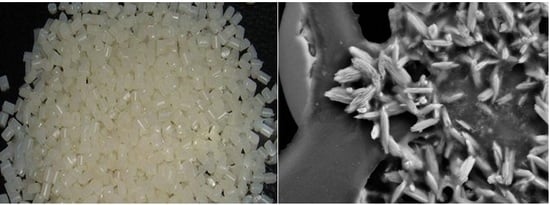

3.1. Morphology and Distribution of Copolyester Particles

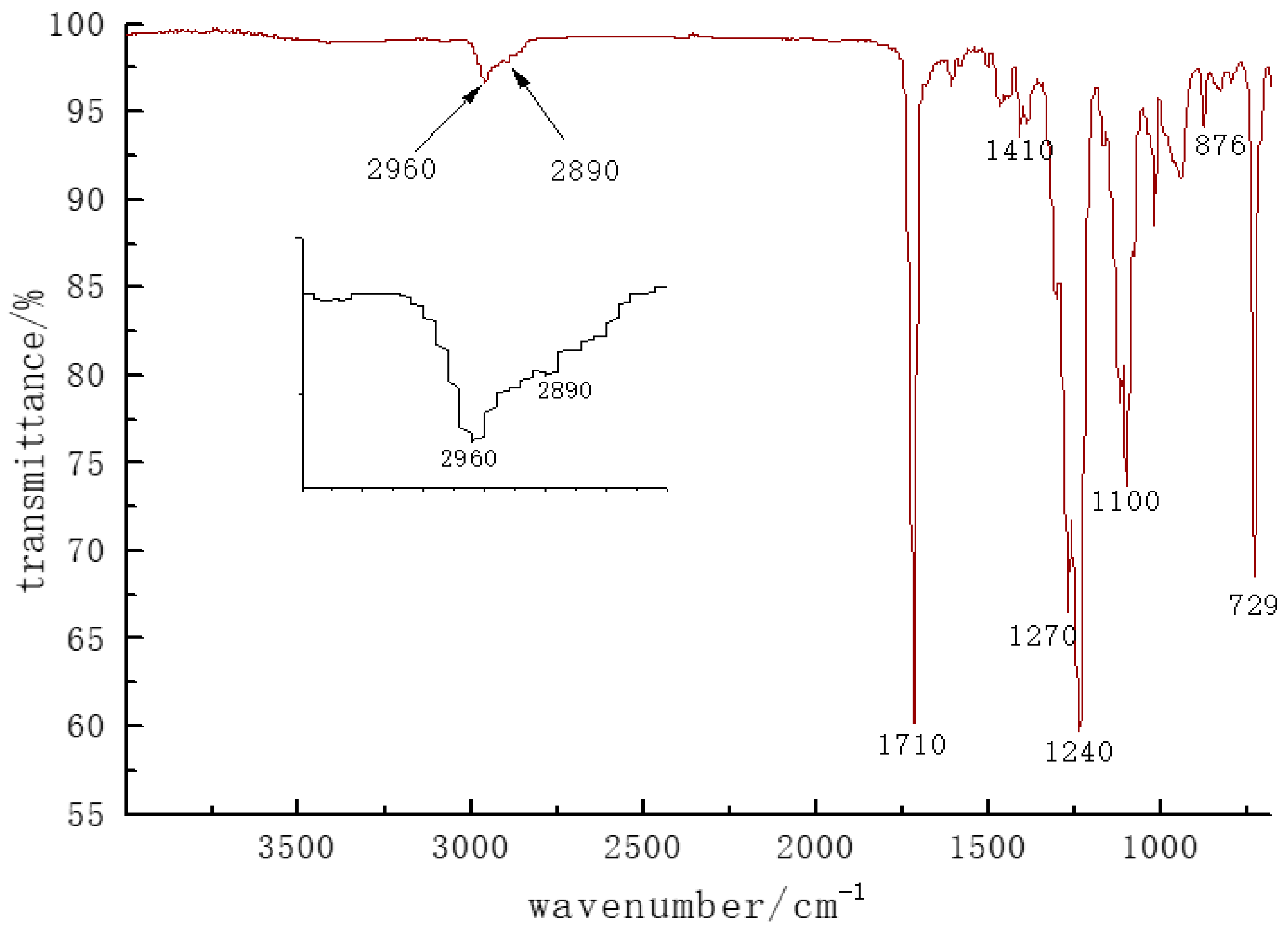

3.2. FT–IR

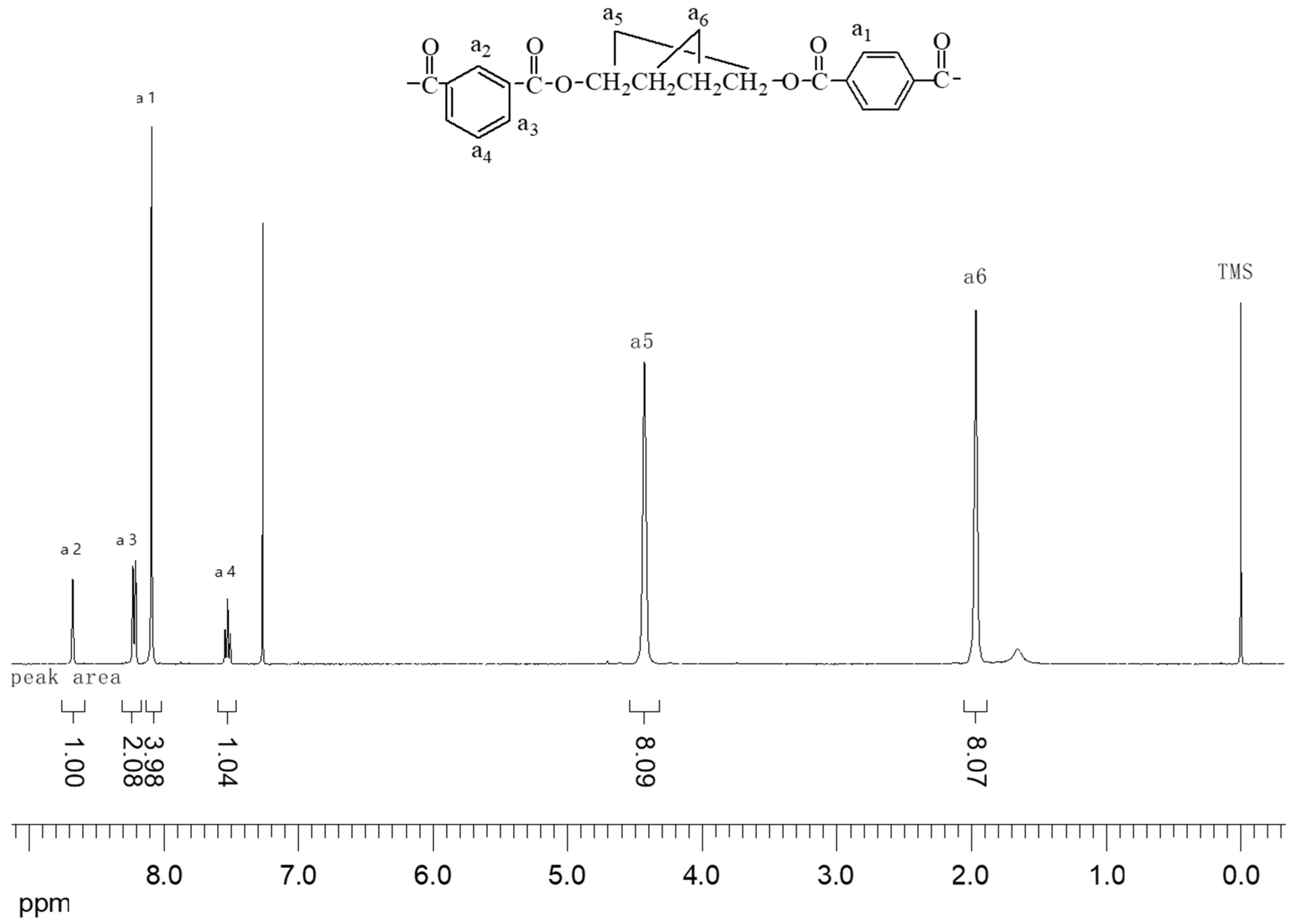

3.3. 1H-NMR

3.4. Thermal Performance

3.5. Intrinsic Viscosity of the Hot Melt Copolyester

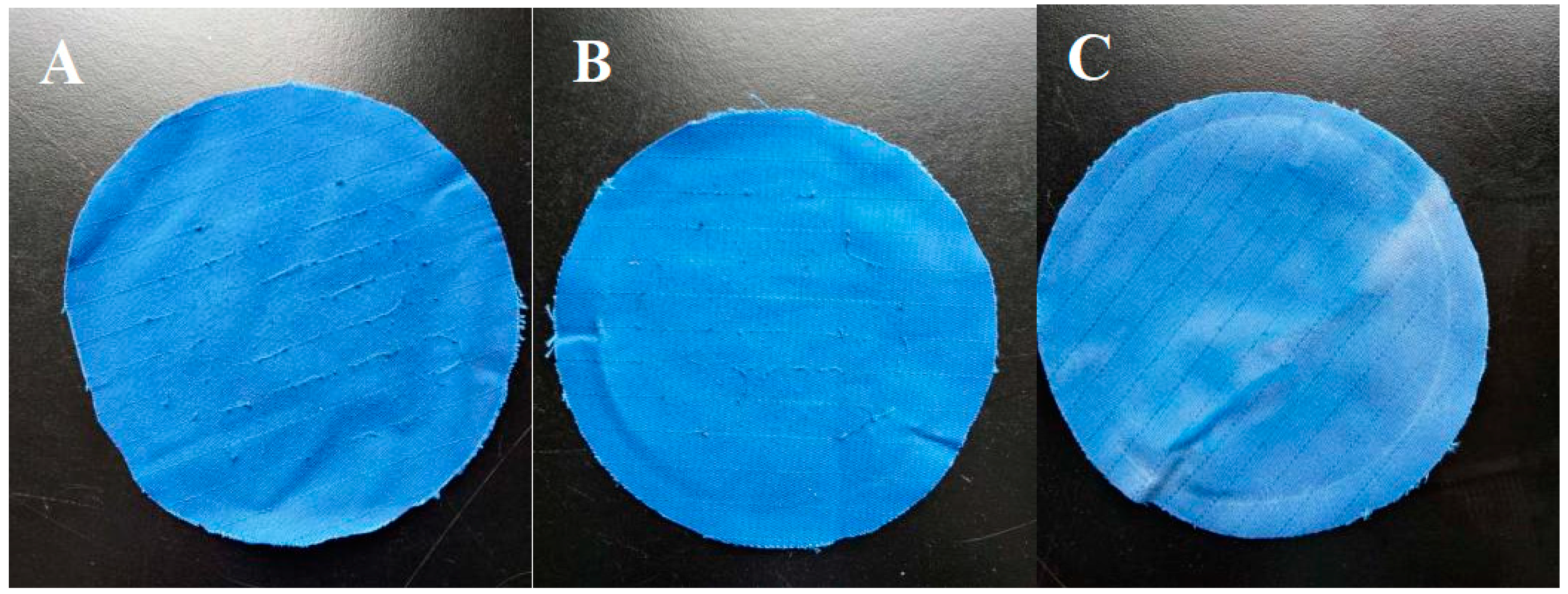

3.6. Anti-Pilling Performance of a Polyester/Cotton Woven Fabric

3.7. Mechanical Properties of Polyester/Cotton Woven Fabrics

3.8. Other Properties of the Treated Fabrics

3.9. Anti-Pilling Mechanism

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Packham, D.E. Handbook of Adhesion; Longman Group Limited: New York, NY, USA, 1990. [Google Scholar]

- Xie, P.; He, H.; Luo, Y.; Jia, D. Research progress of new hot melt adhesives. China Adhes. 2001, 3, 46–48. [Google Scholar]

- Webster, I. Recent developments in pressure-sensitive adhesives for medical applications. Int. J. Adhes. Adhes. 1997, 17, 69–73. [Google Scholar] [CrossRef]

- Li, R.; Yu, L.; Gao, B. Progress in preparation and application of polymer microspheres. Guangzhou Chem. Ind. 2011, 39, 14–16. [Google Scholar]

- Le Corre, P.; Le Guevello, P.; Gajan, V.; Chevanne, F.; Le Verge, R. Preparation and characterization of bupivacaine-loaded polylactide and polylactide-co-glycolide microspheres. Int. J. Pharm. 1994, 107, 41–49. [Google Scholar] [CrossRef]

- Bayomi, M.A.; Al-Suwayeh, S.A.; El-Helw, A.M.; Mesnad, A.F. Preparation of casein–chitosan microspheres containing diltiazem hydrochloride by an aqueous coacervation technique. Pharm. Acta Helv. 1998, 73, 187–192. [Google Scholar] [CrossRef]

- Hou, W.H.; Lloyd, T.B. A new technique for preparing monodisperse polymer particles. J. Appl. Polym. Sci. 1992, 45, 1783–1788. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, D.; Li, C. Study on Swelling and Milling Method of Polyester Hot Melt Adhesive. J. Hebei Inst. Technol. 1993, 22, 8–13. [Google Scholar]

- Textor, T.; Knittel, D.; Bahners, T.; Schollmeyer, E. Inorganic-organic hybrid polymers for coating textile materials. Curr. Trends Polym. Sci. 2003, 8, 127–133. [Google Scholar]

- Yang, S.; Zhang, C.; Shen, X. Reducing pilling of knitted woolen fabric based on micro-scale. Int. J. Cloth. Sci. Technol. 2017, 29, 138–147. [Google Scholar] [CrossRef]

- Dalbasi, E.S.; Ozcelik Kayseri, G. A research about the effect of the anti-pilling treatments on different structured cotton knitted fabrics. Tekstil Konfeksiyon 2015, 25, 54–60. [Google Scholar]

- Periolatto, M.; Ferrero, F.; Vineis, C.; Rombaldoni, F. Multifunctional finishing of wool fabrics by chitosan UV-grafting: An approach. Carbohydr. Polym. 2013, 98, 624–629. [Google Scholar] [CrossRef] [PubMed]

- Montazer, M.; Mazaheri, F.; Khosravian, S.; Azimi, M.; Bameni Moghadam, M.; Sadeghi, A.H. Application of Resins and Crosslinking Agents on Fiber Blend Fabric to Reduce Pilling Performance, Optimized by Response Surface Methodology. J. Vinyl Addit. Technol. 2011, 17, 213–221. [Google Scholar] [CrossRef]

- Cao, W.; Gu, Z. Application of Anti-pilling Finishing and Anti-pilling Agent ATP for Fabrics. Text. Aux. 2003, 20, 35–38. [Google Scholar]

- Xu, W.; Zhou, X. Synthesis and Application of Silicone Modified Polyurethane Anti-pilling Finishing Agent. Text. Aux. 2018, 35, 18–21. [Google Scholar]

- Tusief, M.Q.; Mahmood, N.; Saleem, M. Effect of different anti pilling agents to reduce pilling on polyester/cotton fabric. J. Chem. Soc. Pak. 2012, 34, 53–57. [Google Scholar]

- Rombaldoni, F.; Mossotti, R.; Montarsolo, A.; Songia, M.B.; Innocenti, R.; Mazzuchetti, G. Thin film deposition by PECVD using HMDSO-O(2)-Ar gas mixture on knitted wool fabrics in order to improve pilling resistance. Fiber Polym. 2008, 9, 566–573. [Google Scholar] [CrossRef]

- Kowalczyk, D.; Brzeziński, S.; Kamińska, I. Multifunctional bioactive and improving the performance durability nanocoatings for finishing PET/CO woven fabrics by the sol–gel method. J. Alloys Compd. 2015, 649, 387–393. [Google Scholar] [CrossRef]

- Noreen, H.; Zia, M.A.; Ali, S.; Hussain, T. Optimization of bio-polishing of polyester/cotton blended fabrics with cellulases prepared from Aspergillus niger. Indian J. Biotechnol. 2014, 13, 108–113. [Google Scholar]

- Li, X.; Wu, L.; Cheng, L.; Yu, J. Anti-pilling performance of soybean protein composite fiber fabric. J. Text. Res. 2007, 28, 34–36. [Google Scholar]

- Zhang, Y.; Wu, C.; Feng, Z.; Liu, F.; Zhang, A.; Wang, L. Synthesis and characterization of poly(butylene terephthalate-co-cyclohexane dimethanol terephthalate)-b -polyethylene glycol block copolymer. Chem. J. Chin. Univ. 2004, 25, 376–381. [Google Scholar]

- Chen, Y.; Yang, S. NMR Determination of the Content of Terephthalic Acid in Copolyester. Polyest. Ind. 2003, 16, 18–20. [Google Scholar]

| Chemical Shift (ppm) | H position on the Chain | H Number | Peak Area | Corresponding Peak Area of Each H |

|---|---|---|---|---|

| 8.675 | a2 | 1 | 1 | 1 |

| 8.209~8.229 | a3 | 2 | 2.08 | 1.040 |

| 8.090 | a1 | 4 | 3.98 | 0.995 |

| 7.506~7.545 | a4 | 1 | 1.04 | 1.040 |

| 4.430 | a5 | 4 | 8.09 | 2.023 |

| 1.968 | a6 | 4 | 8.07 | 2.018 |

| Solution | Glass Transition Temperature (°C) | Melting Point (°C) | Inherent Viscosity η/(dL/g) |

|---|---|---|---|

| Hot melt copolyester | 60 | 125.4 | 0.683 |

| Hot melt copolyester particles | 55 | 125.1 | 0.637 |

| Polyester/Cotton Woven Fabric | Grade after Washing 3 Times | Grade after Washing 20 Times | Grade after Washing 50 Times |

|---|---|---|---|

| A (0 g/L) | 2 | 2 | 2 |

| B (0.25 g/L) | 3.5 | 3.5 | 3–3.5 |

| C (0.50 g/L) | 4.5–5 | 4.5–5 | 4.5–5 |

| Polyester/Cotton Woven Fabric | Air Permeability (mm/s) | Bending Stiffness (cN·cm) | Flexuralmodulus (cN/cm2) | Resilience (%) |

|---|---|---|---|---|

| A (0 g/L) | 53.09 | 0.57 | 2.48 | 39.28 |

| B (0.25 g/L) | 52.68 | 0.59 | 2.57 | 47.2 |

| C (0.50 g/L) | 51.33 | 0.60 | 2.61 | 49.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Z.; Chen, W. Preparation and Characterization of Hot Melt Copolyester (PBTI) Ultrafine Particles and Their Effect on the Anti-Pilling Performance of Polyester/Cotton Fabrics. Polymers 2018, 10, 1163. https://doi.org/10.3390/polym10101163

Huang Z, Chen W. Preparation and Characterization of Hot Melt Copolyester (PBTI) Ultrafine Particles and Their Effect on the Anti-Pilling Performance of Polyester/Cotton Fabrics. Polymers. 2018; 10(10):1163. https://doi.org/10.3390/polym10101163

Chicago/Turabian StyleHuang, Zhichao, and Wenxing Chen. 2018. "Preparation and Characterization of Hot Melt Copolyester (PBTI) Ultrafine Particles and Their Effect on the Anti-Pilling Performance of Polyester/Cotton Fabrics" Polymers 10, no. 10: 1163. https://doi.org/10.3390/polym10101163

APA StyleHuang, Z., & Chen, W. (2018). Preparation and Characterization of Hot Melt Copolyester (PBTI) Ultrafine Particles and Their Effect on the Anti-Pilling Performance of Polyester/Cotton Fabrics. Polymers, 10(10), 1163. https://doi.org/10.3390/polym10101163