Effect of Different Compatibilizers on Sustainable Composites Based on a PHBV/PBAT Matrix Filled with Coffee Silverskin

Abstract

:1. Introduction

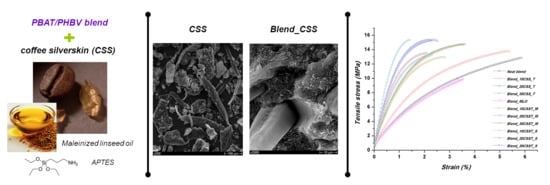

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Characterization of Coffee Silverskin

2.2.2. Production of biocomposites

2.2.3. Mechanical Characterization of Biocomposites

2.2.4. Thermal Characterization of Biocomposites

2.2.5. Morphological Analysis

3. Results

3.1. Chemical, Thermal and Morphological Analysis of Raw and Treated CSS

3.2. Tensile Properties of Composites

3.3. Thermal properties of composites

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Stahel, W.R. The circular economy. Nature 2016, 531, 435–438. [Google Scholar] [CrossRef] [PubMed]

- Kaur, G.; Uisan, K.; Lun Ong, K.; SzeKi Lin, C. Recent Trends in Green and Sustainable Chemistry & Waste Valorisation: Rethinking Plastics in a circular economy. Curr. Opin. Green Sustain. Chem. 2018, 9, 30–39. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Machado, E.M.S.; Martins, S.; Teixeira, J.A. Production, composition, and application of coffee and its industrial residues. Food Bioprocess Technol. 2011, 4, 661–672. [Google Scholar] [CrossRef] [Green Version]

- Costa, A.S.G.; Alvesa, R.C.; Vinha, A.F.; Costa, E.; Costa, C.S.G.; Nunes, M.A.; Almeida, A.A.; Santos-Silva, A.; Oliveira, M.B.P.P. Nutritional, chemical and antioxidant/pro-oxidant profiles of silverskin, a coffee roasting by-product. Food Chem. 2018, 267, 28–35. [Google Scholar] [CrossRef] [PubMed]

- Siriwong, C.; Boopasiri, S.; Jantarapibun, V.; Kongsook, B.; Pattanawanidchai, S.; Sae-Oui, P. Properties of natural rubber filled with untreated and treated spent coffee grounds. J. Appl. Polym. Sci. 2018, 135, 46060. [Google Scholar] [CrossRef]

- Essabir, H.; Raji, M.; Laaziz, S.A.; Rodrique, D.; Bouhfid, R.; el kacem Qaiss, A. Thermo-mechanical performances of polypropylene biocomposites based on untreated, treated and compatibilized spent coffee grounds. Compos. Part B Eng. 2018, 149, 1–11. [Google Scholar] [CrossRef]

- Moustafa, H.; Guizani, C.; Dupont, C.; Martin, V.; Jeguirim, M.; Dufresne, A. Utilization of Torrefied Coffee Grounds as Reinforcing Agent to Produce High-Quality Biodegradable PBAT Composites for Food Packaging Applications. ACS Sustain. Chem. Eng. 2017, 5, 1906–1916. [Google Scholar] [CrossRef]

- Lee, H.K.; Park, Y.G.; Jeong, T.; Song, Y.S. Green nanocomposites filled with spent coffee grounds. J. Appl. Polym. Sci. 2015, 132, 42043. [Google Scholar] [CrossRef]

- Wu, H.; Hu, W.; Zhang, Y.; Huang, L.; Zhang, J.; Tan, S.; Cai, X.; Liao, X. Effect of oil extraction on properties of spent coffee ground–plastic composites. J. Mater. Sci. 2016, 51, 10205–10214. [Google Scholar] [CrossRef]

- Zarrinbakhsh, N.; Wang, T.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A.K. Characterization of wastes and coproducts from the coffee industry for composite material production. BioResources 2016, 11, 7637–7653. [Google Scholar] [CrossRef]

- Campos-Vega, R.; Loarca-Piña, G.; Vergara-Castañeda, H.A.; Oomah, B.D. Spent coffee grounds: A review on current research and future prospects. Trends Food Sci. Technol. 2015, 45, 24–36. [Google Scholar] [CrossRef]

- Esquivel, P.; Jiménez, V.M. Functional properties of coffee and coffee by-products. Food Res. Int. 2012, 16, 488–495. [Google Scholar] [CrossRef]

- Xu, H.; Xie, L.; Hakkarainen, M. Coffee-Ground-Derived Quantum Dots for Aqueous Processable Nanoporous Graphene Membranes. ACS Sustain. Chem. Eng. 2017, 5, 5360–5367. [Google Scholar] [CrossRef]

- Puga, H.; Alves, R.C.; Costa, A.S.; Vinha, A.F.; Oliveira, M.B.P.P. Multi-frequency multimode modulated technology as a clean, fast, and sustainable process to recover antioxidants from a coffee by-product. J. Clean. Prod. 2017, 168, 14–21. [Google Scholar] [CrossRef]

- Bessada, S.M.F.; Alves, R.C.P.P.; Oliveira, M.B. Coffee Silverskin: A Review on Potential Cosmetic Applications. Cosmetics 2018, 5, 5. [Google Scholar] [CrossRef]

- Bessada, S.M.F.; Alves, R.C.; Costa, A.S.G.; Nunes, M.A.; Oliveira, M.B.P.P. Coffea canephora silverskin from different geographical origins: A comparative study. Sci. Total. Environ. 2018, 645, 1021–1028. [Google Scholar] [CrossRef] [PubMed]

- Sarasini, F.; Tirillò, J.; Zuorro, A.; Maffei, G.; Lavecchia, R.; Puglia, D.; Dominici, F.; Luzi, F.; Valente, T.; Torre, L. Recycling coffee silverskin in sustainable composites based on a poly(butylene adipate-co-terephthalate)/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) matrix. Ind. Crops Prod. 2018, 118, 311–320. [Google Scholar] [CrossRef]

- Garcia-Campo, M.J.; Quiles-Carrillo, L.; Masia, J.; Reig-Pérez, M.J.; Montanes, N.; Balart, R. Environmentally Friendly Compatibilizers from Soybean Oil for Ternary Blends of Poly(lactic acid)-PLA, Poly(ε-caprolactone)-PCL and Poly(3-hydroxybutyrate)-PHB. Materials 2017, 10, 1339. [Google Scholar] [CrossRef] [PubMed]

- Ferri, J.M.; Garcia-Garcia, D.; Sánchez-Nacher, L.; Fenollar, O.; Balart, R. The effect of maleinized linseed oil (MLO) on mechanical performance of poly(lactic acid)-thermoplastic starch (PLA-TPS) blends. Carbohydr. Polym. 2016, 147, 60–68. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Quiles-Carrillo, L.; Montanes, N.; Sammon, C.; Balart, R.; Torres-Giner, S. Compatibilization of highly sustainable polylactide/almond shell flour composites by reactive extrusion with maleinized linseed oil. Ind. Crops Prod. 2018, 111, 878–888. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Garcia-Garcia, D.; Carbonell-Verdu, A.; Balart, R.; Torres-Giner, S. Effect of different compatibilizers on injection-molded green composite pieces based on polylactide filled with almond shell flour. Compos. Part B Eng. 2018, 147, 76–85. [Google Scholar] [CrossRef]

- Panusa, A.; Zuorro, A.; Lavecchia, R.; Marrosu, G.; Petrucci, R. Recovery of Natural Antioxidants from Spent Coffee Grounds. J. Agric. Food Chem. 2013, 61, 4162–4168. [Google Scholar] [CrossRef] [PubMed]

- Conde, E.; Cara, C.; Moure, A.; Ruiz, E.; Castro, E.; Domínguez, H. Antioxidant activity of the phenolic compounds released by hydrothermal treatments of olive tree pruning. Food Chem. 2009, 114, 806–812. [Google Scholar] [CrossRef]

- Bittmann, B.; Bouza, R.; Barral, L.; Castro-Lopez, M.; Dopico-Garcia, S. Morphology and thermal behavior of poly (3-hydroxybutyrate-co-3-hydroxyvalerate)/poly(butylene adipate-co-terephthalate)/clay nanocomposites. Polym. Compos. 2015, 36, 2051–2058. [Google Scholar] [CrossRef]

- Javadi, A.; Srithep, Y.; Lee, J.; Pilla, S.; Clemons, C.; Gong, S.; Turng, L.S. Processing and characterization of solid and microcellular PHBV/PBAT blend and its RWF/nanoclay composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 982–990. [Google Scholar] [CrossRef]

- Conde, T.; Mussatto, S.I. Isolation of polyphenols from spent coffee grounds and silverskin by mild hydrothermal pretreatment. Prep. Biochem. Biotechnol. 2016, 46, 406–409. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Farah, A. Chapter 2: Coffee Constituents. In Coffee: Emerging Health Effects and Disease Prevention; Chu, Y.-F., Ed.; Wiley: Hoboken, NJ, USA, 2012; ISBN 978-0-470-95878-0. [Google Scholar]

- Zuorro, A.; Lavecchia, R. Influence of Extraction Conditions on the Recovery of Phenolic Antioxidants from Spent Coffee Grounds. Am. J. Appl. Sci. 2013, 10, 478–486. [Google Scholar] [CrossRef]

- Zarrinbakhsh, N.; Misra, M.; Mohanty, A.K. Biodegradable Green Composites from Distiller−s Dried Grains with Solubles (DDGS) and a Polyhydroxy(butyrate-co-valerate) (PHBV)-Based Bioplastic. Macromol. Mater. Eng. 2011, 296, 1035–1045. [Google Scholar] [CrossRef]

- Floegel, A.; Kim, D.O.; Chung, S.J.; Koo, S.I.; Chun, O.K. Comparison of ABTS/DPPH assays to measure antioxidant capacity in popular antioxidant-rich US foods. J. Food Compos. Anal. 2011, 24, 1043–1048. [Google Scholar] [CrossRef]

- Moreira, A.S.; Nunes, F.M.; Domingues, M.R.; Coimbra, M.A. Coffee melanoidins: Structures, mechanisms of formation and potential health impacts. Food Funct. 2012, 3, 903–915. [Google Scholar] [CrossRef] [PubMed]

- Alghooneh, A.; Mohammad Amini, A.; Behrouzian, F.; Ali Razavi, SH. Characterisation of cellulose from coffee silverskin. Int. J. Food Prop. 2017, 20, 2830–2843. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Abdan, K.; RidzwanIshak, M. Effect of Alkali and Silane Treatments on Mechanical and Fibre-matrix Bond Strength of Kenaf and Pineapple Leaf Fibres. J. Bionic Eng. 2016, 13, 426–435. [Google Scholar] [CrossRef]

- Bennet, C.; Rajini, N.; Winowlin Jappes, J.T.; Siva, I.; Sreenivasan, V.S.; Amico, S.C. Effect of the stacking sequence on vibrational behavior of Sansevieria cylindrica/coconut sheath polyester hybrid composites. J. Reinf. Plast. Compos. 2015, 34, 293–306. [Google Scholar] [CrossRef]

- Moustafa, H.; Guizani, C.; Dufresne, A. Sustainable biodegradable coffee grounds filler and its effect on the hydrophobicity, mechanical and thermal properties of biodegradable PBAT composites. J. Appl. Polym. Sci. 2017, 134, 44498. [Google Scholar] [CrossRef]

- Nyambo, C.; Mohanty, A.K.; Misra, M. Polylactide-Based Renewable Green Composites from Agricultural Residues and Their Hybrids. Biomacromolecules 2010, 11, 1654–1660. [Google Scholar] [CrossRef] [PubMed]

- Panthapulakkal, S.; Sain, M. Agro-residue reinforced high-density polyethylene composites: Fiber characterization and analysis of composite properties. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1445–1454. [Google Scholar] [CrossRef]

- Zhang, K.; Misra, M.; Mohanty, A.K. Toughened Sustainable Green Composites from Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) Based Ternary Blends and Miscanthus Biofiber. ACS Sustain. Chem. Eng. 2014, 2, 2345–2354. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Fenollar, O.; Fombuena, V.; Lopez-Martinez, J.; Balart, R. Improvement of Mechanical Ductile Properties of Poly(3-hydroxybutyrate) by Using Vegetable Oil Derivatives. Macromol. Mater. Eng. 2017, 302, 1600330. [Google Scholar] [CrossRef]

- Balart, J.F.; Fombuena, V.; Fenollar, O.; Boronat, T.; Sánchez-Nacher, L. Processing and characterization of high environmental efficiency composites based on PLA and hazelnut shell flour (HSF) with biobased plasticizers derived from epoxidized linseed oil (ELO). Compos. Part B Eng. 2016, 86, 168–177. [Google Scholar] [CrossRef] [Green Version]

- Carbonell-Verdu, A.; Ferri, J.M.; Dominici, F.; Boronat, T.; Sanchez-Nacher, L.; Balart, R.; Torre, L. Manufacturing and compatibilization of PLA/PBAT binary blends by cottonseed oil-based derivatives. Express Polym. Lett. 2018, 12, 808–823. [Google Scholar] [CrossRef]

- Shanks, R.A.; Hodzic, A.; Wong, S. Thermoplastic Biopolyester Natural Fiber Composites. J. Appl. Polym. Sci. 2004, 91, 2114–2121. [Google Scholar] [CrossRef]

- George, J.; Sreekala, M.S.; Thomas, S. A review on interface modification and characterization of natural fiber reinforced plastic composites. Polym. Eng. Sci. 2001, 41, 1471–1485. [Google Scholar] [CrossRef]

- Masirek, R.; Kulinski, Z.; Chionna, D.; Piorkowska, E.; Pracella, M. Composites of poly(L-lactide) with hemp fibers: Morphology and thermal and mechanical properties. J. Appl. Polym. Sci. 2007, 105, 255–268. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López, J.; Ferrándiz, S.; Peltzer, M.A. Characterization of PLA-limonene blends for food packaging applications. Polym. Test. 2013, 32, 760–768. [Google Scholar] [CrossRef]

- Luzi, F.; Fortunati, E.; Jiménez, A.; Puglia, D.; Pezzolla, D.; Gigliotti, G.; Kenny, J.M.; Chiralt, A.; Torre, L. Production and characterization of PLA_PBS biodegradable blends reinforced with cellulose nanocrystals extracted from hemp fibres. Ind. Crops Prod. 2016, 93, 276–289. [Google Scholar] [CrossRef]

| Specimen ID | Matrix (PBAT/PHBV) (wt %) | As-received CSS (wt %) | Extracted CSS (wt %) | Maleinized Linseed Oil (wt %) | Silane- Treated CSS (wt %) |

|---|---|---|---|---|---|

| Neat blend | 100 | - | - | - | - |

| Blend_10CSS_N | 90 | 10 | - | - | - |

| Blend_20CSS_N | 80 | 20 | - | - | - |

| Blend_30CSS_N | 70 | 30 | - | - | - |

| Blend_10CSS_T | 90 | - | 10 | - | - |

| Blend_20CSS_T | 80 | - | 20 | - | - |

| Blend_30CSS_T | 70 | - | 30 | - | - |

| Blend_MLO | 97 | - | - | 3 | - |

| Blend_10CSST_M | 87 | - | 10 | 3 | - |

| Blend_20CSST_M | 77 | - | 20 | 3 | - |

| Blend_30CSST_M | 67 | - | 30 | 3 | - |

| Blend_10CSST_S | 90 | - | - | - | 10 |

| Blend_20CSST_S | 80 | - | - | - | 20 |

| Blend_30CSST_S | 70 | - | - | - | 30 |

| Specimen ID | Tensile Strength (MPa) | Young’s Modulus (MPa) | Strain at Failure (%) |

|---|---|---|---|

| Neat blend | 12.90 ± 0.83 | 429 ± 30 | 5.92 ± 0.54 |

| Blend_10CSS_N | 13.70 ± 0.44 | 663 ± 62 | 4.56 ± 0.15 |

| Blend_20CSS_N | 14.33 ± 0.15 | 1164 ± 133 | 3.25 ± 0.26 |

| Blend_30CSS_N | 13.52 ± 0.31 | 1432 ± 118 | 1.80 ± 0.27 |

| Blend_10CSS_T | 14.82 ± 0.26 | 1015 ± 70 | 3.57 ± 0.39 |

| Blend_20CSS_T | 15.30 ± 0.19 | 1503 ± 52 | 2.45 ± 0.14 |

| Blend_30CSS_T | 15.01 ± 0.75 | 1902 ± 101 | 1.55 ± 0.32 |

| Blend_MLO | 9.88 ± 0.27 | 394 ± 11 | 3.67 ± 0.16 |

| Blend_10CSST_M | 12.86 ± 0.41 | 656 ± 69 | 2.91 ± 0.09 |

| Blend_20CSST_M | 13.32 ± 0.28 | 1317 ± 84 | 2.14 ± 0.36 |

| Blend_30CSST_M | 13.08 ± 0.37 | 1331 ± 80 | 2.24 ± 0.12 |

| Blend_10CSST_S | 13.74 ± 0.34 | 617 ± 13 | 5.07 ± 0.57 |

| Blend_20CSST_S | 14.71 ± 0.22 | 1034 ± 39 | 3.76 ± 0.20 |

| Blend_30CSST_S | 15.38 ± 0.11 | 1566 ± 51 | 2.26 ± 0.09 |

| Specimen ID | Cooling Scan | Second Heating Scan | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tc PBAT (°C) | ΔHc PBAT (J/g) | Tc PHBV (°C) | ΔH c PHBV (J/g) | Tcc PHBV (°C) | ΔH cc PHBV (J/g) | Tm PBAT (°C) | ΔHm _PBAT (J/g) | Tm1_PHBV (°C) | Tm2_PHBV (°C) | ΔH m PHBV (J/g) | Xc PBHV (%) | |

| Neat blend | 72.1 ± 1.3 | 2.5 ± 0.1 | 117.9 ± 1.2 | 4.0 ± 0.1 | 43.0 ± 1.2 | 9.0 ± 0.5 | 129.6 ± 1.2 | 6.4 ± 0.3 | 160.2 ± 0.8 | 169.3 ± 0.5 | 23.8 ± 1.1 | 38.7 ± 0.5 |

| Blend_10CSS_N | 69.4 ± 1.1 | 1.0 ± 0.2 | 117.7 ± 1.3 | 4.5 ± 0.2 | 43.0 ± 1.1 | 10.1 ± 0.6 | 127.8 ± 1.1 | 5.0 ± 0.2 | 160.3 ± 0.8 | 169.1 ± 0.9 | 23.4 ± 0.8 | 38.8 ± 0.4 |

| Blend_20CSS_N | 64.5 ± 0.5 | 3.5 ± 0.3 | 116.0 ± 1.2 | 4.0 ± 0.2 | 44.2 ± 1.1 | 5.3 ± 0.3 | 129.2 ± 0.9 | 5.2 ± 0.3 | 162.9 ± 0.5 | 171.4 ± 0.8 | 19.7 ± 1.2 | 47.4 ± 0.6 |

| Blend_30CSS_N | 66.1 ± 0.6 | 2.1 ± 0.2 | 115.1 ± 1.1 | 3.9 ± 0.3 | 44.6 ± 1.2 | 6.1 ± 0.4 | 130.3 ± 1.3 | 4.4 ± 0.2 | 160.3 ± 0.4 | 169.8 ± 0.4 | 18.2 ± 1.2 | 45.2 ± 0.7 |

| Blend_10CSS_T | 68.13 ± 0.4 | 4.1 ± 0.2 | 116.4 ± 1.2 | 3.5 ± 0.2 | 42.7± 0.5 | 3.5 ± 0.4 | 129.2 ± 1.2 | 3.2 ± 0.3 | 163.0 ± 0.9 | 171.0 ± 0.5 | 20.9 ± 0.4 | 50.6 ± 0.8 |

| Blend_20CSS_T | 66.0 ± 0.3 | 3.1 ± 0.2 | 116.9 ± 1.5 | 3.1 ± 0.1 | 42.8 ± 0.2 | 3.1 ± 0.2 | 129.7 ± 0.5 | 3.0 ± 0.2 | 161.9 ± 1.2 | 170.5 ± 0.4 | 18.4 ± 0.2 | 50.3 ± 1.5 |

| Blend_30CSS_T | 79.9 ± 1.2 | 4.7 ± 0.5 | 116.5 ± 1.5 | 2.0 ± 0.1 | 43.9 ± 0.4 | 2.1 ± 0.1 | 130.2 ± 1.5 | 2.5 ± 0.1 | 162.7 ± 1.1 | 170.7 ± 0.5 | 17.2 ± 0.4 | 56.7 ± 2.2 |

| Blend_MLO | 72.3 ± 0.6 | 5.1 ± 0.5 | 117.9 ± 1.8 | 2.9 ± 0.2 | 43.1 ± 0.5 | 4.3 ± 0.3 | 128.7 ± 0.8 | 3.0 ± 0.2 | 162.3 ± 1.3 | 170.2 ± 1.1 | 22.6 ± 0.4 | 49.5 ± 1.8 |

| Blend_10CSST_M | 77.8 ± 0.2 | 8.6 ± 0.7 | 116.1 ± 0.5 | 2.2 ± 0.1 | 43.5 ± 0.4 | 1.8 ± 0.1 | 126.8 ± 1.1 | 2.8 ± 0.2 | 162.7 ± 0.4 | 170.7 ± 1.2 | 18.8 ± 0.5 | 51.1 ± 1.7 |

| Blend_20CSST_M | 75.8 ± 0.3 | 6.8 ± 0.4 | 115.7 ± 0.7 | 2.0 ± 0.1 | 43.7 ± 0.7 | 1.5 ± 0.1 | 128.0 ± 1.2 | 3.8 ± 0.5 | 162.5 ± 0.5 | 170.4 ± 0.7 | 17.9 ± 0.6 | 55.9 ± 2.3 |

| Blend_30CSST_M | 79.9 ± 0.4 | 5.7 ± 0.2 | 116.5 ± 0.5 | 2.3 ± 0.1 | 44.4 ± 0.6 | 2.0 ± 0.1 | 129.4 ± 0.4 | 2.7 ± 0.2 | 163.3 ± 0.6 | 170.7 ± 0.5 | 17.3 ± 0.3 | 59.3 ± 2.5 |

| Blend_10CSST_S | 70.7 ± 1.2 | 3.7 ± 0.2 | 117.1 ± 1.1 | 3.5 ± 0.5 | 41.7 ± 0.4 | 5.9 ± 0.3 | 129.7 ± 0.4 | 3.6 ± 0.1 | 162.1 ± 0.5 | 170.9 ± 0.5 | 22.2 ± 1.1 | 47.4 ± 2.4 |

| Blend_20CSST_S | 70.7 ± 1.5 | 1.8 ± 0.1 | 117.2 ± 1.2 | 3.3 ± 0.2 | 41.7 ± 0.8 | 3.8 ± 0.2 | 129.2 ± 0.8 | 3.6 ± 0.2 | 163.0 ± 0.8 | 170.6 ± 0.7 | 21.0 ± 1.2 | 56.1 ± 2.7 |

| Blend_30CSST_S | 73.4 ± 1.2 | 2.8 ± 0.2 | 118.5 ± 1.5 | 3.1 ± 0.2 | 41.4 ± 0.5 | 1.3 ± 0.1 | 131.8 ± 1.1 | 3.3 ± 0.1 | 163.3 ± 0.6 | 170.7 ± 0.4 | 18.2 ± 0.5 | 63.2 ± 2.4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarasini, F.; Luzi, F.; Dominici, F.; Maffei, G.; Iannone, A.; Zuorro, A.; Lavecchia, R.; Torre, L.; Carbonell-Verdu, A.; Balart, R.; et al. Effect of Different Compatibilizers on Sustainable Composites Based on a PHBV/PBAT Matrix Filled with Coffee Silverskin. Polymers 2018, 10, 1256. https://doi.org/10.3390/polym10111256

Sarasini F, Luzi F, Dominici F, Maffei G, Iannone A, Zuorro A, Lavecchia R, Torre L, Carbonell-Verdu A, Balart R, et al. Effect of Different Compatibilizers on Sustainable Composites Based on a PHBV/PBAT Matrix Filled with Coffee Silverskin. Polymers. 2018; 10(11):1256. https://doi.org/10.3390/polym10111256

Chicago/Turabian StyleSarasini, Fabrizio, Francesca Luzi, Franco Dominici, Gianluca Maffei, Annalaura Iannone, Antonio Zuorro, Roberto Lavecchia, Luigi Torre, Alfredo Carbonell-Verdu, Rafael Balart, and et al. 2018. "Effect of Different Compatibilizers on Sustainable Composites Based on a PHBV/PBAT Matrix Filled with Coffee Silverskin" Polymers 10, no. 11: 1256. https://doi.org/10.3390/polym10111256