Multifunctional Hybrid Composites with Enhanced Mechanical and Thermal Properties Based on Polybenzoxazine and Chopped Kevlar/Carbon Hybrid Fibers

Abstract

:1. Introduction

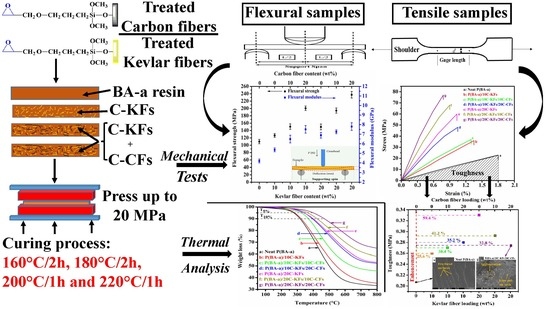

2. Materials and Experimental Study

2.1. Materials

2.2. Hybrid Composites Elaboration

2.3. Experimental Study

3. Results and Discussion

3.1. Surface Characterization of KFs and CFs

3.2. FTIR Studies of the Specimens

3.3. Thermal Properties

3.4. Bending Test

3.5. Tensile Test

3.6. SEM Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ren, D.; Chen, L.; Yuan, Y.; Li, K.; Xu, M.; Liu, X. Designing and Preparation of Fiber-Reinforced Composites with Enhanced Interface Adhesion. Polymers 2018, 10, 1128. [Google Scholar] [CrossRef]

- Agag, T.; Takeichi, T. Preparation and cure behavior of organoclay-modified allyl-functional benzoxazine resin and the properties of their nanocomposites. Polym. Compos. 2008, 29, 750–757. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Lauke, B.; Mäder, E.; Yue, C.-Y.; Hu, X. Tensile properties of short-glass-fiber-and short-carbon-fiber-reinforced polypropylene composites. Compos. Part A 2000, 31, 1117–1125. [Google Scholar] [CrossRef]

- Wu, J.; Cheng, X.H. The tribological properties of Kevlar pulp reinforced epoxy composites under dry sliding and water lubricated condition. Wear 2006, 261, 1293–1297. [Google Scholar] [CrossRef]

- Wan, Y.Z.; Wang, Y.L.; He, F.; Huang, Y.; Jiang, H.J. Mechanical performance of hybrid bismaleimide composites reinforced with three-dimensional braided carbon and Kevlar fabrics. Compos. Part A 2007, 38, 495–504. [Google Scholar] [CrossRef]

- Wang, J.; Chen, P.; Xiong, X.; Jia, C.; Yu, Q.; Ma, K. Interface characteristic of aramid fiber reinforced poly(phthalazinone ether sulfone ketone) composite. Surf. Interface Anal. 2017, 49, 788–793. [Google Scholar] [CrossRef]

- Campbell, F.C. Fibres and Reinforcements: The String That Provides the Strength. In Manufacturing Processes for Advanced Composites; Elsevier: Oxford, UK, 2004; pp. 39–62. ISBN 978-1-85617-415-2. [Google Scholar]

- Brunovska, Z.; Lyon, R.; Ishida, H. Thermal properties of phthalonitrile functional polybenzoxazines. Thermochim. Acta 2000, 357, 195–203. [Google Scholar] [CrossRef]

- Kim, H.J.; Brunovska, Z.; Ishida, H. Molecular characterization of polymerization of acetylene-functional benzoxazine resins. Polymer 1999, 40, 1815–1822. [Google Scholar] [CrossRef]

- Su, Y.C.; Chang, F.C. Synthesis and characterization of fluorinated polybenzoxazine material with low dielectric constant. Polymer 2003, 44, 7989–7996. [Google Scholar] [CrossRef]

- Ishida, H.; Allen, D.J. Mechanical characterization of copolymers based on benzoxazine and epoxy. Polymer 1996, 37, 4487–4495. [Google Scholar] [CrossRef]

- Ishida, H.; Allen, D.J. Physical and mechanical characterization of near-zero shrinkage polybenzoxazines. J. Polym. Sci. Part B 1996, 34, 1019–1030. [Google Scholar] [CrossRef]

- Kishore, V.C.; Dhanya, R.; Sreekumar, K.; Joseph, R.; Kartha, C.S. Spectral distribution of photocurrent in poly(6-tert-butyl-3-methyl-3,4-dihydro-2H-1,3-benzoxazine). Synth. Met. 2008, 158, 676–680. [Google Scholar] [CrossRef]

- Walters, R.N.; Lyon, R.E. Molar group contributions to polymer flammability. J. Appl. Polym. Sci. 2003, 87, 548–563. [Google Scholar] [CrossRef]

- Agag, T.; Takeichi, T. Polybenzoxazine-montmorillonite hybrid nanocomposites: Synthesis and characterization. Polymer 2000, 41, 7083–7090. [Google Scholar] [CrossRef]

- Zhang, H.E.; Zhang, B.F.; Wang, G.F.; Dong, X.H.; Gao, Y. The structure and magnetic properties of Zn1-xNixFe2O4ferrite nanoparticles prepared by sol-gel auto-combustion. J. Magn. Magn. Mater. 2007, 312, 126–130. [Google Scholar] [CrossRef]

- Kiskan, B.; Ghosh, N.N.; Yagci, Y. Polybenzoxazine-based composites as high-performance materials. Polym. Int. 2011, 60, 167–177. [Google Scholar] [CrossRef]

- Soto, M.; Hiller, M.; Oschkinat, H.; Koschek, K. Multifunctional benzoxazines feature low polymerization temperature and diverse polymer structures. Polymers 2016, 8, 278. [Google Scholar] [CrossRef]

- Ramdani, N.; Wang, J.; Wang, H.; Feng, T.; Derradji, M.; Liu, W. Mechanical and thermal properties of silicon nitride reinforced polybenzoxazine nanocomposites. Compos. Sci. Technol. 2014, 105, 73–79. [Google Scholar] [CrossRef]

- Shen, S.B.; Ishida, H. Development and characterization of high-performance polybenzoxazine composites. Polym. Compos. 1996, 17, 710–719. [Google Scholar] [CrossRef]

- Ohsawa, T.; Nakayama, A.; Miwa, M.; Hasegawa, A. Temperature dependence of critical fiber length for glass fiber-reinforced thermosetting resins. J. Appl. Polym. Sci. 1978, 22, 3203–3212. [Google Scholar] [CrossRef]

- Barone, M.R.; Caulk, D.A. The effect of deformation and thermoset cure on heat conduction in a chopped-fiber reinforced polyester during compression molding. Int. J. Heat Mass Transfer 1979, 22, 1021–1032. [Google Scholar] [CrossRef]

- Hong, B.; Xian, G.; Li, H. Comparative study of the durability behaviors of epoxy- and polyurethane-based CFRP plates subjected to the combined effects of sustained bending and water/seawater immersion. Polymers 2017, 9, 603. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, C.; Zhang, S.; Lin, X. Effect of surface modification on carbon fiber and its reinforced phenolic matrix composite. Appl. Surf. Sci. 2012, 259, 288–293. [Google Scholar] [CrossRef]

- Ma, R.; Li, W.; Huang, M.; Liu, X.; Feng, M. Enhancing strength and toughness of carbon fibers reinforced rigid polyurethane composites with low fiber content. Polym. Test. 2018, 71, 156–162. [Google Scholar] [CrossRef]

- Zheng, N.; He, J.; Zhao, D.; Huang, Y.; Gao, J.; Mai, Y.W. Improvement of atomic oxygen erosion resistance of carbon fiber and carbon fiber/epoxy composite interface with a silane coupling agent. Mater. Des. 2016, 109, 171–178. [Google Scholar] [CrossRef]

- Ai, T.; Wang, R.; Zhou, W. Effect of grafting alkoxysilane on the surface properties of Kevlar fiber. Polym. Compos. 2007, 28, 412–416. [Google Scholar] [CrossRef]

- Wang, H.; Sun, T.; Peng, C.; Wu, Z. Effect of different silane coupling agents on cryogenic properties of silica-reinforced epoxy composites. High Perform. Polym. 2018, 30, 24–37. [Google Scholar] [CrossRef]

- Wang, J.; Ren, T.T.; Wang, Y.D.; He, X.Y.; Liu, W.B.; Shen, X.D. Synthesis, curing behavior and thermal properties of fluorene-containing benzoxazines based on linear and branched butylamines. React. Funct. Polym. 2014, 74, 22–230. [Google Scholar] [CrossRef]

- Ning, X.; Ishida, H. Phenolic materials via ring-opening polymerization: Synthesis and characterization of bisphenol-A based benzoxazines and their polymers. J. Polym. Sci. Part A 1994, 32, 1121–1129. [Google Scholar] [CrossRef]

- Sumerlin, B.S.; Vogt, A.P. Macromolecular engineering through click chemistry and other efficient transformations. Macromolecules 2010, 43, 1–13. [Google Scholar] [CrossRef]

- Xu, Y.; Dai, J.; Ran, Q.; Gu, Y. Greatly improved thermal properties of polybenzoxazine via modification by acetylene/aldehyde groups. Polymer 2017, 123, 232–239. [Google Scholar] [CrossRef]

- Zegaoui, A.; Derradji, M.; Ma, R.; Cai, W.; Medjahed, A.; Liu, W.; Qadeer Dayo, A.; Wang, J. Silane-modified carbon fibers reinforced cyanate ester/benzoxazine resin composites: Morphological, mechanical and thermal degradation properties. Vacuum 2018, 150, 12–23. [Google Scholar] [CrossRef]

- Zhang, Q.; Luo, Z.; Guo, Q.; Wu, G. Preparation and thermal properties of short carbon fibers/erythritol phase change materials. Energy Convers. Manage. 2017, 136, 220–228. [Google Scholar] [CrossRef]

- Kumar, S.; Prasad, L.; Patel, V.K. Effect of Hybridization of Glass/kevlar Fiber on Mechanical Properties of Bast Reinforced Polymer Composites: A Review. Am. J. Polym. Sci. Eng. 2017, 5, 13–23. [Google Scholar]

- Zegaoui, A.; Derradji, M.; Ma, R.; Cai, W.-A.; Liu, W.-B.; Wang, J.; Dayo, A.Q.; Song, S.; Zhang, L.-L. High-performance polymeric materials with greatly improved mechanical and thermal properties from cyanate ester/benzoxazine resin reinforced by silane-treated basalt fibers. J. Appl. Polym. Sci. 2018, 135, 46283. [Google Scholar] [CrossRef]

- Zhang, Y. Mechanical and thermal properties of basalt fiber reinforced poly (butylene succinate) composites. Mater. Chem. Phys. 2012, 133, 845–849. [Google Scholar] [CrossRef]

- Derradji, M.; Ramdani, N.; Zhang, T.; Wang, J.; Feng, T.; Wang, H.; Liu, W. Mechanical and thermal properties of phthalonitrile resin reinforced with silicon carbide particles. Mater. Des. 2015, 71, 48–55. [Google Scholar] [CrossRef]

- Abadyan, M.; Bagheri, R.; Kouchakzadeh, M.A.; Hosseini Kordkheili, S.A. Exploring the tensile strain energy absorption of hybrid modified epoxies containing soft particles. Mater. Des. 2011, 32, 2900–2908. [Google Scholar] [CrossRef]

- Jing, M.; Che, J.; Xu, S.; Liu, Z.; Fu, Q. The effect of surface modification of glass fiber on the performance of poly(lactic acid) composites: Graphene oxide vs. silane coupling agents. Appl. Surf. Sci. 2018, 435, 1046–1056. [Google Scholar] [CrossRef]

| Fibers | Diameter (µm) | Length (mm) | Density (g/cm3) | Tensile Strength (MPa) | Young’s Modulus (GPa) |

|---|---|---|---|---|---|

| Kevlar fiber | 12 | 6 | 1.45 | 2860 | 67 |

| Carbon fiber | 7 | 6.2 | 1.76 | 3500 | 260 |

| No. | Material Type | BA-a (wt %) | KFs (wt %) | CFs (wt %) |

|---|---|---|---|---|

| 1 | Neat P(BA-a) | 100 | 0 | 0 |

| 2 | P(BA-a)/10C-KFs | 90 | 10 | 0 |

| 3 | P(BA-a)/10C-KFs/10C-CFs | 80 | 10 | 10 |

| 4 | P(BA-a)/10C-KFs/20C-CFs | 70 | 10 | 20 |

| 5 | P(BA-a)/20C-KFs | 80 | 20 | 0 |

| 6 | P(BA-a)/20C-KFs/10C-CFs | 70 | 20 | 10 |

| 7 | P(BA-a)/20C-KFs/20C-CFs | 60 | 20 | 20 |

| No. | Material Type | T5% (°C) | T10% (°C) | Yc (%) at 800 °C | THRI (°C) |

|---|---|---|---|---|---|

| 1 | Neat P(BA-a) | 277 | 317 | 33.2 | 175 |

| 2 | P(BA-a)/10C-KFs | 286 | 326 | 35.2 | 182 |

| 3 | P(BA-a)/10C-KFs/10C-CFs | 326 | 373 | 45.8 | 203 |

| 4 | P(BA-a)/10C-KFs/20C-CFs | 346 | 393 | 52.2 | 225 |

| 5 | P(BA-a)/20C-KFs | 332 | 398 | 53.7 | 227 |

| 6 | P(BA-a)/20C-KFs/10C-CFs | 366 | 424 | 58.8 | 246 |

| 7 | P(BA-a)/20C-KFs/20C-CFs | 400 | 471 | 64.9 | 275 |

| No. | Material Type | Flexural Strength (MPa) | Flexural Modulus (GPa) |

|---|---|---|---|

| 1 | Neat P(BA-a) | 110 ± 3.3 | 4.20 ± 1.3 |

| 2 | P(BA-a)/10C-KFs | 126.65 ± 2.4 | 5.36 ± 1.4 |

| 3 | P(BA-a)/10C-KFs/10C-CFs | 150.58 ± 5.1 | 6.49 ± 5.8 |

| 4 | P(BA-a)/10C-KFs/20C-CFs | 221.60 ± 4.2 | 7.51 ± 3.4 |

| 5 | P(BA-a)/20C-KFs | 149.78 ± 7.4 | 6.89 ± 5.3 |

| 6 | P(BA-a)/20C-KFs/10C-CFs | 194.26 ± 6.8 | 7.24 ± 1.2 |

| 7 | P(BA-a)/20C-KFs/20C-CFs | 237.35 ± 7.9 | 7.80 ± 5.4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghouti, H.A.; Zegaoui, A.; Derradji, M.; Cai, W.-a.; Wang, J.; Liu, W.-b.; Dayo, A.Q. Multifunctional Hybrid Composites with Enhanced Mechanical and Thermal Properties Based on Polybenzoxazine and Chopped Kevlar/Carbon Hybrid Fibers. Polymers 2018, 10, 1308. https://doi.org/10.3390/polym10121308

Ghouti HA, Zegaoui A, Derradji M, Cai W-a, Wang J, Liu W-b, Dayo AQ. Multifunctional Hybrid Composites with Enhanced Mechanical and Thermal Properties Based on Polybenzoxazine and Chopped Kevlar/Carbon Hybrid Fibers. Polymers. 2018; 10(12):1308. https://doi.org/10.3390/polym10121308

Chicago/Turabian StyleGhouti, Hamid Abdelhafid, Abdeldjalil Zegaoui, Mehdi Derradji, Wan-an Cai, Jun Wang, Wen-bin Liu, and Abdul Qadeer Dayo. 2018. "Multifunctional Hybrid Composites with Enhanced Mechanical and Thermal Properties Based on Polybenzoxazine and Chopped Kevlar/Carbon Hybrid Fibers" Polymers 10, no. 12: 1308. https://doi.org/10.3390/polym10121308