Paper Electrodes Coated with Partially-Exfoliated Graphite and Polypyrrole for High-Performance Flexible Supercapacitors

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PPy-EG-paper

2.3. Characterization

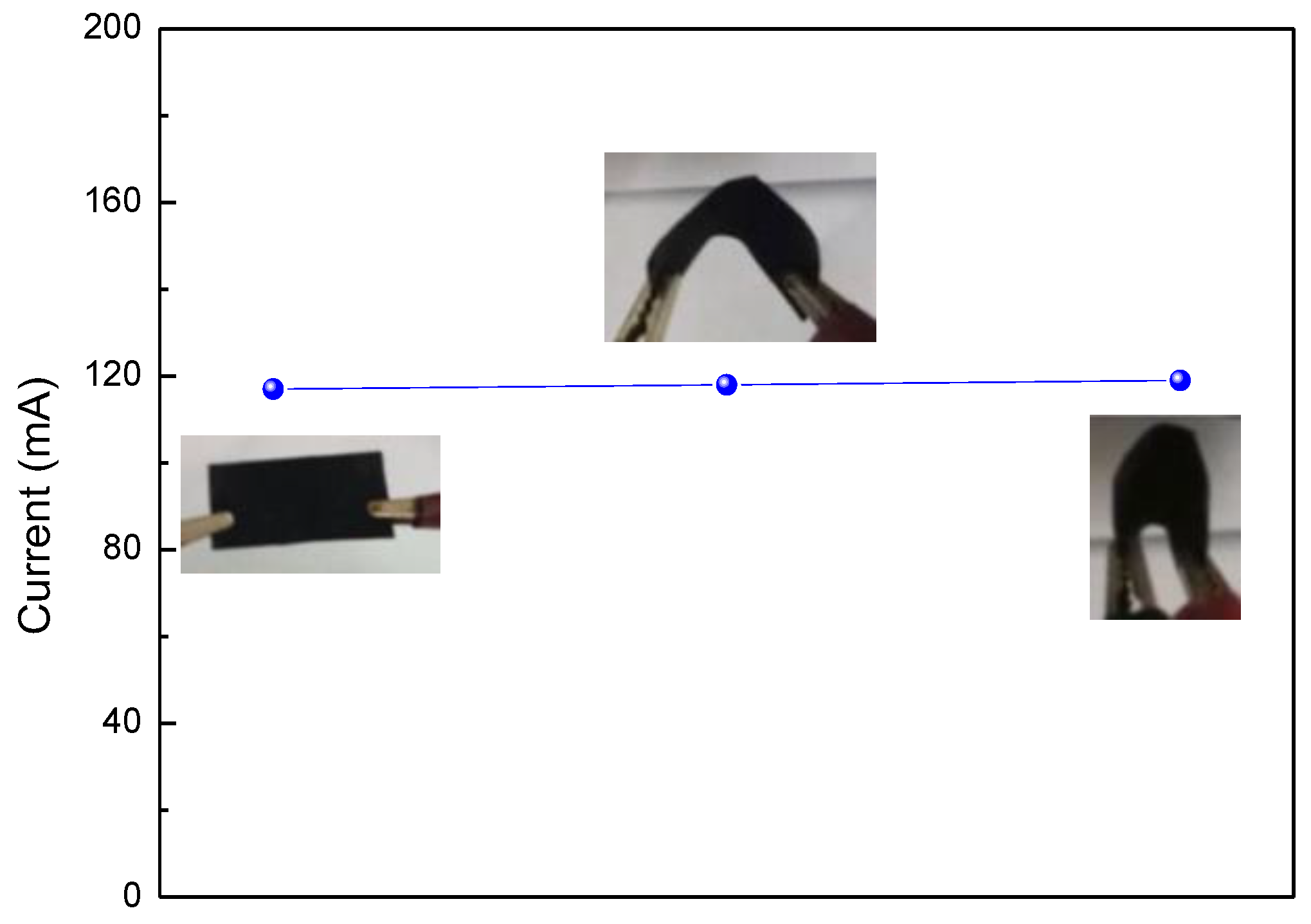

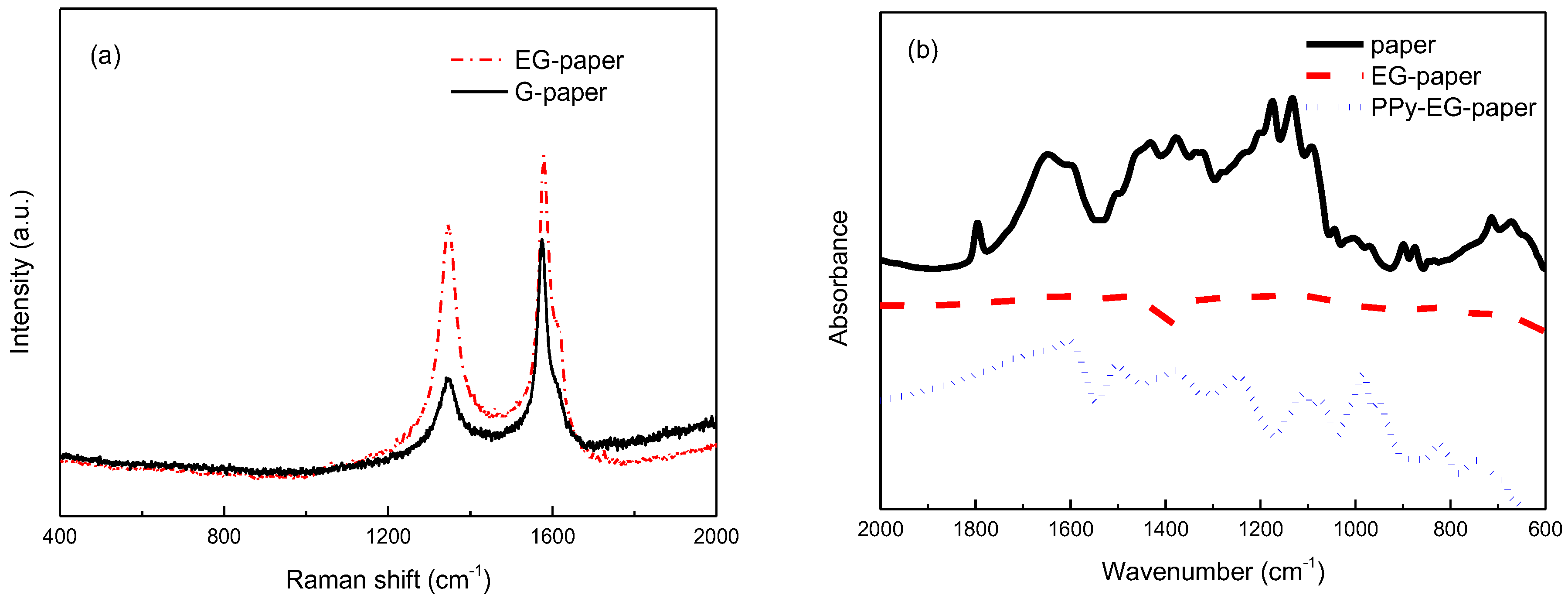

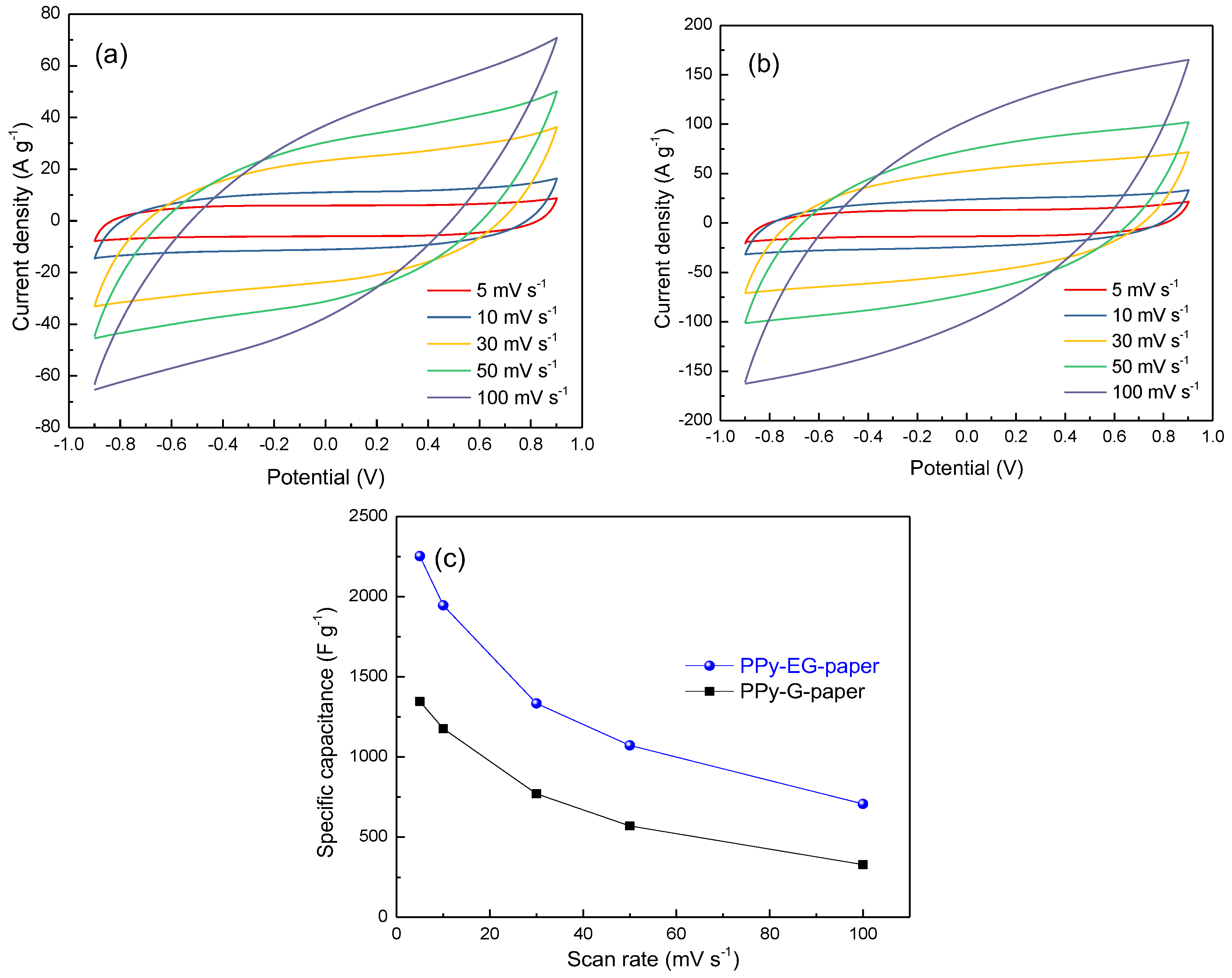

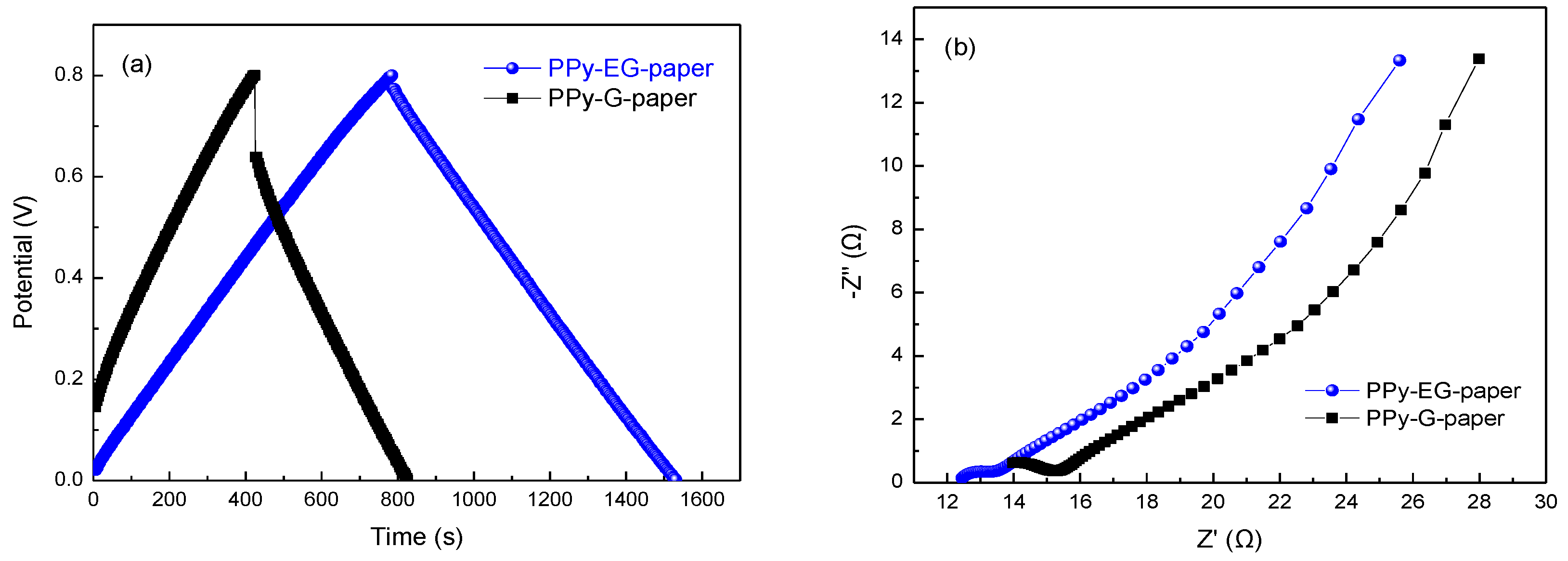

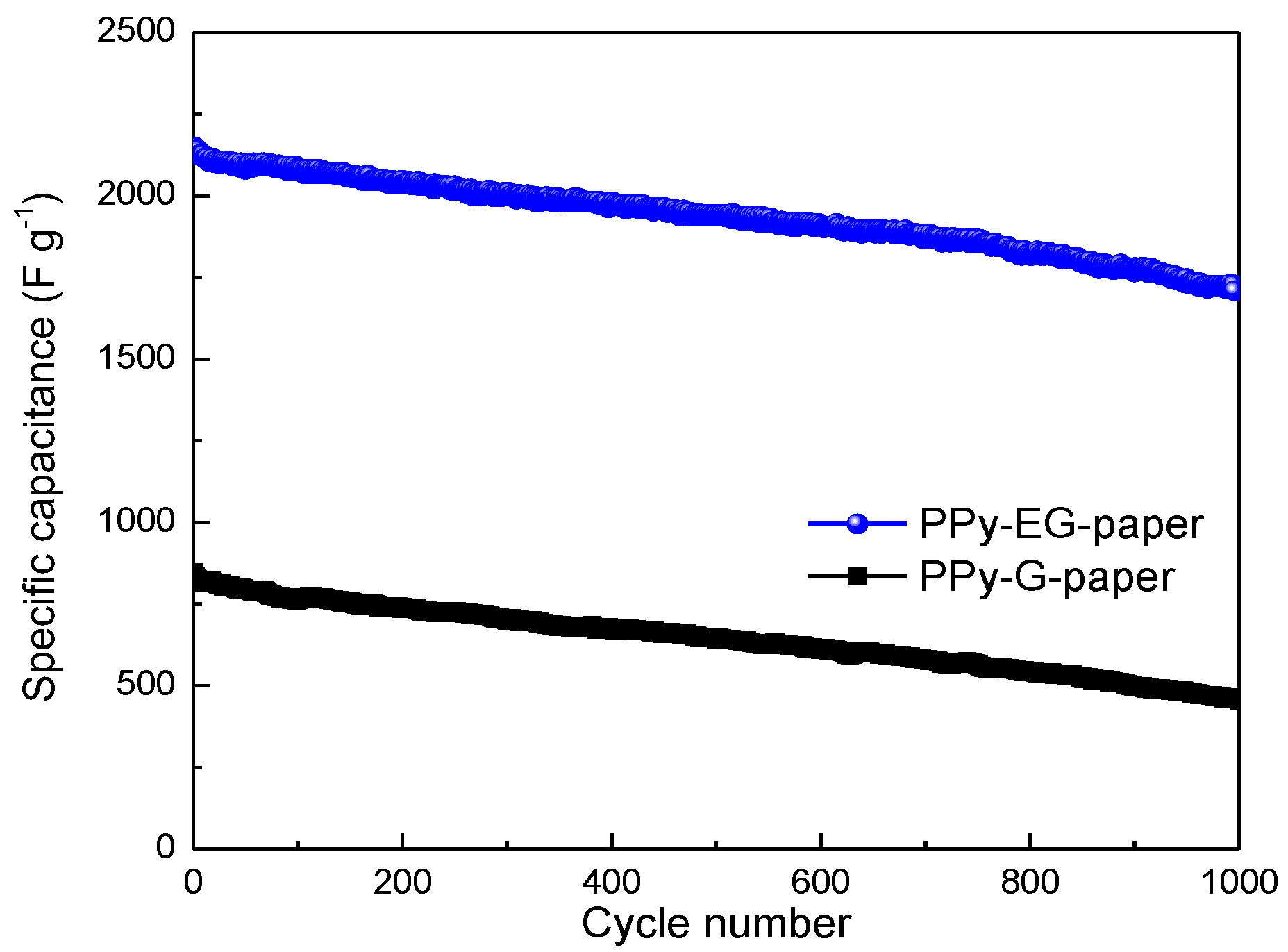

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hu, L.; Pasta, M.; Mantia, F.L.; Cui, L.; Jeong, S.; Deshazer, H.D.; Choi, J.W.; Han, S.M.; Cui, Y. Stretchable, Porous, and Conductive Energy Textiles. Nano Lett. 2010, 10, 708–714. [Google Scholar] [CrossRef] [PubMed]

- Shim, B.S.; Chen, W.; Doty, C.; Xu, C.; Kotov, N.A. Smart electronic yarns and wearable fabrics for human biomonitoring made by carbon nanotube coating with polyelectrolytes. Nano Lett. 2008, 8, 4151–4157. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Wu, H.; Mantia, F.L.; Yang, Y.; Cui, Y. Thin, Flexible Secondary Li-Ion Paper Batteries. ACS Nano 2010, 10, 5843–5848. [Google Scholar] [CrossRef] [PubMed]

- Yuan, C.; Hou, L.; Li, D.; Shen, L.; Zhang, F.; Zhang, X. Synthesis of flexible and porous cobalt hydroxide/conductive cotton textile sheet and its application in electrochemical capacitors. Electrochim. Acta 2011, 56, 6683–6687. [Google Scholar] [CrossRef]

- Liu, W.-W.; Yan, X.-B.; Lang, J.-W.; Peng, C.; Xue, Q.-J. Flexible and conductive nanocomposite electrode based on graphene sheets and cotton cloth for supercapacitor. J. Mater. Chem. 2012, 22, 17245–17253. [Google Scholar] [CrossRef]

- Yao, B.; Jing, Z.; Kou, T.; Yu, S.; Liu, T.; Li, Y. Paper-based Electrodes for Flexible Energy Storage Devices. Adv. Sci. 2017, 4, 1700107. [Google Scholar] [CrossRef] [PubMed]

- Cai, X.; Peng, M.; Yu, X.; Fu, Y.; Zou, D. Flexible planar/fiber-architectured supercapacitors for wearable energy storage. J. Mater. Chem. C 2014, 2, 1184–1200. [Google Scholar] [CrossRef]

- Jost, K.; Dion, G.; Gogotsi, Y. Textile energy storage in perspective. J. Mater. Chem. A 2014, 2, 10776–10787. [Google Scholar] [CrossRef]

- Simon, P.; Gogotsi, Y.; Dunn, B. Where Do Batteries End and Supercapacitors Begin? Science 2014, 343, 1210–1211. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ramya, R.; Sivasubramanian, R.; Sangaranarayanan, M.V. Conducting polymers-based Electrochemical Supercapacitors-Progress and Prospects. Electrochim. Acta 2013, 101, 109–129. [Google Scholar] [CrossRef]

- Wang, X.; Deng, J.; Duan, X.; Liu, D.; Liu, P. Fluorescent brightener CBS-X doped polypyrrole as smart electrode material for supercapacitors. Appl. Energy 2015, 153, 70–77. [Google Scholar] [CrossRef]

- Xu, J.; Zhu, L.; Bai, Z.; Liang, G.; Liu, L.; Fang, D.; Xu, W. Conductive polypyrrole-bacterial cellulose nanocomposite membranes as flexible supercapacitor electrode. Org. Electron. 2013, 14, 3331–3338. [Google Scholar] [CrossRef]

- Liang, G.; Zhu, L.; Xu, J.; Fang, D.; Bai, Z.; Xu, W. Investigations of poly(pyrrole)-coated cotton fabrics prepared in blends of anionic and cationic surfactants as flexible electrode. Electrochim. Acta 2013, 103, 9–14. [Google Scholar] [CrossRef]

- Zhu, L.; Wu, L.; Sun, Y.; Li, M.; Xu, J.; Bai, Z.; Liang, G.; Liu, L.; Fang, D.; Xu, W. Cotton fabrics coated with lignosulfonate-doped polypyrrole for flexible supercapacitor electrodes. RSC Adv. 2014, 4, 6261–6266. [Google Scholar] [CrossRef]

- Xu, J.; Wang, D.; Yuan, Y.; Wei, W.; Gu, S.; Liu, R.; Wang, X.; Liu, L.; Xu, W. Polypyrrole-coated cotton fabrics for flexible supercapacitor electrodes prepared using CuO nanoparticles as template. Cellulose 2015, 22, 1355–1363. [Google Scholar] [CrossRef]

- Xu, J.; Wang, D.; Yuan, Y.; Wei, W.; Duan, L.; Wang, L.; Bao, H.; Xu, W. Polypyrrole/reduced graphene oxide coated fabric electrodes for supercapacitor application. Org. Electron. 2015, 24, 153–159. [Google Scholar] [CrossRef]

- Xu, J.; Wang, D.; Fan, L.; Yuan, Y.; Wei, W.; Liu, R.; Gu, S.; Xu, W. Fabric electrodes coated with polypyrrole nanorods for flexible supercapacitor application prepared via a reactive self-degraded template. Org. Electron. 2015, 26, 292–299. [Google Scholar] [CrossRef]

- Gholami, M.; Nia, P.M.; Alias, Y. Morphology and electrical properties of electrochemically synthesized pyrrole- formyl pyrrole copolymer. Appl. Surf. Sci. 2015, 357, 806–813. [Google Scholar] [CrossRef]

- Huang, Y.; Li, H.; Wang, Z.; Zhu, M.; Pei, Z.; Xue, Q.; Huang, Y.; Zhi, C. Nanostructured Polypyrrole as a flexible electrode material of supercapacitor. Nano Energy 2016, 22, 422–438. [Google Scholar] [CrossRef]

- Wang, Z.L.; He, X.J.; Ye, S.H.; Tong, Y.X.; Li, G.R. Design of Polypyrrole/Polyaniline Double-Walled Nanotube Arrays for Electrochemical Energy Storage. ACS Appl. Mater. Interfaces 2014, 6, 642–647. [Google Scholar] [CrossRef] [PubMed]

- Peng, S.; Fan, L.; Wei, C.; Bao, H.; Zhang, H.; Xu, W.; Xu, J. Polypyrrole/nickel sulfide/bacterial cellulose nanofibrous composite membranes for flexible supercapacitor electrodes. Cellulose 2016, 23, 2639–2651. [Google Scholar] [CrossRef]

- Liu, T.; Finn, L.; Yu, M.; Wang, H.; Zhai, T.; Lu, X.; Tong, Y.; Li, Y. Polyaniline and Polypyrrole Pseudocapacitor Electrodes with Excellent Cycling Stability. Nano Lett. 2014, 14, 2522–2527. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Liu, T.-Y.; Xu, X.-X.; Feng, D.-Y.; Li, Y.; Liu, X.-X. Pushing the Cycling Stability Limit of Polypyrrole for Supercapacitors. Adv. Funct. Mater. 2015, 25, 4626–4632. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Zhou, J.; Bian, L.; Zhu, E.; Hai, J.; Tang, J.; Tang, W. Graphene/polypyrrole intercalating nanocomposites as supercapacitors electrode. Electrochim. Acta 2013, 112, 44–52. [Google Scholar] [CrossRef]

- Fu, H.; Du, Z.J.; Zou, W.; Li, H.Q.; Zhang, C. Carbon nanotube reinforced polypyrrole nanowire network as a high-performance supercapacitor electrode. J. Mater. Chem. A 2013, 1, 14943–14950. [Google Scholar] [CrossRef]

- Shi, K.; Zhitomirsky, I. Influence of current collector on capacitive behavior and cycling stability of Tiron doped polypyrrole electrodes. J. Power Sources 2013, 240, 42–49. [Google Scholar] [CrossRef]

- Chen, S.; Zhitomirsky, I. Polypyrrole electrodes doped with sulfanilic acid azochromotrop for electrochemical supercapacitors. J. Power Sources 2013, 243, 865–871. [Google Scholar] [CrossRef]

- Liu, S.; Yu, T.; Wu, Y.; Li, W.; Li, B. Evolution of cellulose into flexible conductive green electronics: A smart strategy to fabricate sustainable electrodes for supercapacitors. RSC Adv. 2014, 4, 34134–34143. [Google Scholar] [CrossRef]

- Zheng, G.; Hu, L.; Wu, H.; Xie, X.; Cui, Y. Paper supercapacitors by a solvent-free drawing method. Energy Environ. Sci. 2011, 4, 3368–3373. [Google Scholar] [CrossRef]

- Tao, J.; Ma, W.; Liu, N.; Ren, X.; Shi, Y.; Su, J.; Gao, Y. High-Performance Solid-State Supercapacitors Fabricated by Pencil Drawing and Polypyrrole Depositing on Paper Substrate. Nano-Micro Lett. 2015, 7, 276–281. [Google Scholar] [CrossRef]

- Song, Y.; Feng, D.Y.; Liu, T.Y.; Li, Y.; Liu, X.X. Controlled partial-exfoliation of graphite foil and integration with MnO2 nanosheets for electrochemical capacitors. Nanoscale 2015, 7, 3581–3587. [Google Scholar] [CrossRef] [PubMed]

- Down, M.P.; Foster, C.W.; Ji, X.; Banks, C.E. Pencil drawn paper based supercapacitors. RSC Adv. 2016, 6, 81130–81141. [Google Scholar] [CrossRef]

- Bernalte, E.; Foster, C.W.; Brownson, D.A.C.; Mosna, M.; Smith, G.C.; Banks, C.E. Pencil It in: Exploring the Feasibility of Hand-Drawn Pencil Electrochemical Sensors and Their Direct Comparison to Screen-Printed Electrodes. Biosensors 2016, 6, 45. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Xu, J.L.; Liu, X.X. Electrochemical anchoring of dual doping polypyrrole on graphene sheets partially exfoliated from graphite foil for high-performance supercapacitor electrode. J. Power Sources 2014, 249, 48–58. [Google Scholar] [CrossRef]

- Nyström, G.; Razaq, A.; Strømme, M.; Nyholm, L.; Mihranyan, A. Ultrafast All-Polymer Paper-Based Batteries. Nano Lett. 2009, 9, 3635–3639. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Huang, D.; Yang, J.; Zhang, B.; Zhang, X.; Yang, G.; Wang, M.; Shen, Y. Freestanding bacterial cellulose-polypyrrole nanofibres paper electrodes for advanced energy storage devices. Nano Energy 2014, 9, 309–317. [Google Scholar] [CrossRef]

- Wang, D.; Li, Y.X.; Shi, Z.; Qin, H.L.; Wang, L.; Pei, X.F.; Jin, J. Spontaneous Growth of Free-Standing Polypyrrole Films at an Air/Ionic Liquid Interface. Langmuir 2010, 26, 14405–14408. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Zhang, L.; Wu, L.; Sun, Y.; Bai, Z.; Xu, J.; Liang, G.; Xu, W. Conductive Cotton Fabrics for Heat Generation Prepared by Mist Polymerization. Fibers Polym. 2014, 15, 1804–1809. [Google Scholar] [CrossRef]

- Xu, Q.; Fan, L.; Yuan, Y.; Wei, C.; Bai, Z.; Xu, J. All-solid-state yarn supercapacitors based on hierarchically structured bacterial cellulose nanofiber-coated cotton yarns. Cellulose 2016, 23, 3987–3997. [Google Scholar] [CrossRef]

- Yan, D.; Liu, Y.; Li, Y.; Zhuo, R.; Wu, Z.; Ren, P.; Li, S.; Wang, J.; Yan, P.; Geng, Z. Synthesis and electrochemical properties of MnO2/rGO/PEDOT:PSS ternary composite electrode material for supercapacitors. Mater. Lett. 2014, 127, 53–55. [Google Scholar] [CrossRef]

- Wang, Z.-L.; Guo, R.; Li, G.-R.; Lu, H.-L.; Liu, Z.-Q.; Xiao, F.-M.; Zhang, M.; Tong, Y.-X. Polyaniline nanotube arrays as high-performance flexible electrodes for electrochemical energy storage devices. J. Mater. Chem. 2012, 22, 2401–2404. [Google Scholar] [CrossRef]

- Feng, J.X.; Li, Q.; Lu, X.F.; Tong, Y.X.; Li, G.R. Flexible symmetrical planar supercapacitors based on multi-layered MnO2/Ni/graphite/paper electrodes with high-efficient electrochemical energy storage. J. Mater. Chem. A 2014, 2, 2985–2992. [Google Scholar] [CrossRef]

- Feng, J.X.; Ye, S.H.; Lu, X.F.; Tong, Y.X.; Li, G.R. Asymmetric Paper Supercapacitor Based on Amorphous Porous Mn3O4 Negative Electrode and Ni(OH)2 Positive Electrode: A Novel and High-Performance Flexible Electrochemical Energy Storage Device. ACS Appl. Mater. Interfaces 2015, 7, 11444–11451. [Google Scholar] [CrossRef] [PubMed]

- Devarayan, K.; Lei, D.; Kim, H.Y.; Kim, B.S. Flexible transparent electrode based on PANi nanowire/nylon nanofiber reinforced cellulose acetate thin film as supercapacitor. Chem. Eng. J. 2015, 273, 603–609. [Google Scholar] [CrossRef]

- Gui, Z.; Zhu, H.; Gillette, E.; Han, X.; Rubloff, G.W.; Hu, L.; Sang, B.L. Natural Cellulose Fiber as Substrate for Supercapacitor. ACS Nano 2013, 7, 6037–6046. [Google Scholar] [CrossRef] [PubMed]

- Qian, J.; Jin, H.; Chen, B.; Lin, M.; Lu, W.; Tang, W.M.; Xiong, W.; Chan, L.W.; Lau, S.P.; Yuan, J. Aqueous manganese dioxide ink for paper-based capacitive energy storage devices. Angew. Chem. Int. Ed. 2015, 54, 6800–6803. [Google Scholar] [CrossRef] [PubMed]

- Yuan, L.; Yao, B.; Hu, B.; Huo, K.; Chen, W.; Zhou, J. Polypyrrole-coated paper for flexible solid-state energy storage. Energy Environ. Sci. 2013, 6, 470–476. [Google Scholar] [CrossRef]

- Yuan, L.; Xiao, X.; Ding, T.; Zhong, J.; Zhang, X.; Shen, Y.; Hu, B.; Huang, Y.; Zhou, J.; Wang, Z.L. Paper-based supercapacitors for self-powered nanosystems. Angew. Chem. Int. Ed. 2012, 51, 4934–4938. [Google Scholar] [CrossRef] [PubMed]

- Kang, Y.R.; Li, Y.L.; Hou, F.; Wen, Y.Y.; Su, D. Fabrication of electric papers of graphene nanosheet shelled cellulose fibres by dispersion and infiltration as flexible electrodes for energy storage. Nanoscale 2012, 4, 3248–3253. [Google Scholar] [CrossRef] [PubMed]

- Akhter, T.; Islam, M.M.; Faisal, S.N.; Haque, E.; Minett, A.I.; Liu, H.K.; Konstantinov, K.; Dou, S. Self-assembled N/S co-doped Flexible Graphene Paper for High Performance Energy Storage and Oxygen Reduction Reaction. ACS Appl. Mater. Interfaces 2016, 8, 2078–2087. [Google Scholar] [CrossRef] [PubMed]

- Perera, S.D.; Rudolph, M.; Mariano, R.G.; Nijem, N.; Ferraris, J.P.; Chabal, Y.J., Jr.; Balkus, K.J. Manganese oxide nanorod-graphene/vanadium oxide nanowire-graphene binder-free paper electrodes for metal oxide hybrid supercapacitors. Nano Energy 2013, 2, 966–975. [Google Scholar] [CrossRef]

- Foo, C.Y.; Sumboja, A.; Tan, D.J.H.; Wang, J.; Lee, P.S. Flexible and Highly Scalable V2O5-rGO Electrodes in an Organic Electrolyte for Supercapacitor Devices. Adv. Energy Mater. 2014, 4, 1400236. [Google Scholar] [CrossRef]

- Kong, L.; Zhang, C.; Wang, J.; Qiao, W.; Ling, L.; Long, D. Free-Standing T-Nb2O5/Graphene Composite Papers with Ultrahigh Gravimetric/Volumetric Capacitance for Li-Ion Intercalation Pseudocapacitor. ACS Nano 2015, 9, 11200–11208. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, A.; Ra, E.J.; Jin, M.; Jeong, H.K.; Kim, T.H.; Biswas, C.; Lee, Y.H. High Pseudocapacitance from Ultrathin V2O5 Films Electrodeposited on Self-Standing Carbon-Nanofiber Paper. Adv. Funct. Mater. 2011, 21, 2541–2547. [Google Scholar] [CrossRef]

- Hu, S.; Rajamani, R.; Yu, X. Flexible solid-state paper based carbon nanotube supercapacitor. Appl. Phys. Lett. 2012, 100, 104103–104104. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, L.; Rao, W.; Fan, L.; Xu, J.; Bai, Z.; Xu, W.; Bao, H. Paper Electrodes Coated with Partially-Exfoliated Graphite and Polypyrrole for High-Performance Flexible Supercapacitors. Polymers 2018, 10, 135. https://doi.org/10.3390/polym10020135

Huang L, Rao W, Fan L, Xu J, Bai Z, Xu W, Bao H. Paper Electrodes Coated with Partially-Exfoliated Graphite and Polypyrrole for High-Performance Flexible Supercapacitors. Polymers. 2018; 10(2):135. https://doi.org/10.3390/polym10020135

Chicago/Turabian StyleHuang, Leping, Weida Rao, Lingling Fan, Jie Xu, Zikui Bai, Weilin Xu, and Haifeng Bao. 2018. "Paper Electrodes Coated with Partially-Exfoliated Graphite and Polypyrrole for High-Performance Flexible Supercapacitors" Polymers 10, no. 2: 135. https://doi.org/10.3390/polym10020135