Morphology, Mechanical Properties and Dimensional Stability of Biomass Particles/High Density Polyethylene Composites: Effect of Species and Composition

Abstract

:1. Introduction

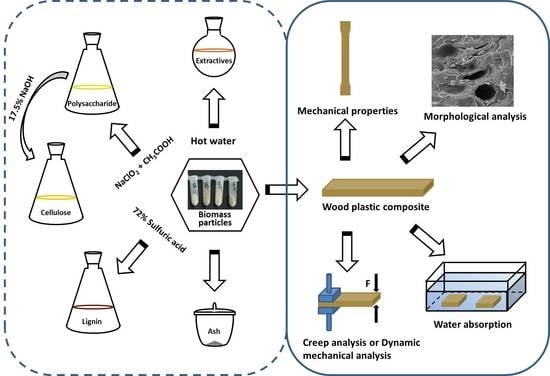

2. Materials and Methods

2.1. Materials

2.2. Preparation of Composite Specimens

2.3. Characterization of Biomass Particles

2.3.1. Chemical Composition

2.3.2. FT-IR Analysis

2.3.3. X-ray Diffraction

2.3.4. Morphological Analysis

2.3.5. Mechanical Test

2.3.6. Water Absorption

2.3.7. Creep Analysis

2.3.8. Dynamic Mechanical Analysis (DMA)

3. Results and Discussion

3.1. Characterization of Wood Particles

3.1.1. Chemical Composition Content

3.1.2. FT-IR Analysis

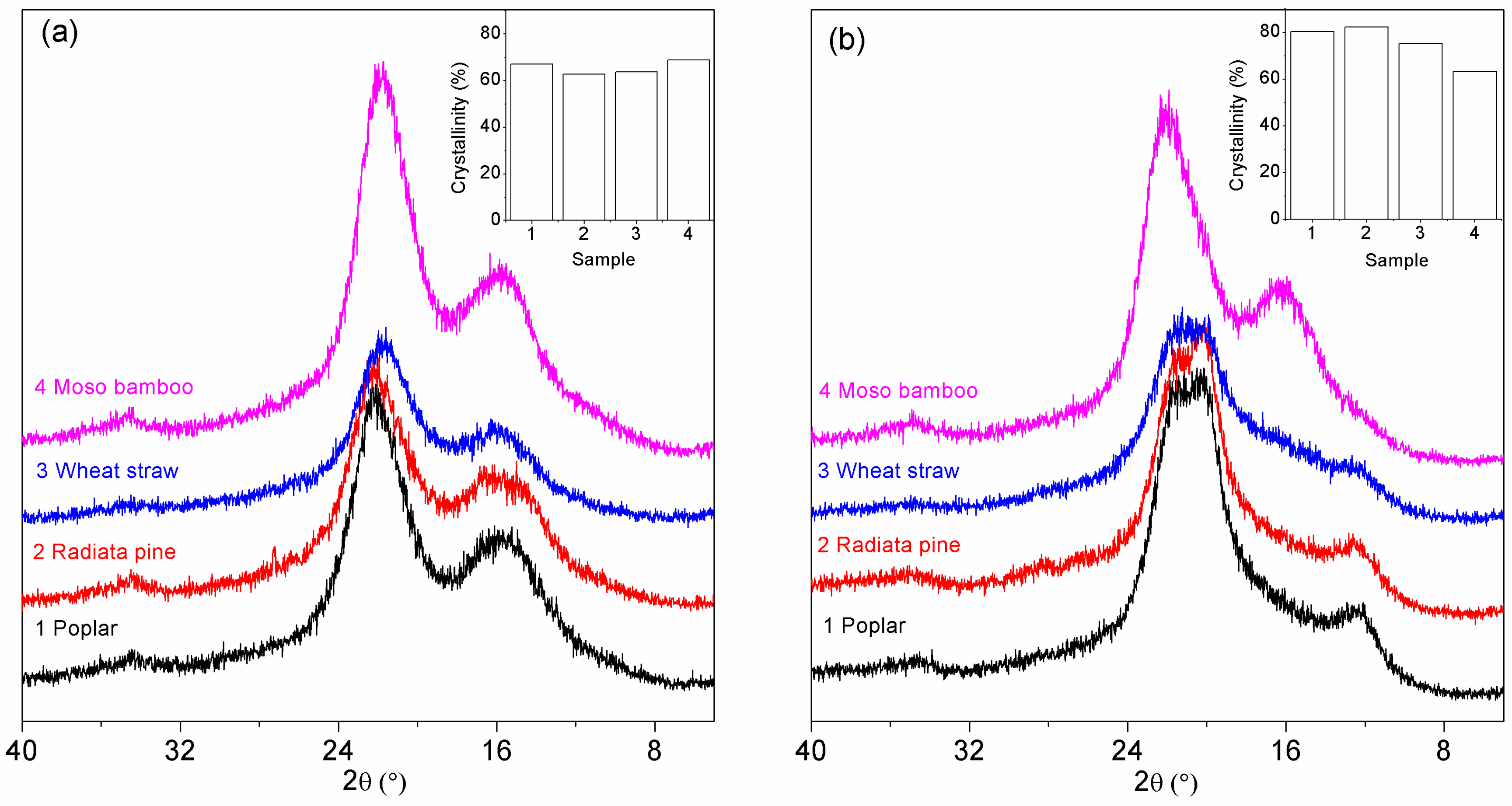

3.1.3. XRD Analysis

3.2. Characterization of Bio-Composites

3.2.1. Morphological Analysis

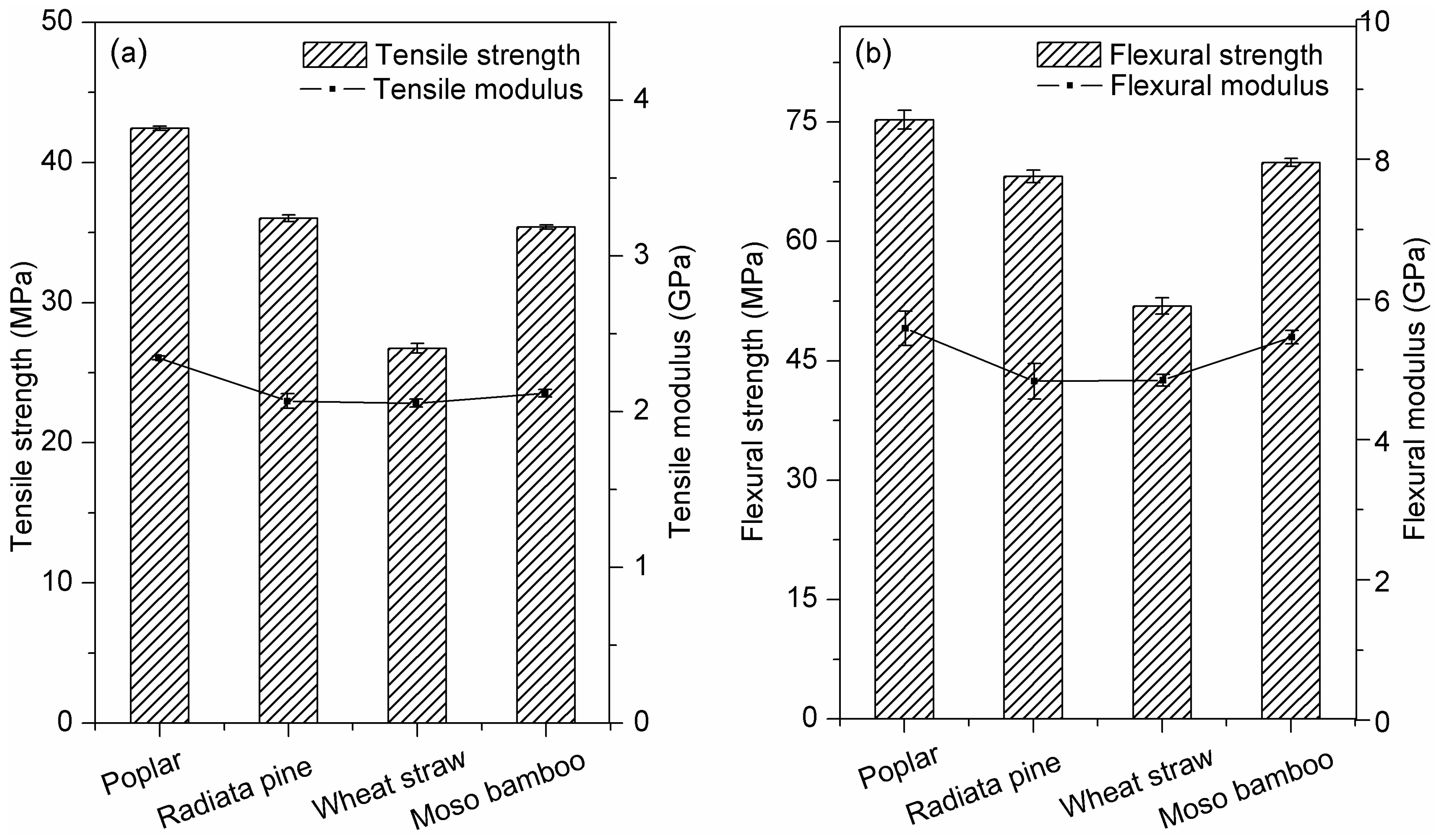

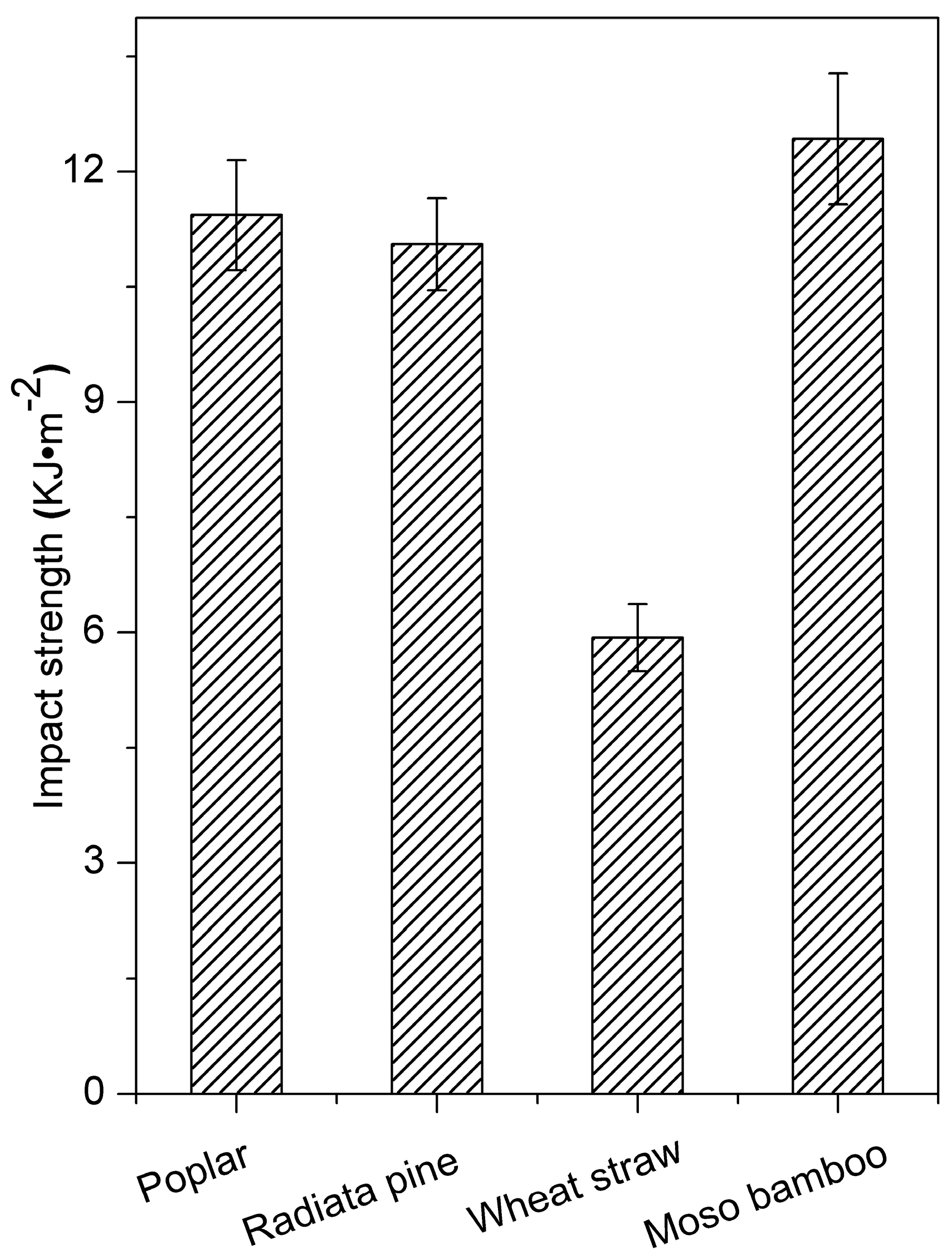

3.2.2. Mechanical Properties

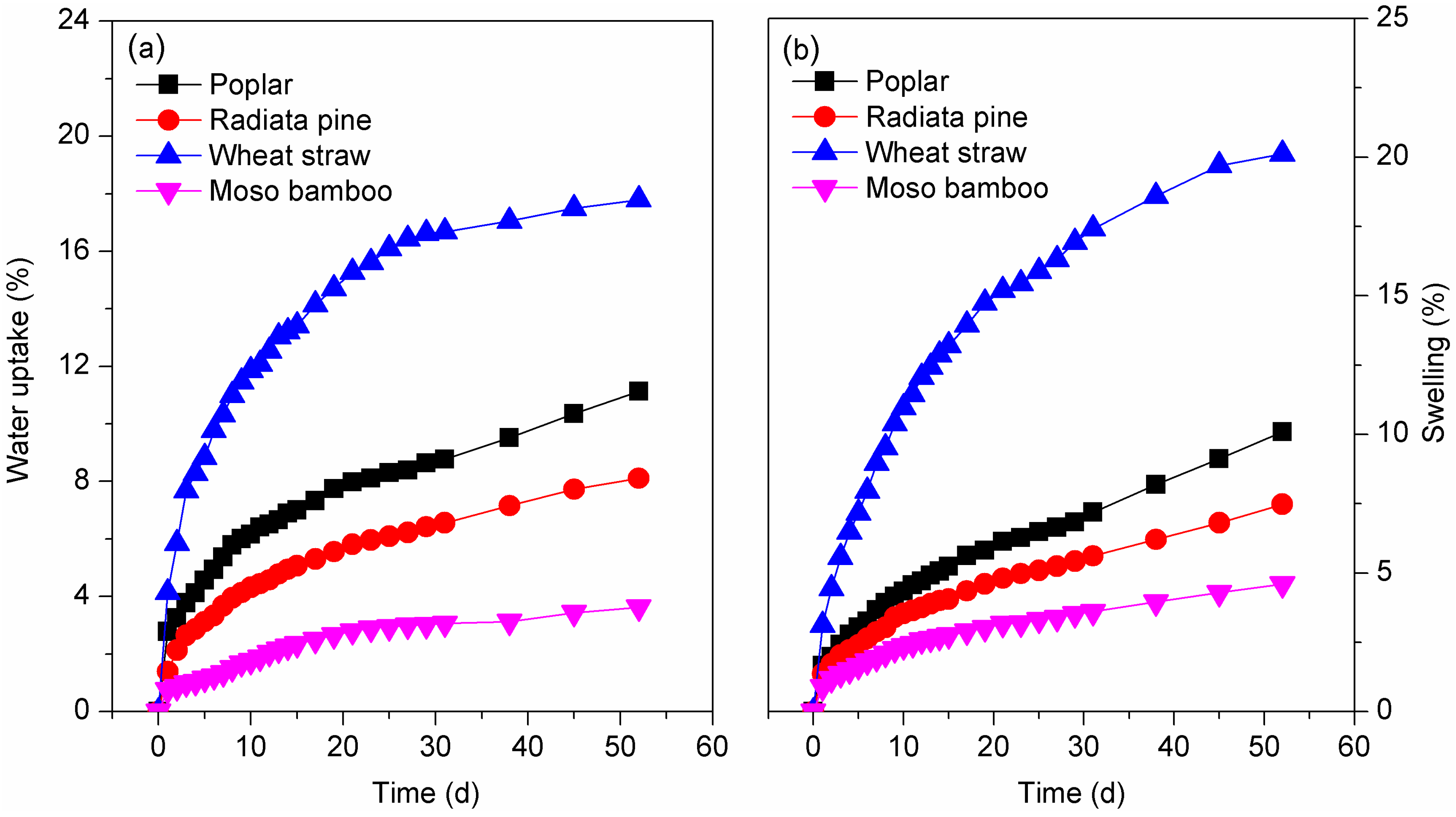

3.2.3. Water Absorption

3.2.4. Creep Analysis

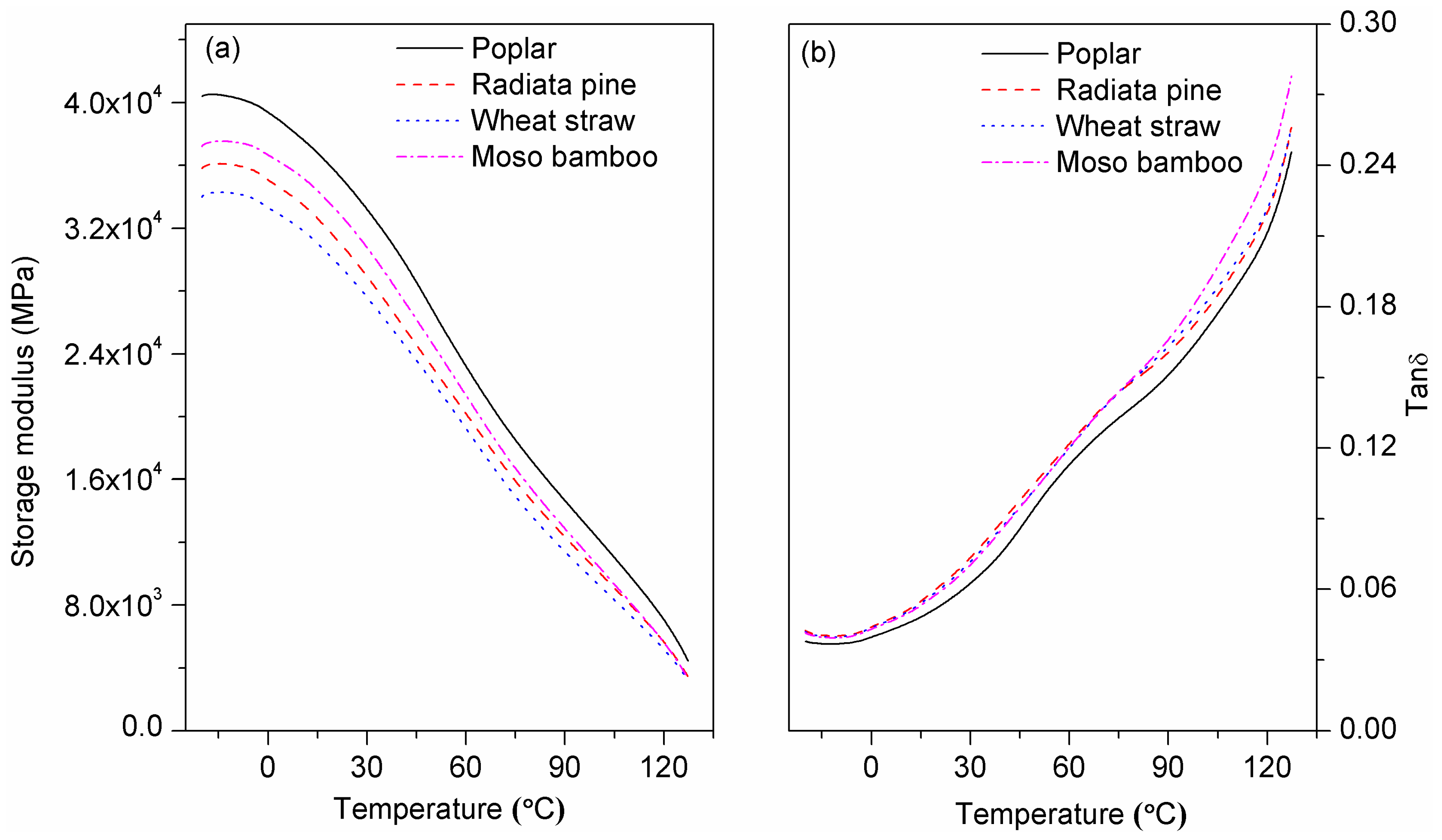

3.2.5. Dynamic Mechanical Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, S.; Lu, A.; Zhang, L. Recent advances in regenerated cellulose materials. Prog. Polym. Sci. 2016, 53, 169–206. [Google Scholar] [CrossRef]

- Yao, F.; Wu, Q.; Lei, Y.; Xu, Y. Rice straw fiber-reinforced high-density polyethylene composite: Effect of fiber type and loading. Ind. Crops Prod. 2008, 28, 63–72. [Google Scholar] [CrossRef]

- Kim, J.W.; Harper, D.P.; Taylor, A.M. Effect of wood species on the mechanical and thermal properties of wood-plastic composites. J. Appl. Polym. Sci. 2009, 112, 1378–1385. [Google Scholar] [CrossRef]

- Hosseinaei, O.; Wang, S.Q.; Taylor, A.M.; Kim, J.W. Effect of hemicellulose extraction on water absorption and mold susceptibility of wood-plastic composites. Int. Biodeterior. Biodegrad. 2012, 71, 29–35. [Google Scholar] [CrossRef]

- Mohanty, S.; Nayak, S.K.; Verma, S.K.; Tripathy, S.S. Effect of MAPP as a coupling agent on the performance of jute-PP composites. J. Reinf. Plast. Compos. 2004, 23, 625–637. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Hassine, B.; Ahmed, K.; Patrick, P.; Alain, C.; Bernard, R. Analysis of among-species variability in wood fiber surface using DRIFTS and XPS: Effects on esterification efficiency. J. Wood Chem. Technol. 2008, 28, 296–315. [Google Scholar] [CrossRef]

- Shebani, A.N.; Van Reenen, A.J.; Meincken, M. The effect of wood species on the mechanical and thermal properties of wood–LLDPE composites. J. Compos. Mater. 2009, 43, 1305–1318. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Mamun, A.A.; Volk, J. Barley husk and coconut shell reinforced polypropylene composites: The effect of fibre physical, chemical and surface properties. Compos. Sci. Technol. 2010, 70, 840–846. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Mamun, A.A.; Volk, J. Physical, chemical and surface properties of wheat husk, rye husk and soft wood and their polypropylene composites. Compos. Part A 2010, 41, 480–488. [Google Scholar] [CrossRef]

- Ou, R.; Xie, Y.; Wolcott, M.P.; Sui, S.; Wang, Q. Morphology, mechanical properties and dimensional stability of wood particle/high density polyethylene composites: Effect of removal of wood cell wall composition. Mater. Des. 2014, 58, 339–345. [Google Scholar] [CrossRef]

- Ashori, A.; Nourbakhsh, A. Reinforced polypropylene composites: Effects of chemical compositions and particle size. Bioresour. Technol. 2010, 101, 2515–2519. [Google Scholar] [CrossRef] [PubMed]

- Ou, R.X.; Xie, Y.J.; Wang, Q.W.; Sui, S.J.; Wolcott, M.P. Thermal, crystallization and dynamic rheological behavior of wood particle/HDPE composites: Effect of removal of wood cell wall composition. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Hosseinaei, O.; Wang, S.; Rials, T.G.; Xing, C.; Zhang, Y. Effects of decreasing carbohydrate content on properties of wood strands. Cellulose 2011, 18, 841–850. [Google Scholar] [CrossRef]

- Nobuta, K.; Teramura, H.; Ito, H.; Hongo, C.; Kawaguchi, H.; Ogino, C.; Kondo, A.; Nishino, T. Characterization of cellulose nanofiber sheets from different refining processes. Cellulose 2015, 23, 403–414. [Google Scholar] [CrossRef]

- Owen, N.L.; Thomas, D.W. Infrared studies of “hard” and “soft” woods. Appl. Spectrosc. 1989, 43, 451–455. [Google Scholar] [CrossRef]

- Huang, L.; Mu, B.; Yi, X.; Li, S.; Wang, Q. Sustainable use of coffee husks for reinforcing polyethylene composites. J. Polym. Environ. 2016. [Google Scholar] [CrossRef]

- Yao, J.; Xu, X.W.; Feng, Y.Y. FTIR studies on the chemical composition of wheat straw in different layers. Spectrosc. Spect. Anal. 2003, 23, 58–60. [Google Scholar] [CrossRef]

- Oudiani, A.E.; Chaabouni, Y.; Msahli, S.; Sakli, F. Crystal transition from cellulose I to cellulose II in NaOH treated Agave americana L. Fibre. Carbohydr. Polym. 2011, 86, 1221–1229. [Google Scholar] [CrossRef]

- Perel, J. An X-ray study of regain-dependent deformations in cotton crystallites. J. Text. Inst. 1990, 81, 241–244. [Google Scholar] [CrossRef]

- Zhou, L.M.; Yeung, K.W.; Yuen, C.W.M.; Zhou, X. Characterization of ramie yarn treated with sodium hydroxide and crosslinked by 1,2,3,4-butanetetracarboxylic acid. J. Appl. Polym. Sci. 2004, 91, 1857–1864. [Google Scholar] [CrossRef]

- Jähn, A.; Schröder, M.W.; Füting, M.; Schenzel, K.; Diepenbrock, W. Characterization of alkali treated flax fibres by means of FT Raman spectroscopy and environmental scanning electron microscopy. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2002, 58, 2271–2279. [Google Scholar] [CrossRef]

- Kaushik, A.; Singh, M.; Verma, G. Green nanocomposites based on thermoplastic starch and steam exploded cellulose nanofibrils from wheat straw. Carbohydr. Polym. 2010, 82, 337–345. [Google Scholar] [CrossRef]

- Yu, Z.; Jameel, H.; Chang, HM.; Park, S. The effect of delignification of forest biomass on enzymatic hydrolysis. Bioresour. Technol. 2011, 102, 9083–9089. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Soykeabkaew, N.; Ni, X.; Peijs, T. The effect of fibre volume fraction and mercerization on the properties of all-cellulose composites. Carbohydr. Polym. 2008, 71, 458–467. [Google Scholar] [CrossRef]

- Gao, H.; Xie, Y.; Ou, R.; Wang, Q. Grafting effects of polypropylene/polyethylene blends with maleic anhydride on the properties of the resulting wood–plastic composites. Compos. Part A 2012, 43, 150–157. [Google Scholar] [CrossRef]

- Hornsby, P.R.; Hinrichsen, E.; Tarverdi, K. Preparation and properties of polypropylene composites reinforced with wheat and flax straw fibres: Part I fibre characterization. J. Mater. Sci. 1997, 32, 443–449. [Google Scholar] [CrossRef]

- Hornsby, P.R.; Hinrichsen, E.; Tarverdi, K. Preparation and properties of polypropylene composites reinforced with wheat and flax straw fibres: Part II analysis of composite microstructure and mechanical properties. J. Mater. Sci. 1997, 32, 1009–1015. [Google Scholar] [CrossRef]

- Xie, Y.; Xiao, Z.; Grüneberg, T.; Militz, H.; Hill, C.A.S.; Steuernagel, L.; Mai, C. Effects of chemical modification of wood particles with glutaraldehyde and 1,3-dimethylol-4,5-dihydroxyethyleneurea on properties of the resulting polypropylene composites. Compos. Sci. Technol. 2010, 70, 2003–2011. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kaymakci, A. Fast growing biomass as reinforcing filler in thermoplastic composites: Paulownia elongata wood. Ind. Crop. Prod. 2013, 43, 457–464. [Google Scholar] [CrossRef]

- Saputra, H.; Simonsen, J.; Li, K. Effect of extractives on the flexural properties of wood/plastic composites. Instrum Sci. Technol. 2004, 11, 515–524. [Google Scholar] [CrossRef]

- Yi, S.; Xu, S.; Fang, Y.; Wang, H.; Wang, Q. Effect of matrix modification on the mechanical properties of wood –polupropylene conposites. Polymers. 2017, 9, 712. [Google Scholar] [CrossRef]

- López, J.P.; Gironès, J.; Mendez, J.A.; Pèlach, M.A.; Vilaseca, F.; Mutjé, P. Impact and flexural properties of stone-ground wood pulp-reinforced polypropylene composites. Polym. Compos. 2013, 34, 842–848. [Google Scholar] [CrossRef]

- Herrera-Franco, P.J.; Valadez-González, A. A study of the mechanical properties of short natural-fiber reinforced composites. Compos. Part B 2005, 36, 597–608. [Google Scholar] [CrossRef]

- Lu, J.Z.; Wu, Q.; Negulescu, I.I. Wood-fiber/high-density-polyethylene composites: Coupling agent performance. J. Appl. Polym. Sci. 2010, 96, 93–102. [Google Scholar] [CrossRef]

- Gelfuso, M.V.; Silva, P.V.G.D.; Thomazini, D. Polypropylene matrix composites reinforced with coconut fibers. Mater. Res. 2011, 14, 360–365. [Google Scholar] [CrossRef]

- Azeh, Y.; Mamza, P.A.; Olatunji, G.A. Scanning electron microscopy and kinetic studies of ketene-acetylated wood/cellulose high-density polyethylene blends. Int. J. Carbohydr. Chem. 2012, 2012. [Google Scholar] [CrossRef]

- Das, S.; Saha, A.K.; Choudhury, P.K.; Basak, R.K.; Mitra, B.C.; Todd, T.; Lang, S.; Rowell, R.M. Effect of steam pretreatment of jute fiber on dimensional stability of jute composite. J. Appl. Polym. Sci. 2015, 76, 1652–1661. [Google Scholar] [CrossRef]

- Jiang, Z.H. A comparative in SiO2 gel loading performance of wood, bamboo and their carbonized products. Sci. Silvae Sin. 2013, 49, 98–102. [Google Scholar] [CrossRef]

- Lee, S.Y.; Yang, H.S.; Kim, H.J.; Jeong, C.S.; Lim, B.S.; Lee, J.N. Creep behavior and manufacturing parameters of wood flour filled polypropylene composites. Compos. Struct. 2004, 65, 459–469. [Google Scholar] [CrossRef]

- Acha, B.A.; Reboredo, M.M.; Marcovich, N.E. Creep and dynamic mechanical behavior of PP–jute composites: Effect of the interfacial adhesion. Compos. Part A 2007, 38, 1507–1516. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Faruk, O. Creep and impact properties of wood fibre–polypropylene composites: Influence of temperature and moisture content. Compos. Sci. Technol. 2004, 64, 693–700. [Google Scholar] [CrossRef]

- Tamrakar, S.; Lopez-Anido, R.A.; Kiziltas, A.; Gardner, D.J. Time and temperature dependent response of a wood–polypropylene composite. Compos. Part A 2011, 42, 834–842. [Google Scholar] [CrossRef]

- Hristov, V.; Vasileva, S. Dynamic mechanical and thermal properties of modified poly(propylene) wood fiber composites. Macromol. Mater. Eng. 2003, 288, 798–806. [Google Scholar] [CrossRef]

- Mohanty, S.; Verma, S.K.; Nayak, S.K. Dynamic mechanical and thermal properties of MAPE treated jute/HDPE composites. Compos. Sci. Technol. 2006, 66, 538–547. [Google Scholar] [CrossRef]

- Chang, F.C.; Kadla, J.F.; Lam, F. The effects of wood flour content and coupling agent on the dynamic mechanical and relaxation properties of wood-plastic composites. Eur. J. Wood. Wood. Prod. 2016, 74, 23–30. [Google Scholar] [CrossRef]

- Nair, K.C.M.; Thomas, S.; Groeninckx, G. Thermal and dynamic mechanical analysis of polystyrene composites reinforced with short sisal fibres. Compos. Sci. Technol. 2001, 61, 2519–2529. [Google Scholar] [CrossRef]

- Mohanty, S.; Nayak, S.K. Interfacial, dynamic mechanical and thermal fiber reinforced behavior of MAPE treated sisal fiber reinforced HDPE composites. J. Appl. Polym. Sci. 2006, 102, 3306–3315. [Google Scholar] [CrossRef]

- López-Manchado, M.A.; Biagitti, J.; Kenny, J.M. Comparative study of the effects of different fibers on the processing and properties of ternary composites based on PP-EPDM blends. Polym. Compos. 2002, 23, 779–789. [Google Scholar] [CrossRef]

| Chemical Components | Poplar | Radiata Pine | WHEAT Straw | Moso Bamboo |

|---|---|---|---|---|

| Polysaccharide (%) | 78.48 ± 0.30 | 73.79 ± 0.41 | 72.14 ± 0.24 | 71.75 ± 0.65 |

| Hemicellulose (%) | 31.73 ± 0.72 | 27.48 ± 0.66 | 32.93 ± 0.26 | 25.38 ± 0.65 |

| Cellulose (%) | 46.74 ± 0.89 | 46.31 ± 1.06 | 40.10 ± 0.13 | 46.37 ± 0.41 |

| Lignin (%) | 23.92 ± 0.18 | 28.84 ± 0.46 | 18.39 ± 0.43 | 26.44 ± 0.41 |

| Hot water extracts (%) | 3.89 ± 0.59 | 3.90 ± 0.52 | 10.60 ± 0.59 | 6.33 ± 0.40 |

| Ash (%) | 1.67 ± 0.11 | 2.35 ± 0.31 | 5.29 ± 0.28 | 0.74 ± 0.14 |

| Species | Particle Size (μm) | Aspect Ratio 1 (L/D) |

|---|---|---|

| Poplar | 122.96 ± 39.65 | 5.82 ± 2.50 |

| Radiata pine | 182.47 ± 51.66 | 4.10 ± 1.58 |

| Wheat straw | 93.54 ± 27.07 | 6.59 ± 2.02 |

| Moso bamboo | 133.60 ± 34.32 | 4.32 ± 1.56 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mu, B.; Wang, H.; Hao, X.; Wang, Q. Morphology, Mechanical Properties and Dimensional Stability of Biomass Particles/High Density Polyethylene Composites: Effect of Species and Composition. Polymers 2018, 10, 308. https://doi.org/10.3390/polym10030308

Mu B, Wang H, Hao X, Wang Q. Morphology, Mechanical Properties and Dimensional Stability of Biomass Particles/High Density Polyethylene Composites: Effect of Species and Composition. Polymers. 2018; 10(3):308. https://doi.org/10.3390/polym10030308

Chicago/Turabian StyleMu, Binshan, Haigang Wang, Xiaolong Hao, and Qingwen Wang. 2018. "Morphology, Mechanical Properties and Dimensional Stability of Biomass Particles/High Density Polyethylene Composites: Effect of Species and Composition" Polymers 10, no. 3: 308. https://doi.org/10.3390/polym10030308

APA StyleMu, B., Wang, H., Hao, X., & Wang, Q. (2018). Morphology, Mechanical Properties and Dimensional Stability of Biomass Particles/High Density Polyethylene Composites: Effect of Species and Composition. Polymers, 10(3), 308. https://doi.org/10.3390/polym10030308