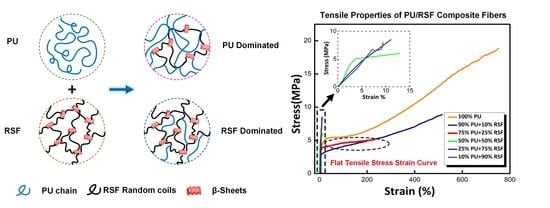

Bioinspired Fabrication of Polyurethane/Regenerated Silk Fibroin Composite Fibres with Tubuliform Silk-Like Flat Stress–Strain Behaviour

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of Polyurethane

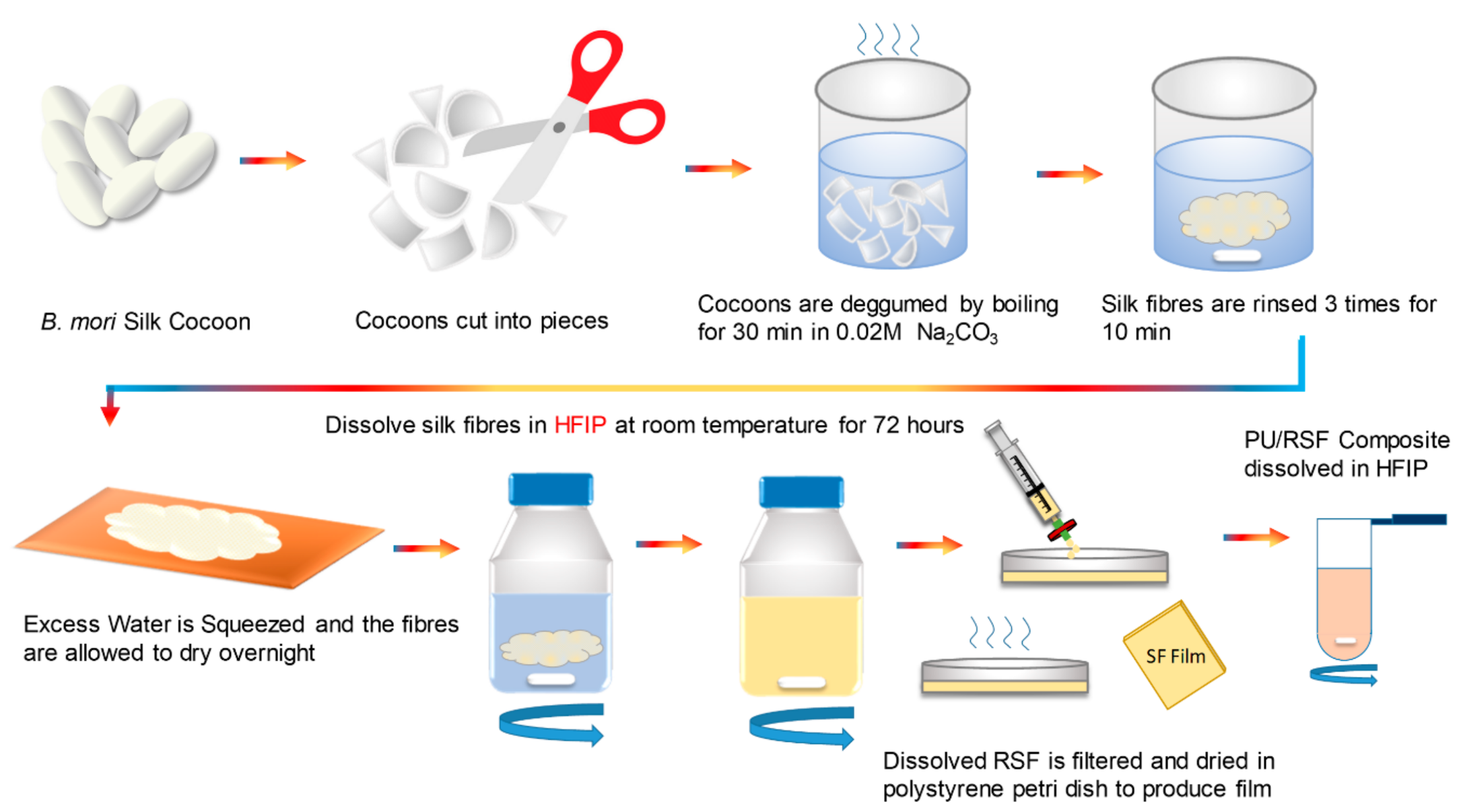

2.2. Extraction of Silk Fibroin from B. mori Cocoons

2.3. Preparation of PU/RSF Composite Fibres

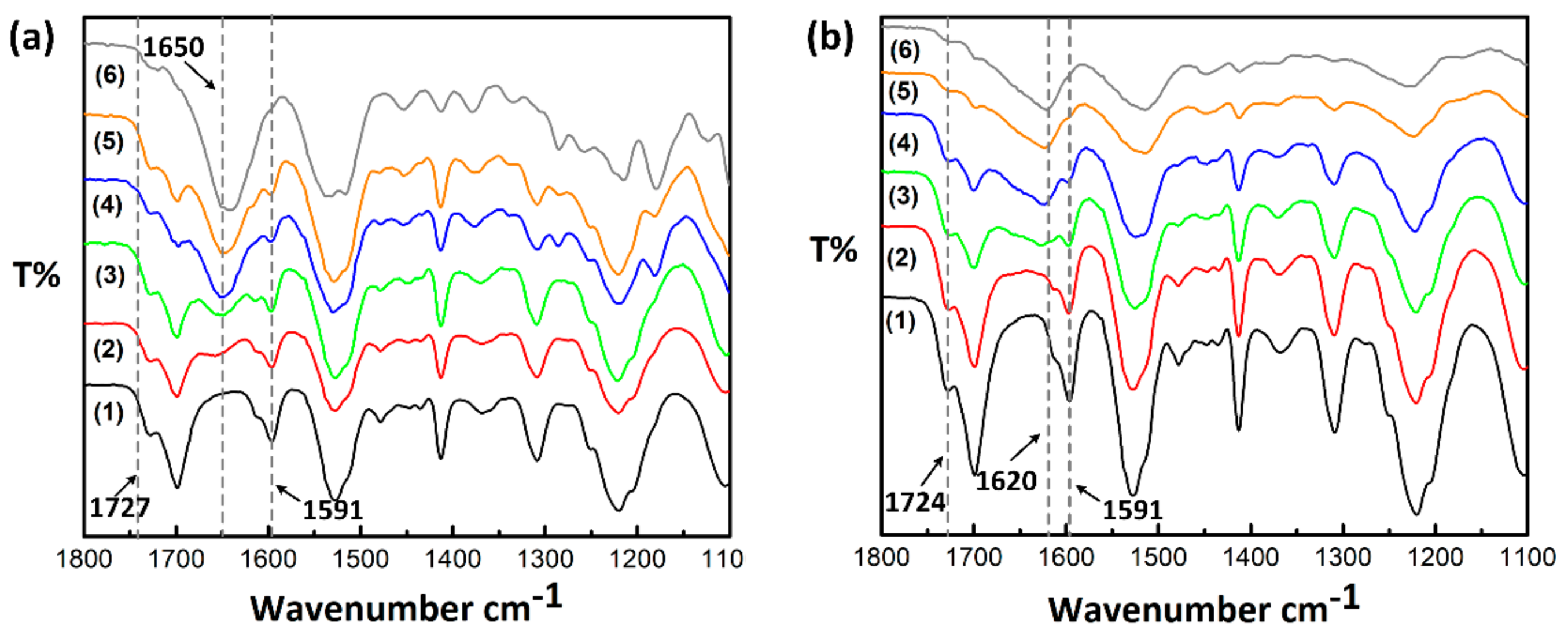

2.4. FTIR-ATR Spectroscopy

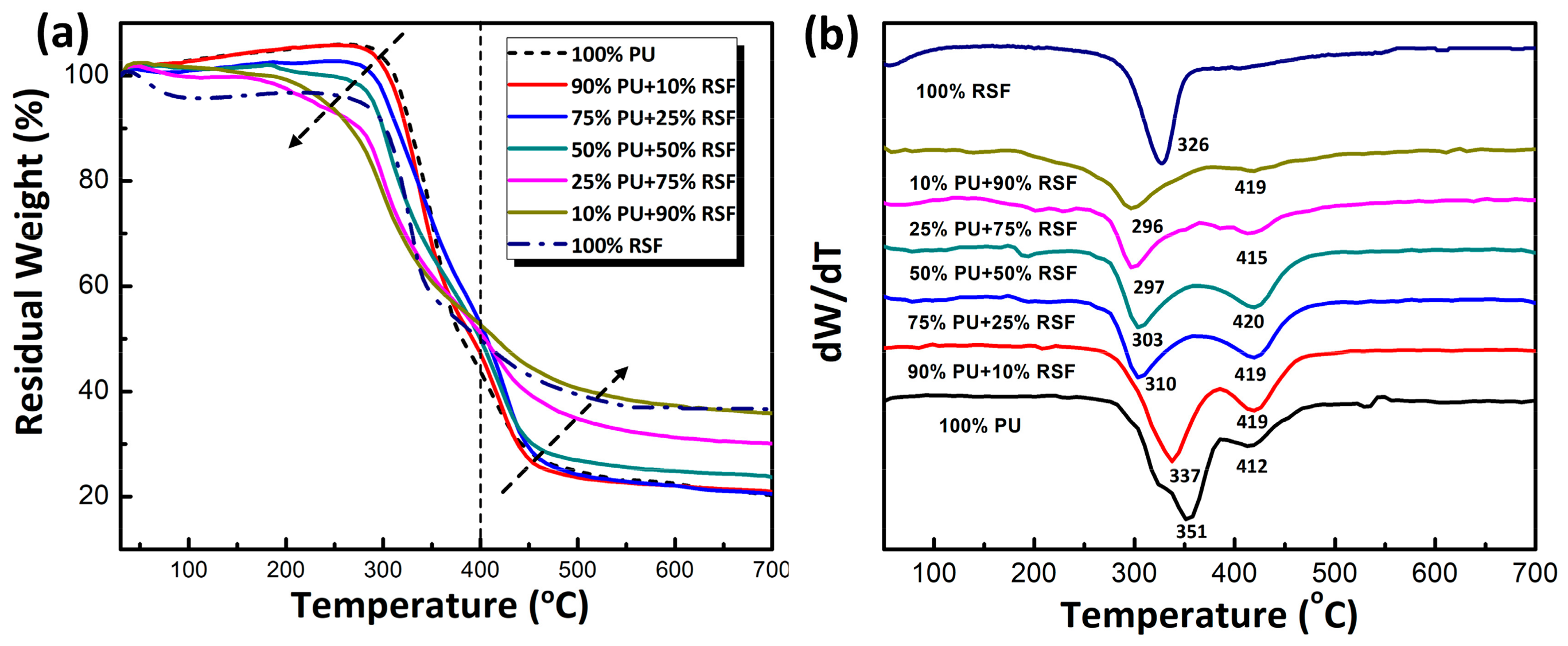

2.5. Thermal Analysis

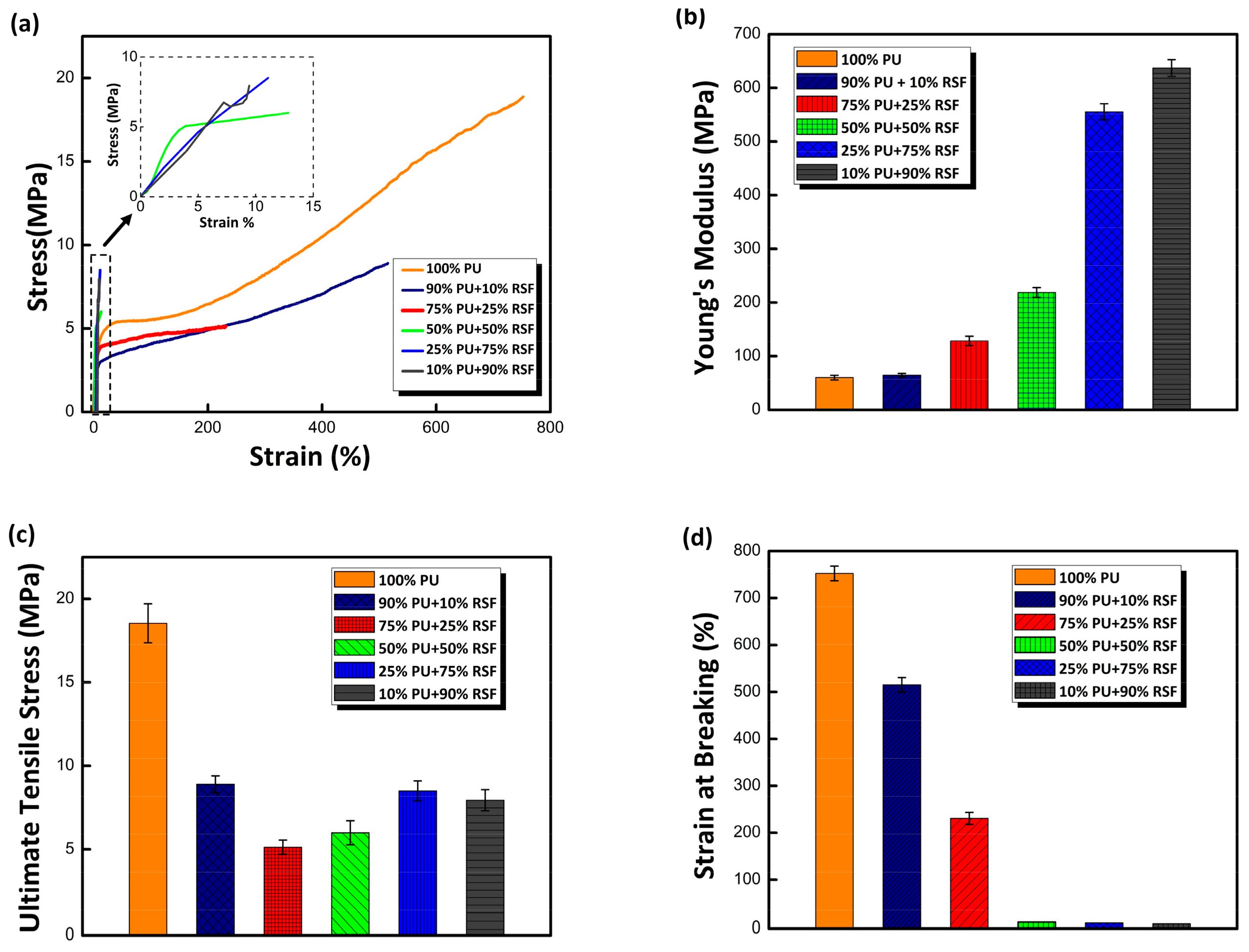

2.6. Tensile Properties

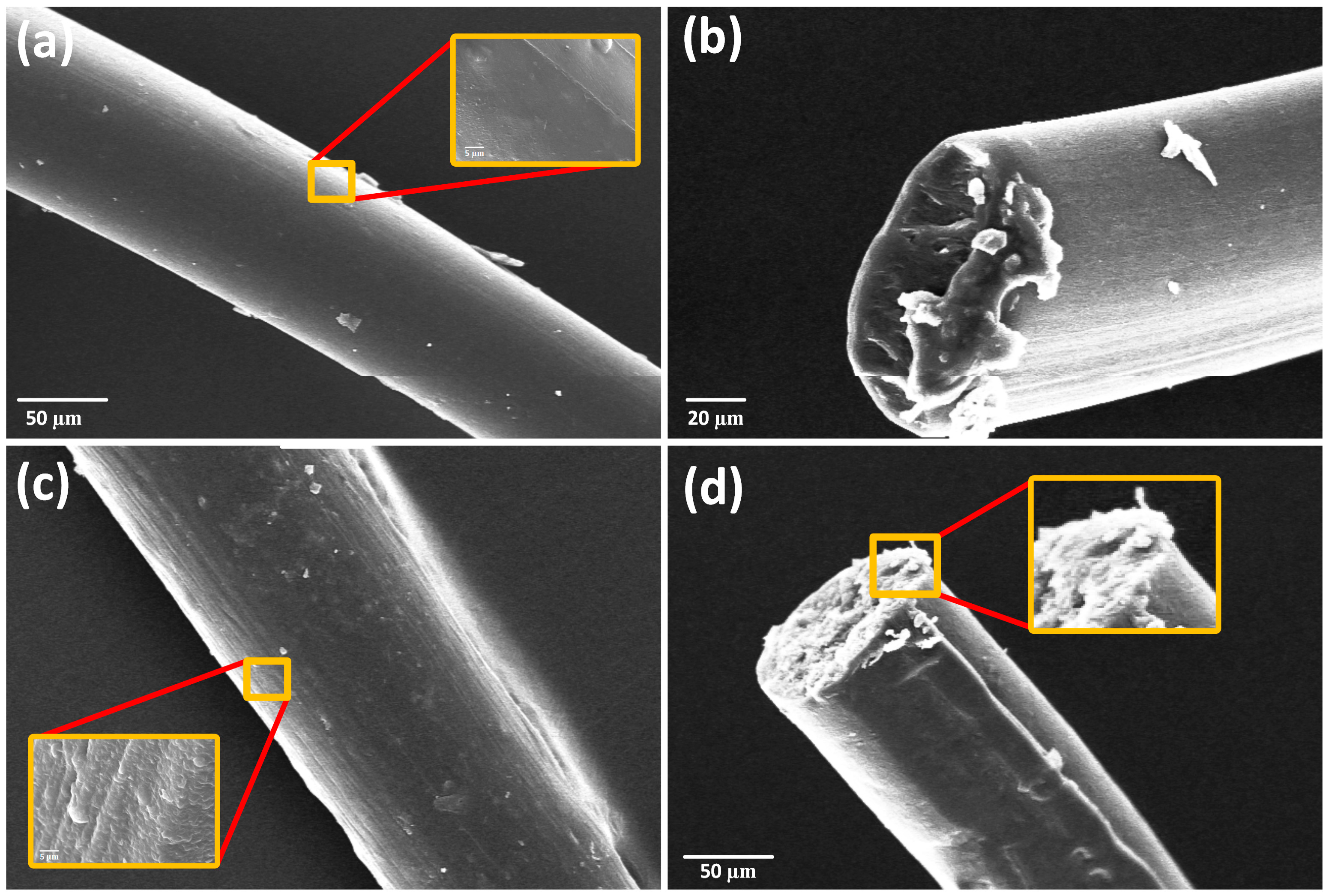

2.7. Scanning Electron Microscopy Analysis

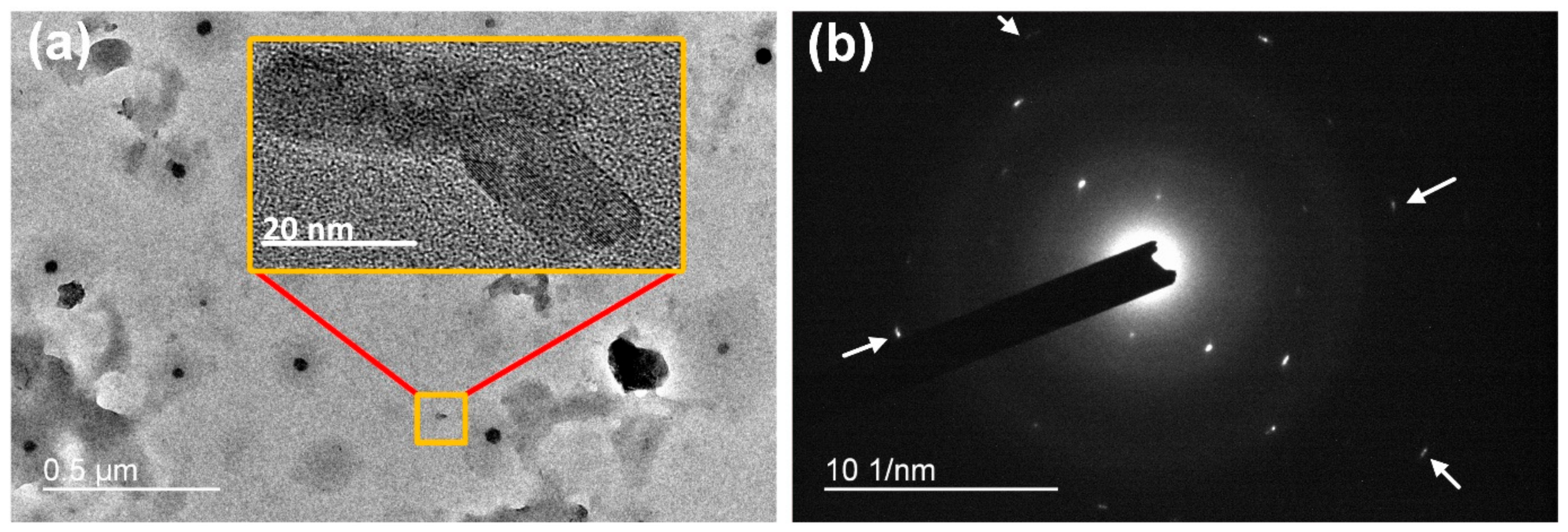

2.8. Transmission Electron Microscopy (TEM)

3. Results and Discussions

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Xiao, X.; Hu, J.; Gui, X.; Lu, J.; Luo, H. Is biopolymer hair a multi-responsive smart material? Polym. Chem. UK 2017, 8, 283–294. [Google Scholar] [CrossRef]

- Humenik, M.; Smith, A.M.; Scheibel, T. Recombinant spider silks—Biopolymers with potential for future applications. Polymers 2011, 3, 640–661. [Google Scholar] [CrossRef]

- Blackledge, T.A.; Hayashi, C.Y. Silken toolkits: Biomechanics of silk fibers spun by the orb web spider Argiope argentata (fabricius 1775). J. Exp. Biol. 2006, 209, 2452–2461. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Vasanthavada, K.; Kohler, K.; McNary, S.; Moore, A.M.; Vierra, C.A. Molecular mechanisms of spider silk. Cell. Mol. Life Sci. 2006, 63, 1986–1999. [Google Scholar] [CrossRef] [PubMed]

- Kovoor, J.; Zylberberg, L. Fine structural aspects of silk secretion in a spider (Araneus diadematus). I. Elaboration in the pyriform glands. Tissue Cell 1980, 12, 547–556. [Google Scholar] [CrossRef]

- Vollrath, F.; Porter, D. Spider silk as archetypal protein elastomer. Soft Matter 2006, 2, 377–385. [Google Scholar] [CrossRef]

- Van Nimmen, E.; Gellynck, K.; Van Langenhove, L.; Mertens, J. The tensile properties of cocoon silk of the spider Araneus diadematus. Text. Res. J. 2006, 76, 619–628. [Google Scholar] [CrossRef]

- Blackledge, T.A.; Kuntner, M.; Agnarsson, I. The form and function of spider orb webs: Evolution from silk to ecosystems. Adv. Insect Physiol. 2011, 41, 175–262. [Google Scholar]

- Van Nimmen, E.; Gellynck, K.; Gheysens, T.; Van Langenhove, L.; Mertens, J. Modeling of the stress-strain behavior of egg sac silk of the spider Araneus diadematus. J. Arachnol. 2005, 33, 629–639. [Google Scholar] [CrossRef]

- Barghout, J.Y.J.; Czernuszka, J.T.; Viney, C. Multiaxial anisotropy of spider (Araneus diadematus) cocoon silk fibres. Polymer 2001, 42, 5797–5800. [Google Scholar] [CrossRef]

- Barghout, J.Y.; Thiel, B.L.; Viney, C. Spider (Araneus diadematus) cocoon silk: A case of non-periodic lattice crystals with a twist? Int. J. Biol. Macromol. 1999, 24, 211–217. [Google Scholar] [CrossRef]

- Thiel, B.L.; Guess, K.B.; Viney, C. Non-periodic lattice crystals in the hierarchical microstructure of spider (major ampullate) silk. Biopolymers 1997, 41, 703–719. [Google Scholar] [CrossRef]

- Vollrath, F.; Knight, D.P. Liquid crystalline spinning of spider silk. Nature 2001, 410, 541–548. [Google Scholar] [CrossRef] [PubMed]

- Xia, X.X.; Qian, Z.G.; Ki, C.S.; Park, Y.H.; Kaplan, D.L.; Lee, S.Y. Native-sized recombinant spider silk protein produced in metabolically engineered escherichia coli results in a strong fiber. Proc. Natl. Acad. Sci. USA 2010, 107, 14059–14063. [Google Scholar] [CrossRef] [PubMed]

- Albertson, A.E.; Teulé, F.; Weber, W.; Yarger, J.L.; Lewis, R.V. Effects of different post-spin stretching conditions on the mechanical properties of synthetic spider silk fibers. J. Mech. Behav. Biomed. Mater. 2014, 29, 225–234. [Google Scholar] [CrossRef] [PubMed]

- Heidebrecht, A.; Eisoldt, L.; Diehl, J.; Schmidt, A.; Geffers, M.; Lang, G.; Scheibel, T. Biomimetic fibers made of recombinant spidroins with the same toughness as natural spider silk. Adv. Mater. 2015, 27, 2189–2194. [Google Scholar] [CrossRef] [PubMed]

- Andersson, M.; Jia, Q.; Abella, A.; Lee, X.Y.; Landreh, M.; Purhonen, P.; Hebert, H.; Tenje, M.; Robinson, C.V.; Meng, Q.; et al. Biomimetic spinning of artificial spider silk from a chimeric minispidroin. Nat. Chem. Biol. 2017, 13, 262–264. [Google Scholar] [CrossRef] [PubMed]

- Gnesa, E.; Hsia, Y.; Yarger, J.L.; Weber, W.; Lin-Cereghino, J.; Lin-Cereghino, G.; Tang, S.; Agari, K.; Vierra, C. Conserved c-terminal domain of spider tubuliform spidroin 1 contributes to extensibility in synthetic fibers. Biomacromolecules 2012, 13, 304–312. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Hu, J.; Yeung, K. Effect of soft segment crystallization and hard segment physical crosslink on shape memory function in antibacterial segmented polyurethane ionomers. Acta Biomater. 2009, 5, 3346–3357. [Google Scholar] [CrossRef] [PubMed]

- Meng, Q.; Hu, J. A temperature-regulating fiber made of peg-based smart copolymer. Sol. Energy Mater. Sol. Cells 2008, 92, 1245–1252. [Google Scholar] [CrossRef]

- Narayana, H.; Hu, J.; Kumar, B.; Shang, S.; Han, J.; Liu, P.; Lin, T.; Ji, F.; Zhu, Y. Stress-memory polymeric filaments for advanced compression therapy. J. Mater. Chem. B 2017, 5, 1905–1916. [Google Scholar] [CrossRef]

- Park, H.-S.; Gong, M.-S.; Park, J.-H.; Moon, S.-I.; Wall, I.B.; Kim, H.-W.; Lee, J.H.; Knowles, J.C. Silk fibroin–polyurethane blends: Physical properties and effect of silk fibroin content on viscoelasticity, biocompatibility and myoblast differentiation. Acta Biomater. 2013, 9, 8962–8971. [Google Scholar] [CrossRef] [PubMed]

- Zhuohong, Y.; Jinlian, H.; Yeqiu, L.; Lapyan, Y. The study of crosslinked shape memory polyurethanes. Mater. Chem. Phys. 2006, 98, 368–372. [Google Scholar] [CrossRef]

- Hong, B.; Xian, G.; Li, H. Comparative study of the durability behaviors of epoxy- and polyurethane-based CFRP plates subjected to the combined effects of sustained bending and water/seawater immersion. Polymers 2017, 9, 603. [Google Scholar] [CrossRef]

- Um, I.-C.; Kweon, H.-Y.; Min, B.-G.; Park, Y.-H. Structural characteristics and properties of silk fibroin/polyurethane blend films. Int. J. Ind. Entomol. 2002, 5, 163–170. [Google Scholar]

- Tao, Y.; Hasan, A.; Deeb, G.; Hu, C.; Han, H. Rheological and mechanical behavior of silk fibroin reinforced waterborne polyurethane. Polymers 2016, 8, 94. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, C.; Xu, W.; Liu, H.; Ouyang, C. Blend films of silk fibroin and water-insoluble polyurethane prepared from an ionic liquid. Mater. Lett. 2011, 65, 2489–2491. [Google Scholar] [CrossRef]

- Liu, X.-Y.; Zhang, C.-C.; Xu, W.-L.; Ouyang, C.-X. Controlled release of heparin from blended polyurethane and silk fibroin film. Mater. Lett. 2009, 63, 263–265. [Google Scholar] [CrossRef]

- Liu, H.; Xu, W.; Zou, H.; Ke, G.; Li, W.; Ouyang, C. Feasibility of wet spinning of silk-inspired polyurethane elastic biofiber. Mater. Lett. 2008, 62, 1949–1952. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, B.; Xu, G.; Hao, W. Swelling behaviours and mechanical properties of silk fibroin–polyurethane composite hydrogels. Compos. Sci. Technol. 2013, 84, 15–22. [Google Scholar] [CrossRef]

- Kumar, B.; Hu, J.; Pan, N. Smart medical stocking using memory polymer for chronic venous disorders. Biomaterials 2016, 75, 174–181. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.Q.; Shao, Z.Z.; Knight, D.P.; Yan, J.P.; Chen, X. Silk fibers extruded artificially from aqueous solutions of regenerated bombyx mori silk fibroin are tougher than their natural counterparts. Adv. Mater. 2009, 21, 366–370. [Google Scholar] [CrossRef]

- Callone, E.; Dire, S.; Hu, X.; Motta, A. Processing influence on molecular assembling and structural conformations in silk fibroin: Elucidation by solid-state NMR. ACS Biomater. Sci. Eng. 2016, 2, 758–767. [Google Scholar] [CrossRef]

- Yue, X.; Zhang, F.; Wu, H.; Ming, J.; Fan, Z.; Zuo, B. A novel route to prepare dry-spun silk fibers from CaCl2–formic acid solution. Mater. Lett. 2014, 128, 175–178. [Google Scholar] [CrossRef]

- Yan, J.; Zhou, G.; Knight, D.P.; Shao, Z.; Chen, X. Wet-spinning of regenerated silk fiber from aqueous silk fibroin solution: Discussion of spinning parameters. Biomacromolecules 2009, 11, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Rockwood, D.N.; Preda, R.C.; Yucel, T.; Wang, X.; Lovett, M.L.; Kaplan, D.L. Materials fabrication from bombyx mori silk fibroin. Nat. Protoc. 2011, 6, 1612–1631. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Yao, J.; Masuda, H.; Kishore, R.; Asakura, T. Structural characterization and artificial fiber formation of bombyx mori silk fibroin in hexafluoro-iso-propanol solvent system. Biopolymers 2003, 69, 253–259. [Google Scholar] [CrossRef] [PubMed]

- Hong, D.P.; Hoshino, M.; Kuboi, R.; Goto, Y. Clustering of fluorine-substituted alcohols as a factor responsible for their marked effects on proteins and peptides. J. Am. Chem. Soc. 1999, 121, 8427–8433. [Google Scholar] [CrossRef]

- Cheung, H.-Y.; Lau, K.-T.; Tao, X.-M.; Hui, D. A potential material for tissue engineering: Silkworm silk/PLA biocomposite. Compos. Part B Eng. 2008, 39, 1026–1033. [Google Scholar] [CrossRef]

- Shao, Z.; Young, R.J.; Vollrath, F. The effect of solvents on spider silk studied by mechanical testing and single-fibre raman spectroscopy. Int. J. Biol. Macromol. 1999, 24, 295–300. [Google Scholar] [CrossRef]

- Tsukada, M.; Freddi, G.; Kasai, N.; Monti, P. Structure and molecular conformation of tussah silk fibroin films treated with water–methanol solutions: Dynamic mechanical and thermomechanical behavior. J. Polym. Sci. B Polym. Phys. 1998, 36, 2717–2724. [Google Scholar] [CrossRef]

- Kweon, H.Y.; Park, Y.H. Structural and conformational changes of regenerated antheraea pernyi silk fibroin films treated with methanol solution. J. Appl. Polym. Sci. 1999, 73, 2887–2894. [Google Scholar] [CrossRef]

- Fang, G.Q.; Huang, Y.F.; Tang, Y.Z.; Qi, Z.M.; Yao, J.; Shao, Z.Z.; Chen, X. Insights into silk formation process: Correlation of mechanical properties and structural evolution during artificial spinning of silk fibers. ACS Biomater. Sci. Eng. 2016, 2, 1992–2000. [Google Scholar] [CrossRef]

- Verheyen, C.; De Wijn, J.; Van Blitterswijk, C.; De Groot, K. Evaluation of hydroxylapatite/poly (l-lactide) composites: Mechanical behavior. J. Biomed. Mater. Res. A 1992, 26, 1277–1296. [Google Scholar] [CrossRef] [PubMed]

- Ha, S.-W.; Tonelli, A.E.; Hudson, S.M. Structural studies of bombyx m ori silk fibroin during regeneration from solutions and wet fiber spinning. Biomacromolecules 2005, 6, 1722–1731. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.Y.; Shao, Z.Z.; Ma, M.H.; Hu, P.; Liu, Y.S.; Yu, T.Y. Acrylic polymer silk fibroin blend fibers. J. Appl. Polym. Sci. 1997, 65, 959–966. [Google Scholar] [CrossRef]

- Lu, Q.; Hu, X.; Wang, X.; Kluge, J.A.; Lu, S.; Cebe, P.; Kaplan, D.L. Water-insoluble silk films with silk i structure. Acta Biomater. 2010, 6, 1380–1387. [Google Scholar] [CrossRef] [PubMed]

- Nova, A.; Keten, S.; Pugno, N.M.; Redaelli, A.; Buehler, M.J. Molecular and nanostructural mechanisms of deformation, strength and toughness of spider silk fibrils. Nano Lett. 2010, 10, 2626–2634. [Google Scholar] [CrossRef] [PubMed]

- Vollrath, F.; Porter, D. Spider silk as a model biomaterial. Appl. Phys. A Mater. 2006, 82, 205–212. [Google Scholar] [CrossRef]

- Vollrath, F.; Porter, D.; Holland, C. There are many more lessons still to be learned from spider silks. Soft Matter 2011, 7, 9595–9600. [Google Scholar] [CrossRef]

- Termonia, Y. Molecular modeling of spider silk elasticity. Macromolecules 1994, 27, 7378–7381. [Google Scholar] [CrossRef]

- Prisacariu, C. Structural studies on polyurethane elastomers. In Polyurethane Elastomers; Springer: Vienna, Austria, 2011; pp. 23–60. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Venkatesan, H.; Hu, J.; Chen, J. Bioinspired Fabrication of Polyurethane/Regenerated Silk Fibroin Composite Fibres with Tubuliform Silk-Like Flat Stress–Strain Behaviour. Polymers 2018, 10, 333. https://doi.org/10.3390/polym10030333

Venkatesan H, Hu J, Chen J. Bioinspired Fabrication of Polyurethane/Regenerated Silk Fibroin Composite Fibres with Tubuliform Silk-Like Flat Stress–Strain Behaviour. Polymers. 2018; 10(3):333. https://doi.org/10.3390/polym10030333

Chicago/Turabian StyleVenkatesan, Harun, Jinlian Hu, and Jianming Chen. 2018. "Bioinspired Fabrication of Polyurethane/Regenerated Silk Fibroin Composite Fibres with Tubuliform Silk-Like Flat Stress–Strain Behaviour" Polymers 10, no. 3: 333. https://doi.org/10.3390/polym10030333