Comparative Analysis of Existing RC Columns Jacketed with CFRP or FRCC

Abstract

:1. Introduction

2. Experimental Study

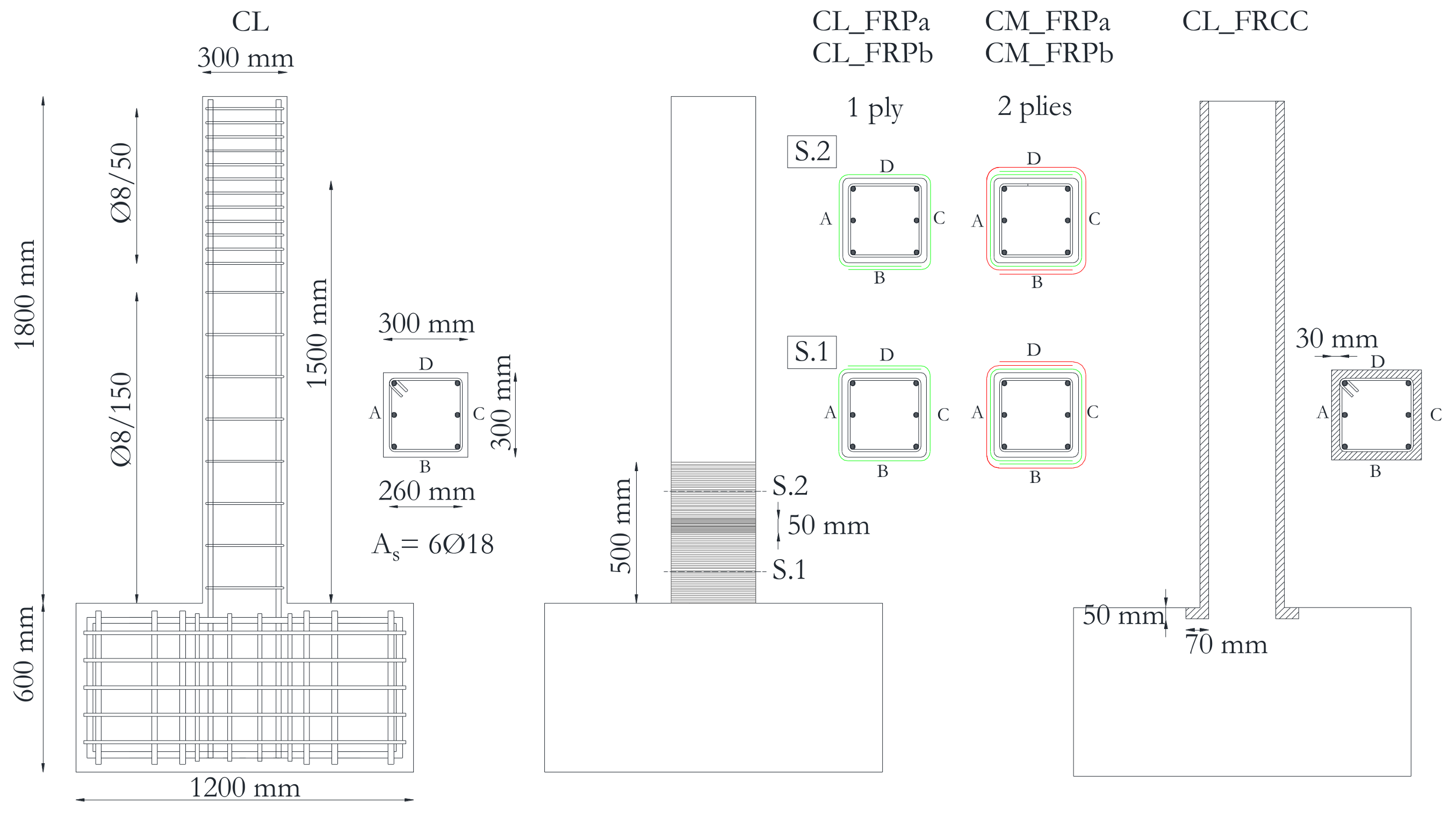

2.1. Test Matrix

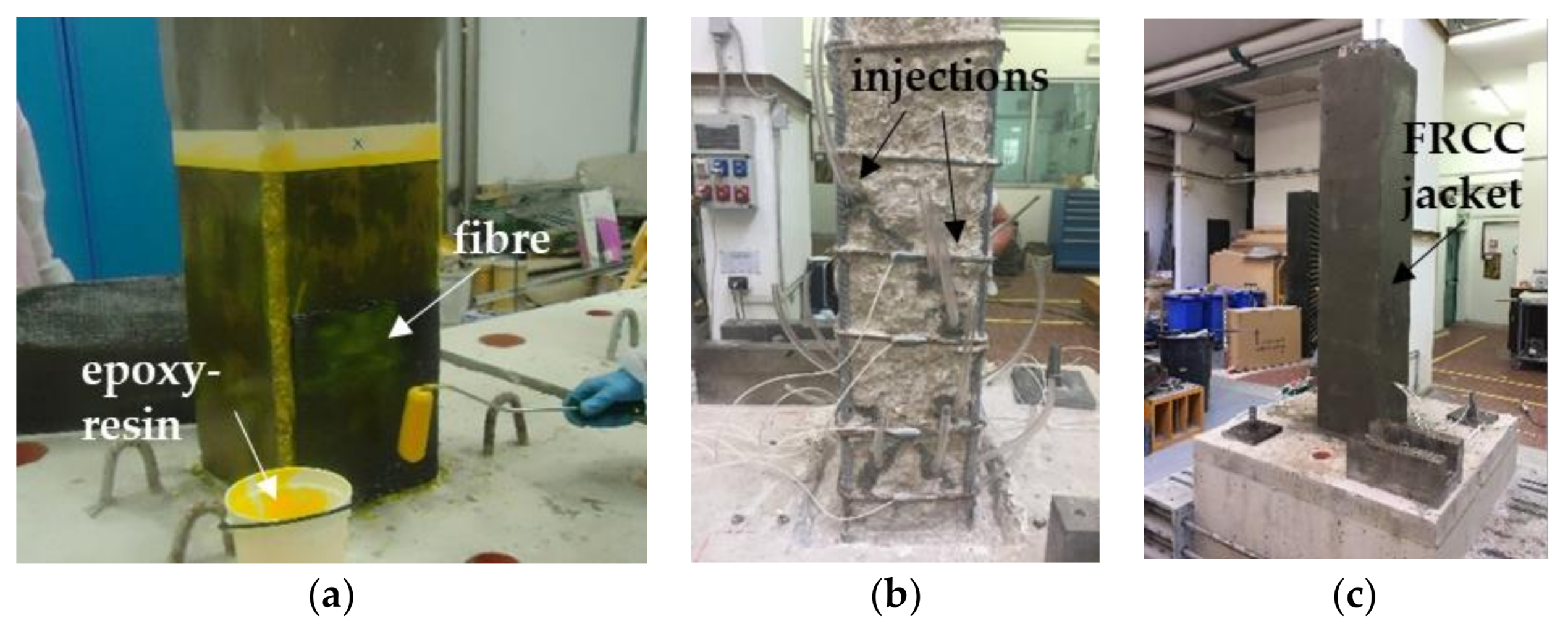

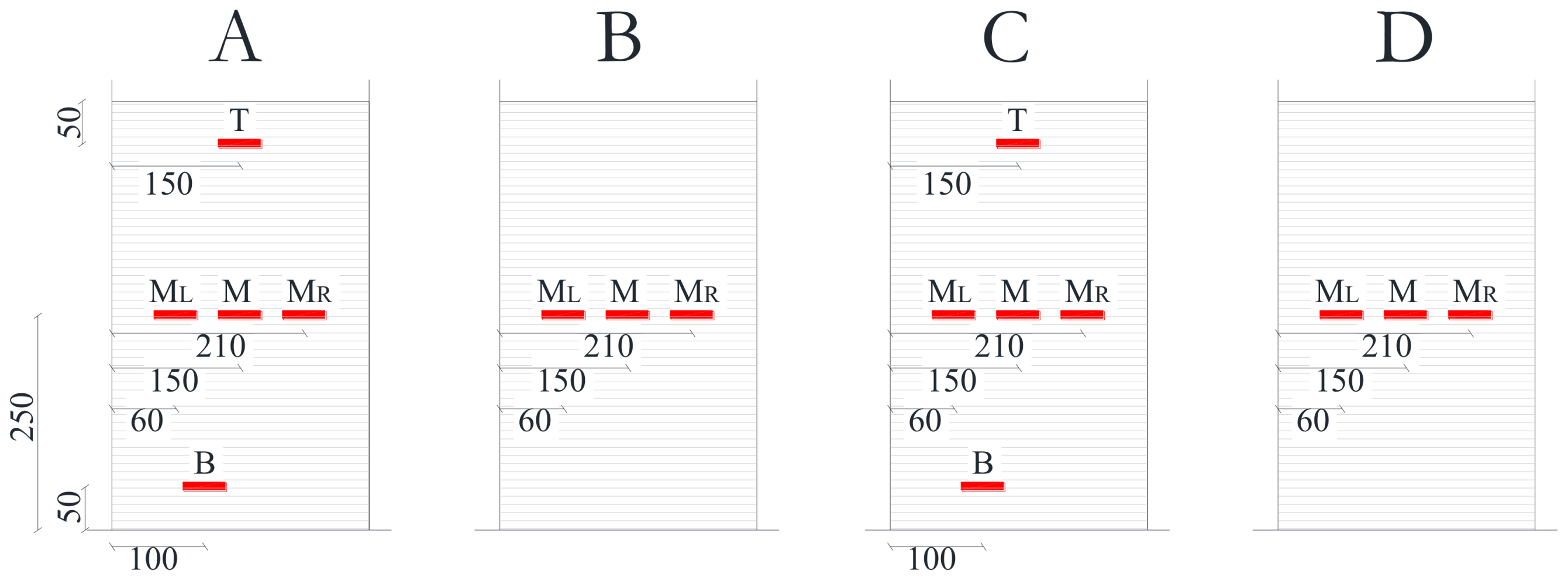

2.2. Geometric Details and Strengthening Description

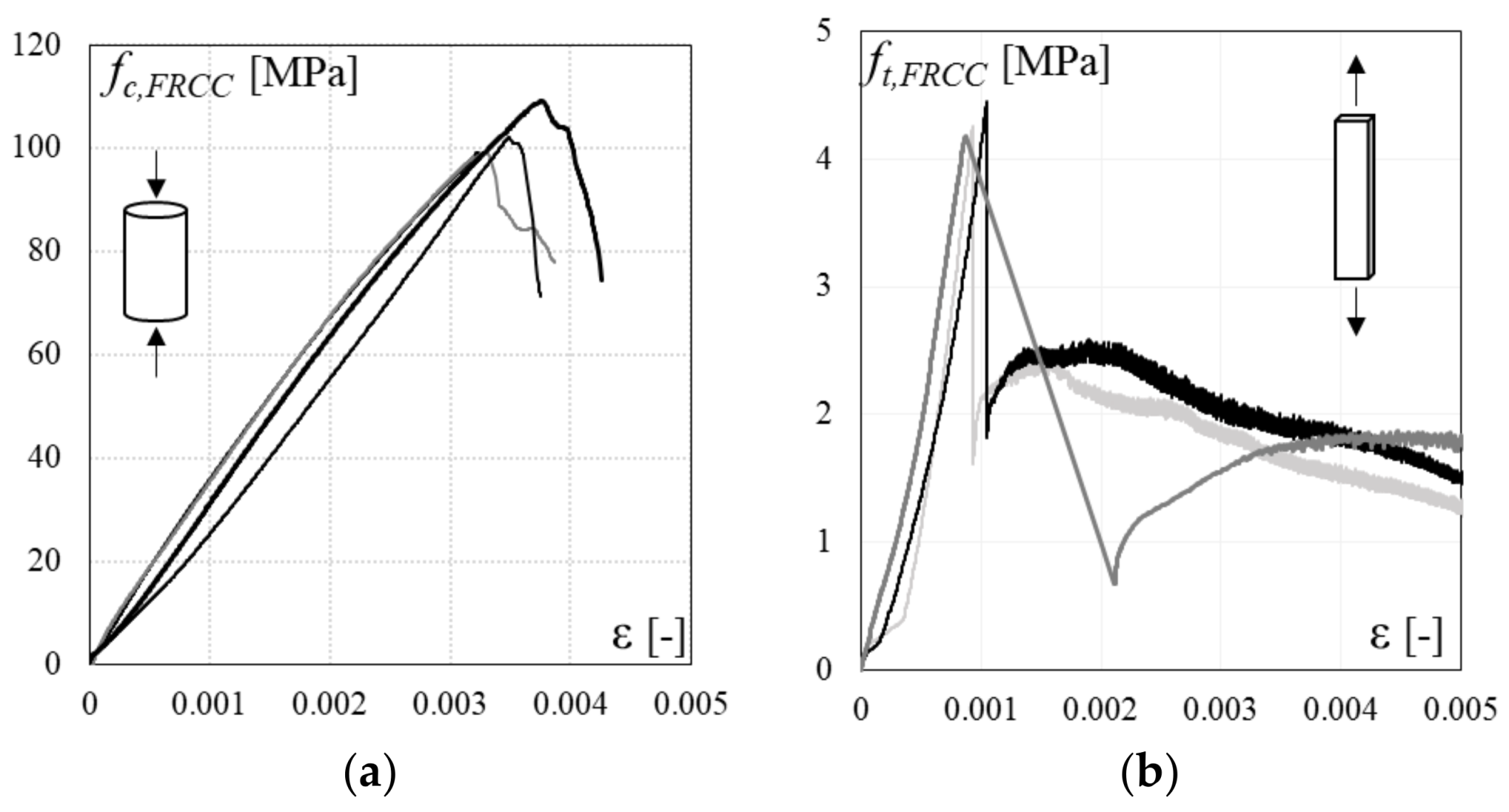

2.3. Mechanical Properties

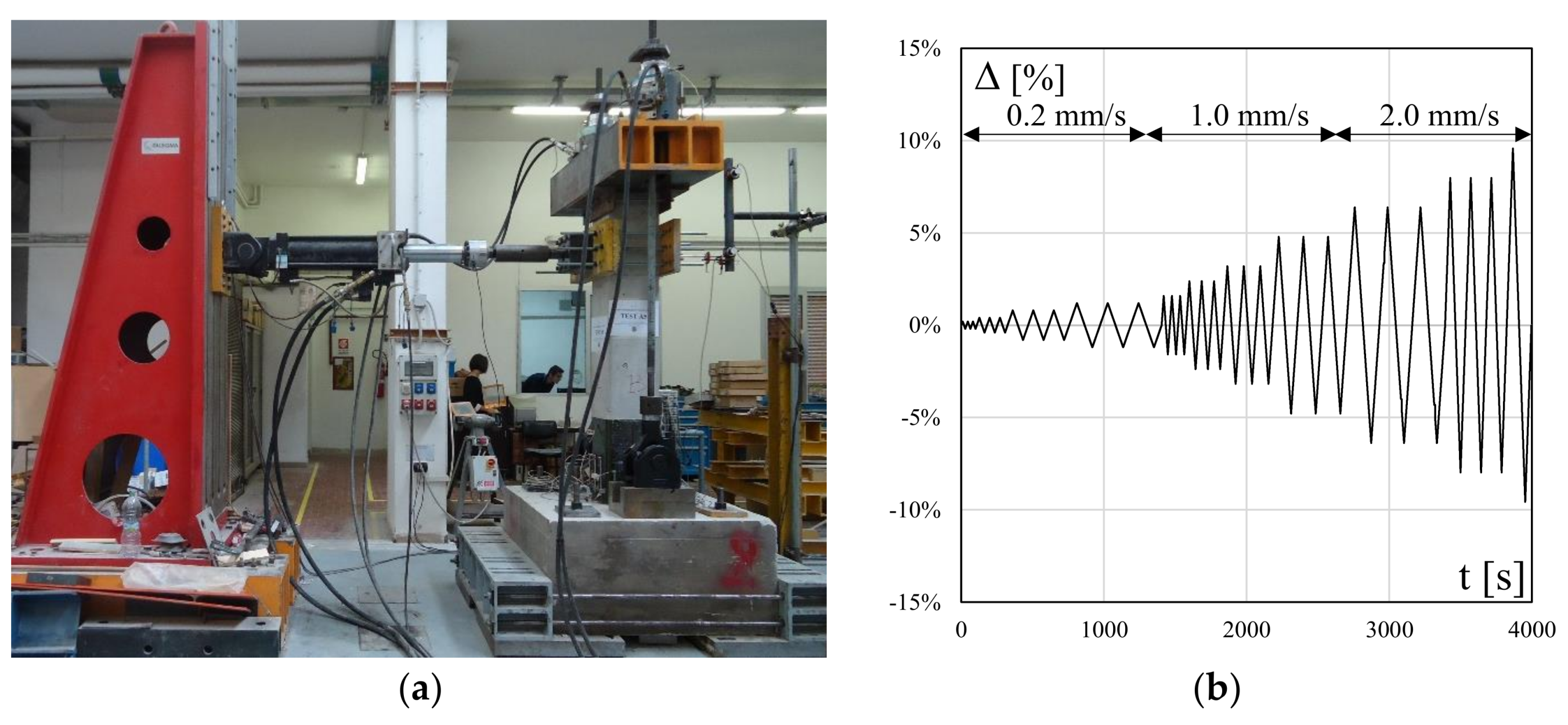

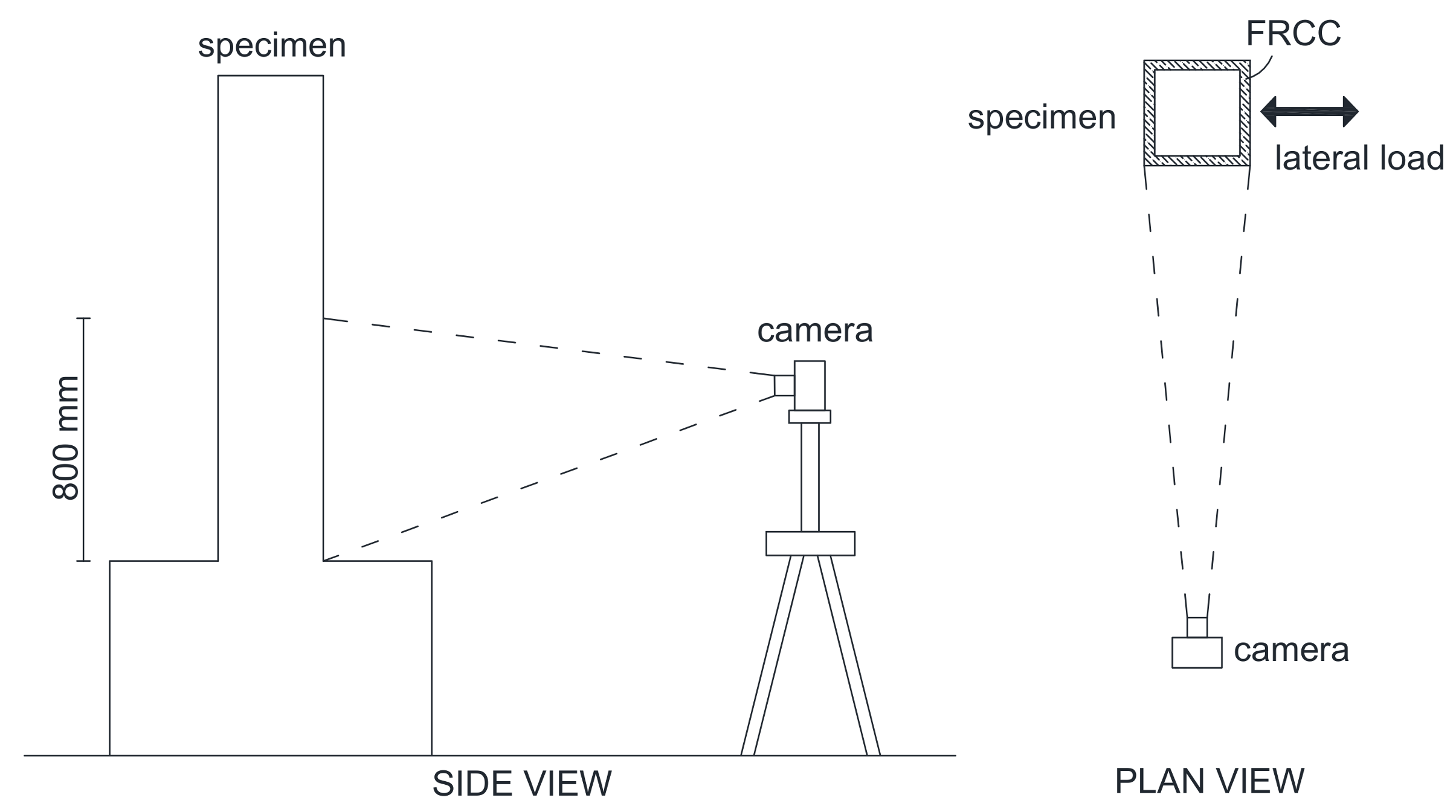

2.4. Test Setup, Instrumentation and Loading Protocol

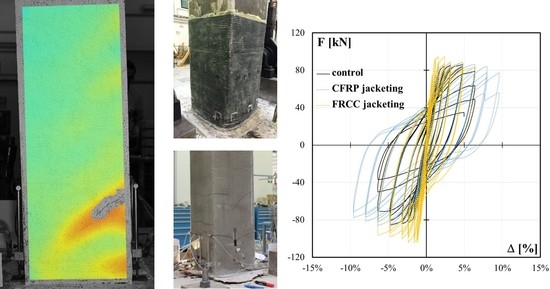

3. Experimental Outcomes

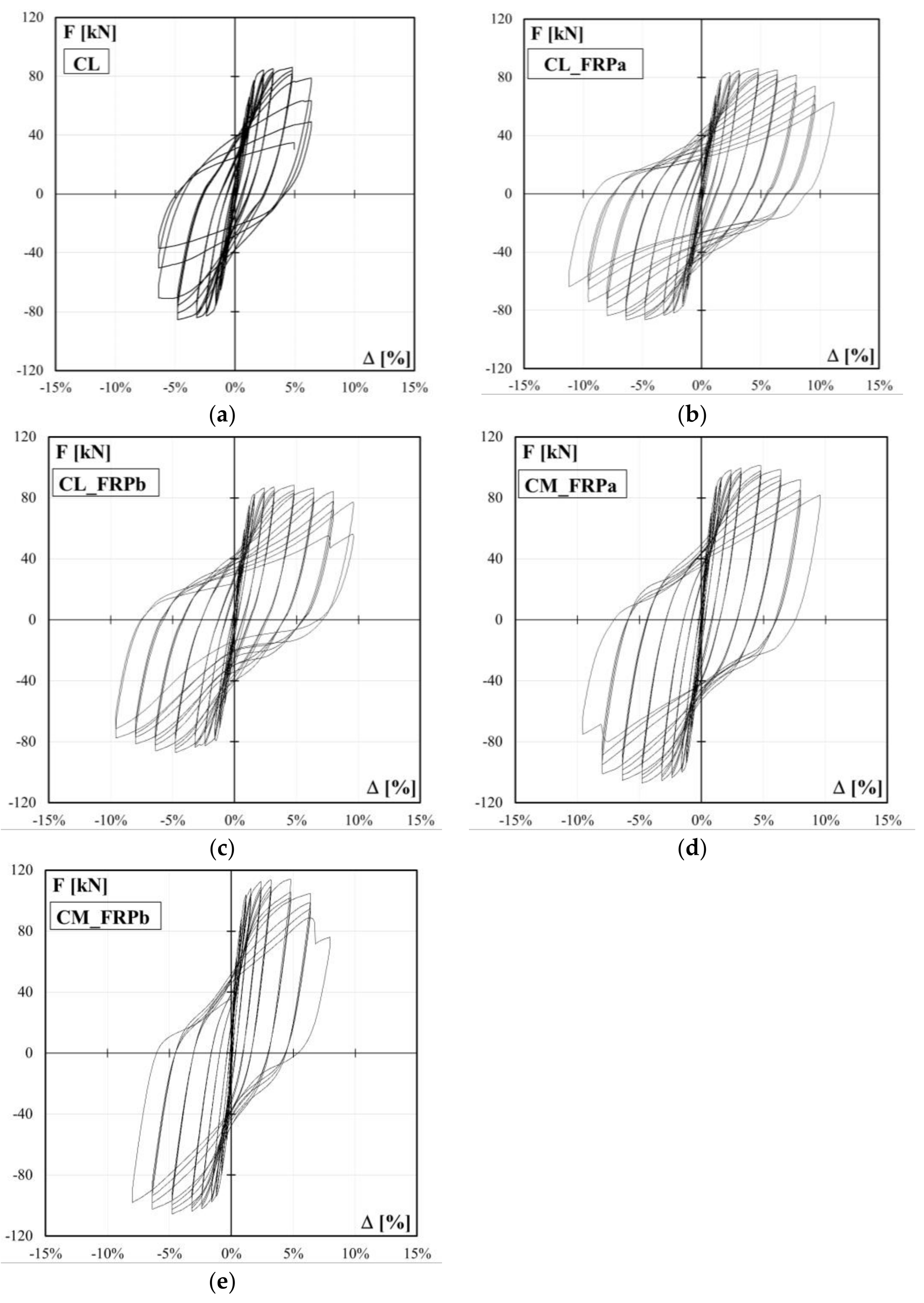

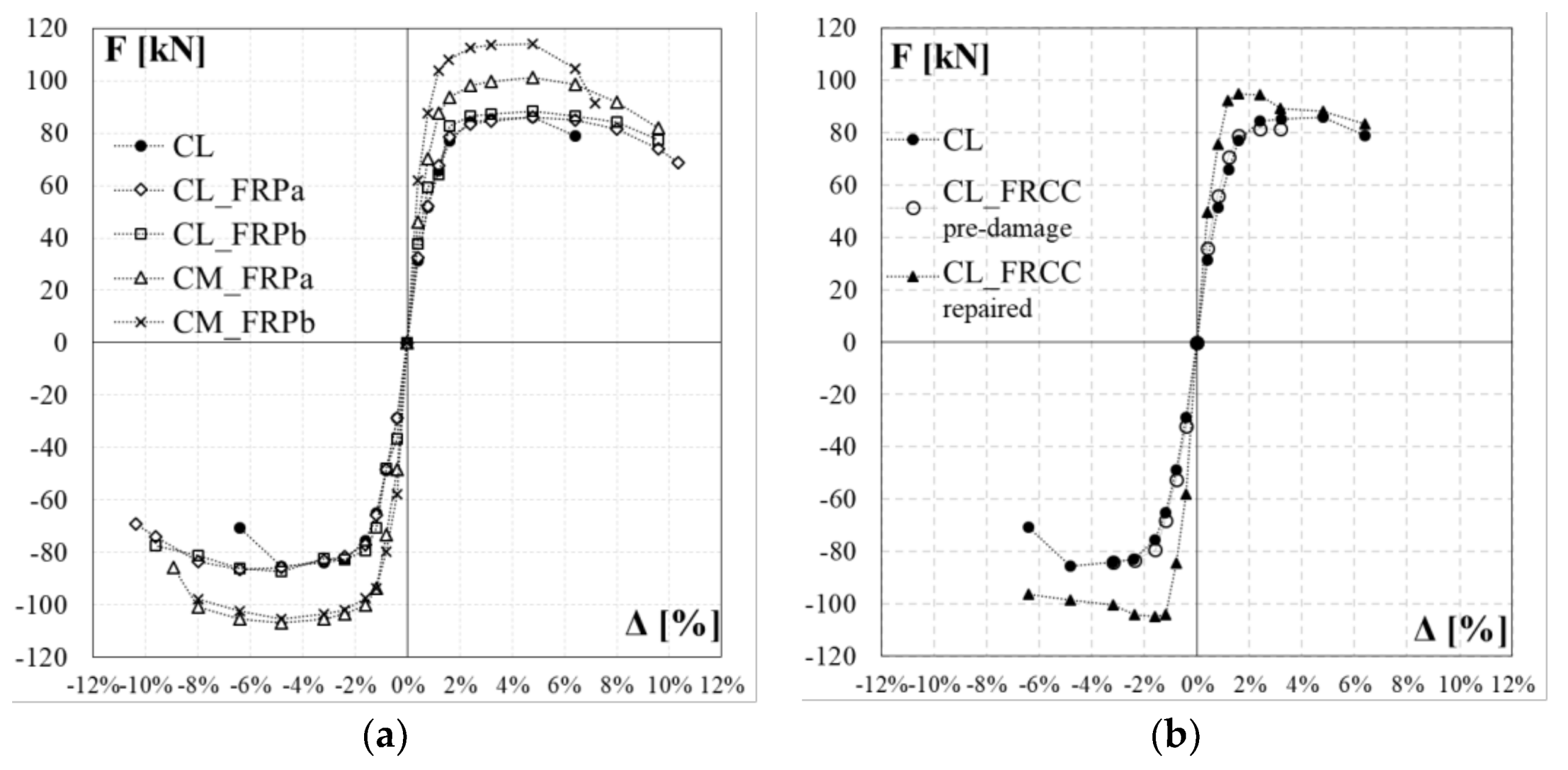

3.1. Global Behavior

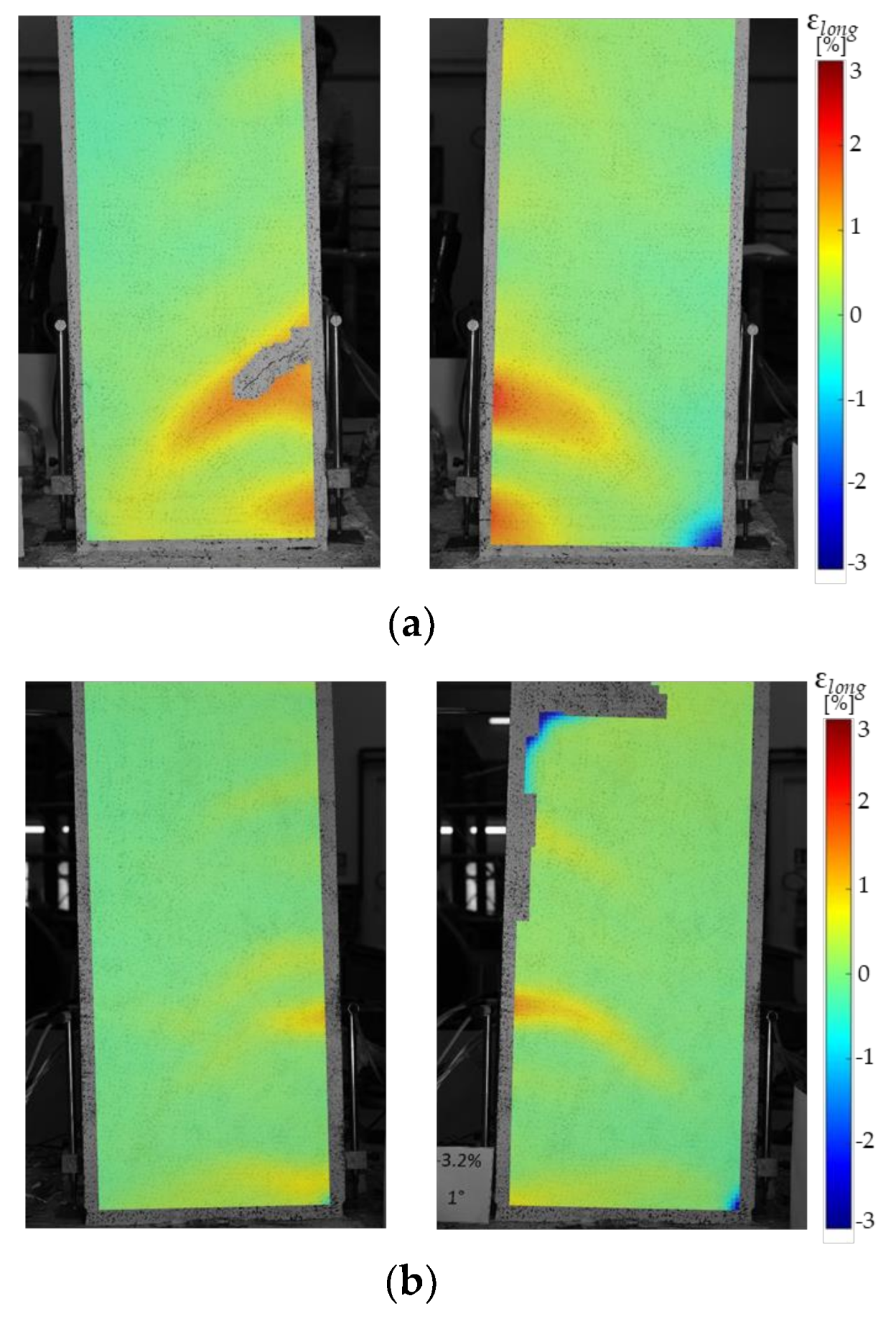

3.2. Failure Modes and Strengthening Effectiveness

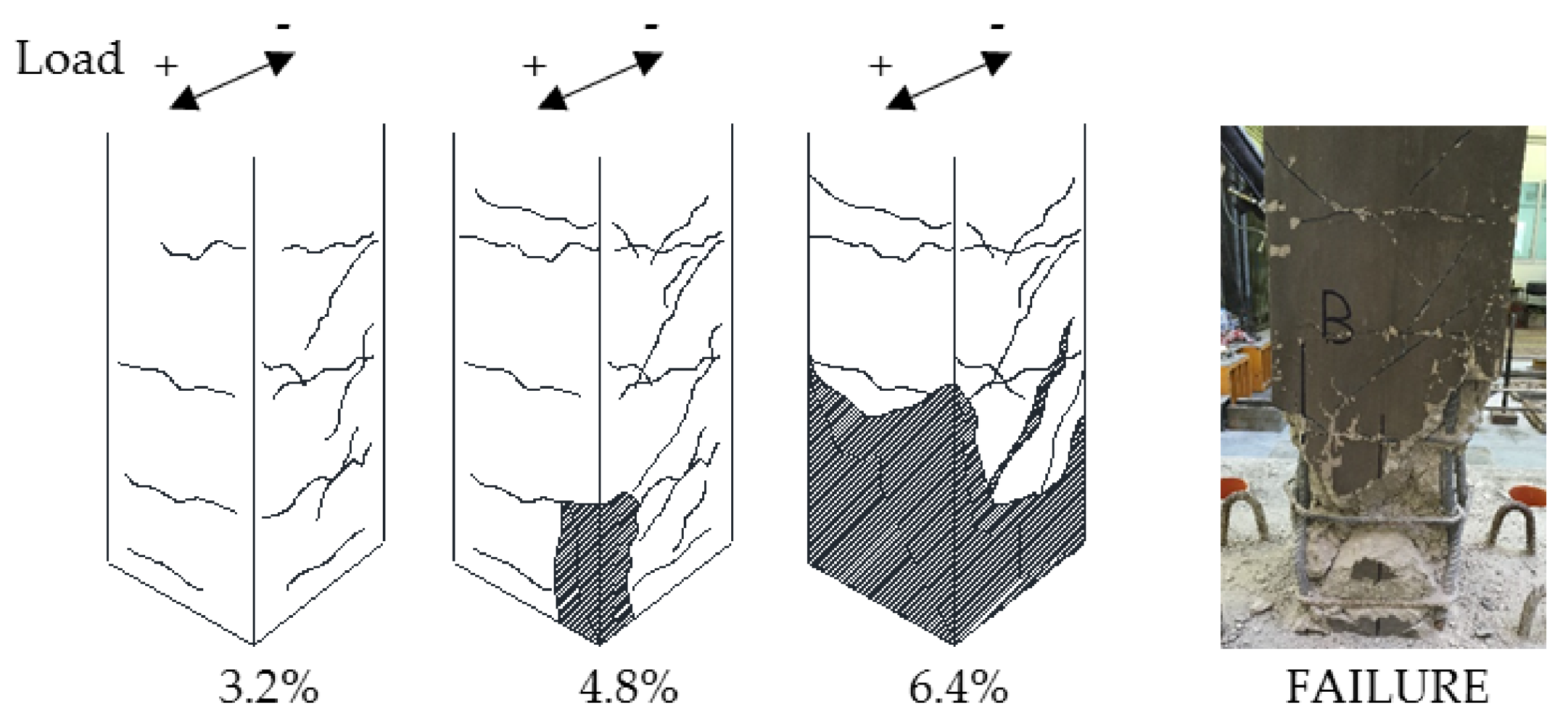

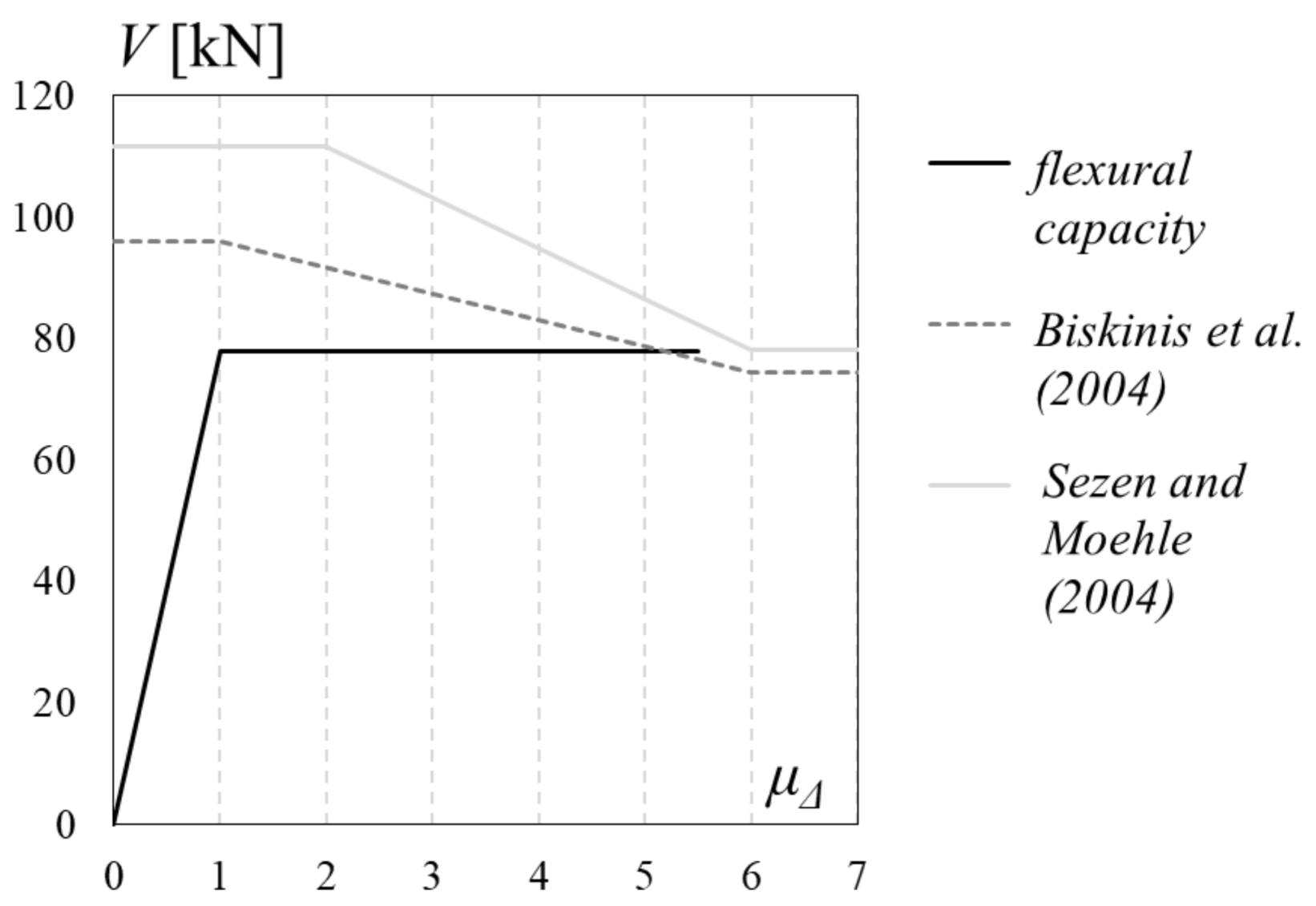

3.2.1. Control Column (CL)

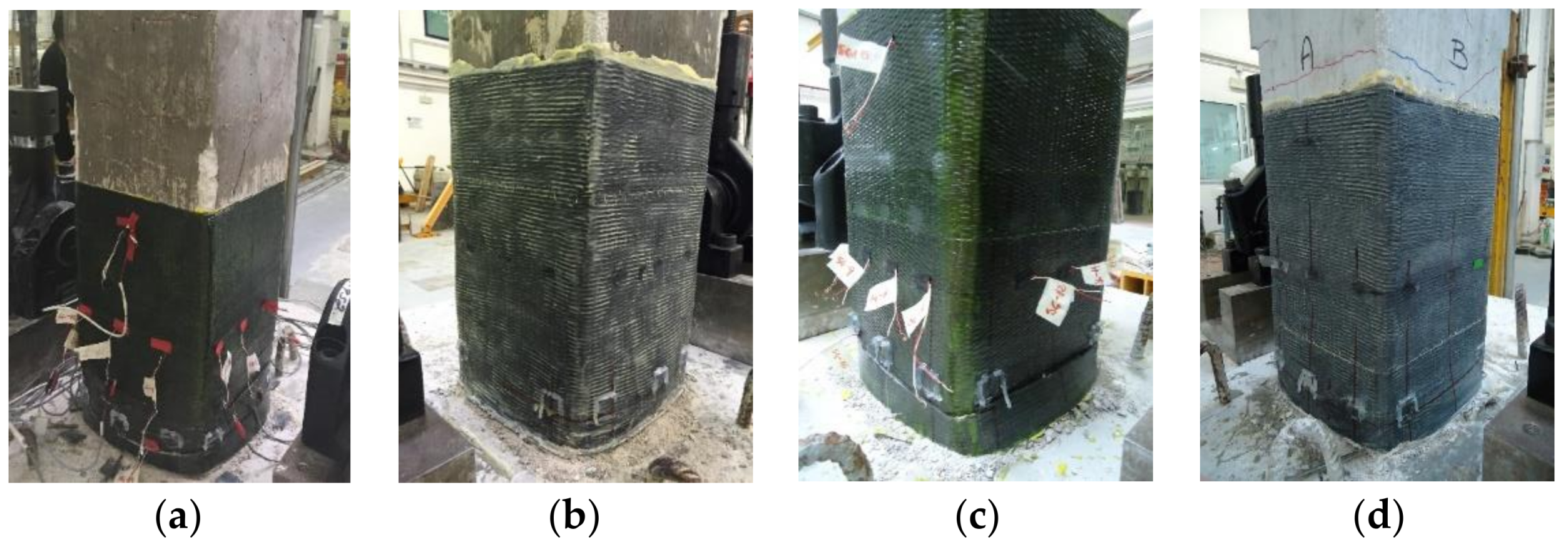

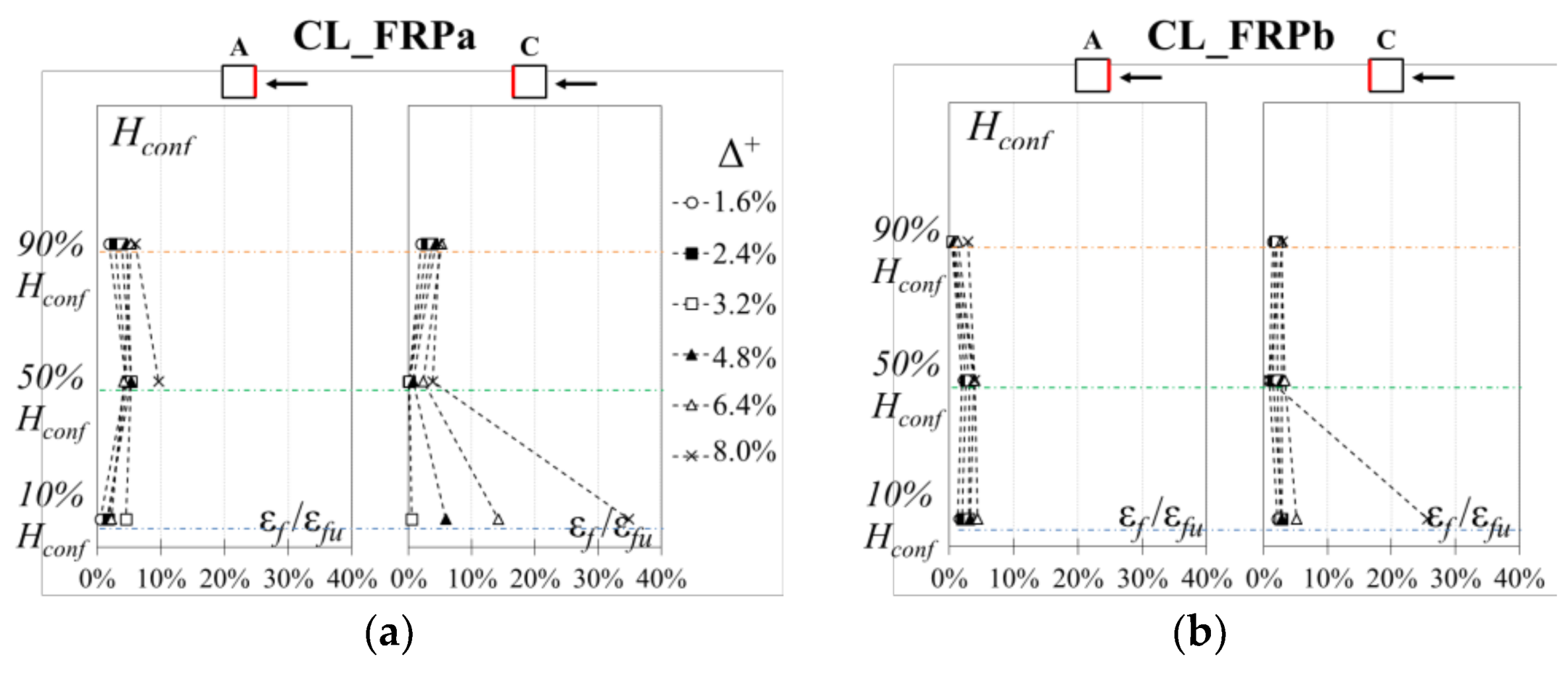

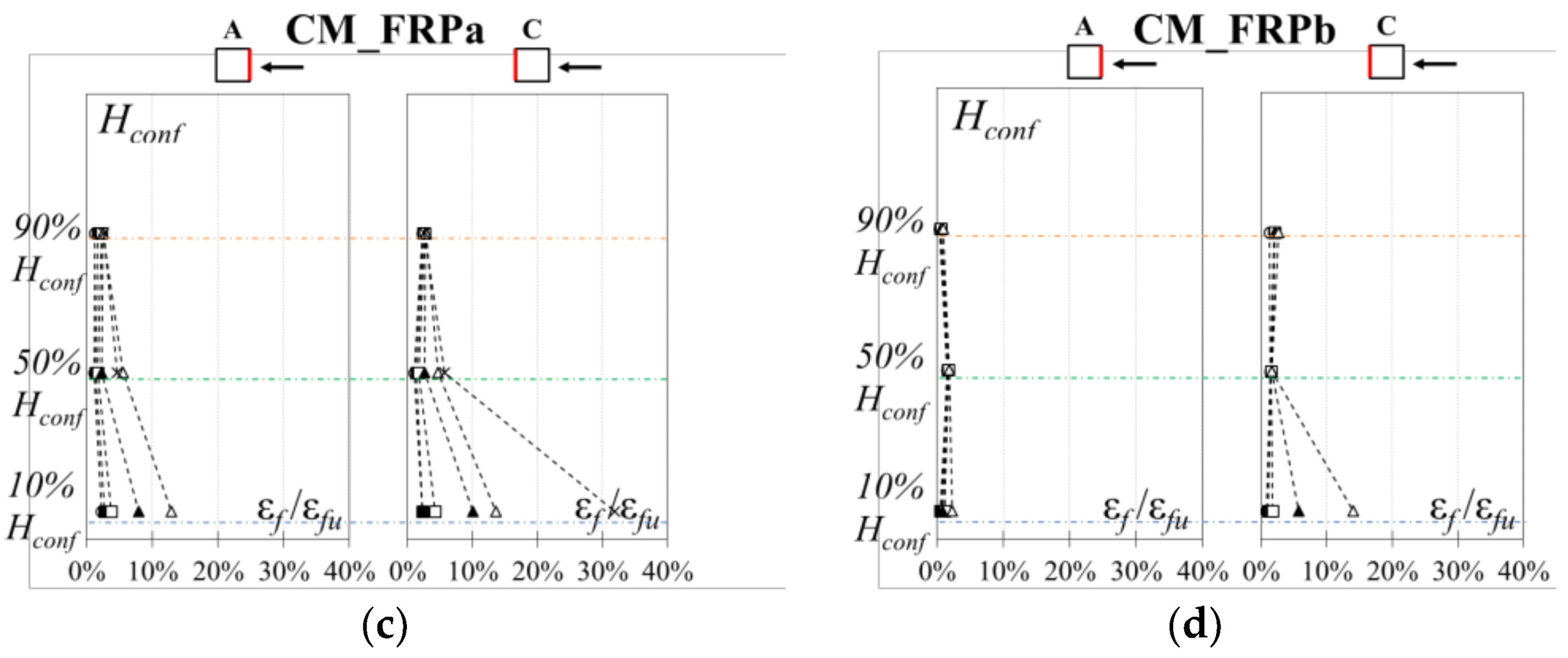

3.2.2. CFRP Strengthened Columns (CL_FRPa, CL_FRPb, CM_FRPa, CM_FRPb)

3.2.3. FRCC Strengthened Column (CL_FRCC)

4. Discussion and Comparison between Strengthening Techniques

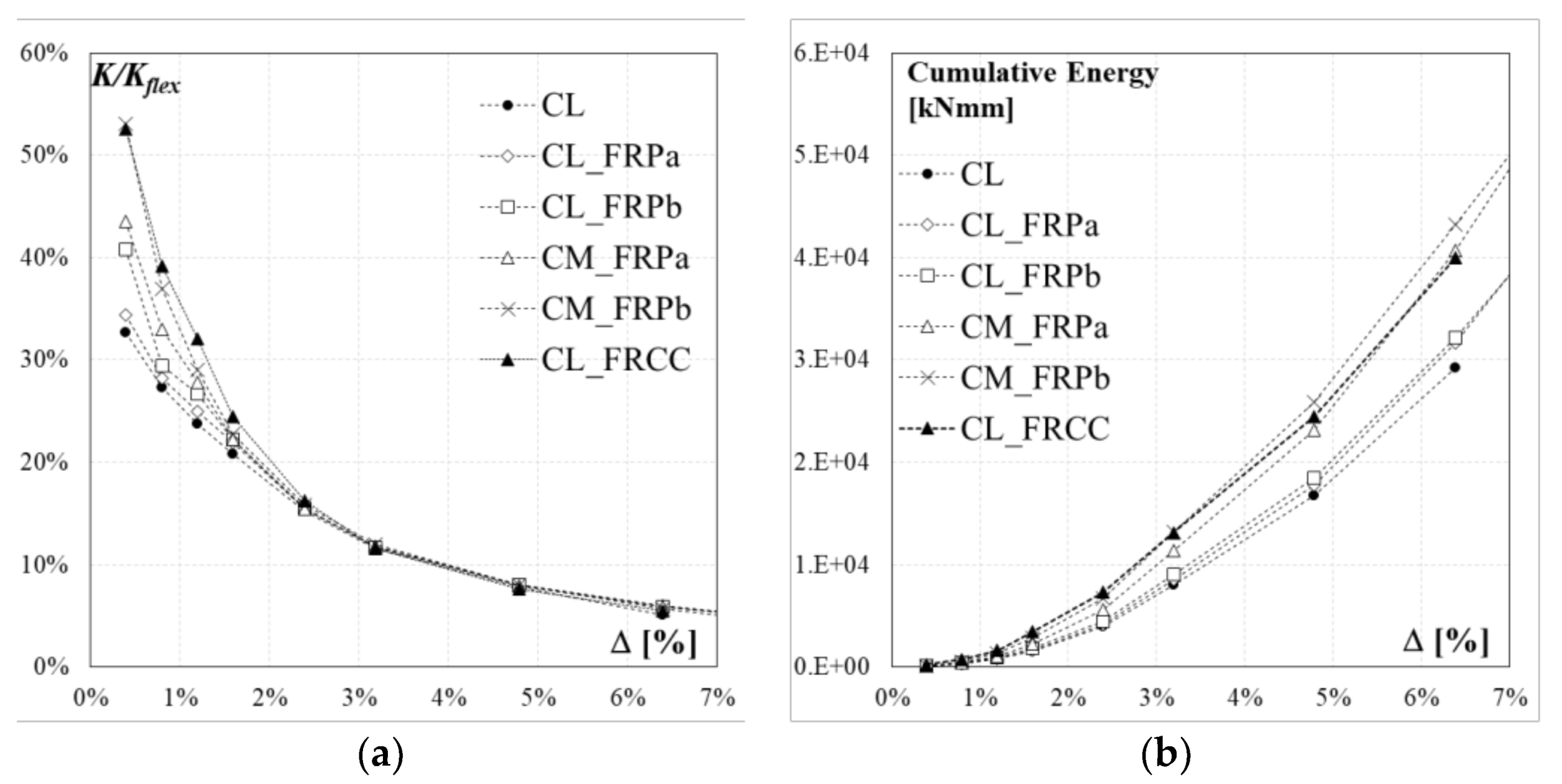

4.1. Stiffness Degradation

4.2. Energy Dissipation

4.3. Damage Index

5. Conclusions

- The control specimen, non-conforming to current standards, was not able to fully develop its ductility capacity, due to the buckling of longitudinal bars and the shear interaction mechanism, as typically observed in damaged structures after recent earthquakes.

- Specimens jacketed with CFRP in the potential plastic hinge region experienced a flexural behavior avoiding the shear interaction mechanism, with significant ductility improvement with respect to the control specimen.

- The CFRP jacketing were more effective in the case of poor quality concrete columns. The axial rigidity of composite system influenced the columns initial lateral stiffness and the post-peak strength degradation.

- FRCC jacketing can be seen as a viable alternative to FRP external reinforcement, since the jacket avoided failure phenomena like bars bucking and shear interaction mechanism and significantly reduced the concrete deterioration. Furthermore, an increase in lateral capacity and energy dissipation was observed.

- More research is needed to avoid the rocking behavior, by providing a proper anchorage with the foundation able to better increase the flexural capacity and the ductility.

Acknowledgements

Author Contributions

Conflicts of Interest

References and Note

- Kam, W.Y.; Pampanin, S.; Elwood, K. Seismic performance of reinforced concrete buildings in the 22 February Christchurch (Lyttelton) earthquake. Bull. N. Z. Soc. Earthq. Eng. 2011, 44, 239–278. [Google Scholar]

- Ricci, P.; De Luca, F.; Verderame, G.M. 6th April 2009 L’Aquila earthquake, Italy: Reinforced concrete building performance. Bull. Earthq. Eng. 2011, 9, 285–305. [Google Scholar] [CrossRef]

- Del Vecchio, C.; Prota, A.; Da Porto, F.; Modena, C. Report Fotografico Relativo ad Alcuni Edifici Delle Frazioni di Amatrice Situati Lungo La SP20. 2016. Available online: http://www.reluis.it/images/stories/report%20fotografico_Amatrice_SP20_definitivo.pdf (accessed on 11 December 2017).

- Del Zoppo, M.; Di Ludovico, M.; Balsamo, A.; Prota, A.; Manfredi, G. FRP for seismic strengthening of shear controlled RC columns: Experience from earthquakes and experimental analysis. Compos. Part B Eng. 2017, 129, 47–57. [Google Scholar] [CrossRef]

- Lynn, A.C.; Moehle, J.P.; Mahin, S.A.; Holmes, W.T. Seismic evaluation of existing reinforced concrete building columns. Earthq. Spectra 1996, 12, 715–739. [Google Scholar] [CrossRef]

- Sezen, H.; Moehle, J.P. Seismic tests of concrete columns with light transverse reinforcement. ACI Struct. J. 2006, 103, 842. [Google Scholar]

- Verderame, G.M.; Fabbrocino, G.; Manfredi, G. Seismic response of rc columns with smooth reinforcement. Part II: Cyclic tests. Eng. Struct. 2008, 30, 2289–2300. [Google Scholar] [CrossRef]

- Di Ludovico, M.; Verderame, G.M.; Prota, A.; Manfredi, G.; Cosenza, E. Experimental behavior of nonconforming RC columns with plain bars under constant axial load and biaxial bending. J. Struct. Eng. 2012, 139, 897–914. [Google Scholar] [CrossRef]

- Di Ludovico, M.; Verderame, G.M.; Prota, A.; Manfredi, G.; Cosenza, E. Cyclic Behavior of Nonconforming Full-Scale RC Columns. J. Struct. Eng. 2013, 140, 04013107. [Google Scholar] [CrossRef]

- Arani, K.K.; Marefat, M.S.; Di Ludovico, M.; Prota, A.; Manfredi, G. Hysteretic cyclic response of concrete columns reinforced with smooth bars. Bull. Earthq. Eng. 2013, 11, 2033–2053. [Google Scholar] [CrossRef]

- Arani, K.K.; Di Ludovico, M.; Marefat, M.S.; Prota, A.; Manfredi, G. Lateral response evaluation of old type reinforced concrete columns with smooth bars. ACI Struct. J. 2014, 111, 827. [Google Scholar] [CrossRef]

- Del Zoppo, M.; Di Ludovico, M.; Verderame, G.M.; Prota, A. Experimental Behavior of Nonconforming RC Columns with Deformed Bars under Constant Axial Load and Fixed Biaxial Bending. J. Struct. Eng. 2017, 143, 04017153. [Google Scholar] [CrossRef]

- Biskinis, D.E.; Roupakias, G.K.; Fardis, M.N. Degradation of shear strength of reinforced concrete members with inelastic cyclic displacements. Struct. J. 2004, 101, 773–783. [Google Scholar]

- Sezen, H.; Moehle, J.P. Shear strength model for lightly reinforced concrete columns. J. Struct. Eng. 2004, 130, 1692–1703. [Google Scholar] [CrossRef]

- Del Vecchio, C.; Del Zoppo, M.; Di Ludovico, M.; Verderame, G.M.; Prota, A. Comparison of available shear strength models for non-conforming reinforced concrete columns. Eng. Struct. 2017, 148, 312–327. [Google Scholar] [CrossRef]

- Seible, F.; Priestley, M.N.; Hegemier, G.A.; Innamorato, D. Seismic retrofit of RC columns with continuous carbon fiber jackets. J. Compos. Constr. 1997, 1, 52–62. [Google Scholar] [CrossRef]

- Biskinis, D.; Fardis, M.N. Models for FRP-wrapped rectangular RC columns with continuous or lap-spliced bars under cyclic lateral loading. Eng. Struct. 2013, 57, 199–212. [Google Scholar] [CrossRef]

- Ghatte, F.H.; Comert, M.; Demir, C.; Ilki, A. Evaluation of FRP Confinement Models for Substandard Rectangular RC Columns Based on Full-Scale Reversed Cyclic Lateral Loading Tests in Strong and Weak Directions. Polymers 2016, 8, 323. [Google Scholar] [CrossRef]

- Xiao, Y.; Wu, H.; Martin, G.R. Prefabricated composite jacketing of RC columns for enhanced shear strength. J. Struct. Eng. 1999, 125, 255–264. [Google Scholar] [CrossRef]

- Bencardino, F.; Condello, A. Innovative solution to retrofit RC members: Inhibiting-Repairing-Strengthening (IRS). Constr. Build. Mater. 2016, 117, 171–181. [Google Scholar] [CrossRef]

- Beschi, C.; Meda, A.; Riva, P. Column and Joint Retrofitting with High Performance Fiber Reinforced Concrete Jacketing. J. Earthq. Eng. 2011, 15, 989–1014. [Google Scholar] [CrossRef]

- Meda, A.; Mostosi, S.; Rinaldi, Z.; Riva, P. Corroded RC columns repair and strengthening with high performance fiber reinforced concrete jacket. Mater. Struct. 2016, 49, 1967–1978. [Google Scholar] [CrossRef]

- Ilki, A.; Demir, C.; Bedirhanoglu, I.; Kumbasar, N. Seismic retrofit of brittle and low strength RC columns using fiber reinforced polymer and cementitious composites. Adv. Struct. Eng. 2009, 12, 325–347. [Google Scholar] [CrossRef]

- ACI Committee 318. Building Code Requirements for Structural Concrete (ACI 318-08); American Concrete Institute: Farmington Hills, MI, USA, 2008; Volume 2007. [Google Scholar]

- Ordinance of the President of the Council of Ministers, OPCM no. 3881 (2010) Urgent interventions to deal with seismic events occurring in the Abruzzo region on April 6, 2009 and other urgent civil protection provisions, published in the Official Journal no. 142 of 24 June 2010. OPCM n. 3881 del 11 giugno 2010—”Ulteriori interventi urgenti diretti a fronteggiare gli eventi sismici verificatisi nella regione Abruzzo il giorno 6 aprile 2009 e altre disposizioni urgenti di protezione civile”, Pubblicata nella Gazzetta Ufficiale n. 142 del 24 Giugno 2010. (In Italian)

- MathWorks. Available online: https://it.mathworks.com/matlabcentral/profile/authors/3384127-elizabeth-jones?requesteddomain=true (accessed on 13 April 2017).

- Comité Européen de Normalisation. Design of Structures for Earthquake Resistance—Part 3: Assessment and Reofitting of Buildings; EN-1998-3, Eurocode 8; European Committee for Standardization: Brussell, Belgium, 2005. [Google Scholar]

- Elwood, K.J.; Moehle, J.P. Drift capacity of reinforced concrete columns with light transverse reinforcement. Earthq. Spectra 2005, 21, 71–89. [Google Scholar] [CrossRef]

- Rao, P.S.; Sarma, B.S.; Lakshmanan, N.; Stangenberg, F. Damage Model for Reinforced Concrete Elements under Cyclic Loading. ACI Mater. 1998, 95, 682–690. [Google Scholar]

- Promis, G.; Ferrier, E. Performance indices to assess the efficiency of external FRP retrofitting of reinforced concrete short columns for seismic strengthening. Constr. Build. Mater. 2012, 26, 32–40. [Google Scholar] [CrossRef]

- Park, Y.J.; Ang, A.H.S. Mechanistic Seismic Damage Model for Reinforced Concrete. J. Struct. Eng. 1985, 111, 722–739. [Google Scholar] [CrossRef]

- Promis, G.; Ferrier, E.; Hamelin, P. Effect of external FRP retrofitting on reinforced concrete short columns for seismic strengthening. Compos. Struct. 2009, 88, 367–379. [Google Scholar] [CrossRef]

| Test | Concrete | Steel | CFRP | FRCC | Strengthening Thickness | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| fc | fy,long | fy,tran | n° Layers | Ef | εfu | fc,FRCC | Ec,FRCC | εcu | ft,FRCC | tf | |

| [MPa] | [MPa] | [MPa] | [GPa] | [%] | [MPa] | [GPa] | [%] | [MPa] | [mm] | ||

| CL | 16.3 | 525 | 531 | - | - | - | - | - | - | - | - |

| CL_FRPa | 14.9 | 1 | 230 | 1.3 | - | - | - | - | 0.33 | ||

| CL_FRPb | 16.0 | 1 | 252 | 1.9 | - | - | - | - | 0.33 | ||

| CM_FRPa | 29.1 | 2 | 230 | 1.3 | - | - | - | - | 0.66 | ||

| CM_FRPb | 33.3 | 2 | 252 | 1.9 | - | - | - | - | 0.66 | ||

| CL_FRCC 1 | 15.1 | - | - | - | 104.3 | 31.3 | 4.0 | 4.3 | 30.00 | ||

| Test | fc | Fmax | Δy | ΔFmax | Δ0.8Fmax | μΔ | ΔμΔ | |

|---|---|---|---|---|---|---|---|---|

| [MPa] | [kN] | [%] | [%] | [%] | [–] | [%] | ||

| CL | 16.3 | 86.1 | 1.5 | 4.8 | 6.4 1 | 4.3 | - | |

| −85.4 | −1.5 | −4.8 | −6.4 1 | 4.2 | - | |||

| CL_FRPa | 14.9 | 86.0 | 1.4 | 4.8 | 10.4 | 7.2 | +67% | |

| −86.5 | −1.5 | −4.8 | −10.4 | 6.7 | +60% | |||

| CL_FRPb | 16.0 | 88.2 | 1.2 | 4.8 | 9.6 1 | 7.8 | +81% | |

| −87.2 | −1.5 | −4.8 | −9.6 1 | 6.5 | +55% | |||

| CM_FRPa | 29.1 | 101.3 | 1.2 | 4.8 | 9.6 | 8.2 | - | |

| −107.1 | −1.2 | −4.8 | −8.9 | 7.5 | - | |||

| CM_FRPb | 33.3 | 114.1 | 1.2 | 4.8 | 7.2 | 6.2 | - | |

| −105.5 | −1.2 | −4.8 | −8.0 | 6.7 | - | |||

| CL_FRCC | pre-damage | 15.1 | 81.6 | 1.5 | 2.4 | - | - | - |

| −84.0 | −1.5 | −3.2 | - | - | - | |||

| repaired | 15.1 | 94.8 | 0.9 | 1.6 | 6.4 1 | 6.8 | +58% | |

| −104.7 | −0.9 | −1.6 | −6.4 1 | 7.1 | +69% |

| Drift | K/Kflex | ||||||

|---|---|---|---|---|---|---|---|

| [%] | CL | CL_FRPa | CL_FRPb | CM_FRPa | CM_FRPb | CL_FRCC | |

| Pre-Damage | Repaired | ||||||

| 0.4 | 0.33 | 0.34 | 0.41 | 0.43 | 0.53 | 0.38 | 0.53 |

| 0.8 | 0.27 | 0.28 | 0.29 | 0.33 | 0.37 | 0.30 | 0.39 |

| 1.2 | 0.24 | 0.25 | 0.27 | 0.28 | 0.29 | 0.26 | 0.32 |

| 1.6 | 0.21 | 0.22 | 0.22 | 0.22 | 0.23 | 0.22 | 0.24 |

| 2.4 | 0.15 | 0.15 | 0.15 | 0.15 | 0.16 | 0.15 | 0.16 |

| 3.2 | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 | 0.12 |

| 4.8 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | |

| 6.4 | 0.05 | 0.06 | 0.06 | 0.06 | 0.06 | 0.05 | |

| 8.0 | 0.33 | 0.05 | 0.05 | 0.04 | 0.04 | ||

| 9.6 | 0.03 | 0.04 | 0.03 | ||||

| Drift | Cumulative Energy [kNmm] | ||||||

|---|---|---|---|---|---|---|---|

| [%] | CL | CL_FRPa | CL_FRPb | CM_FRPa | CM_FRPb | CL_FRCC | |

| Pre-Damage | Repaired | ||||||

| 0.4 | 94.6 | 100.4 | 117.1 | 130.8 | 155.4 | 110.4 | 226.9 |

| 0.8 | 338.6 | 361.5 | 402.7 | 435.1 | 520.6 | 385.1 | 729.5 |

| 1.2 | 788.1 | 815.7 | 885.2 | 991.3 | 1292.4 | 854.0 | 1616.5 |

| 1.6 | 1560.4 | 1594.6 | 1801.7 | 2235.4 | 2844.6 | 1789.0 | 3422.9 |

| 2.4 | 3985.4 | 4189.7 | 4515.6 | 5640.4 | 6731.8 | 4507.7 | 7277.3 |

| 3.2 | 8022.7 | 8494.7 | 9015.9 | 11,418.5 | 13,174.4 | 8829.0 | 13,147.6 |

| 4.8 | 16,703.8 | 17,713.7 | 18,498.5 | 23,180.9 | 25,828.8 | 24,482.4 | |

| 6.4 | 29,211.5 | 31,677.9 | 32,174.9 | 40,650.5 | 43,175.0 | 40,012.2 | |

| 8.0 | 49,145.8 | 48,041.3 | 61,540.5 | 60,991.3 | |||

| 9.6 | 67,001.0 | 64,626.2 | 82,146.2 | ||||

| [%] | CL | CL_FRPa | CL_FRPb | CM_FRPa | CM_FRPb | CL_FRCC |

|---|---|---|---|---|---|---|

| Repaired | ||||||

| 0.4 | 0.1 | 0.0 | 0.0 | 0.0 | 0.1 | 0.1 |

| 0.8 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| 1.2 | 0.2 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 |

| 1.6 | 0.3 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 |

| 2.4 | 0.5 | 0.3 | 0.4 | 0.4 | 0.5 | 0.5 |

| 3.2 | 0.7 | 0.5 | 0.5 | 0.5 | 0.7 | 0.8 |

| 4.8 | 0.8 | 0.9 | 0.9 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Del Zoppo, M.; Di Ludovico, M.; Balsamo, A.; Prota, A. Comparative Analysis of Existing RC Columns Jacketed with CFRP or FRCC. Polymers 2018, 10, 361. https://doi.org/10.3390/polym10040361

Del Zoppo M, Di Ludovico M, Balsamo A, Prota A. Comparative Analysis of Existing RC Columns Jacketed with CFRP or FRCC. Polymers. 2018; 10(4):361. https://doi.org/10.3390/polym10040361

Chicago/Turabian StyleDel Zoppo, Marta, Marco Di Ludovico, Alberto Balsamo, and Andrea Prota. 2018. "Comparative Analysis of Existing RC Columns Jacketed with CFRP or FRCC" Polymers 10, no. 4: 361. https://doi.org/10.3390/polym10040361

APA StyleDel Zoppo, M., Di Ludovico, M., Balsamo, A., & Prota, A. (2018). Comparative Analysis of Existing RC Columns Jacketed with CFRP or FRCC. Polymers, 10(4), 361. https://doi.org/10.3390/polym10040361