Effects of Die Configuration on the Electrical Conductivity of Polypropylene Reinforced Milled Carbon Fibers: An Application on a Bipolar Plate

Abstract

:1. Introduction

2. Electrical Conductivity Model

3. Materials and Method

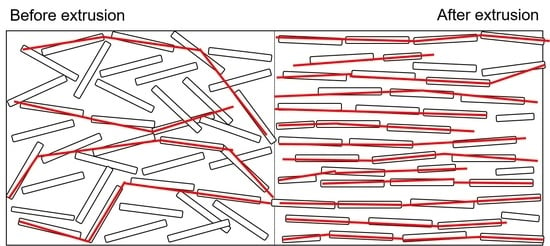

4. Results and Discussion

4.1. Thermogravimetric Analysis

4.2. X-ray Diffraction Analysis

4.3. Electrical Conductivity

4.4. Mechanical Properties

4.5. Effectiveness of Electrical Conductivity on Mechanical Properties

4.6. Electrical Conductivity Model

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Jimenez, G.A.; Jana, S.C. Electrically conductive polymer nanocomposites of polymethylmethacrylate and carbon nanofibers prepared by chaotic mixing. Compos. Part A Appl. Sci. Manuf. 2007, 38, 983–993. [Google Scholar] [CrossRef]

- Harun, W.S.W.; Kamariah, M.S.I.N.; Muhamad, N.; Ghani, S.A.C.; Ahmad, F.; Mohamed, Z. A review of powder additive manufacturing processes for metallic biomaterials. Powder Technol. 2017. [Google Scholar] [CrossRef]

- Zakaria, M.Y.; Sulong, A.B.; Sahari, J.; Suherman, H. Effect of the addition of milled carbon fiber as a secondary filler on the electrical conductivity of graphite/epoxy composites for electrical conductive material. Compos. Part B Eng. 2015, 83, 75–80. [Google Scholar] [CrossRef]

- Mejía, A.; García, N.; Guzmán, J.; Tiemblo, P. Extrusion Processed Polymer Electrolytes based on Poly(ethylene oxide) and Modified Sepiolite Nanofibers: Effect of Composition and Filler Nature on Rheology and Conductivity. Electrochim. Acta 2014, 137, 526–534. [Google Scholar] [CrossRef]

- Nakayama, Y.; Takeda, E.; Shigeishi, T.; Tomiyama, H.; Kajiwara, T. Melt-mixing by novel pitched-tip kneading disks in a co-rotating twin-screw extruder. Chem. Eng. Sci. 2011, 66, 103–110. [Google Scholar] [CrossRef]

- Zhang, Z.-X.; Gao, C.; Xin, Z.X.; Kim, J.K. Effects of extruder parameters and silica on physico-mechanical and foaming properties of PP/wood-fiber composites. Compos. Part B Eng. 2012, 43, 2047–2057. [Google Scholar] [CrossRef]

- Kostic, M.; Reifschneider, L. Design of extrusion dies. Encycl. Chem. Process. 2006, 10. [Google Scholar] [CrossRef]

- Samsudin, M.S.F.; Ishak, Z.A.M.; Jikan, S.S.; Ariff, Z.M.; Ariffin, A. Effect of filler treatments on rheological behavior of calcium carbonate and talc-filled polypropylene hybrid composites. J. Appl. Polym. Sci. 2006, 102, 5421–5426. [Google Scholar] [CrossRef]

- Fan, Z.; Advani, S.G. Characterization of orientation state of carbon nanotubes in shear flow. Polymer 2005, 46, 5232–5240. [Google Scholar] [CrossRef]

- Tang, W.; Santare, M.H.; Advani, S.G. Melt processing and mechanical property characterization of multi-walled carbon nanotube/high density polyethylene (MWNT/HDPE) composite films. Carbon N. Y. 2003, 41, 2779–2785. [Google Scholar] [CrossRef]

- Kuriger, R.J.; Alam, M.K.; Anderson, D.P.; Jacobsen, R.L. Processing and characterization of aligned vapor grown carbon fiber reinforced polypropylene. Compos. Part A Appl. Sci. Manuf. 2002, 33, 53–62. [Google Scholar] [CrossRef]

- Wang, Z.; Fan, X.; Wang, K.; Deng, H.; Chen, F.; Fu, Q. Fabrication of polypropylene/carbon nanotubes composites via a sequential process of (rotating solid-state mixing)-plus-(melt extrusion). Compos. Sci. Technol. 2011, 71, 1397–1403. [Google Scholar] [CrossRef]

- Kim, Y.A.; Hayashi, T.; Endo, M.; Gotoh, Y.; Wada, N.; Seiyama, J. Fabrication of aligned carbon nanotube-filled rubber composite. Scr. Mater. 2006, 54, 31–35. [Google Scholar] [CrossRef]

- Taipalus, R.; Harmia, T.; Zhang, M.Q.; Friedrich, K. The electrical conductivity of carbon-fibre-reinforced polypropylene/polyaniline complex-blends: Experimental characterisation and modelling. Compos. Sci. Technol. 2001, 61, 801–814. [Google Scholar] [CrossRef]

- Ausias, G.; Jarrin, J.; Vincent, M. Optimization of the tube-extrusion die for short-fiber-filled polymers. Compos. Sci. Technol. 1996, 56, 719–724. [Google Scholar] [CrossRef]

- Hine, P.J.; Davidson, N.; Duckett, R.A.; Ward, I.M. Measuring the fibre orientation and modelling the elastic properties of injection-moulded long-glass-fibre-reinforced nylon. Compos. Sci. Technol. 1995, 53, 125–131. [Google Scholar] [CrossRef]

- Kakati, B.K.; Yamsani, V.K.; Dhathathreyan, K.S.; Sathiyamoorthy, D.; Verma, A. The electrical conductivity of a composite bipolar plate for fuel cell applications. Carbon N. Y. 2009, 47, 2413–2418. [Google Scholar] [CrossRef]

- Wang, J.; Geng, C.; Luo, F.; Liu, Y.; Wang, K.; Fu, Q.; He, B. Shear induced fiber orientation, fiber breakage and matrix molecular orientation in long glass fiber reinforced polypropylene composites. Mater. Sci. Eng. A 2011, 528, 3169–3176. [Google Scholar] [CrossRef]

- Antunes, R.A.; de Oliveira, M.C.L.; Ett, G.; Ett, V. Carbon materials in composite bipolar plates for polymer electrolyte membrane fuel cells: A review of the main challenges to improve electrical performance. J. Power Sources 2011, 196, 2945–2961. [Google Scholar] [CrossRef]

- Feller, J.F.; Linossier, I.; Grohens, Y. Conductive polymer composites: Comparative study of poly(ester)-short carbon fibres and poly(epoxy)-short carbon fibres mechanical and electrical properties. Mater. Lett. 2002, 57, 64–71. [Google Scholar] [CrossRef]

- Feller, J.F.; Chauvelon, P.; Linossier, I.; Glouannec, P. Characterization of electrical and thermal properties of extruded tapes of thermoplastic conductive polymer composites (CPC). Polym. Test. 2003, 22, 831–837. [Google Scholar] [CrossRef]

- Dweiri, R.; Sahari, J. Microstructural image analysis and structure–electrical conductivity relationship of single- and multiple-filler conductive composites. Compos. Sci. Technol. 2008, 68, 1679–1687. [Google Scholar] [CrossRef]

- Suherman, H.; Sahari, J.; Sulong, A.B. Effect of small-sized conductive filler on the properties of an epoxy composite for a bipolar plate in a PEMFC. Ceram. Int. 2013, 39, 7159–7166. [Google Scholar] [CrossRef]

- Alomayri, T.; Shaikh, F.U.A.; Low, I.M. Effect of fabric orientation on mechanical properties of cotton fabric reinforced geopolymer composites. Mater. Des. 2014, 57, 360–365. [Google Scholar] [CrossRef]

- Tungjitpornkull, S.; Sombatsompop, N. Processing technique and fiber orientation angle affecting the mechanical properties of E-glass fiber reinforced wood/PVC composites. J. Mater. Process. Technol. 2009, 209, 3079–3088. [Google Scholar] [CrossRef]

- Dweiri, R.; Sahari, J. Electrical properties of carbon-based polypropylene composites for bipolar plates in polymer electrolyte membrane fuel cell (PEMFC). J. Power Sources 2007, 171, 424–432. [Google Scholar] [CrossRef]

- Liang, J.Z.; Peng, W. Melt viscosity of PP and FEP/PP blends at low shear rates. Polym. Test. 2009, 28, 386–391. [Google Scholar] [CrossRef]

- Planes, E.; Flandin, L.; Alberola, N. Polymer Composites Bipolar Plates for PEMFCs. Energy Procedia 2012, 20, 311–323. [Google Scholar] [CrossRef]

- Mohd Radzuan, N.A.; Yusuf Zakaria, M.; Sulong, A.B.; Sahari, J. The effect of milled carbon fibre filler on electrical conductivity in highly conductive polymer composites. Compos. Part B Eng. 2017, 110, 153–160. [Google Scholar] [CrossRef]

- Mohd Radzuan, N.A.; Sulong, A.B.; Sahari, J. A review of electrical conductivity models for conductive polymer composite. Int. J. Hydrogen Energy 2017, 42, 9262–9273. [Google Scholar] [CrossRef]

- Barton, R.L.; Keith, J.M.; King, J.A. Development and modeling of electrically conductive carbon filled liquid crystal polymer composites for fuel cell bipolar plate applications. J. New Mater. Electrochem. Syst. 2007, 10, 225. [Google Scholar]

- Kakati, B.K.; Sathiyamoorthy, D.; Verma, A. Semi-empirical modeling of electrical conductivity for composite bipolar plate with multiple reinforcements. Int. J. Hydrogen Energy 2011, 36, 14851–14857. [Google Scholar] [CrossRef]

- Köpplmayr, T.; Milosavljevic, I.; Aigner, M.; Hasslacher, R.; Plank, B.; Salaberger, D.; Miethlinger, J. Influence of fiber orientation and length distribution on the rheological characterization of glass-fiber-filled polypropylene. Polym. Test. 2013, 32, 535–544. [Google Scholar] [CrossRef]

- Keith, J.M.; King, J.A.; Barton, R.L. Electrical conductivity modeling of carbon-filled liquid-crystalline polymer composites. J. Appl. Polym. Sci. 2006, 102, 3293–3300. [Google Scholar] [CrossRef]

- Tavares, L.B.; Rocha, R.G.; Rosa, D.S. An organic bioactive pro-oxidant behavior in thermal degradation kinetics of polypropylene films. Iran. Polym. J. 2017, 26, 273–280. [Google Scholar] [CrossRef]

- Eberhardt, C.; Clarke, A.; Vincent, M.; Giroud, T.; Flouret, S. Fibre-orientation measurements in short-glass-fibre composites—II: A quantitative error estimate of the 2D image analysis technique. Compos. Sci. Technol. 2001, 61, 1961–1974. [Google Scholar] [CrossRef]

- Hobbie, E.K.; Wang, H.; Kim, H.; Lin-Gibson, S.; Grulke, E.A. Orientation of carbon nanotubes in a sheared polymer melt. Phys. Fluids 2003, 15, 1196–1202. [Google Scholar] [CrossRef]

- Dweiri, R. The Potential of Using Graphene Nanoplatelets for Electrically Conductive Compression-Molded Plates. JJMIE 2015, 9, 1–8. [Google Scholar]

- Dweiri, R.; Sahari, J. Computer simulation of electrical conductivity of graphite-based polypropylene composites based on digital image analysis. J. Mater. Sci. 2007, 42, 10098–10102. [Google Scholar] [CrossRef]

- Radzuan, N.A.M.; Sulong, A.B.; Rao Somalu, M. Electrical properties of extruded milled carbon fibre and polypropylene. J. Compos. Mater. 2017, 51, 3187–3195. [Google Scholar] [CrossRef]

- Suherman, H.; Sulong, A.B.; Sahari, J. Effect of the compression molding parameters on the in-plane and through-plane conductivity of carbon nanotubes/graphite/epoxy nanocomposites as bipolar plate material for a polymer electrolyte membrane fuel cell. Ceram. Int. 2013, 39, 1277–1284. [Google Scholar] [CrossRef]

- Sulong, A.B.; Ramli, M.I.; Hau, S.L.; Sahari, J.; Muhamad, N.; Suherman, H. Rheological and mechanical properties of carbon nanotube/Graphite/SS316L/polypropylene nanocomposite for a conductive polymer composite. Compos. Part B Eng. 2013, 50, 54–61. [Google Scholar] [CrossRef]

- Liu, S.-P.; Hwang, S.-S.; Yeh, J.-M.; Hung, C.-C. Mechanical properties of polyamide-6/montmorillonite nanocomposites—Prepared by the twin-screw extruder mixed technique. Int. Commun. Heat Mass Transf. 2011, 38, 37–43. [Google Scholar] [CrossRef]

- Adloo, A.; Sadeghi, M.; Masoomi, M.; Pazhooh, H.N. High performance polymeric bipolar plate based on polypropylene/graphite/graphene/nano-carbon black composites for PEM fuel cells. Renew. Energy 2016, 99, 867–874. [Google Scholar] [CrossRef]

- Mustafa, A.; Muhammed Ali, S.A.; Abdalla, A.M.; Somalu, M.R.; Muchtar, A. Effect of sintering temperature on the microstructure and ionic conductivity of Ce0.8Sm0.1Ba0.1O2-δ electrolyte. Process. Appl. Ceram. 2017, 11, 67–74. [Google Scholar] [CrossRef]

- Muhammed Ali, S.A.; Anwar, M.; Abdalla, A.M.; Somalu, M.R.; Muchtar, A. Ce0.80Sm0.10Ba0.05Er0.05O2-δ multi-doped ceria electrolyte for intermediate temperature solid oxide fuel cells. Ceram. Int. 2017, 43, 1265–1271. [Google Scholar] [CrossRef]

- Muhammed Ali, S.A.; Anwar, M.; Somalu, M.R.; Muchtar, A. Enhancement of the interfacial polarization resistance of La0.6Sr0.4Co0.2Fe0.8O3-δ cathode by microwave-assisted combustion method. Ceram. Int. 2017, 43, 4647–4654. [Google Scholar] [CrossRef]

- Pötschke, P.; Bhattacharyya, A.R.; Janke, A. Melt mixing of polycarbonate with multiwalled carbon nanotubes: Microscopic studies on the state of dispersion. Eur. Polym. J. 2004, 40, 137–148. [Google Scholar] [CrossRef]

- Taherian, R.; Hadianfard, M.J.; Golikand, A.N. Manufacture of a polymer-based carbon nanocomposite as bipolar plate of proton exchange membrane fuel cells. Mater. Des. 2013, 49, 242–251. [Google Scholar] [CrossRef]

- Dhakate, S.R.; Sharma, S.; Borah, M.; Mathur, R.B.; Dhami, T.L. Development and characterization of expanded graphite-based nanocomposite as bipolar plate for polymer electrolyte membrane fuel cells (PEMFCs). Energy Fuels 2008, 22, 3329–3334. [Google Scholar] [CrossRef]

- Solaimurugan, S.; Velmurugan, R. Influence of in-plane fibre orientation on mode I interlaminar fracture toughness of stitched glass/polyester composites. Compos. Sci. Technol. 2008, 68, 1742–1752. [Google Scholar] [CrossRef]

- Zhou, Y.; Rangari, V.; Mahfuz, H.; Jeelani, S.; Mallick, P.K. Experimental study on thermal and mechanical behavior of polypropylene, talc/polypropylene and polypropylene/clay nanocomposites. Mater. Sci. Eng. A 2005, 402, 109–117. [Google Scholar] [CrossRef]

- Huang, G.; Han, Y.; Guo, X.; Qiu, D.; Wang, L.; Lu, W.; Zhang, D. Effects of extrusion ratio on microstructural evolution and mechanical behavior of in situ synthesized Ti-6Al-4V composites. Mater. Sci. Eng. A 2017, 688, 155–163. [Google Scholar] [CrossRef]

| Type | Size | Density, ρs (g/cm3) | Relative Density (ρs/ρTH) (%) |

|---|---|---|---|

| Sheet (Thickness) | 3 mm | 1.194 | 96.06 |

| 5 mm | 1.2 | 96.54 | |

| Rod | 5 mm | 1.192 | 95.89 |

| Type | Size | Hardness (Extrude) | Hardness (Compress) | Flexural Strength (MPa) | Tensile Modulus (MPa) |

|---|---|---|---|---|---|

| Sheet (Thickness) | 3 mm | 47.42 | 47.8 | 14.93 | 842 |

| 5 mm | 52.58 | 53.9 | 13.93 | 945 | |

| Rod | 5 mm | 43.5 | 50.6 | 25.05 | 1225 |

| Paraneters Symbol | Values |

|---|---|

| 10−16 S/cm | |

| 100 S/cm | |

| d | 9 µm |

| l | 300 µm |

| φ | 0.7 |

| dc | 10−9 cm |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohd Radzuan, N.A.; Sulong, A.B.; Rao Somalu, M.; Majlan, E.H.; Husaini, T.; Rosli, M.I. Effects of Die Configuration on the Electrical Conductivity of Polypropylene Reinforced Milled Carbon Fibers: An Application on a Bipolar Plate. Polymers 2018, 10, 558. https://doi.org/10.3390/polym10050558

Mohd Radzuan NA, Sulong AB, Rao Somalu M, Majlan EH, Husaini T, Rosli MI. Effects of Die Configuration on the Electrical Conductivity of Polypropylene Reinforced Milled Carbon Fibers: An Application on a Bipolar Plate. Polymers. 2018; 10(5):558. https://doi.org/10.3390/polym10050558

Chicago/Turabian StyleMohd Radzuan, Nabilah Afiqah, Abu Bakar Sulong, Mahendra Rao Somalu, Edy Herianto Majlan, Teuku Husaini, and Masli Irwan Rosli. 2018. "Effects of Die Configuration on the Electrical Conductivity of Polypropylene Reinforced Milled Carbon Fibers: An Application on a Bipolar Plate" Polymers 10, no. 5: 558. https://doi.org/10.3390/polym10050558

APA StyleMohd Radzuan, N. A., Sulong, A. B., Rao Somalu, M., Majlan, E. H., Husaini, T., & Rosli, M. I. (2018). Effects of Die Configuration on the Electrical Conductivity of Polypropylene Reinforced Milled Carbon Fibers: An Application on a Bipolar Plate. Polymers, 10(5), 558. https://doi.org/10.3390/polym10050558