Self-Erasable Nanocone Antireflection Films Based on the Shape Memory Effect of Polyvinyl Alcohol (PVA) Polymers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Preformed PVA-SMP Film Sample

2.2. Fabrication of Self-Erase Nanocones Films

2.3. Characterization

3. Results and Discussion

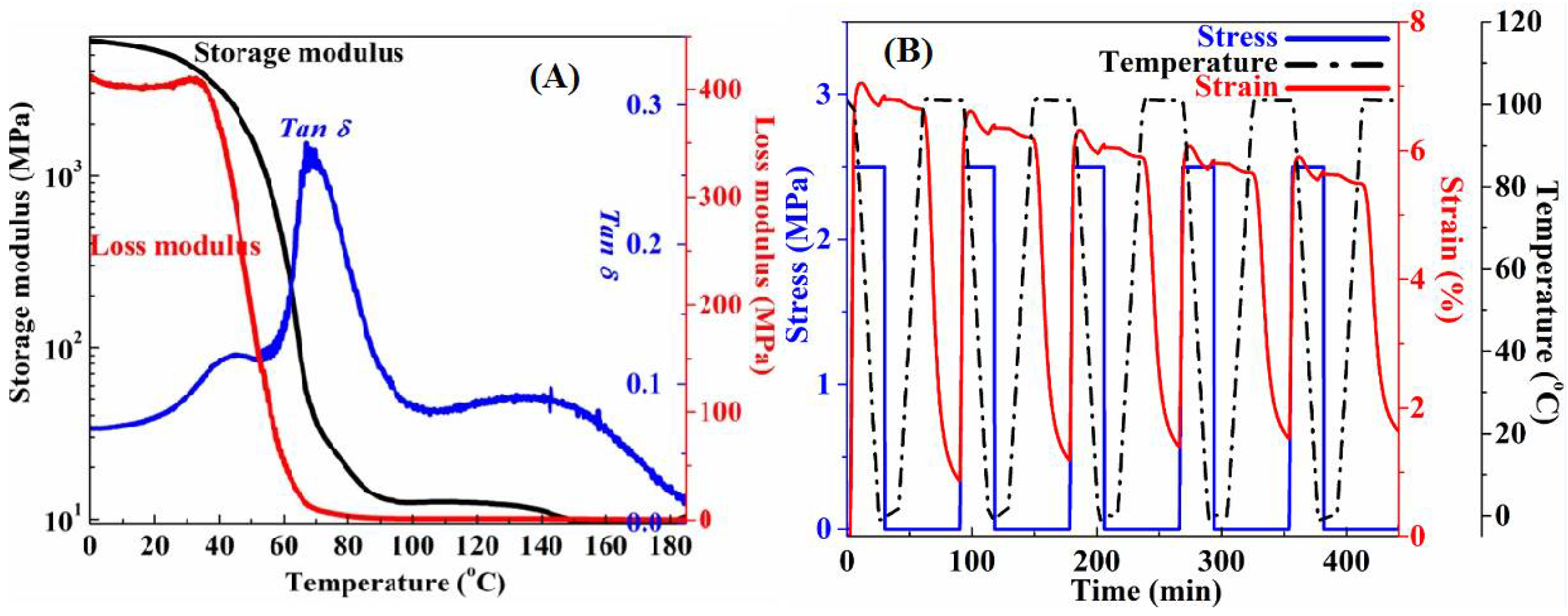

3.1. Characterization of PVA-SMP Film with Nanocone Arrays

3.2. Theoretical Model

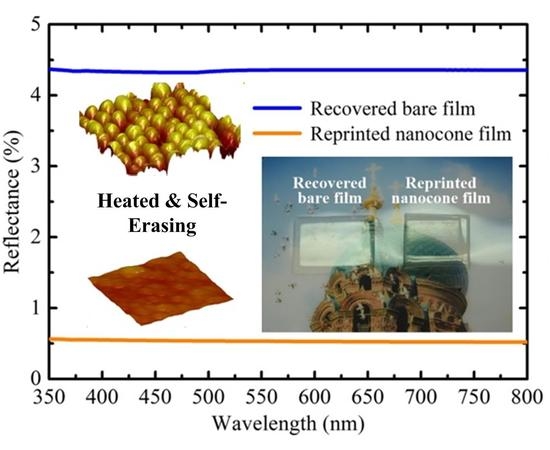

3.3. Optical Properties Measurements of Bare Film and Nanocone Film

3.4. Self-Erase Properties of PVA-SMP Film with Nanocone Arrays

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Raut, H.K.; Ganesh, V.A.; Nair, A.S.; Ramakrishna, S. Antireflective coatings: A critical, in-depth review. Energy Environ. Sci. 2011, 4, 3779–3804. [Google Scholar] [CrossRef]

- Kats, M.A.; Blanchard, R.; Genevet, P.; Capasso, F. Nanometre optical coatings based on strong interference effects in highly absorbing media. Nat. Mater. 2013, 12, 20–24. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Hsu, C.M.; Yu, Z.; Fan, S.; Cui, Y. Nanodome solar cells with efficient light management and self-cleaning. Nano Lett. 2010, 10, 1979–1984. [Google Scholar] [CrossRef] [PubMed]

- Grandidier, J.; Callahan, D.M.; Munday, J.N.; Atwater, H.A. Light absorption enhancement in thin-film solar cells using whispering gallery modes in dielectric nanospheres. Adv. Mater. 2011, 23, 1272–1276. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Yao, J.; Narasimhan, V.K.; Ruan, Z.C.; Xie, C.; Fan, S.H.; Cui, Y. Broadband light management using low-Q whispering gallery modes in spherical nanoshells. Nat. Commun. 2012, 3, 664. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mana, T.; Gabriel, L.; Robert, M. Corn fabrication of broadband antireflective plasmonic gold nanocone arrays on flexible polymer films. Nano Lett. 2013, 13, 6164–6169. [Google Scholar]

- Ying, S.H.; Jaeseok, J.; Tae, J.S.; Seunghyun, L.; Jason, H.H.; Rebekah, A.D.; Hyuck, C. Enhanced raman scattering from nanoparticle-decorated nanocone substrates: A practical approach to harness in-plane excitation. ACS Nano 2010, 4, 5721–5730. [Google Scholar]

- Erik, C.G.; Mark, L.B.; Yi, C.; Michael, D.M. Nanowire Solar Cells. Annu. Rev. Mater. Res. 2011, 41, 269–295. [Google Scholar]

- Fan, Z.Y.; Razavi, H.; Do, J.W.; Moriwaki, A.; Ergen, O.; Chueh, Y.L.; Leu, P.W.; Ho, J.C.; Takahashi, T.; Reichertz, L.A.; et al. Three-dimensional nanopillar-array photovoltaics on low-cost and flexible substrates. Nat. Mater. 2009, 8, 648–653. [Google Scholar] [CrossRef] [PubMed]

- Wei, W.R.; Tsai, M.L.; Ho, S.T.; Tai, S.H.; Ho, C.R.; Tsai, S.H.; Liu, C.W.; Chung, R.J.; He, J.H. Above-11%-efficiency organic–inorganic hybrid solar cells with omnidirectional harvesting characteristics by employing hierarchical photon-trapping structures. Nano Lett. 2013, 13, 3658–3663. [Google Scholar] [CrossRef] [PubMed]

- Song, J.E.; Park, J.S.; Lee, B.; Pyun, S.B.; Lee, J.; Kim, M.G.; Han, Y.; Cho, E.C. Tunable colloidal crystalline patterns on flat and periodically micropatterned surfaces as antireflctive layers and printable–erasable substrates. Adv. Mater. Interfaces 2018. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, Y.; Chen, S.; Lu, H.; Chen, K.; Cao, Y.; Miroshnichenko, A.E.; Gu, M.; Li, X. Ultra-broadband directional scattering by colloidally lithographed high-index mie resonant oligomers and their energy-harvesting applications. ACS Appl. Mater. Interfaces 2018. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Luo, F.; Kao, T.S.; Li, X.; Ho, G.W.; Teng, J.; Luo, F.; Hong, M. Design and fabrication of broadband ultralow reflectivity black Si surfaces by laser micro/nanoprocessing. Light Sci. Appl. 2014, 3, e185. [Google Scholar] [CrossRef]

- Cai, B.; Chen, H.; Xu, G.; Zhao, H.; Sugihara, O. Ultra-broadband THz antireflective coating with polymer composites. Polymers 2017, 9, 574. [Google Scholar] [CrossRef]

- Li, J.; Zhu, J.; Gao, X. Bio-inspired high-performance antireflection and antifogging polymer films. Small 2014, 10, 2578–2582. [Google Scholar] [CrossRef] [PubMed]

- Tsui, K.H.; Lin, Q.; Chou, H.; Zhang, Q.; Fu, H.; Qi, P.; Fan, Z. Low-Cost, Flexible, and self-cleaning 3D nanocone antireflection films for high-efficiency photovoltaics. Adv. Mater. 2014. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Lin, G.; Li, J.; Xue, H.; Luo, Y.; Gao, X. Fabrication of biomimetic polymer nanocone films with condensate microdrop self-removal function. Adv. Mater. Interfaces 2015, 2. [Google Scholar] [CrossRef]

- Hiller, J.; Mendelsohn, J.D.; Rubner, M.F. Reversibly erasable nanoporous anti-reflection coatings from polyelectrolyte multilayers. Nat. Mater. 2002, 1, 59–63. [Google Scholar] [CrossRef] [PubMed]

- Leng, J.; Lan, X.; Liu, Y.; Du, S. Shape memory polymers and their composites: Stimulus methods and applications. Prog. Mater. Sci. 2011, 56, 1077–1135. [Google Scholar] [CrossRef]

- Meng, H.; Li, G. A review of stimuli-responsive shape memory polymer composites. Polymer 2013, 54, 2199–2221. [Google Scholar] [CrossRef]

- Zhao, Q.; Qi, H.J.; Xie, T. Recent progress in shape memory polymer: New behavior, enabling materials, and mechanistic understanding. Prog. Polym. Sci. 2015, 49, 79–120. [Google Scholar] [CrossRef]

- Khaldi, A.; Elliott, J.A.; Smoukov, S.K. Electro-mechanical actuator with muscle memory. J. Mater. Chem. C 2014, 2, 8029–8034. [Google Scholar] [CrossRef] [Green Version]

- Jill, K.; Taekwoong, C.; Patrick, T.M.; Christoph, W. Shape memory polymers with built-in threshold temperature sensors. J. Mater. Chem. 2008, 18, 1082–1086. [Google Scholar]

- Hu, J.; Chen, S. A review of actively moving polymers in textile applications. J. Mater. Chem. 2010, 20, 3346–3355. [Google Scholar] [CrossRef]

- Xu, H.; Yu, C.; Wang, S.; Malyarchuk, V.; Xie, T.; Rogers, J.A. Deformable, programmable, and shape memorizing micro-optics. Adv. Funct. Mater. 2013, 23, 3299–3306. [Google Scholar] [CrossRef]

- Li, P.; Han, Y.; Wang, W.; Liu, Y.; Jin, P.; Leng, J. Novel programmable shape memory polystyrene film: A thermally induced beam-power splitter. Sci. Rep. 2017, 7, 44333. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Liu, Y.; Leng, J. Recent developments in shape memory polymer nanocomposites: Actuation methods and mechanisms. Coord. Chem. Rev. 2016, 320, 38–52. [Google Scholar] [CrossRef]

- Lin, Q.; Hua, B.; Leung, S.; Duan, X.; Fan, Z. Efficient light absorption with integrated Nanopillar/Nanowell Arrays for three-dimensional thin-film photovoltaic applications. ACS Nano 2013, 7, 2725–2732. [Google Scholar] [CrossRef] [PubMed]

- Leung, S.F.; Yu, M.; Lin, Q.; Kwon, K.; Ching, K.L.; Gu, L.; Yu, K.; Fan, Z. Efficient photon capturing with ordered three-dimensional nanowell arrays. Nano Lett. 2012, 12, 3682–3689. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Han, Y.; Wang, W.; Chen, X.; Jin, P.; Liu, S. Self-Erasable Nanocone Antireflection Films Based on the Shape Memory Effect of Polyvinyl Alcohol (PVA) Polymers. Polymers 2018, 10, 756. https://doi.org/10.3390/polym10070756

Li P, Han Y, Wang W, Chen X, Jin P, Liu S. Self-Erasable Nanocone Antireflection Films Based on the Shape Memory Effect of Polyvinyl Alcohol (PVA) Polymers. Polymers. 2018; 10(7):756. https://doi.org/10.3390/polym10070756

Chicago/Turabian StyleLi, Peng, Yu Han, Wenxin Wang, Xinlong Chen, Peng Jin, and Shengchun Liu. 2018. "Self-Erasable Nanocone Antireflection Films Based on the Shape Memory Effect of Polyvinyl Alcohol (PVA) Polymers" Polymers 10, no. 7: 756. https://doi.org/10.3390/polym10070756