Characterization and Evaluation of Controlled Antimicrobial Release from Petrochemical (PU) and Biodegradable (PHB) Packaging

Abstract

:1. Introduction

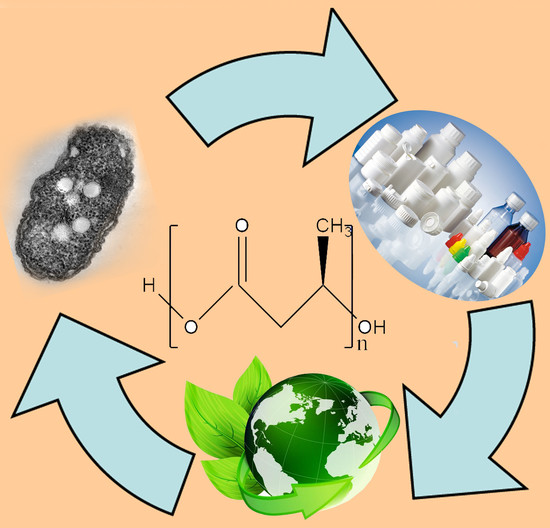

- the possibility for using food industrial and agricultural wastes as substrates for a biotechnological PHB production that improve environment situation and approaches this biotechnology maximally to the “green” industry category;

- the intermediate products of PHB biodegradation, e.g., 3-hydrobutiric acid, are involved in the biological Krebs cycle, and therefore do not reveal toxicity or an immune response in living systems;

- the terminal groups of its biodegradation in soil or aqueous media are water and carbon dioxide;

- microbial technology does not involve harmful chemicals such as initiators, catalyzers, toxic monomers, and other chemical reagents which accompany the synthesis of petropolymers; therefore the modern biotechnology of PHB and PLA packaging manufacture satisfies EU and USA legislation, taking into account toxic agent migration from polymer packaging to interior food areas [13];

- molecular stereoregularity and hence high crystallinity with perfect crystalline entities (lamellas, spherulites), but here it is appropriate to note that the high crystallinity degree negatively affects the mechanical behavior of PHB;

- processability due to thermoplasticity and good solubility in organic solvents that promotes versatility to produce films, nanofibers and nanoparticles; besides, the conditions for blending with petrochemical and natural polymers;

- the potential for controlled biodegradation and addressing controlled release.

2. Materials and Methods

2.1. Materials

2.2. Controlled Release Study

2.3. Bacterial Inhibition Assessment

2.4. Instrumental Methods

2.5. Statistics

3. Results and Discussion

3.1. Controlled Release from PU Films

3.2. Controlled Release Features for Poly(3-hydroxybutyrate)

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hillmyer, M.A. The promise of plastics from plants (Short Survey). Science 2017, 358, 868–870. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.-Q.; Patel, M.K. Plastics Derived from Biological Sources Present and Future A Technical and Environmental Review. Chem. Rev. 2012, 112, 2082–2099. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Romain, C.; Williams, C.K. Sustainable polymers from renewable resources (Review). Nature 2016, 540, 354–362. [Google Scholar] [CrossRef] [PubMed]

- Braskem, J. Line of Renewable Products. Retrieved on July 9 of 2012. Available online: http://www.braskem.com.br/plasticoverde/eng/Produto.html (accessed on 9 July 2012).

- McKetta, J.J.; Cunningham, W.A. Encyclopedia of Chemical Processing and Design; CRC Press: Boca Raton, FL, USA, 1976. [Google Scholar]

- Gómez, E.F.; Michel, F.C., Jr. Biodegradability of conventional and bio-based plastics and natural fiber composites during composting, anaerobic digestion and long-term soil incubation. Polym. Degrad. Stab. 2013, 98, 2583–2594. [Google Scholar] [CrossRef]

- Huynh, T.T.N.; Padois, K.; Sonvico, F.; Rossi, A.; Zani, F.; Pirot, F.; Doury, J.; Falson, F. Characterization of a polyurethane-based controlled release system for local delivery of chlorhexidine diacetate. Eur. J. Pharm. Biopharm. 2010, 74, 255–264. [Google Scholar] [CrossRef] [PubMed]

- Thermoplastic Polyurethane Elastomers Elastollan®—Material Properties Elastollan® Infopoint 2017 1-52. PM/K F204. Available online: www.elastollan.de (accessed on 26 March 2017).

- Tan, G.-Y.A.; Chen, C.-L.; Li, L.; Ge, L.; Wang, L.; Razaad, M.N.I.; Li, Y.; Zhao, L.; Mo, Y.; Wang, J.-Y. Start a Research on Biopolymer Polyhydroxyalkanoate (PHA): A Review. Polymers 2014, 6, 706–754. [Google Scholar] [CrossRef] [Green Version]

- Albuquerque, P.B.S.; Malafaia, C.B. Perspectives on the production, structural characteristics and potential applications of bioplastics derived from polyhydroxyalkanoates. Int. J. Biol. Macromol. 2018, 107, 615–625. [Google Scholar] [CrossRef] [PubMed]

- Castilho, L.R.; Mitchell, D.A.; Freire, D.M.G. Production of polyhydroxyalkanoates (PHAs) from waste materials and by-products by submerged and solid-state fermentation. Bioresour. Technol. 2009, 100, 5996–6009. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Ray, S.; Kalia, V.C. Production of co-polymers of polyhydroxyalkanoates by regulating the hydrolysis of biowastes. Bioresour. Technol. 2016, 200, 413–419. [Google Scholar] [CrossRef] [PubMed]

- Muncke, J.; Backhaus, T.; Geueke, B.; Maffini, M.V.; Martin, O.V.; Myers, J.P.; Soto, A.M.; Trasande, L.; Trier, X.; Scheringer, M. Scientific Challenges in the Risk Assessment of Food Contact Materials. Environ. Health Perspect. 2017, 125, 095001-1–095001-9. [Google Scholar] [CrossRef] [PubMed]

- Sevastianov, V.I.; Perova, N.V.; Shishatskaya, E.I.; Kalacheva, G.S.; Volova, T.G. Production of purified polyhydroxyalkanoates (PHAs) for applications in contact with blood. J. Biomater. Sci. Polym. Ed. 2003, 14, 1029–1042. [Google Scholar] [CrossRef] [PubMed]

- Artsis, M.I.; Bonartsev, A.P.; Iordanskii, A.L.; Bonartseva, G.A.; Zaikov, G.E. Biodegradation and Medical Application of Microbial Poly(3-hydroxybutyrate). Mol. Cryst. Liquid Cryst. 2010, 523, 593–621. [Google Scholar] [CrossRef]

- Manavitehrani, I.; Fathi, A.; Badr, H.; Daly, S.; Shirazi, A.N.; Dehghani, F. Biomedical Applications of Biodegradable Polyesters. Polymers 2016, 8, 20. [Google Scholar] [CrossRef]

- Ol’khov, A.; Gur’ev, V.; Akatov, V.; Mastalygina, E.; Sevastyanov, V.I.; Iordanskii, A. Composite Tendon Implant Based on Nanofibrillar Polyhydroxybutyrate and Polyamide Filaments. J. Biomed. Mater. Res. Ser. A 2018, in press. [Google Scholar]

- Tang, X.; Thankappan, S.K.; Lee, P.; Fard, S.E.; Harmon, M.D.; Tran, K.; Yu, X. Polymeric Biomaterials in Tissue Engineering and Regenerative Medicine. Natural and Synthetic Biomedical Polymers. In Natural and Synthetic Biomedical Polymers; Kumbar, S.G., Laurencin, C.T., Deng, M., Eds.; Elsevier: New York, NY, USA, 2014; pp. 351–371. ISBN 978-0-12-396983-5. [Google Scholar]

- Der Van Walle, G.A.; Buisman, G.J.; Weusthuis, R.A.; Eggink, G. Development of environmentally friendly coatings and paints using medium-chain-lengthpoly(3-hydroxyalkanoates) as the polymer binder. Int. J. Biol. Macromol. 1999, 25, 123–128. [Google Scholar] [CrossRef]

- Shen, L.; Haufe, J.; Patel, M. Product Overview and Market Projection of Emerging Bio-Based Plastics; PRO-BIP 2009, Final Report; Utrecht University: Utrecht, The Netherlands, 2009. [Google Scholar]

- Bucci, D.Z.; Tavares, L.B.B.; Sell, I. PHB packaging for the storage of food products. Polym. Test. 2005, 24, 564–571. [Google Scholar] [CrossRef]

- Bugnicourt, E.; Cinelli, P.; Lazzeri, A.; Alvarez, V. Polyhydroxyalkanoate (PHA): Review of synthesis, characteristics, processing and potential applications in packaging. eXPRESS Polym. Lett. 2014, 8, 791–808. [Google Scholar] [CrossRef] [Green Version]

- Miguel, O.; Fernandez-Berridi, M.J.; Iruin, J.J. Survey on transport properties of liquids, vapors, and gases in biodegradable poly(3-hydroxybutyrate) (PHB). J. Appl. Polym. Sci. 1997, 64, 1849–1859. [Google Scholar] [CrossRef]

- Siracusa, V.; Ingrao, C.; Karpova, S.G.; Olkhov, A.A.; Iordanskii, A.L. Gas transport and characterization of poly(3 hydroxybutyrate) films. Eur. Polym. J. 2017, 91, 149–161. [Google Scholar] [CrossRef]

- Levkane, V.; Muizniece-Brasava, S.; Dukalska, L. Pasteurization effect to quality of salad with meat in mayonnaise. Foodbalt 2008, 1, 69–73. [Google Scholar]

- Tortajada, M.; Ferreira da Silva, L.; Prieto, M.A. Second-generation functionalized medium chain-length polyhydroxyalkanoates: The gateway to high-value bioplastics applications. Int. Microbiol. 2013, 16, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Raza, Z.A.; Riaz, S.; Banat, I.M. Polyhydroxyalkanoates: Properties and Chemical Modification Approaches for Their Functionalization. Biotechnol. Prog. 2017, 34, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Babinot, J.; Renard, E.; Langlois, V. Controlled Synthesis of Well Defined Poly(3-hydroxyalkanoate)s-based Amphiphilic Diblock Copolymers Using Click Chemistry. Macromol. Chem. Phys. 2011, 212, 278–285. [Google Scholar] [CrossRef]

- Ma, Y.-M.; Wei, D.-X.; Yao, H.; Wu, L.-P.; Chen, G.-Q. Synthesis, Characterization and Application of Thermoresponsive Polyhydroxyalkanoate-graft-Poly(N-isopropylacrylamide). Biomacromolecules 2016, 17, 2680–2690. [Google Scholar] [CrossRef] [PubMed]

- Cyras, V.P.; Soledad, C.M.; Analıa, V. Biocomposites based on renewable resource: Acetylated and non acetylated cellulose cardboard coated with polyhydroxybutyrate. Polymer 2009, 50, 6274–6280. [Google Scholar] [CrossRef]

- Realini, C.E.; Marcos, B. Active and intelligent packaging systems for a modern society. Meat Sci. 2014, 98, 404–419. [Google Scholar] [CrossRef] [PubMed]

- Angiolillo, L.; Spinelli, S.; Conte, A.; Del Nobile, M.A. Recent Advances in Food Packaging with a Focus on Nanotechnology. Recent Pat. Eng. 2017, 11, 174–187. [Google Scholar] [CrossRef]

- Poyatos-Racionero, E.; Ros-Lis, J.V.; Vivancos, J.L.; Martinez-Manez, R. Recent advances on intelligent packaging as tools to reduce food waste. J. Clean. Prod. 2018, 172, 3398–3409. [Google Scholar] [CrossRef]

- Zhang, Y.D.C.; Yam, K.L.; Chikindas, M.L. Effective control of Listeria monocytogenes by combination of nisin formulated and slowly released into a broth system. Int. J. Food Microbiol. 2004, 90, 15–22. [Google Scholar] [CrossRef]

- Barouti, G.; Jaffredo, C.G.; Guillaume, S.M. Advances in drug delivery systems based on synthetic poly(hydroxybutyrate) (co)polymers. Prog. Polym. Sci. 2017, 73, 1–31. [Google Scholar] [CrossRef]

- Iordanskii, A.L.; Bychkova, A.V.; Gumargalieva, K.Z.; Berlin, A.A. Magnetoanisotropic biodegradable nanocomposites for controlled drug release. In Nanobiomaterials in Drug Delivery. Applications of Nanobiomaterials. V.9; Grumzescu, A.M., Ed.; Elsevier: New York, NY, USA, 2016; Volume 9, Chapter 6; pp. 171–196. ISBN 978-0-323-42866-8. [Google Scholar]

- Attin, T.; Abouassi, T.; Becker, K.; Wiegand, A.; Roos, M.; Attin, R. A new method for chlorhexidine (CHX) determination: CHX release after application of differently concentrated CHX-containing preparations on artificial fissures. Clin. Oral Investig. 2008, 12, 189–196. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Senel, S.; Ikinci, G.; Kas, S.; Yousefi-Rad, A.; Sargon, M.F.; Hıncal, A.A. Chitosan films and hydrogels of chlorhexidine gluconate for oral mucosal delivery. Int. J. Pharm. 2000, 193, 197–203. [Google Scholar] [CrossRef]

- Raso, E.M.G.; Cortes, M.; Teixeira, K.; Franco, M.; Mohallem, N.; Sinisterra, R. A new controlled release system of chlorhexidine and chlorhexidine: BCD inclusion compounds based on porous silica. J. Incl. Phenom. Macrocycl. Chem. 2010, 67, 159–168. [Google Scholar] [CrossRef]

- Lavoine, N.; Desloges, I.; Sillard, C.; Bras, J. Controlled release and long-term antibacterial activity of chlorhexidine digluconate through the nanoporous network of microfibrillated cellulose. Cellulose 2014, 21, 4429–4442. [Google Scholar] [CrossRef]

- Lavoine, N.; Desloges, I.; Manship, B.; Bras, J. Antibacterial paperboard packaging using microfibrillated cellulose. J. Food Sci. Technol. 2015, 52, 5590–5600. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Subramanian, R.; Fordsmand, H.; Paulapuro, H. Precipitated calcium carbonate (PCC)—Cellulose composite fillers; effect of PCC particle structure on the production and properties of uncoated fine paper. BioResources 2007, 2, 91–105. [Google Scholar]

- Lavoine, N.; Guillar, V.; Desloges, I.; Gontar, N.; Bras, J. Active bio-based food-packaging: Diffusion and release of active substances through and from cellulose nanofiber coating toward food-packaging design. Carbohydr. Polym. 2016, 149, 40–50. [Google Scholar] [CrossRef] [PubMed]

- Barbosa, A.M.; Robles, E.; Ribeiro, J.S.; Lund, R.G.; Carreño, N.L.V.; Labidi, J. Cellulose Nanocrystal Membranes as Excipients for Drug Delivery Systems. Materials 2016, 9, 1002. [Google Scholar] [CrossRef] [PubMed]

- Questions and Answers Elastollan® Food Contact (FC) Grades. BASF Technical Report. 2008. Available online: http://www.interowa.com/website/file/qunda-food-contact_extern_eng_final.pdf (accessed on 14 July 2008).

- Crank, J. The Mathematics of Diffusion; Clarendon Press: Oxford, UK, 1992. [Google Scholar]

- Iordanskii, A.L.; Razurnovskii, L.P.; Krivandin, A.V. Lebedeva, T.L. Diffusion and sorption of water in moderately hydrophilic polymers: From segmented polyetherurethanes to poly-3-hydroxybutyrate. Desalination 1996, 104, 27–35. [Google Scholar] [CrossRef]

- Sharma, J.; Tewari, K.; Arya, R.K. Diffusion in polymeric systems—A review on free volume theory. Prog. Org. Coat. 2017, 111, 83–92. [Google Scholar] [CrossRef]

- Cozzolino, C.A.; Nilsson, F.; Iotti, M.; Sacchi, B.; Piga, A.; Farris, S. Exploiting the nano-sized features of microfibrillated cellulose (MFC) for the evelopment of controlled-release packaging Colloids Surf. B Biointerfaces 2013, 110, 208–216. [Google Scholar] [CrossRef] [PubMed]

- Kolakovic, R.; Peltonen, L.; Laukkanen, A.; Hellman, M.; Laaksonen, P.; Linder, M.B.; Hirvonen, J.; Laaksonen, T. Evaluation of drug interactions with nanofibrillar cellulose. Eur. J. Pharm. Biopharm. 2013, 85, 1238–1244. [Google Scholar] [CrossRef] [PubMed]

- Drew, W.L.; Barry, A.L.; O’Toole, R.; Sherris, J.C. Reliability of the Kirby-Bauer Disc Diffusion Method for Detecting Methicillin-Resistant Strains of Staphylococcus aureus. Appl. Microbiol. 1972, 24, 240–247. [Google Scholar] [PubMed]

- Schwaab, M.; Steffani, E.; Barbosa-Coutinho, E.; Severo Júnior, J.B. Critical analysis of adsorption/diffusion modelling as a function of time square root. Chem. Eng. Sci. 2017, 173, 179–186. [Google Scholar] [CrossRef]

- Copeland, R.A.; Pompliano, D.L.; Meek, T.D. Drug–target residence time and its implications for lead optimization. Nat. Rev. Drug Discov. 2006, 5, 730–740. [Google Scholar] [CrossRef] [PubMed]

- Iordanskii, A.L. Water Transport in Synthetic Polymers; Iordanskii, A.L., Startsev, O.V., Zaikov, G.E., Eds.; Nova Science: New York, NY, USA, 2004. [Google Scholar]

- Miguel, O.; Iruin, J.J. Water transport properties in poly(3-hydroxybutyrate) and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) biopolymers. J. Appl. Polym. Sci. 1999, 73, 455–468. [Google Scholar] [CrossRef]

- Miguel, O.; Iruin, J.J. Evaluation of the transport properties of Poly(3-hydroxybutyrate) and its 3-hydroxyvalerate copolymers for packaging applications. Macromol. Symp. 2011, 144, 427–438. [Google Scholar] [CrossRef]

- Gleadall, A.; Pan, J.; Kruft, M.-A.; Kellomäki, M. Degradation mechanisms of bioresorbable polyesters. Part 1. Effects of random scission, end scission and autocatalysis. Acta Biomater. 2014, 10, 2223–2232. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Altaee, N.; El-Hiti, G.A.; Fahdil, A.; Sudesh, K.; Yousif, E. Biodegradation of different formulations of polyhydroxybutyrate films in soil. SpringerPlus 2016, 5, 762–774. [Google Scholar] [CrossRef] [PubMed]

- Sevim, K.; Pan, J. A model for hydrolytic degradation and erosion of biodegradable polymers. Acta Biomater. 2018, 66, 192–199. [Google Scholar] [CrossRef] [PubMed]

- Christian, S.J.; Billington, S.L. Moisture diffusion and its impact on uniaxial tensile response of biobased composites. Compos. Part B Eng. 2012, 43, 2303–2312. [Google Scholar] [CrossRef]

- Wei, L.; McDonald, A.G. Accelerated weathering studies on the bioplastic, poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Polym. Degrad. Stab. 2016, 126, 93–100. [Google Scholar] [CrossRef]

- Iordanskii, A.L.; Rudakova, T.E.; Zaikov, G.E. New Concepts in Polymer Science; VCP Science: Utrecht, The Netherlands, 1994; p. 298. [Google Scholar]

- Seebach, D.; Brunner, A.; Bachmann, B.M.; Hoffmann, T.; Kühnle, F.N.; Lengweiler, U.D. Biopolymers and Oligomers of (R)-3-Hydroxyalkanoic Acids—Contribution of Synthetic Organic Chemists; Ernst-Schering Foundation: Berlin, Germany, 1995. [Google Scholar]

- Gӧpferich, A. Mechanisms of polymer degradation and erosion. Biomaterials 1996, 17, 103–114. [Google Scholar] [CrossRef]

- Ivantsova, E.L.; Iordanskii, A.L.; Kosenko, R.Y.; Rogovina, S.Z.; Grachev, A.V.; Prut, E.V. Poly(3-hydroxybutyrate)-chitosan: A new biodegradable composition for prolonged delivery of biologically active substances. Pharm. Chem. J. 2011, 45, 51–55. [Google Scholar] [CrossRef]

- Mlalila, N.; Hilonga, A.; Swai, H.; Devlieghere, F.; Ragaert, P. Antimicrobial packaging based on starch, poly(3-hydroxybutyrate) and poly(lactic-co-glycolide) materials and application challenges. Trends Food Sci. Technol. 2018, 74, 1–11. [Google Scholar] [CrossRef]

- Morris, J.G., Jr. How Safe Is Our Food? Emerg. Infect. Dis. 2011, 17, 126–128. [Google Scholar] [CrossRef] [PubMed]

- Arora, D.; Sharma, N.; Sharma, V.; Abrol, V.; Shankar, R.; Jaglan, S. An update on polysaccharide-based nanomaterials for antimicrobial applications. Appl. Microbiol. Biotechnol. 2016, 100, 2603–2615. [Google Scholar] [CrossRef] [PubMed]

- Siracusa, V.; Dalla Rosa, M.; Iordanskii, A.L. Performance of poly(lactic acid) surface modified films for food packaging application. Materials 2017, 10, 850. [Google Scholar] [CrossRef] [PubMed]

- Siracusa, V.; Blanco, I.; Romani, S.; Tylewicz, U.; Rocculi, P.; Rosa, M.D. Poly(lactic acid)-modified films for food packaging application: Physical, mechanical, and barrier behavior. J. Appl. Polym. Sci. 2012, 125, E390–E401. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López, J.; Ferrándiz, S.; Peltzer, M.A. Characterization of PLA-limonene blends for food packaging applications. Polym. Test. 2013, 32, 760–768. [Google Scholar] [CrossRef]

- Raquez, J.-M.; Habibi, Y.; Murariu, M.; Dubois, P. Polylactide (PLA)-based nanocomposites. Prog. Polym. Sci. 2013, 38, 1504–1542. [Google Scholar] [CrossRef]

- Murariu, M.; Dubois, P. PLA composites: From production to properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef] [PubMed]

- Jost, V. Packaging related properties of commercially available biopolymers—An overview of the status quo. Express Polym. Lett. 2018, 12, 429–435. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; Aldas, M.; López, J. On the use of PLA-PHB blends for sustainable food packaging applications. Materials 2017, 10, 1008. [Google Scholar] [CrossRef] [PubMed]

- Correa, J.P.; Molina, V.; Sanchez, M.; Kainz, C.; Eisenberg, P.; Massani, M.B. Improving ham shelf life with a polyhydroxybutyrate-polycaprolactone biodegradable film activated with nisin. Food Packag. Shelf Life 2017, 11, 31–39. [Google Scholar] [CrossRef]

| Grade | CO2 | N2 | O2 | H2 | CH4 | Ar | He | H2O |

|---|---|---|---|---|---|---|---|---|

| 1180 A | 230 | 6 | 21 | 70 | 18 | 14 | 50 | 388 |

| 1185 A | 180 | 5 | 16 | 60 | 14 | 9 | 40 | 183 |

| Polymer | Mη, kDa | ρ, g/cm3 | H, MPa | ε, % | Tg, °C | TM, °C | Water Uptake, % | Hydrolysis Resistance | Bioresistance |

|---|---|---|---|---|---|---|---|---|---|

| Elastolan 1154 D, (PU) | 350 | 1.17 | 30 | 400 | −16 | 140 * | 0.3 | high | very high |

| Biomer Krailing, (PHB) | 460 | 1.25 | 80 | ~10 | 7 | 175 | 0.9 | poor | very poor |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iordanskii, A.; Zhulkina, A.; Olkhov, A.; Fomin, S.; Burkov, A.; Stilman, M. Characterization and Evaluation of Controlled Antimicrobial Release from Petrochemical (PU) and Biodegradable (PHB) Packaging. Polymers 2018, 10, 817. https://doi.org/10.3390/polym10080817

Iordanskii A, Zhulkina A, Olkhov A, Fomin S, Burkov A, Stilman M. Characterization and Evaluation of Controlled Antimicrobial Release from Petrochemical (PU) and Biodegradable (PHB) Packaging. Polymers. 2018; 10(8):817. https://doi.org/10.3390/polym10080817

Chicago/Turabian StyleIordanskii, Alexey, Anna Zhulkina, Anatoliy Olkhov, Sergey Fomin, Andrey Burkov, and Mikhail Stilman. 2018. "Characterization and Evaluation of Controlled Antimicrobial Release from Petrochemical (PU) and Biodegradable (PHB) Packaging" Polymers 10, no. 8: 817. https://doi.org/10.3390/polym10080817

APA StyleIordanskii, A., Zhulkina, A., Olkhov, A., Fomin, S., Burkov, A., & Stilman, M. (2018). Characterization and Evaluation of Controlled Antimicrobial Release from Petrochemical (PU) and Biodegradable (PHB) Packaging. Polymers, 10(8), 817. https://doi.org/10.3390/polym10080817