Vortical Fountain Flows in Plasticating Screws

Abstract

:1. Introduction

2. Materials and Methods

2.1. Process Investigation

2.2. Process Simulation

3. Results

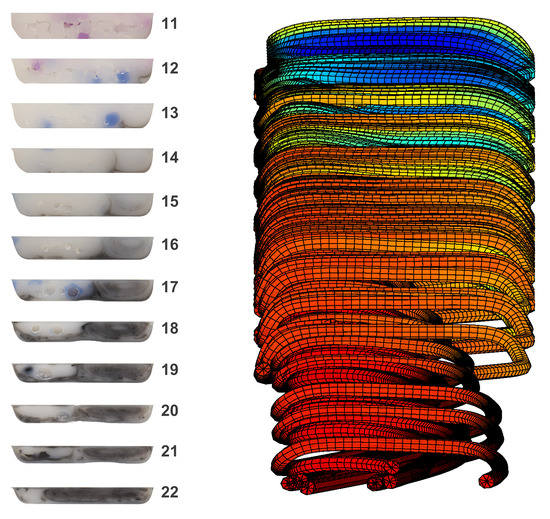

3.1. Observed Behavior

3.2. Simulation Results

4. Discussion

5. Conclusions

- Minimize the temperature variation between the solids bed and the melt pool by supplying heated polymer feedstock. Such heating will tend to precondition the feedstock and provide improved consistency with a reduced melting length and thus improve melt temperature homogeneity.

- Increase the time for heat conduction to the solids bed by operating the extruder at reduced screw speeds. The reverse (operating the extruder at high speeds) will tend to increase the vortical fountain flow due to less time for heat conduction concurrent with greater shear heating. We now believe that this vortical fountain flow is a predominant cause of the “surging” phenomenon in extrusion and loss of control at higher screw speeds.

- Incorporate additional mixing sections within screw designs. Since the vortical fountain flow is caused by persistently growing melt recirculations in the melt pool adjacent the active flank, intermittently breaking up the melt channel will cause the vortical fountain flows to disperse. All the results, both experimental and theoretical, suggest that the use of early, coarse mixing channels would be highly effective.

Author Contributions

Funding

Conflicts of Interest

References

- Maddock, B.H. A visual analysis of flow and mixing in extruder screws. Spe Antec. Tech. Pap. 1959, 15, 383–389. [Google Scholar]

- Tadmor, Z.; Duvdevani, I.; Klein, I. Melting in plasticating extuders theory and experiments. Polym. Eng. Sci. 1967, 7, 198–217. [Google Scholar] [CrossRef]

- Klein, I.; Tadmor, Z. The simulation of the plasticating screw extrusion process with a computer programmed theoretical model. Polym. Eng. Sci. 1969, 9, 11–21. [Google Scholar] [CrossRef]

- Shapiro, J.; Halmos, A.; Pearson, J. Melting in single screw extruders. Polymer 1976, 17, 905–918. [Google Scholar] [CrossRef]

- Fenner, R.T. Extruder Screw Design; Newnes-Butterworth: London, UK, 1970. [Google Scholar]

- White, J.L.; Potente, H. Screw Extrusion: Science and Technology; Hanser Gardner Publications: Cincinnati, OH, USA, 2003. [Google Scholar]

- Womer, T.P. Single Screw Design: 20 Years of Society of Plastics Engineers’ Practical and Theoretical Technical Papers; DESTech Publications: Lancaster, PA, USA, 2006. [Google Scholar]

- Carley, J.; Strub, R. Application of theory to design of screw extruders. Ind. Eng. Chem. 1953, 45, 978–982. [Google Scholar] [CrossRef]

- Elbirli, B.; Lindt, J.; Gottgetreu, S.; Baba, S. Mathematical modeling of melting of polymers in barrier-screw extruders. Polym. Eng. Sci. 1983, 23, 86–94. [Google Scholar] [CrossRef]

- Han, C.D.; Lee, K.Y.; Wheeler, N.C. A study on the performance of barrier-screw extruders. Polym. Eng. Sci. 1991, 31, 831–841. [Google Scholar] [CrossRef]

- Wong, A.-Y.; Liu, T.; Lam, J.; Zhu, F. Dynamic performance of single-screws of different configurations. Int. Polym. Proc. 1999, 14, 35–43. [Google Scholar] [CrossRef]

- Gaspar-Cunha, A.; Covas, J. The plasticating sequence in barrier extrusion screws part ii: Experimental assessment. Polym. Plast. Technol. Eng. 2014, 53, 1456–1466. [Google Scholar] [CrossRef]

- Fisches, M.; Kazmer, D.; Gordon, G. Verification of rheological mixing rules to the application of masterbatches. In Proceedings of the Society of Plastics Engineers (SPE) ANTEC, Nashville, TN, USA, 4–8 May 2003. [Google Scholar]

- Rudolph, N.; Osswald, T.A. 4.2 balance equations. In Polymer Rheology: Fundamentals and Applications; Carl Hanser Verlag GmbH Co KG: Midland, MI, USA, 2016; pp. 106–117. [Google Scholar]

- Cross, M.M. Rheology of non-newtonian fluids: A new flow equation for pseudoplastic systems. J. Colloid Sci. 1965, 20, 417–437. [Google Scholar] [CrossRef]

- Williams, M.L.; Landel, R.F.; Ferry, J.D. Temperature dependence of relaxation mechanisms in amorphous polymers and other glassforming liquids. J. Appl. Phys. 1953, 24, 911. [Google Scholar]

- Patankar, S.V. Numerical Heat Transfer and Fluid Flow; Hemisphere Publishing Corporation: New York, NY, USA, 1989. [Google Scholar]

- Kim, K.; Li, C.-F.; Sureshkumar, R.; Balachandar, S.; Adrian, R.J. Effects of polymer stresses on eddy structures in drag-reduced turbulent channel flow. J. Fluid Mech. 2007, 584, 281–299. [Google Scholar] [CrossRef]

- Volkov, K.; Emel’yanov, V.; Teterina, I.; Yakovchuk, M. Visualization of vortical flows in computational fluid dynamics. Comp. Math. Math. Phys. 2017, 57, 1360–1375. [Google Scholar] [CrossRef]

- Rauwendaal, C. Polymer Extrusion; Carl Hanser Verlag GmbH Co KG: Midland, MI, USA, 2014. [Google Scholar]

- Kamal, M.; Chu, E.; Lafleur, P.; Ryan, M. Computer simulation of injection mold filling for viscoelastic melts with fountain flow. Polym. Eng. Sci. 1986, 26, 190–196. [Google Scholar] [CrossRef]

- Young, W.-B. Lattice boltzmann simulation of polymer melt flow with a low reynolds number. Int. J. Heat Mass Trans. 2017, 115, 784–792. [Google Scholar] [CrossRef]

- Pinto, G.; Tadmor, Z. Mixing and residence time distribution in melt screw extruders. Polym. Eng. Sci. 1970, 10, 279–288. [Google Scholar] [CrossRef]

- Richardson, S. On the no-slip boundary condition. J. Fluid Mech. 1973, 59, 707–719. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Patlazhan, S. Wall slip for complex liquids–phenomenon and its causes. Adv. Colloid Interface Sci. 2018, 257, 42–57. [Google Scholar] [CrossRef] [PubMed]

| Screw | General Purpose | Barrier | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Turn | n | W | w | H | dH/dL | n | W | w | H | dH/dL |

| 1 | 1 | 34.29 | 3.81 | 7.57 | 0.0000 | 1 | 34.29 | 3.81 | 7.57 | 0.0000 |

| 2 | 1 | 34.29 | 3.81 | 7.57 | 0.0000 | 1 | 34.29 | 3.81 | 7.57 | 0.0000 |

| 3 | 1 | 34.29 | 3.81 | 7.57 | 0.0000 | 1 | 34.29 | 3.81 | 7.57 | 0.0000 |

| 4 | 1 | 34.29 | 3.81 | 7.57 | 0.0000 | 1 | 34.29 | 3.81 | 7.57 | 0.0000 |

| 5 | 1 | 34.29 | 3.81 | 7.57 | 0.0000 | 1 | 34.29 | 3.81 | 7.57 | 0.0000 |

| 6 | 1 | 34.29 | 3.81 | 7.57 | 0.0000 | 1 | 34.29 | 3.81 | 7.57 | 0.0000 |

| 7 | 1 | 34.29 | 3.81 | 7.32 | 0.0000 | 2 | 34.29 | 3.81 | 7.57 | 0.0000 |

| 8 | 1 | 34.29 | 3.81 | 7.06 | −0.0020 | 2 | 34.29 | 3.81 | 7.57 | −0.0064 |

| 9 | 1 | 34.29 | 3.81 | 6.81 | −0.0020 | 2 | 34.29 | 9.91 | 6.77 | −0.0063 |

| 10 | 1 | 34.29 | 3.81 | 6.55 | −0.0020 | 2 | 34.29 | 11.11 | 5.98 | −0.0063 |

| 11 | 1 | 34.29 | 3.81 | 6.30 | −0.0020 | 2 | 34.29 | 12.31 | 5.18 | −0.0063 |

| 12 | 1 | 34.29 | 3.81 | 6.05 | −0.0020 | 2 | 34.29 | 13.51 | 4.38 | −0.0063 |

| 13 | 1 | 34.29 | 3.81 | 5.79 | −0.0020 | 2 | 34.29 | 14.70 | 3.59 | −0.0062 |

| 14 | 1 | 34.29 | 3.81 | 5.54 | −0.0020 | 2 | 34.29 | 15.90 | 2.79 | −0.0062 |

| 15 | 1 | 34.29 | 3.81 | 5.28 | −0.0020 | 2 | 34.29 | 17.10 | 1.99 | −0.0062 |

| 16 | 1 | 34.29 | 3.81 | 5.03 | −0.0020 | 2 | 34.29 | 18.30 | 1.20 | −0.0054 |

| 17 | 1 | 34.29 | 3.81 | 4.78 | −0.0020 | 2 | 34.29 | 19.50 | 0.50 | −0.0039 |

| 18 | 1 | 34.29 | 3.81 | 4.52 | −0.0020 | Not plasticating | ||||

| 19 | 1 | 34.29 | 3.81 | 4.27 | −0.0020 | |||||

| 20 | 1 | 34.29 | 3.81 | 4.01 | −0.0020 | |||||

| 21 | 1 | 34.29 | 3.81 | 3.76 | 0.0000 | |||||

| 22 | 1 | 34.29 | 3.81 | 3.76 | 0.0000 | |||||

| 23 | 1 | 34.29 | 3.81 | 3.76 | 0.0000 | |||||

| 24 | 1 | 34.29 | 3.81 | 3.76 | 0.0000 | |||||

| 25 | 1 | 34.29 | 3.81 | 3.76 | 0.0000 | |||||

| 26 | 1 | 34.29 | 3.81 | 3.76 | 0.0000 | |||||

| 27 | 1 | 34.29 | 3.81 | 3.76 | 0.0000 | |||||

| Thermal Conductivity | Heat Capacity | Cross-WLF Model (Pa s) | |||

|---|---|---|---|---|---|

| T (°C) | k (W/m K) | T (°C) | Cp (J/kg K) | Coefficient | Value |

| 38 | 0.135 | 51 | 1511 | tau* | 10,300 |

| 101 | 0.163 | 102 | 2035 | a1 | 25.29 |

| 121 | 0.159 | 110 | 2087 | a2 | 51.6 |

| 141 | 0.167 | 150 | 2221 | d1 | 1.0 × 1012 |

| 160 | 0.164 | 180 | 2319 | d2 | 373.15 |

| 180 | 0.169 | 210 | 2394 | d3 | 0 |

| 199 | 0.175 | n | 0.335 | ||

| 218 | 0.180 | ||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kazmer, D.O.; Grosskopf, C.M.; Venoor, V. Vortical Fountain Flows in Plasticating Screws. Polymers 2018, 10, 823. https://doi.org/10.3390/polym10080823

Kazmer DO, Grosskopf CM, Venoor V. Vortical Fountain Flows in Plasticating Screws. Polymers. 2018; 10(8):823. https://doi.org/10.3390/polym10080823

Chicago/Turabian StyleKazmer, David O., Clemens M. Grosskopf, and Varun Venoor. 2018. "Vortical Fountain Flows in Plasticating Screws" Polymers 10, no. 8: 823. https://doi.org/10.3390/polym10080823

APA StyleKazmer, D. O., Grosskopf, C. M., & Venoor, V. (2018). Vortical Fountain Flows in Plasticating Screws. Polymers, 10(8), 823. https://doi.org/10.3390/polym10080823