Effects of Lubricant and Toughening Agent on the Fluidity and Toughness of Poplar Powder-Reinforced Polylactic Acid 3D Printing Materials

Abstract

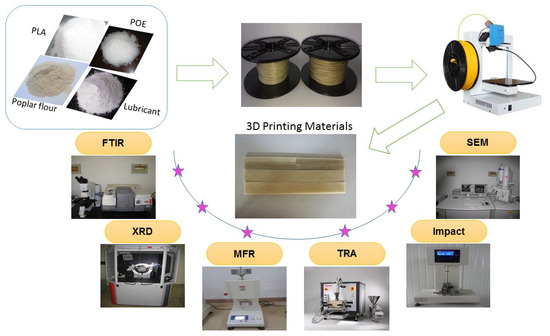

:1. Introduction

2. Materials and Method

2.1. Materials

2.2. 3D Printing Materials Fabrication

2.3. Measurements and Characterization

3. Results and Discussion

3.1. Fourier Transform Infrared Spectroscopy

3.2. X-ray Diffraction

3.3. Melt Flow Rate

3.4. Torque Rheometry Analysis

3.5. Impact Strength

3.6. Microstructure

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lee, J.Y.; An, J.; Chee, K.C. Fundamentals and Applications of 3D Printing for Novel Materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Choi, S.K. 3D Printing Technology and Architectural Application. Rev. Arch. Build. Sci. 2014, 58, 17–25. [Google Scholar]

- Lee, J.Y.; Tan, W.S.; An, J.; Chee, K.C.; Tang, C.Y.; Fane, A.G.; Chong, T.H. The Potential to Enhance Membrane Module Design with 3D Printing Technology. J. Membran. Sci. 2016, 499, 480–490. [Google Scholar] [CrossRef]

- Tseng, T.-L.B.; Chilukuri, A.; Park, S.C.; Kwon, Y.J. Automated Quality Characterization of 3D Printed Bone Scaffolds. J. Comput. Des. Eng. 2014, 1, 194–201. [Google Scholar]

- Liu, H.Z.; Song, W.J.; Chen, F.; Li, G.; Zhang, J.W. Interaction of Microstructure and Interfacial Adhesion on Impact Performance of Polylactide (PLA) Ternary Blends. Macromolecules 2011, 44, 1513–1522. [Google Scholar] [CrossRef]

- Nampoothiri, K.M.; Nair, N.R.; John, R.P. An Overview of the Recent Developments in Polylactide (PLA) Research. Bioresour Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef] [PubMed]

- Fortunati, E.; Armentano, I.; Zhou, Q.; Iannoni, A.; Saino, E.; Visai, L.; Berglund, L.A.; Kenny, J.M. Multifunctional Bionanocomposite Films of Poly(Lactic Acid), Cellulose Nanocrystals and Silver Nanoparticles. Carbohydr. Polym. 2012, 87, 1596–1605. [Google Scholar] [CrossRef]

- Zhang, J.; Yin, H.M.; Hsiao, B.S.; Zhong, G.J.; Li, Z.M. Biodegradable Poly(Lactic Acid)/Hydroxyl Apatite 3D Porous Scaffolds Using High-Pressure Molding and Salt Leaching. J. Mater. Sci. 2014, 49, 1648–1658. [Google Scholar] [CrossRef]

- Ferri, J.M.; Fenollar, O.; Jorda-Vilaplana, A.; García-Sanoguera, D.; Balart, R. Effect of Miscibility on Mechanical and Thermal Properties of Poly (Lactic Acid)/Polycaprolactone Blends. Polym. Int. 2016, 65, 453–463. [Google Scholar] [CrossRef]

- Chun, K.S.; Husseinsyah, S.; Osman, H. Properties of Coconut Shell Powder-Filled Polylactic Acid Ecocomposites: Effect of Maleic Acid. Polym. Eng. Sci. 2013, 53, 1109–1116. [Google Scholar] [CrossRef]

- Tao, Y.; Wang, H.; Li, Z.; Li, P.; Shi, S.Q. Development and Application of Wood Flour-Filled Polylactic Acid Composite Filament for 3D Printing. Materials 2017, 10, 339. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Bürger, D. Experimental Characterization and Micrography of 3D Printed PLA and PLA Reinforced with Short Carbon Fibers. Compos. Part B Eng. 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Invernizzi, M.; Natale, G.; Levi, M.; Turri, S.; Griffini, G. UV-Assisted 3D Printing of Glass and Carbon Fiber-Reinforced Dual-Cure Polymer Composites. Materials 2016, 9, 583. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.Z.; Feng, X.H.; Bi, Y.B.; Zhou, Z.F.; Yue, J.Q.; Xu, M. Bleached Extruder Chemi-Mechanical Pulp Fiber-PLA Composites: Comparison of Mechanical, Thermal, and Rheological Properties with Those of Wood Flour-PLA Bio-Composites. J. Appl. Polym. Sci. 2016, 133, 44241. [Google Scholar] [CrossRef]

- Patanwala, H.S.; Hong, D.T.; Vora, S.R.; Bognet, B.; Ma, A.W.S. The Microstructure and Mechanical Properties of 3D Printed Carbon Nanotube-Polylactic Acid Composites. Polym. Compos. 2017, 39, 1060–1071. [Google Scholar] [CrossRef]

- Yin, X.C.; Wang, L.; Li, S.; He, G.J.; Yang, Z.T.; Feng, Y.H.; Qu, J.P. Preparation and Characterization of Carbon Fiber/Polylactic Acid/Thermoplastic Polyurethane (Cf/PLA/Tpu) Composites Prepared by a Vane Mixer. J. Polym. Eng. 2017, 37, 355–364. [Google Scholar] [CrossRef]

- Petchwattana, N.; Covavisaruch, S.; Watkrut, C. Toughening of Wood/Poly(Vinyl Chloride) Composites by Using Ultrafine Rubber Particles: Mechanical and Rheological Investigations. Appl. Mech. Mater. 2014, 534, 25–30. [Google Scholar] [CrossRef]

- Li, J.J.; Li, J.; Feng, D.J.; Zhao, J.F.; Sun, J.R.; Li, D.G. Excellent Rheological Performance and Impact Toughness of Cellulose Nanofibers/PLA/Ionomer Composite. RSC Adv. 2017, 7, 28889–28897. [Google Scholar] [CrossRef]

- Liu, W.J.; Zhou, J.P.; Li, Y.S.; Wang, J.; Xu, J. Influence of Addition of Atbc on the Preparation and Properties of PLA/PCL Filaments for FDM 3D Printing. J. Funct. Mater. 2017, 11, 11168–11173. [Google Scholar]

- Prapruddivongs, C.; Sombatsompop, N. Roles and Evidence of Wood Flour as an Antibacterial Promoter for Triclosan-Filled Poly(Lactic Acid). Compos. Part B 2012, 43, 2730–2737. [Google Scholar] [CrossRef]

- Lee, C.H.; Wu, T.L.; Chen, Y.L.; Wu, J.H. Characteristics and Discrimination of Five Types of Wood-Plastic Composites by FTIR Spectroscopy Combined with Principal Component Analysis. Holzforschung 2010, 64, 699–704. [Google Scholar] [CrossRef]

- Zhou, X.X.; Yu, Y.; Lin, Q.J.; Chen, L.H. Effects of Maleic Anhydride-Grafted Polypropylene (Mapp) on the Physico-Mechanical Properties and Rheological Behavior of Bamboo Powder-Polypropylene Foamed Composites. Bioresources 2013, 8, 6263–6279. [Google Scholar] [CrossRef]

- Cai, G.F.; Wang, J.K.; Nie, Y.N.; Tian, X.C.; Zhu, X.D.; Zhou, X.P. Effects of Toughening Agents on the Behaviors of Bamboo Plastic Composites. Polym. Compos. 2011, 32, 1945–1952. [Google Scholar] [CrossRef]

- Mathew, A.P.; Oksman, K.; Sain, M. Mechanical Properties of Biodegradable Composites from Poly Lactic Acid (PLA) and Microcrystalline Cellulose (MCC). J. Polym. Sci. 2005, 97, 2014–2025. [Google Scholar] [CrossRef]

- Feng, D.U. Study on Structure and Properties of PLA/POE Blends. China Plast. 2011, 25, 39–42. [Google Scholar]

- Rajabian, M.; Dubois, C.; Grmela, M.; Carreau, P.J. Effects of Polymer–Fiber Interactions on Rheology and Flow Behavior of Suspensions of Semi-Flexible Fibers in Polymeric Liquids. Rheol. Acta 2008, 47, 701–717. [Google Scholar] [CrossRef]

- Zhang, Q.F.; Yi, W.M.; Li, Z.H.; Wang, L.H.; Cai, H.Z. Mechanical Properties of Rice Husk Biochar Reinforced High Density Polyethylene Composites. Polymers 2018, 10, 286. [Google Scholar] [CrossRef]

- Kundu, P.P.; Kukreja, T.R. Surface Modification of Carbon Black by Vegetable Oil—Its Effect on the Rheometric, Hardness, Abrasion, Rebound Resilience, Tensile, Tear, and Adhesion Properties. J. Appl. Polym. Sci. 2010, 84, 256–260. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, G.; Wei, Z.; Song, P.; Yuan, R.; Liang, J.; Zhang, W. Effect of Different Compatibilizers on the Property of PLA/POE Composites. Polym. Mater. Sci. Eng. 2012, 28, 57–60. [Google Scholar]

- Huang, T.H.; Chen, C.S.; Chang, S.W. Microcrack Patterns Control the Mechanical Strength in the Biocomposites. Mater. Des. 2018, 140, 505–515. [Google Scholar] [CrossRef]

- Xie, G.; Zhang, Y.; Lin, W. Plasticizer Combinations and Performance of Wood Flour-Poly (Lactic Acid) 3D Printing Filaments. Bioresources 2017, 12, 6736–6748. [Google Scholar] [CrossRef]

- Li, B.; Dong, R.; Gao, L.; Yang, J.; Shi, Q.F.; Guo, W.H. Toughening and Crystallization Behavior of Poly (Lactic Acid)/Wood Flour Composite. Polym. Mater. Sci. Eng. 2011, 27, 33–36. [Google Scholar]

| No. | Polylactic Acid (PLA) | Poplar Powder | TPW604 | Polyolefin Elastomer (POE) |

|---|---|---|---|---|

| 1(PLA) | 100 | 0 | 0 | 0 |

| 2(WF10) | 90 | 10 | 0 | 0 |

| 3(TPW5) | 85 | 10 | 5 | 0 |

| 4(POE5) | 80 | 10 | 5 | 5 |

| 5(POE10) | 75 | 10 | 5 | 10 |

| 6(POE15) | 70 | 10 | 5 | 15 |

| 7(POE20) | 65 | 10 | 5 | 20 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Cai, H.; Zhang, A.; Lin, X.; Yi, W.; Zhang, J. Effects of Lubricant and Toughening Agent on the Fluidity and Toughness of Poplar Powder-Reinforced Polylactic Acid 3D Printing Materials. Polymers 2018, 10, 932. https://doi.org/10.3390/polym10090932

Zhang Q, Cai H, Zhang A, Lin X, Yi W, Zhang J. Effects of Lubricant and Toughening Agent on the Fluidity and Toughness of Poplar Powder-Reinforced Polylactic Acid 3D Printing Materials. Polymers. 2018; 10(9):932. https://doi.org/10.3390/polym10090932

Chicago/Turabian StyleZhang, Qingfa, Hongzhen Cai, Andong Zhang, Xiaona Lin, Weiming Yi, and Jibing Zhang. 2018. "Effects of Lubricant and Toughening Agent on the Fluidity and Toughness of Poplar Powder-Reinforced Polylactic Acid 3D Printing Materials" Polymers 10, no. 9: 932. https://doi.org/10.3390/polym10090932