Design of Ethylene-Vinyl Acetate Copolymer Fiber with Two-Way Shape Memory Effect

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

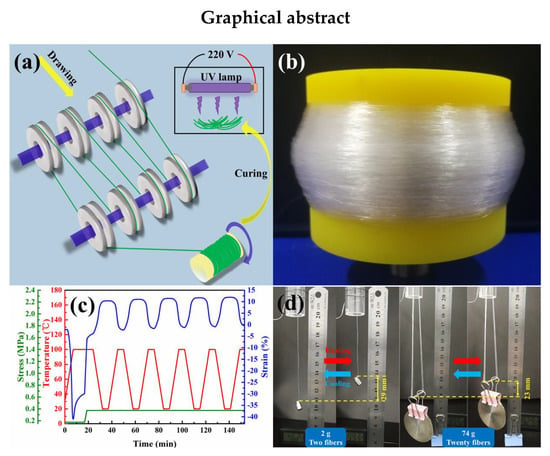

2.2. Fabrication of EVA Fiber

2.3. Morphology Characterization

2.4. Gel Fraction Measurement

2.5. Thermal and Mechanical Properties Tests

2.6. Shape Memory Experiments

3. Results and Discussion

3.1. Morphology of EVA Fiber

3.2. Thermal and Mechanical Properties of EVA Fiber

3.3. Creep and 2W-SME of EVA Fiber

3.4. 1W- and 2W-SME of EVA Fiber

3.5. Effect of Crosslink Density and Applied Stress on Reversible Strain of EVA Fiber

3.6. Macroscopic Thermo-Actuated 2W-SME of EVA Fiber under Constant Stress

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bogue, R. Smart materials: A review of capabilities and applications. Assem. Autom. 2014, 34, 16–22. [Google Scholar] [CrossRef]

- Leng, J.; Lan, X.; Liu, Y.; Du, S. Shape-memory polymers and their composites: Stimulus methods and applications. Prog. Mater. Sci. 2011, 56, 1077–1135. [Google Scholar] [CrossRef]

- Hu, J.; Zhu, Y.; Huang, H.; Lu, J. Recent advances in shape-memory polymers: Structure, mechanism, functionality, modeling and applications. Prog. Polym. Sci. 2012, 37, 1720–1763. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Keki, S. Review of progress in shape memory epoxies and their composites. Polymers 2017, 10, 34. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Du, H.; Liu, L.; Leng, J. Shape memory polymers and their composites in aerospace applications: A review. Smart Mater. Struct. 2014, 23, 023001. [Google Scholar] [CrossRef]

- Dong, Y.; Xia, H.; Zhu, Y.; Ni, Q.Q.; Fu, Y. Effect of epoxy-graft-polyoxyethylene octyl phenyl ether on preparation, mechanical properties and triple-shape memory effect of carbon nanotube/water-borne epoxy nanocomposites. Compos. Sci. Technol. 2015, 120, 17–25. [Google Scholar] [CrossRef]

- Li, X.; Zhu, Y.; Dong, Y.; Liu, M.; Ni, Q.; Fu, Y. Epoxy resin composite bilayers with triple-shape memory effect. J. Nanomater. 2015. [Google Scholar] [CrossRef]

- Zhao, Q.; Qi, H.J.; Xie, T. Recent progress in shape memory polymer: New behavior, enabling materials, and mechanistic understanding. Prog. Polym. Sci. 2015, 49, 79–120. [Google Scholar] [CrossRef]

- Gao, J.; Chen, W.; Yu, B.; Fan, P.; Zhao, B.; Hu, J.; Zhang, D.; Fang, G.; Peng, F. Effect of temperature on the mechanical behaviours of a single-ply weave-reinforced shape memory polymer composite. Compos. Part B 2019, 159, 336–345. [Google Scholar] [CrossRef]

- Pan, Z.; Huang, R.; Liu, Z. Prediction of the thermomechanical behavior of particle reinforced shape memory polymers. Polym. Compos. 2019, 40, 353–363. [Google Scholar] [CrossRef]

- Wang, E.; Dong, Y.; Islam, M.Z.; Yu, L.; Liu, F.; Chen, S.; Qi, X.; Zhu, Y.; Fu, Y.; Xu, Z. Effect of graphene oxide-carbon nanotube hybrid filler on the mechanical property and thermal response speed of shape memory epoxy composites. Compos. Sci. Technol. 2019, 169, 209–216. [Google Scholar] [CrossRef]

- Liu, R.; Kuang, X.; Deng, J.; Wang, Y.C.; Wang, A.C.; Ding, W.; Lai, Y.C.; Chen, J.; Wang, P.; Lin, Z. Shape memory polymers for body motion energy harvesting and self-powered mechanosensing. Adv. Mater. 2018, 30, 1705195. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Wang, T.X.; Chen, H.M.; Salvekar, A.V.; Naveen, B.S.; Xu, Q.; Weng, Y.; Guo, X.; Chen, Y.; Huang, W.M. A Brief Review of the Shape Memory Phenomena in Polymers and Their Typical Sensor Applications. Polymers 2019, 11, 1049. [Google Scholar]

- Besse, N.; Rosset, S.; Zarate, J.J.; Shea, H. Flexible active skin: Large reconfigurable arrays of individually addressed shape memory polymer actuators. Adv. Mater. Technol. 2017, 2, 1700102. [Google Scholar] [CrossRef]

- Ge, F.; Lu, X.; Xiang, J.; Tong, X.; Zhao, Y. An optical actuator based on gold-nanoparticle-containing temperature-memory semicrystalline polymers. Angew. Chem. Int. Ed. 2017, 56, 6126–6130. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Chen, S. A review of actively moving polymers in textile applications. J. Mater. Chem. 2010, 20, 3346–3355. [Google Scholar] [CrossRef]

- Castano, L.M.; Flatau, A.B. Smart fabric sensors and e-textile technologies: A review. Smart Mater. Struct. 2014, 23, 053001. [Google Scholar] [CrossRef]

- Lee, J.H.; Hinchet, R.; Kim, S.K.; Kim, S.H.; Kim, S.W. Shape memory polymer-based self-healing triboelectric nanogenerator. Energy Environ. Sci. 2015, 8, 3605–3613. [Google Scholar] [CrossRef]

- Luo, X.; Mather, P.T. Shape memory assisted self-healing coating. ACS Macro Lett. 2013, 2, 152–156. [Google Scholar] [CrossRef]

- Mirvakili, S.M.; Hunter, I.W. Artificial muscles: Mechanisms, applications, and challenges. Adv. Mater. 2018, 30, 1704407. [Google Scholar] [CrossRef]

- Yip, M.C.; Niemeyer, G. On the control and properties of supercoiled polymer artificial muscles. IEEE Trans. Robot. 2017, 33, 689–699. [Google Scholar] [CrossRef]

- Wang, J.; Sun, L.; Zou, M.; Gao, W.; Liu, C.; Shang, L.; Gu, Z.; Zhao, Y. Bioinspired shape-memory graphene film with tunable wettability. Sci. Adv. 2017, 3, e1700004. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Qiu, L.; Zhang, B.; Li, D.; Liu, C.Y. Robust Vacuum-/Air-Dried Graphene Aerogels and Fast Recoverable Shape-Memory Hybrid Foams. Adv. Mater. 2016, 28, 1510–1516. [Google Scholar] [CrossRef] [PubMed]

- Santo, L. Shape memory polymer foams. Prog. Aerosp. Sci. 2016, 81, 60–65. [Google Scholar] [CrossRef]

- van Meerbeek, I.M.; Murray, B.C.M.; Kim, J.W.; Robinson, S.S.; Zou, P.X.; Silberstein, M.N.; Shepherd, R.F. Morphing Metal and Elastomer Bicontinuous Foams for Reversible Stiffness, Shape Memory, and Self-Healing Soft Machines. Adv. Mater. 2016, 28, 2801–2806. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Zhang, Z.; Zhou, T.; Liu, Y.; Leng, J. Shape memory polymer nanofibers and their composites: Electrospinning, structure, performance, and applications. Front. Mater. 2015, 2, 1–10. [Google Scholar] [CrossRef]

- Aslan, S.; Kaplan, S. Thermomechanical and shape memory performances of thermo-sensitive polyurethane fibers. Fibers Polym. 2018, 19, 272–280. [Google Scholar] [CrossRef]

- Hu, J.; Lu, J. Shape memory fibers. In Handbook of Smart Textiles; Tao, X., Ed.; Springer: Singapore, 2015; pp. 183–207. [Google Scholar]

- Li, G.; Zhang, P. A self-healing particulate composite reinforced with strain hardened short shape memory polymer fibers. Polymer 2013, 54, 5075–5086. [Google Scholar] [CrossRef]

- Zhang, P.; Li, G. Structural relaxation behavior of strain hardened shape memory polymer fibers for self-healing applications. J. Polym. Sci. Part B 2013, 51, 966–977. [Google Scholar] [CrossRef]

- Gök, M.O.; Bilir, M.Z.; Gürcüm, B.H. Shape-memory applications in textile design. Procedia Soc. Behav. Sci. 2015, 195, 2160–2169. [Google Scholar] [CrossRef]

- Hu, J.; Meng, H.; Li, G.; Ibekwe, S.I. A review of stimuli-responsive polymers for smart textile applications. Smart Mater. Struct. 2012, 21, 053001. [Google Scholar] [CrossRef]

- Yang, Q.; Li, G. Investigation into stress recovery behavior of shape memory polyurethane fiber. J. Polym. Sci. Part B 2014, 52, 1429–1440. [Google Scholar] [CrossRef]

- Chung, T.; Romo-Uribe, A.; Mather, P.T. Two-way reversible shape memory in a semicrystalline network. Macromolecules 2008, 41, 184–192. [Google Scholar] [CrossRef]

- Burke, K.A.; Mather, P.T. Soft shape memory in main-chain liquid crystalline elastomers. J. Mater. Chem. 2010, 20, 3449–3457. [Google Scholar] [CrossRef]

- Li, J.; Rodgers, W.R.; Xie, T. Semi-crystalline two-way shape memory elastomer. Polymer 2011, 52, 5320–5325. [Google Scholar] [CrossRef]

- Haines, C.S.; Lima, M.D.; Li, N.; Spinks, G.M.; Foroughi, J.; Madden, J.D.; Kim, S.H.; Fang, S.; de Andrade, M.J.; Göktepe, F. Artificial muscles from fishing line and sewing thread. Science 2014, 343, 868–872. [Google Scholar] [CrossRef]

- Kanik, M.; Orguc, S.; Varnavides, G.; Kim, J.; Benavides, T.; Gonzalez, D.; Anikeeva, P. Strain-programmable fiber-based artificial muscle. Science 2019, 365, 145–150. [Google Scholar]

- Zhao, J.; Chen, M.; Wang, X.; Zhao, X.; Wang, Z.; Dang, Z.M.; Ma, L.; Hu, G.H.; Chen, F. Triple shape memory effects of cross-linked polyethylene/polypropylene blends with cocontinuous architecture. ACS Appl. Mater. Interfaces 2013, 5, 5550–5556. [Google Scholar] [CrossRef]

- Dolynchuk, O.; Kolesov, I.; Androsch, R.; Radusch, H.J. Kinetics and dynamics of two-way shape-memory behavior of crosslinked linear high-density and short-chain branched polyethylenes with regard to crystal orientation. Polymer 2015, 79, 146–158. [Google Scholar] [CrossRef]

- Navarro-Baena, I.; Sessini, V.; Dominici, F.; Torre, L.; Kenny, J.M.; Peponi, L. Design of biodegradable blends based on PLA and PCL: From morphological, thermal and mechanical studies to shape memory behavior. Polym. Degrad. Stab. 2016, 132, 97–108. [Google Scholar] [CrossRef]

- Qian, C.; Dong, Y.; Zhu, Y.; Fu, Y. Two-way shape memory behavior of semi-crystalline elastomer under stress-free condition. Smart Mater. Struct. 2016, 25, 085023. [Google Scholar] [CrossRef]

- Wang, K.; Jia, Y.G.; Zhu, X. Two-way reversible shape memory polymers made of cross-linked cocrystallizable random copolymers with tunable actuation temperatures. Macromolecules 2017, 50, 8570–8579. [Google Scholar] [CrossRef]

- Xie, H.; Li, L.; Deng, X.Y.; Cheng, C.Y.; Yang, K.K.; Wang, Y.Z. Reinforcement of shape-memory poly (ethylene-co-vinyl acetate) by carbon fibre to access robust recovery capability under resistant condition. Compos. Sci. Technol. 2018, 157, 202–208. [Google Scholar] [CrossRef]

- Qian, C.; Zhu, Y.; Dong, Y.; Fu, Y. Vapor-grown carbon nanofiber/poly (ethylene-co-vinyl acetate) composites with electrical-active two-way shape memory behavior. J. Intell. Mater. Syst. Struct. 2017, 28, 2749–2756. [Google Scholar] [CrossRef]

- Yao, Y.; Wei, H.; Wang, J.; Lu, H.; Leng, J.; Hui, D. Fabrication of hybrid membrane of electrospun polycaprolactone and polyethylene oxide with shape memory property. Compos. Part B 2015, 83, 264–269. [Google Scholar] [CrossRef]

- Budun, S.; İşgören, E.; Erdem, R.; Yüksek, M. Morphological and mechanical analysis of electrospun shape memory polymer fibers. Appl. Surf. Sci. 2016, 380, 294–300. [Google Scholar] [CrossRef]

- Iregui, A.; Irusta, L.; Llorente, O.; Martin, L.T.; Calvo-Correas, A.; Eceiza, A. Gonzalez, Electrospinning of cationically polymerized epoxy/polycaprolactone blends to obtain shape memory fibers (SMF). Eur. Polym. J. 2017, 94, 376–383. [Google Scholar] [CrossRef]

- Yao, Y.; Luo, Y.; Lu, B.; Wang, B. Remotely actuated porous composite membrane with shape memory property. Composite Struct. 2018, 192, 507–515. [Google Scholar] [CrossRef]

- Ma, L.; Zhao, J.; Wang, X.; Chen, M.; Liang, Y.; Wang, Z.; Yu, Z.; Hedden, R.C. Effects of carbon black nanoparticles on two-way reversible shape memory in crosslinked polyethylene. Polymer 2015, 56, 490–497. [Google Scholar] [CrossRef]

- Amintowlieh, Y.; Tzoganakis, C.; Penlidis, A. The effect of depth and duration of UV radiation on polypropylene modification via photoinitiation. J. Appl. Polym. Sci. 2014, 131, 21. [Google Scholar] [CrossRef]

- Zhang, H.; Shang, Y.; Li, M.; Zhao, H.; Wang, X.; Han, B. Theoretical study on the reaction mechanism in the UV radiation cross-linking process of polyethylene. RSC Adv. 2016, 6, 110831–110839. [Google Scholar] [CrossRef]

- Xu, H.; Zhang, Y.; Yang, J.; Ye, L.; Wu, Q.; Qu, B.; Wang, Q.; Wang, Z. Simultaneous enhancements of toughness and tensile strength for thermoplastic/elastomer blends through interfacial photocrosslinking with UV radiation. Polym. Chem. 2013, 4, 3028–3038. [Google Scholar] [CrossRef]

- Jin, J.; Chen, S.; Zhang, J. UV aging behaviour of ethylene-vinyl acetate copolymers (EVA) with different vinyl acetate contents. Polym. Degrad. Stab. 2010, 95, 725–732. [Google Scholar] [CrossRef]

- Han, J.L.; Lai, S.M.; Chiu, Y.T. Two-way multi-shape memory properties of peroxide crosslinked ethylene viny-acetate copolymer (EVA)/polycaprolactone (PCL) blends. Polym. Adv. Technol. 2018, 29, 2010–2024. [Google Scholar] [CrossRef]

- Xie, H.; Cheng, C.Y.; Deng, X.Y.; Fan, C.J.; Du, L.; Yang, K.K.; Wang, Y.Z. Creating poly (tetramethylene oxide) glycol-based networks with tunable two-way shape memory effects via temperature-switched netpoints. Macromolecules 2017, 50, 5155–5164. [Google Scholar] [CrossRef]

- Li, Q.; Zhou, J.; Vatankhah-Varnoosfaderani, M.; Nykypanchuk, D.; Gang, O.; Sheiko, S.S. Advancing reversible shape memory by tuning the polymer network architecture. Macromolecules 2016, 49, 1383–1391. [Google Scholar] [CrossRef]

- Dolynchuk, O.; Kolesov, I.; Jehnichen, D.; Reuter, U.; Radusch, H.J.; Sommer, J.U. Reversible shape-memory effect in cross-linked linear poly (ε-caprolactone) under stress and stress-free conditions. Macromolecules 2017, 50, 3841–3854. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, W.; Zhu, S. Polyolefin thermoplastics for multiple shape and reversible shape memory. ACS Appl. Mater. Interfaces 2017, 9, 4882–4889. [Google Scholar] [CrossRef]

| Samples | Tm (°C) | Tc (°C) | G (%) | Xc (%) | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|---|---|---|

| EVA-2M | 82.37 | 66.25 | 1.62 | 19.42 | 69.27 ± 3.34 | 151.33 ± 12.39 |

| EVA-4M | 81.87 | 65.82 | 11.98 | 18.73 | 69.95 ± 3.16 | 159.33 ± 12.40 |

| EVA-6M | 81.25 | 65.75 | 21.92 | 17.60 | 67.93 ± 3.63 | 143.66 ± 7.07 |

| EVA-8M | 80.69 | 65.16 | 34.27 | 16.86 | 65.56 ± 2.78 | 130.67 ± 5.27 |

| EVA-10M | 79.63 | 65.42 | 43.68 | 17.02 | 64.46 ± 2.65 | 114.33 ± 4.65 |

| Cycles | EVA-6M | EVA-8M | EVA-10M | |||

|---|---|---|---|---|---|---|

| Rf,1W (%) | Rr,1W (%) | Rf,1W (%) | Rr,1W (%) | Rf,1W (%) | Rr,1W (%) | |

| 1 | 98.39 | 85.32 | 97.58 | 87.88 | 95.86 | 92.28 |

| 2 | 98.21 | 95.73 | 97.33 | 95.20 | 95.94 | 96.32 |

| 3 | 98.24 | 97.25 | 97.13 | 98.52 | 95.73 | 96.19 |

| 4 | 98.06 | 98.14 | 97.18 | 98.09 | 95.83 | 96.82 |

| 5 | 98.01 | 98.86 | 97.16 | 98.19 | 95.13 | 97.51 |

| Cycles | EVA-6M | EVA-8M | EVA-10M | |||

|---|---|---|---|---|---|---|

| Ra,2W (%) | Rr,2W (%) | Ra,2W (%) | Rr,2W (%) | Ra,2W (%) | Rr,2W (%) | |

| 1 | 10.32 | 84.24 | 13.75 | 86.88 | 12.20 | 93.59 |

| 2 | 9.18 | 93.68 | 13.62 | 92.07 | 12.33 | 93.59 |

| 3 | 8.94 | 95.53 | 13.50 | 93.56 | 12.26 | 95.27 |

| 4 | 8.81 | 96.48 | 13.35 | 96.03 | 12.20 | 96.72 |

| 5 | 8.69 | 97.12 | 13.35 | 96.23 | 12.26 | 97.39 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, X.; Yang, W.; Yu, L.; Wang, W.; Lu, H.; Wu, Y.; Zhu, S.; Zhu, Y.; Liu, X.; Dong, Y.; et al. Design of Ethylene-Vinyl Acetate Copolymer Fiber with Two-Way Shape Memory Effect. Polymers 2019, 11, 1599. https://doi.org/10.3390/polym11101599

Qi X, Yang W, Yu L, Wang W, Lu H, Wu Y, Zhu S, Zhu Y, Liu X, Dong Y, et al. Design of Ethylene-Vinyl Acetate Copolymer Fiber with Two-Way Shape Memory Effect. Polymers. 2019; 11(10):1599. https://doi.org/10.3390/polym11101599

Chicago/Turabian StyleQi, Xiaoming, Wentong Yang, Laiming Yu, Wenjun Wang, Haohao Lu, Yanglong Wu, Shanwen Zhu, Yaofeng Zhu, Xiangdong Liu, Yubing Dong, and et al. 2019. "Design of Ethylene-Vinyl Acetate Copolymer Fiber with Two-Way Shape Memory Effect" Polymers 11, no. 10: 1599. https://doi.org/10.3390/polym11101599

APA StyleQi, X., Yang, W., Yu, L., Wang, W., Lu, H., Wu, Y., Zhu, S., Zhu, Y., Liu, X., Dong, Y., & Fu, Y. (2019). Design of Ethylene-Vinyl Acetate Copolymer Fiber with Two-Way Shape Memory Effect. Polymers, 11(10), 1599. https://doi.org/10.3390/polym11101599