Investigation of the Effect of Carbonyl Iron Micro-Particles on the Mechanical and Rheological Properties of Isotropic and Anisotropic MREs: Constitutive Magneto-Mechanical Material Model

Abstract

:1. Introduction

2. Materials and Methods

2.1. Solenoid Characterization and Particle Alignment

2.2. Fourier Transform Infrared

2.3. X-Ray Diffraction (XRD)

2.4. Morphology and Particle Distribution

2.5. Tensile Tests

2.6. Rheological Test

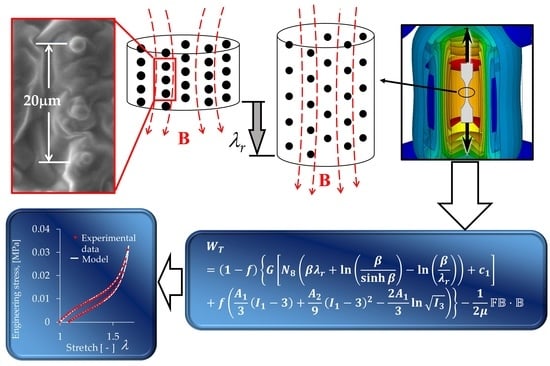

3. A Stress-Softening Magnetorheological Constitutive Material Model

4. Results

4.1. Particle Alignment

4.2. Particle Morphology

4.3. FTIR Analysis

4.4. X-Ray Diffraction (XRD)

4.5. Tensile Test Results

4.6. Rheology Test Results

4.7. Loading and Unloading Uniaxial Magnetostatic Extension Tests

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, X.; Gordaninejad, F.; Calgar, M.; Liu, Y.; Sutrisno, J.; Fuchs, A. Sensing Behavior of Magnetorheological Elastomers. J. Mech. Des. 2009, 131, 091004. [Google Scholar] [CrossRef]

- Sohoni, G.B.; Mark, J.E. Anisotropic reinforcement in elastomers containing magnetic filler particles. J. Appl. Polym. Sci. 1987, 34, 2853–2859. [Google Scholar] [CrossRef]

- Li, R.; Sun, L.Z. Viscoelastic Responses of Silicone-Rubber-Based Magnetorheological Elastomers under Compressive and Shear Loadings. J. Eng. Mater. Technol. 2013, 135, 021008. [Google Scholar] [CrossRef]

- Tian, T.; Nakano, M. Fabrication and characterization of anisotropic magnetorheological elastomer with 45° iron particle alignment at various silicone oil concentrations. J. Intell. Mater. Syst. Struct. 2018, 29, 151–159. [Google Scholar] [CrossRef]

- Gong, X.L.; Zhang, X.Z.; Zhang, P.Q. Fabrication and characterization of isotropic magnetorheological elastomers. Polym. Test. 2005, 24, 669–676. [Google Scholar] [CrossRef]

- Chen, L.; Gong, X.; Jiang, W.; Yao, J.; Deng, H.; Li, W. Investigation on magnetorheological elastomers based on natural rubber. J. Mater. Sci. 2007, 42, 5483–5489. [Google Scholar] [CrossRef] [Green Version]

- Stepanov, G.V.; Abramchuk, S.S.; Grishin, D.A.; Nikitin, L.V.; Kramarenko, Y.E.; Khokhlov, A.R. Effect of a homogeneous magnetic field on the viscoelastic behavior of magnetic elastomers. Polymer 2007, 48, 488–495. [Google Scholar] [CrossRef]

- Böse, H.; Röder, R. Magnetorheological Elastomers with High Variability of Their Mechanical Properties. J. Phys. Conf. Ser. 2009, 149, 012090. [Google Scholar] [CrossRef]

- Zhang, W.; Gong, X.L.; Jiang, W.Q.; Fan, Y.C. Investigation of the durability of anisotropic magnetorheological elastomers based on mixed rubber. Smart Mater. Struct. 2010, 19, 085008. [Google Scholar] [CrossRef]

- Yu, M.; Ju, B.; Fu, J.; Liu, X.; Yang, Q. Influence of composition of carbonyl iron particles on dynamic mechanical properties of magnetorheological elastomers. J. Magn. Mater. 2012, 324, 2147–2152. [Google Scholar] [CrossRef]

- Li, W.H.; Nakano, M. Fabrication and characterization of PDMS based magnetorheological elastomers. Smart Mater. Struct. 2013, 22, 055035. [Google Scholar] [CrossRef]

- Stoll, A.; Mayer, M.; Monkman, G.J.; Shamonin, M. Evaluation of Highly Compliant Magneto-Active Elastomers with Colossal Magnetorheological Response. J. Appl. Polym. Sci. 2013, 131, 39793. [Google Scholar] [CrossRef]

- An, J.S.; Kwon, S.H.; Choi, H.J.; Jung, J.H.; Kim, Y.G. Modified silane-coated carbonyl iron/natural rubber composite elastomer and its magnetorheological performance. Compos. Struct. 2017, 160, 1020–1026. [Google Scholar] [CrossRef]

- Khairi, M.H.A.; Fatah, A.Y.A.; Mazlan, S.A.; Ubaidillah, U.; Nordin, N.A.; Ismail, N.I.N.; Choi, B.S.; Aziz, S.A.A. Enhancement of Particle Alignment Using Silicone Oil Plasticizer and Its Effects on the Field-Dependent Properties of Magnetorheological Elastomers. Int. J. Mol. Sci. 2019, 20, 4085. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Li, W.; Du, H. A state-of-the-art review on magnetorheological elastomer devices. Smart Mater. Struct. 2014, 23, 2873–2891. [Google Scholar] [CrossRef]

- Kim, Y.; Parada, G.A.; Liu, S.; Zhao, X. Ferromagnetic soft continuum robots. Sci. Robot. 2019, 4, eaax7329. [Google Scholar] [CrossRef]

- Lu, H.; Zhang, M.; Yang, Y.; Huang, Q.; Fukuda, T.; Wang, Z.; Shen, Y. A bioinspired multilegged soft millirobot that functions in both dry and wet conditions. Nat. Commun. 2018, 9, 3944. [Google Scholar] [CrossRef]

- Hu, W.; Lum, G.Z.; Mastrangeli, M.; Sitti, M. Small-scale soft-bodied robot with multimodal locomotion. Nature 2018, 554, 81–85. [Google Scholar] [CrossRef]

- Puente-Córdova, J.G.; Reyes-Melo, M.E.; Palacios-Pineda, L.M.; Martínez-Perales, I.A.; Martínez-Romero, O.; Elías-Zúñiga, A. Fabrication and Characterization of Isotropic and Anisotropic Magnetorheological Elastomers, Based on Silicone Rubber and Carbonyl Iron Microparticles. Polymers 2018, 10, 1343. [Google Scholar] [CrossRef]

- Cantournet, S.; Boyce, M.C.; Tsou, A.H. Micromechanics and macromechanics of carbon nanotube-enhanced elastomers. J. Mech. Phys. Solids 2007, 55, 1321–1339. [Google Scholar] [CrossRef] [Green Version]

- Elías-Zúñiga, A.; Baylón, K.; Ferrer, I.; Serenó, L.; García-Romeu, M.L.; Bagudanch, I.; Grabalosa, J.; Pérez-Recio, T.; Martínez-Romero, O.; Ortega-Lara, W.; et al. On the Rule of Mixtures for Predicting Stress-Softening and Residual Strain Effects in Biological Tissues and Biocompatible Materials. Materials 2014, 7, 441–456. [Google Scholar] [CrossRef] [PubMed]

- Bertotti, G. Hysterisis in Magnetism: For. Physicists, Materials Scientists, and Engineers, 1st ed.; Academic Press-Elsevier: Waltham, MA, USA, 1998. [Google Scholar]

- Ogden, R.W. Mechanics of Rubberlike Solids. In Proceedings of the XXI ICTAM, Warsaw, Poland, 15–21 August 2004. [Google Scholar]

- Saxena, P.; Hossain, M.; Steinmann, P. Nonlinear magneto-viscoelasticity of transversally isotropic magneto-active polymers. Proc. R. Soc. Lond. A Math. Phys. Eng. Sci. 2014, 470, 2166. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Hong, W.; Faidley, L.E. Field-stiffening effect of magneto-rheological elastomers. Int. J. Solids Struct. 2013, 50, 2281–2288. [Google Scholar] [CrossRef] [Green Version]

- Mehnert, M.; Hossain, M.; Steinmann, P. Towards a thermo-magneto-mechanical framework for magneto-rheological elastomers. Int. J. Solids Struct. 2017, 128, 117–132. [Google Scholar] [CrossRef]

- Zhao, R.K.; Kim, Y.; Chester, S.A. Mechanics of hard-magnetic soft materials. J. Mech. Phys. Solids 2018, 124, 244–263. [Google Scholar] [CrossRef]

- Garcia-Gonzalez, D. Magneto-visco-hyperelasticity for hard-magnetic soft materials: Theory and numerical applications. Smart Mater. Struct. 2019, 28, 085020. [Google Scholar] [CrossRef]

- Boyce, M.C.; Arruda, E. Constitutive models of rubber elasticity: A review. Chem. Technol. 2000, 73, 504–523. [Google Scholar] [CrossRef]

- Elías-Zúñiga, A.; Beatty, M.F. Constitutive equations for amended non-Gaussian network models of rubber elasticity. Int. J. Eng. Sci. 2002, 40, 2265–2294. [Google Scholar] [CrossRef]

- Steinmann, P.; Hossain, M.; Possart, G. Hyperelastic models for rubber-like materials: Consistent tangent operators and suitability for Treloar’s data. Arch. Appl. Mech. 2002, 82, 1183–1217. [Google Scholar] [CrossRef]

- Córdova, R.K.; Elías-Zúñiga, A.; Elizalde, L.E.; Siller, H.R.; Sánchez, J.A.; Rodríguez, C.A.; Ortega, W. Polymeric Materials Reinforced with Multiwall Carbon Nanotubes: A Constitutive Material Model. Materials 2013, 6, 2873–2891. [Google Scholar] [CrossRef]

- Tian, T.F.; Li, W.H.; Alici, G.; Du, H.; Deng, Y.M. Microstructure and magnetorheology of graphite-based MR elastomers. Rheol. Acta 2011, 50, 825–836. [Google Scholar] [CrossRef]

- Hanoosh, W.S.; Abdelrazaq, E.M. Polydimethyl siloxane toughened epoxy resins: Tensile strength and dynamic mechanical analysis. Malays. Polym. J. 2009, 4, 52–61. [Google Scholar]

- Perales-Martínez, I.A.; Palacios-Pineda, L.M.; Lozano-Sánchez, L.M.; Martínez-Romero, O.; Puente-Cordova, J.G.; Elías-Zúñiga, A. Enhancement of a magnetorheological PDMS elastomer with carbonyl iron particles. Polym. Test. 2017, 57, 78–86. [Google Scholar] [CrossRef]

- Kuo, A.C.M. Polymer Data Handbook; Oxford University Press, Inc.: Oxford, UK, 1999. [Google Scholar]

- Haddad, P.S.; Duarte, E.L.; Baptista, M.S.; Goya, G.F.; Leite, C.A.P.; Itri, R. Synthesis and characterization of silica-coated magnetic nanoparticles. Progr. Colloid Polym. Sci. 2004, 128, 232–238. [Google Scholar]

- Stuart, B. Infrared Spectroscopy: Fundamentals and Applications; John Wiley & Sons Ltd.: Chichester, UK, 2004; pp. 46–76. [Google Scholar]

- Gorodkin, S.R.; James, R.O.; Kordonski, W.I. Magnetic Properties of Carbonyl Iron Particles in Magnetorheological Fluids. J. Phys. Conf. Ser. 2009, 149, 012051. [Google Scholar] [CrossRef]

| CIPs wt % | G (MPa) | N8 (-) | A1 (MPa) | A2 (MPa) | b (-) | c (MPa) | f (-) | μr (-) |

|---|---|---|---|---|---|---|---|---|

| 20 | 0.0126 | 1.550 | 881.305 | −0.48 | 0.21 | 580 | 0.034 | 1.23 |

| 27 | 0.0132 | 1.560 | 840.350 | −0.33 | 0.27 | 450 | 0.049 | 1.29 |

| 45 | 0.0237 | 1.495 | 699.355 | −0.27 | 0.40 | 230 | 0.103 | 1.55 |

| 63 | 0.0424 | 1.700 | 573.520 | −0.20 | 0.51 | 85 | 0.192 | 1.89 |

| 70 | 0.0481 | 1.475 | 528.800 | −0.11 | 0.58 | 80 | 0.247 | 2.05 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soria-Hernández, C.G.; Palacios-Pineda, L.M.; Elías-Zúñiga, A.; Perales-Martínez, I.A.; Martínez-Romero, O. Investigation of the Effect of Carbonyl Iron Micro-Particles on the Mechanical and Rheological Properties of Isotropic and Anisotropic MREs: Constitutive Magneto-Mechanical Material Model. Polymers 2019, 11, 1705. https://doi.org/10.3390/polym11101705

Soria-Hernández CG, Palacios-Pineda LM, Elías-Zúñiga A, Perales-Martínez IA, Martínez-Romero O. Investigation of the Effect of Carbonyl Iron Micro-Particles on the Mechanical and Rheological Properties of Isotropic and Anisotropic MREs: Constitutive Magneto-Mechanical Material Model. Polymers. 2019; 11(10):1705. https://doi.org/10.3390/polym11101705

Chicago/Turabian StyleSoria-Hernández, Cintya G., Luis M. Palacios-Pineda, Alex Elías-Zúñiga, Imperio A. Perales-Martínez, and Oscar Martínez-Romero. 2019. "Investigation of the Effect of Carbonyl Iron Micro-Particles on the Mechanical and Rheological Properties of Isotropic and Anisotropic MREs: Constitutive Magneto-Mechanical Material Model" Polymers 11, no. 10: 1705. https://doi.org/10.3390/polym11101705