Synthesis and Morphological Control of Biocompatible Fluorescent/Magnetic Janus Nanoparticles Based on the Self-Assembly of Fluorescent Polyurethane and Fe3O4 Nanoparticles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterizations

2.3. Synthesis of 4-bromo-N-(2-hydroxy-1-hydroxymethylethyl)-1,8-naphthalimide (BHHNA)

2.4. Synthesis of 4-methoxyl-N-(2-hydroxy-1-hydroxymethylethyl)-1,8-naphthalimide (MHHNA)

2.5. Synthesis of 4-diethylamino-N-(2-hydroxy-1-hydroxymethylethyl)-1,8-naphthalimide (DHHNA)

2.6. Synthesis of PU Prepolymer

2.7. Preparation of Composite Nanoparticles

3. Results and Discussion

3.1. Characterization of Fluorescent Polyurethane

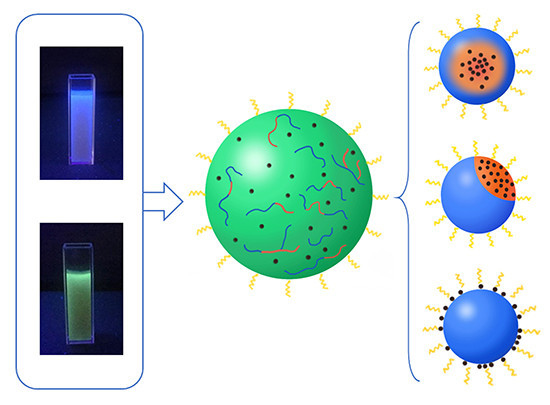

3.2. Fabrication of Composite Nanoparticles

3.3. Nanostructure of Composite Nanoparticles

3.4. Magnetic and Fluorescent Properties of Composite Nanoparticles

3.5. Cytocompatibility

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| FMNP | fluorescent/magnetic nanoparticle |

| FMJNP | fluorescent/magnetic Janus nanoparticle |

| HMNP | hydrophobic magnetic nanoparticle |

| BHHNA | 4-bromo-N-(2-hydroxy-1-hydroxymethylethyl)-1,8-naphthalimide |

| MHHNA | 4-methoxyl-N-(2-hydroxy-1-hydroxymethylethyl)-1,8-naphthalimide |

| DHHNA | 4-diethylamino-N-(2-hydroxy-1-hydroxymethylethyl)-1,8-naphthalimide |

| PU | polyurethane |

| TMP | trimethylol propane |

| CO | castor oil |

| PU-TMP | polyurethane from trimethylol propane |

| PU-CO | polyurethane from castor oil |

| PU-MHHNA | polyurethane from 4-methoxyl-N-(2-hydroxy-1-hydroxymethylethyl)-1,8-naphthalimide |

| PU-DHHNA | polyurethane from 4-diethylamino-N-(2-hydroxy-1-hydroxymethylethyl)-1,8-naphthalimide |

| PTCP | PU-TMP magnetic composite nanoparticle |

| PCCP | PU-CO magnetic composite nanoparticle |

| PMCP | PU-MHHNA magnetic composite nanoparticle |

| PDCP | PU-DHHNA magnetic composite nanoparticle |

| HDO | 1,2-hexadecanediol |

| BDO | 1,4-butanediol |

| NA | 1,8-naphthalimide |

| SDS | sodium dodecyl sulfate |

| IPDI | isophorone diisocyanate |

| THF | tetrahydrofuran |

| DMSO | dimethyl sulfoxide |

| XRD | X-ray diffraction |

| TEM | transmission electron microscopy |

| SEM | scanning electron microscopy |

| DLS | dynamic light scattering |

| GPC | gel permeation chromatography |

References

- Wen, C.Y.; Xie, H.Y.; Zhang, Z.L.; Wu, L.L.; Hu, J.; Tang, M.; Wu, M.; Pang, D.W. Fluorescent/magnetic micro/nano-spheres based on quantum dots and/or magnetic nanoparticles: Preparation, properties, and their applications in cancer studies. Nanoscale 2016, 8, 12406–12429. [Google Scholar] [CrossRef] [PubMed]

- Bigall, N.C.; Parak, W.J.; Dorfs, D. Fluorescent, magnetic and plasmonic-Hybrid multifunctional colloidal nano objects. Nano Today 2012, 7, 282–296. [Google Scholar] [CrossRef]

- Wang, G.N.; Su, X.G. The synthesis and bio-applications of magnetic and fluorescent bifunctional composite nanoparticles. Analyst 2011, 136, 1783–1798. [Google Scholar] [CrossRef] [PubMed]

- Ganipineni, L.P.; Ucakar, B.; Joudiou, N.; Bianco, J.; Danhier, P.; Zhao, M.N.; Bastiancich, C.; Gallez, B.; Danhier, F.; Préat, V. Magnetic targeting of paclitaxel-loaded poly(lactic-co-glycolic acid)-based nanoparticles for the treatment of glioblastoma. Int. J. Nanomed. 2018, 13, 4509–4521. [Google Scholar] [CrossRef] [PubMed]

- Yan, K.; Li, H.; Li, P.H.; Zhu, H.E.; Shen, J.; Yi, C.F.; Wu, S.L.; Yeung, K.W.; Xu, Z.S.; Xu, H.B.; et al. Self-assembled magnetic fluorescent polymeric micelles for magnetic resonance and optical imaging. Biomaterials 2014, 35, 344–355. [Google Scholar] [CrossRef] [PubMed]

- Xi, P.X.; Cheng, K.; Sun, X.L.; Zeng, Z.Z.; Sun, S.H. Magnetic Fe3O4 nanoparticles coupled with a fluorescent Eu complex for dual imaging applications. Chem. Commun. 2012, 48, 2952–2954. [Google Scholar]

- Mahmoudi, M.; Shokrgozar, M.A. Multifunctional stable fluorescent magnetic nanoparticles. Chem. Commun. 2012, 48, 3957–3959. [Google Scholar]

- Wang, M.; Fei, X.F.; Lv, S.W.; Sheng, Y.; Zou, H.F.; Song, Y.H.; Yan, F.; Zhu, Q.L.; Zheng, K.Y. Synthesis and characterization of a flexible fluorescent magnetic Fe3O4@SiO2/CdTe-NH2 nanoprobe. J. Inorg. Biochem. 2018, 186, 307–316. [Google Scholar] [CrossRef]

- Sun, Y.Q.; Wang, D.D.; Zhao, T.X.; Jiang, Y.N.; Zhao, Y.Q.; Wang, C.X.; Sun, H.C.; Yang, B.; Lin, Q. Fluorescence-magnetism functional EuS nanocrystals with controllable morphologies for dual bioimaging. ACS Appl. Mater. Interfaces 2016, 8, 33539–33545. [Google Scholar] [CrossRef]

- Resch-Genger, U.; Grabolle, M.; Cavaliere-Jaricot, S.; Nitschke, R.; Nann, T. Quantum dots versus organic dyes as fluorescent labels. Nat. Methods 2008, 5, 763–775. [Google Scholar] [CrossRef]

- Jackeray, R.; Abid, C.K.; Singh, G.; Jain, S.; Chattopadhyaya, S.; Sapra, S.; Shrivastav, T.G.; Singh, H. Selective capturing and detection of Salmonella typhi on polycarbonate membrane using bioconjugated quantum dots. Talanta 2011, 84, 952–962. [Google Scholar] [CrossRef] [PubMed]

- Li, B.T.; Shen, J.; Liang, R.B.; Ji, W.J.; Kan, C.Y. Synthesis and characterization of covalently colored polymer latex based on new polymerizable anthraquinone dyes. Colloid Polym. Sci. 2012, 290, 1893–1900. [Google Scholar] [CrossRef]

- Li, B.T.; Shen, J.; Jiang, Y.M.; Wang, J.S.; Kan, C.Y. Preparation and properties of covalently colored polymer latex based on a new anthraquinone monomer. J. Appl. Polym. Sci. 2013, 129, 1484–1490. [Google Scholar] [CrossRef]

- Peyer, K.E.; Zhang, L.; Nelson, B.J. Bio-inspired magnetic swimming microrobots for biomedical applications. Nanoscale 2013, 5, 1259–1272. [Google Scholar] [CrossRef] [PubMed]

- Orozco, J.; Pan, G.Q.; Sattayasamitsathit, S.; Galarnyk, M.; Wang, J. Micromotors to capture and destroy anthrax simulant spores. Analyst 2015, 140, 1421–1427. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.H.; Yang, S.Y.; Yin, S.N.; Chen, L.; Chen, S. Janus suprabead displays derived from the modified photonic crystals toward temperature magnetism and optics multiple responses. ACS Appl. Mater. Interfaces 2015, 7, 8827–8833. [Google Scholar] [CrossRef] [PubMed]

- Schick, I.; Lorenz, S.; Gehrig, D.; Schilmann, A.M.; Bauer, H.; Panthöfer, M.; Fischer, K.; Strand, D.; Laquai, F.; Tremel, W. Multifunctional two-photon active silica-coated Au@MnO Janus particles for selective dual functionalization and imaging. J. Am. Chem. Soc. 2014, 136, 2473–2483. [Google Scholar] [CrossRef]

- Kim, S.H.; Sim, J.Y.; Lim, J.M.; Yang, S.M. Magnetoresponsive microparticles with nanoscopic surface structures for remote-controlled locomotion. Angew. Chem. 2010, 49, 3786–3790. [Google Scholar] [CrossRef]

- Kaewsaneha, C.; Tangboriboonrat, P.; Polpanich, D.; Elaissari, A. Multifunctional fluorescent-magnetic polymeric colloidal particles: Preparations and bioanalytical applications. ACS Appl. Mater. Interfaces 2015, 7, 23373–23386. [Google Scholar] [CrossRef]

- Yi, Y.; Sanchez, L.; Gao, Y.; Yu, Y. Janus particles for biological imaging and sensing. Analyst 2016, 141, 3526–3539. [Google Scholar] [CrossRef] [Green Version]

- Liang, F.X.; Liu, B.; Cao, Z.; Yang, Z.Z. Janus colloids toward interfacial engineering. Langmuir 2018, 34, 4123–4131. [Google Scholar] [CrossRef]

- Yin, S.N.; Wang, C.F.; Yu, Z.Y.; Wang, J.; Liu, S.S.; Chen, S. Versatile bifunctional magnetic-fluorescent responsive Janus supraballs towards the flexible bead display. Adv. Mater. 2011, 23, 2915–2919. [Google Scholar] [CrossRef] [PubMed]

- Lan, J.W.; Chen, J.Y.; Li, N.X.; Ji, X.H.; Yu, M.X.; He, Z.K. Microfluidic generation of magnetic-fluorescent Janus microparticles for biomolecular detection. Talanta 2016, 151, 126–131. [Google Scholar] [CrossRef]

- Li, P.; Li, K.; Niu, X.F.; Fan, Y.B. Electrospraying magnetic-fluorescent bifunctional Janus PLGA microspheres with dual rare earth ions fluorescent-labeling drugs. RSC Adv. 2016, 6, 99034–99043. [Google Scholar] [CrossRef]

- Teo, B.M.; Young, D.J.; Loh, X.J. Magnetic anisotropic particles: Toward remotely actuated applications. Part. Part. Syst. Charact. 2016, 33, 709–728. [Google Scholar] [CrossRef]

- Hu, S.H.; Gao, X.H. Nanocomposites with spatially separated functionalities for combined imaging and magnetolytic therapy. J. Am. Chem. Soc. 2010, 132, 7234–7237. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.M.; Montagne, F.; Fessi, H.; Elaissari, A. Anisotropic magnetic microparticles from ferrofluid emulsion. Soft Matter 2011, 7, 1483–1490. [Google Scholar] [CrossRef]

- Kaewsaneha, C.; Bitar, A.; Tangboriboonrat, P.; Polpanich, D.; Elaissari, A. Fluorescent-magnetic Janus particles prepared via seed emulsion polymerization. J. Colloid Interface Sci. 2014, 424, 98–103. [Google Scholar] [CrossRef]

- Jin, Q.J.; Hu, Y.; Shen, J.; Li, B.T.; Kan, C.Y. A novel 1,8-naphthalimide green fluorescent dye and its corresponding intrinsically fluorescent polyurethane latexes. J. Coat. Technol. Res. 2017, 14, 571–582. [Google Scholar] [CrossRef]

- Jin, Q.J.; Li, B.T.; Zhang, H.; Li, L.X.; Shen, J.; Kan, C.Y. Investigation of covalently colored polyurethane latexes based on novel anthraquinone polyurethane chain extenders. J. Macromol. Sci. A 2017, 54, 52–59. [Google Scholar] [CrossRef]

- Park, J.; An, K.J.; Hwang, Y.S.; Park, J.G.; Noh, H.J.; Kim, J.Y.; Park, J.H.; Hwang, N.M.; Hyeon, T. Ultra-large-scale syntheses of monodisperse nanocrystals. Nat. Mater. 2004, 3, 891–895. [Google Scholar] [CrossRef]

- Sutradhar, T.; Misra, A. Role of electron-donating and electron-withdrawing Groups in tuning the optoelectronic properties of difluoroboron-napthyridine analogues. J. Phys. Chem. A 2018, 122, 4111–4120. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.B.; Xia, S.; Fang, M.X.; Mazi, W.; Zeng, Y.B.; Johnston, T.; Pap, A.; Luck, R.L.; Liu, H.Y. New near-infrared rhodamine dyes with large Stokes shifts for sensitive sensing of intracellular pH changes and fluctuations. Chem. Commun. 2018, 54, 7625–7628. [Google Scholar]

- Heider, F.; Dunlop, D.J.; Sugiura, N. Magnetic properties of hydrothermally recrystallized magnetite crystals. Science 1987, 236, 1287–1290. [Google Scholar] [CrossRef] [PubMed]

- Kaewsaneha, C.; Tangboriboonrat, P.; Polpanich, D.; Eissa, M.; Elaissari, A. Facile method for preparation of anisotropic submicron magnetic Janus particles using miniemulsion. J. Colloid Interface Sci. 2013, 409, 66–71. [Google Scholar] [CrossRef] [PubMed]

- Ngamwongsatit, P.; Banada, P.P.; Panbangred, W.; Bhunia, A.K. WST-1-based cell cytotoxicity assay as a substitute for MTT-based assay for rapid detection of toxigenic Bacillus species using CHO cell line. J. Microbiol. Methods 2008, 73, 211–215. [Google Scholar] [CrossRef] [PubMed]

| Prepolymer | IPDI/g | CO/g | TMP/g | HDO/g | BDO/g | Fluorescent dye/g | THF/g |

|---|---|---|---|---|---|---|---|

| PU-TMP | 2.22 | 0 | 0.158 | 0 | 0.534 | 0 | 10 |

| PU-CO | 2.22 | 0.75 | 0 | 0 | 0.592 | 0 | 10 |

| PU-MHHNA | 2.22 | 0.4 | 0 | 0.2 | 0.572 | 0.016 a | 10 |

| PU-DHHNA | 2.22 | 0.4 | 0 | 0.2 | 0.572 | 0.018 b | 10 |

| Sample | PU Prepolymer/mg | HMNPs/mg | |

|---|---|---|---|

| PTCP-20 | PU-TMP | 80 | 20 |

| PCCP-20 | PU-CO | 80 | 20 |

| PMCP-0 | PU-MHHNA | 100 | 0 |

| PMCP-10 | 90 | 10 | |

| PMCP-20 | 80 | 20 | |

| PMCP-30 | 70 | 30 | |

| PDCP-0 | PU-DHHNA | 100 | 0 |

| PDCP-10 | 90 | 10 | |

| PDCP-20 | 80 | 20 | |

| PDCP-30 | 70 | 30 | |

| Sample | Mean Diameter/nm | Polydis | Zeta Potential/mV |

|---|---|---|---|

| PTCP-20 | 135.5 | 0.143 | −67.3 |

| PCCP-20 | 189.0 | 0.259 | −65.1 |

| PMCP-10 | 125.7 | 0.052 | −69.5 |

| PMCP-20 | 128.4 | 0.083 | −68.8 |

| PMCP-30 | 129.0 | 0.095 | −64.1 |

| PDCP-10 | 130.2 | 0.064 | −59.7 |

| PDCP-20 | 122.8 | 0.090 | −69.9 |

| PDCP-30 | 128.8 | 0.121 | −66.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Shao, W.; Wang, Y.; Xiao, D.; Xiong, Y.; Ye, H.; Zhou, Q.; Jin, Q. Synthesis and Morphological Control of Biocompatible Fluorescent/Magnetic Janus Nanoparticles Based on the Self-Assembly of Fluorescent Polyurethane and Fe3O4 Nanoparticles. Polymers 2019, 11, 272. https://doi.org/10.3390/polym11020272

Li B, Shao W, Wang Y, Xiao D, Xiong Y, Ye H, Zhou Q, Jin Q. Synthesis and Morphological Control of Biocompatible Fluorescent/Magnetic Janus Nanoparticles Based on the Self-Assembly of Fluorescent Polyurethane and Fe3O4 Nanoparticles. Polymers. 2019; 11(2):272. https://doi.org/10.3390/polym11020272

Chicago/Turabian StyleLi, Botian, Wei Shao, Yanzan Wang, Da Xiao, Yi Xiong, Haimu Ye, Qiong Zhou, and Qingjun Jin. 2019. "Synthesis and Morphological Control of Biocompatible Fluorescent/Magnetic Janus Nanoparticles Based on the Self-Assembly of Fluorescent Polyurethane and Fe3O4 Nanoparticles" Polymers 11, no. 2: 272. https://doi.org/10.3390/polym11020272