Effects of Cavity Structure on Tuning Properties of Polymer Lasers in a Liquid Environment

Abstract

:1. Introduction

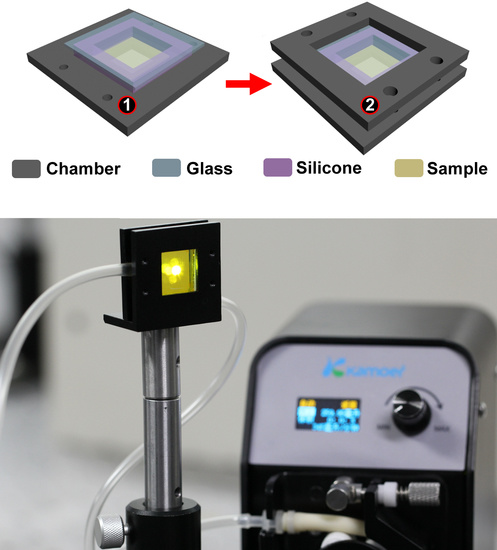

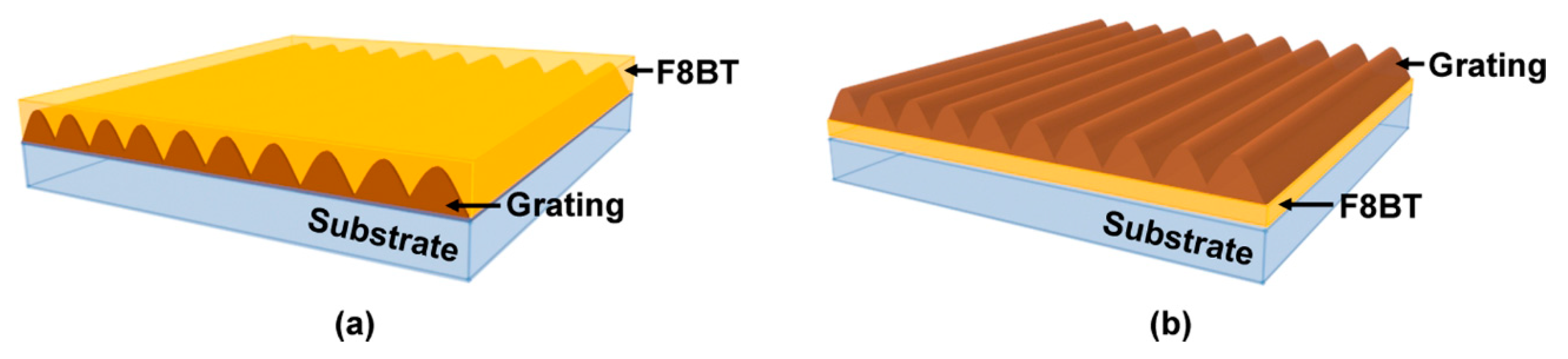

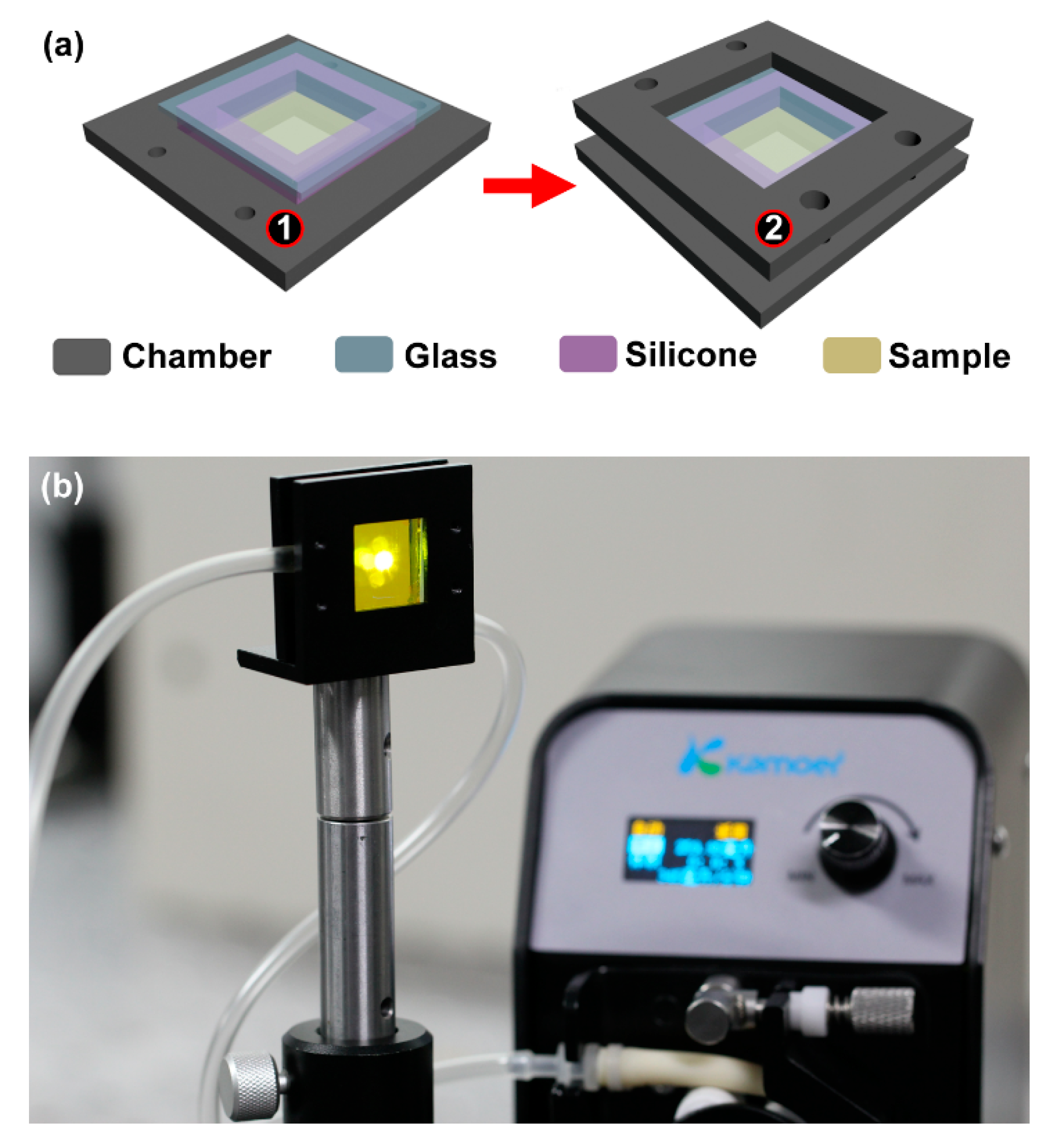

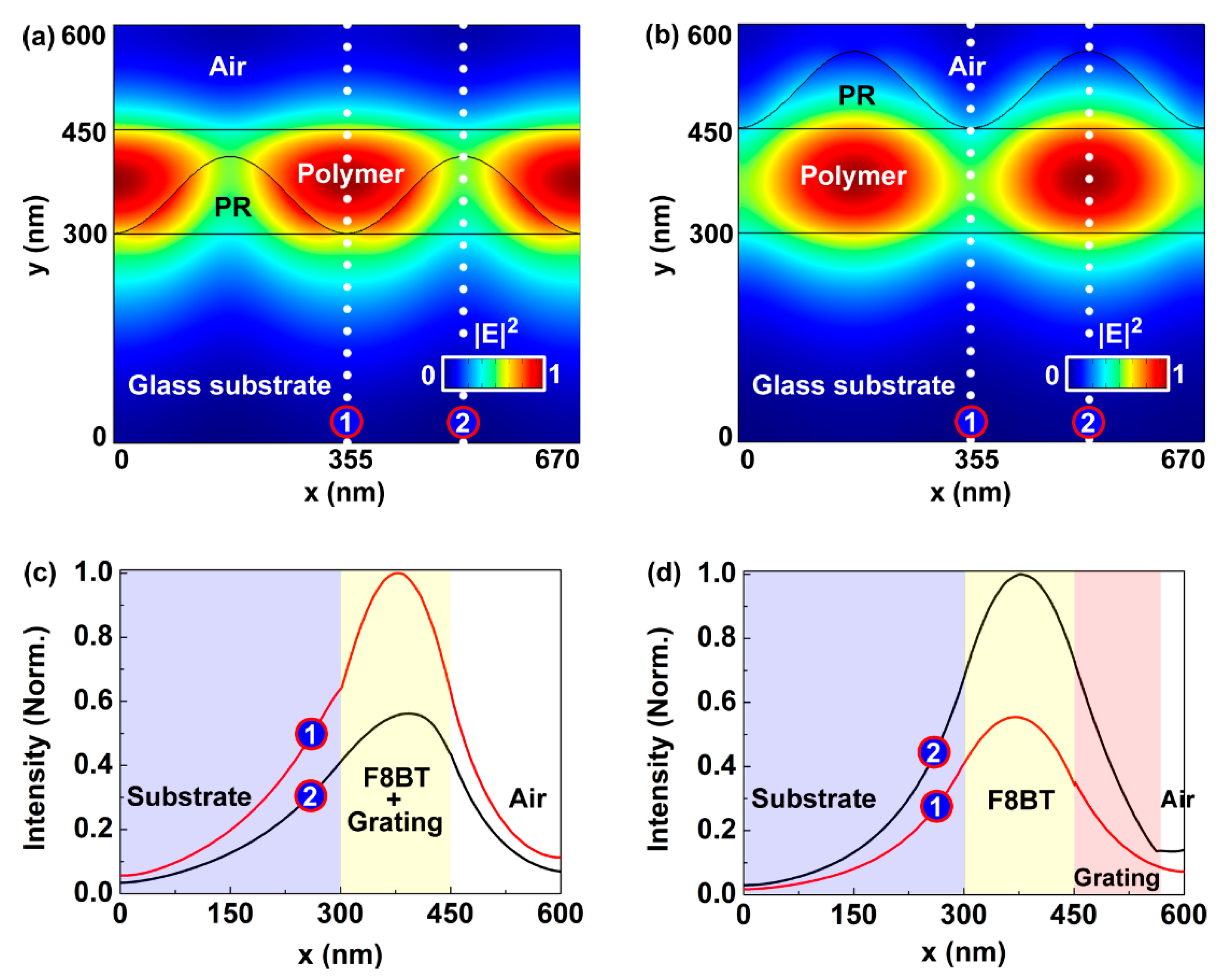

2. Fabrication of the SGA and SAG Cavities

3. Spectra Characterization of the SGA and SAG Cavities

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fang, H.H.; Ding, R.; Lu, S.Y.; Wang, L.; Feng, J.; Chen, Q.D.; Sun, H.B. Direct laser interference ablating nanostructures on organic crystals. Opt. Lett. 2012, 37, 686–688. [Google Scholar] [CrossRef] [PubMed]

- Klinkhammer, S.; Liu, X.; Huska, K.; Shen, Y.X.; Vanderheiden, S.; Valouch, S.; Vannahme, C.; Brase, S.; Mappes, T.; Lemmer, U. Continuously tunable solution-processed organic semiconductor DFB lasers pumped by laser diode. Opt. Express 2012, 20, 6357–6364. [Google Scholar] [CrossRef] [PubMed]

- Gaal, M.; Gadermaier, C.; Plank, H.; Moderegger, E.; Pogantsch, A.; Leising, G.; List, E.J.W. Imprinted conjugated polymer laser. Adv. Mater. 2003, 15, 1165–1167. [Google Scholar] [CrossRef]

- Ge, C.; Lu, M.; Jian, X.; Tan, Y.F.; Cunningham, B.T. Large-area organic distributed feedback laser fabricated by nanoreplica molding and horizontal dipping. Opt. Express 2010, 18, 12980–12991. [Google Scholar] [CrossRef] [PubMed]

- Pisignano, D.; Persano, L.; Cingolani, R.; Gigli, G.; Babudri, F.; Farinola, G.M.; Naso, F. Soft molding lithography of conjugated polymers. Appl. Phys. Lett. 2004, 84, 1365–1367. [Google Scholar] [CrossRef]

- Zhai, T.R.; Wang, Y.L.; Chen, L.; Zhang, X.P. Direct writing of tunable multi-wavelength polymer lasers on a flexible substrate. Nanoscale 2015, 7, 12312–12317. [Google Scholar] [CrossRef] [PubMed]

- Fang, H.H.; Ding, R.; Lu, S.Y.; Yang, J.; Zhang, X.L.; Yang, R.; Feng, J.; Chen, Q.D.; Song, J.F.; Sun, H.B. Distributed feedback lasers based on thiophene/phenylene Co-Oligomer Single Crystals. Adv. Funct. Mater. 2012, 22, 33–38. [Google Scholar] [CrossRef]

- Salerno, M.; Gigli, G.; Zavelani-Rossi, M.; Perissinotto, S.; Lanzani, G. Effects of morphology and optical contrast in organic distributed feedback lasers. Appl. Phys. Lett. 2007, 90, 111110. [Google Scholar] [CrossRef]

- Del Carro, P.; Camposeo, A.; Stabile, R.; Mele, E.; Persano, L.; Cingolani, R.; Pisignano, D. Near-infrared imprinted distributed feedback lasers. Appl. Phys. Lett. 2006, 89, 201105. [Google Scholar] [CrossRef]

- Zhai, T.R.; Wu, X.F.; Li, S.T.; Liang, S.Y.; Niu, L.Z.; Wang, M.; Feng, S.F.; Liu, H.M.; Zhang, X.P. Polymer lasing in a periodic-random compound cavity. Polymers 2018, 10, 1194. [Google Scholar] [CrossRef]

- Zhai, T.R.; Cao, F.Z.; Chu, S.S.; Gong, Q.H.; Zhang, X.P. Continuously tunable distributed feedback polymer laser. Opt. Express 2018, 26, 4491–4497. [Google Scholar] [CrossRef] [PubMed]

- Zhai, T.R.; Chen, L.; Li, S.T.; Hu, Y.J.; Wang, Y.M.; Wang, L.; Zhang, X.P. Free-standing membrane polymer laser on the end of an optical fiber. Appl. Phys. Lett. 2016, 108, 041904. [Google Scholar] [CrossRef]

- Liu, X.; Klinkhammer, S.; Sudau, K.; Mechau, N.; Vannahme, C.; Kaschke, J.; Mappes, T.; Wegener, M.; Lemmer, U. Ink-jet-printed organic semiconductor distributed feedback laser. Appl. Phys. Express. 2012, 5, 072101. [Google Scholar] [CrossRef]

- Dhillon, S.; Alton, J.; Barbieri, S.; Sirtori, C.; de Rossi, A.; Calligaro, M.; Beere, H.E.; Ritchie, D. Ultralow threshold current terahertz quantum cascade lasers based on double-metal buried strip waveguides. Appl. Phys. Lett. 2005, 87, 071107. [Google Scholar] [CrossRef] [Green Version]

- Tsiminis, G.; Wang, Y.; Kanibolotsky, A.L.; Inigo, A.R.; Skabara, P.J.; Samuel, I.D.W.; Turnbull, G.A. Nanoimprinted organic semiconductor laser pumped by a light-emitting diode. Adv. Mater. 2013, 25, 2826–2830. [Google Scholar] [CrossRef] [PubMed]

- Sakata, H.; Takeuchi, H. Diode-pumped polymeric dye lasers operating at a pump power level of 10 mW. Appl. Phys. Lett. 2008, 92, 113310. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Turnbull, G.A.; Samuel, I.D.W. Hybrid optoelectronics: A polymer laser pumped by a nitride light-emitting diode. Appl. Phys. Lett. 2008, 92, 163306. [Google Scholar] [CrossRef]

- Klinkhammer, S.; Woggon, T.; Geyer, U.; Vannahme, C.; Dehm, S.; Mappes, T.; Lemmer, U. A continuously tunable low-threshold organic semiconductor distributed feedback laser fabricated by rotating shadow mask evaporation. Appl. Phys. B 2009, 97, 787–791. [Google Scholar] [CrossRef]

- Schutte, B.; Gothe, H.; Hintschich, S.I.; Sudzius, M.; Frob, H.; Lyssenko, V.G.; Leo, K. Continuously tunable laser emission from a wedge-shaped organic microcavity. Appl. Phys. Lett. 2008, 92, 163309. [Google Scholar] [CrossRef]

- Wang, J.; Weimann, T.; Hinze, P.; Ade, G.; Schneider, D.; Rabe, T.; Riedl, T.; Kowalsky, Y. A continuously tunable organic DFB laser. Microelectron. Eng. 2005, 78, 364–368. [Google Scholar] [CrossRef]

- Schneider, D.; Hartmann, S.; Benstem, T.; Dobbertin, T.; Heithecker, D.; Metzdorf, D.; Becker, E.; Riedl, T.; Johannes, H.H.; Kowalsky, W.; et al. Wavelength-tunable organic solid-state distributed-feedback laser. Appl. Phys. B 2003, 77, 399–402. [Google Scholar] [CrossRef]

- Huang, W.B.; Yuan, C.L.; Shen, D.; Zheng, Z.G. Dynamically manipulated lasing enabled by a reconfigured fingerprint texture of a cholesteric self-organized superstructure. J. Mater. Chem. C Mater. 2017, 5, 6923–6928. [Google Scholar] [CrossRef]

- Chen, C.; Tong, F.; Cao, F.Z.; Tong, J.H.; Zhai, T.R.; Zhang, X.P. Tunable polymer lasers based on a metal-dielectric hybrid cavity. Optics Express 2018, 26, 32048–32054. [Google Scholar] [CrossRef] [PubMed]

- Li, S.T.; Wang, L.; Zhai, T.R.; Tong, J.H.; Niu, L.Z.; Tong, F.; Cao, F.Z.; Liu, H.M.; Zhang, X.P. A dual-wavelength polymer random laser with the step-type cavity. Org. Electron. 2018, 57, 323–326. [Google Scholar] [CrossRef]

- Doring, S.; Kollosche, M.; Rabe, T.; Stumpe, J.; Kofod, G. Electrically tunable polymer DFB laser. Adv. Mater. 2011, 23, 4265–4269. [Google Scholar] [CrossRef]

- Suzuki, K.; Takahashi, K.; Seida, Y.; Shimizu, K.; Kumagai, M.; Taniguch, Y. A continuously tunable organic solid-state laser based on a flexible distributed-feedback resonator. Jpn. J. Appl. Phys. 2003, 42, L249–L251. [Google Scholar] [CrossRef]

- Yu, K.Y.; Chang, S.H.; Lee, C.R.; Hsu, T.Y.; Kuo, C.T. Thermally tunable liquid crystal distributed feedback laser based on a polymer grating with nanogrooves fabricated by nanoimprint lithography. Opt. Mater. Express 2014, 4, 234–240. [Google Scholar] [CrossRef]

- Nishijima, Y.; Ueno, K.; Juodkazis, S.; Mizeikis, V.; Misawa, H.; Maeda, M.; MinakiYu, M. Tunable single-mode photonic lasing from zirconia inverse opal photonic crystals. Opt. Express 2008, 16, 13676–13684. [Google Scholar]

- Nishijima, Y.; Juodkazis, S. Optical characterization and lasing in three-dimensional opal-structures. Front. Mater. 2015, 2, 00049. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, F.; Zhang, S.; Tong, J.; Chen, C.; Niu, L.; Zhai, T.; Zhang, X. Effects of Cavity Structure on Tuning Properties of Polymer Lasers in a Liquid Environment. Polymers 2019, 11, 329. https://doi.org/10.3390/polym11020329

Cao F, Zhang S, Tong J, Chen C, Niu L, Zhai T, Zhang X. Effects of Cavity Structure on Tuning Properties of Polymer Lasers in a Liquid Environment. Polymers. 2019; 11(2):329. https://doi.org/10.3390/polym11020329

Chicago/Turabian StyleCao, Fengzhao, Shuai Zhang, Junhua Tong, Chao Chen, Lianze Niu, Tianrui Zhai, and Xinping Zhang. 2019. "Effects of Cavity Structure on Tuning Properties of Polymer Lasers in a Liquid Environment" Polymers 11, no. 2: 329. https://doi.org/10.3390/polym11020329