Preparation and Properties of Polyvinylidene Fluoride Nanocomposited Membranes based on Poly(N-Isopropylacrylamide) Modified Graphene Oxide Nanosheets

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Amide Graphene Oxide(GO-1)

2.3. Synthesis of Halogenated Initiators (GO-2)

2.4. Synthesis of GO-g-PNIPAAM via ATRP Method

2.5. Preparation of PVDF/GO-g-PNIPAAm Nanocomposite Membrane

2.6. Characterization of Nanoparticles and Membranes

2.7. Characterization of Ultrafiltration Membranes

3. Results and Discussion

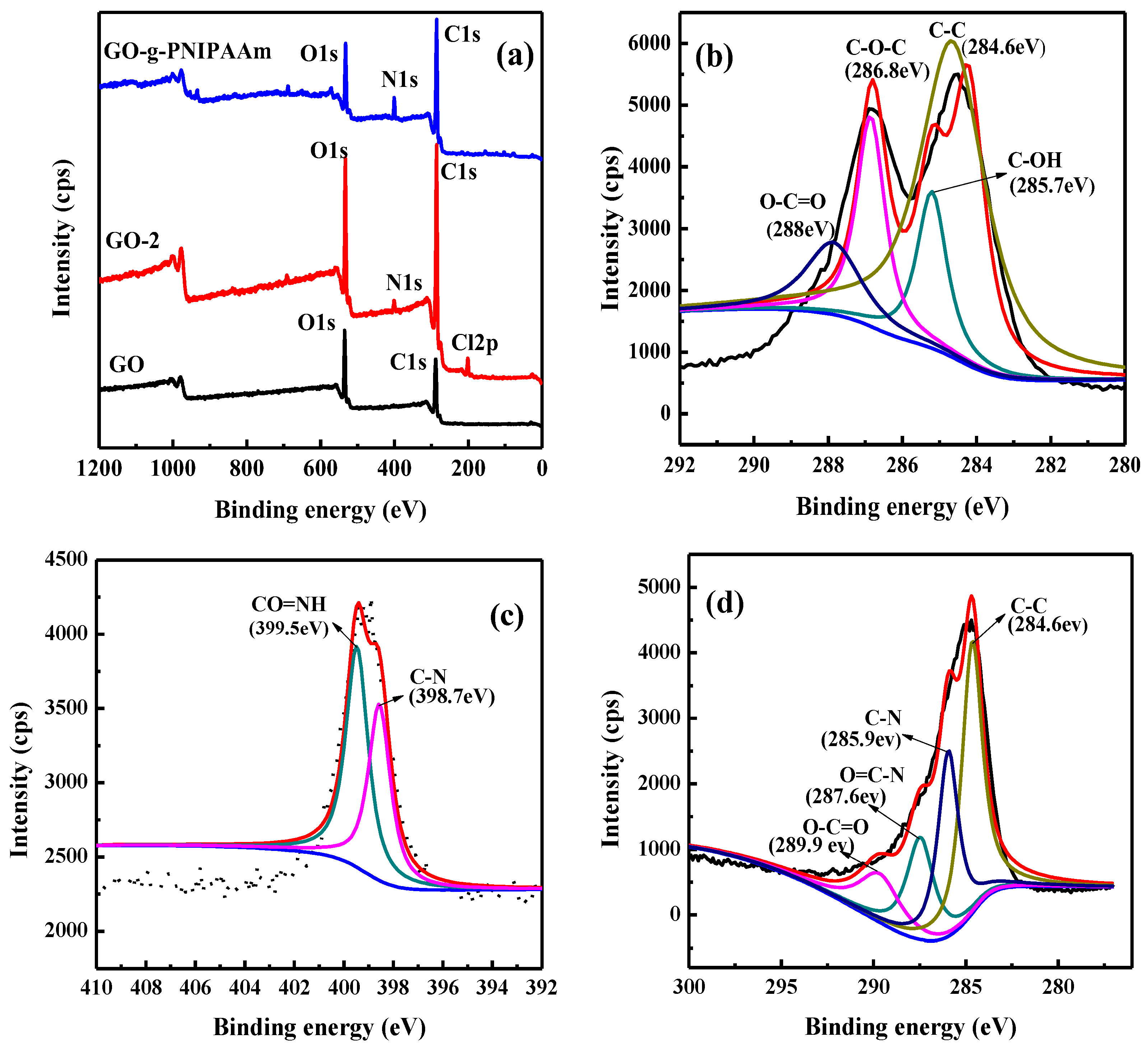

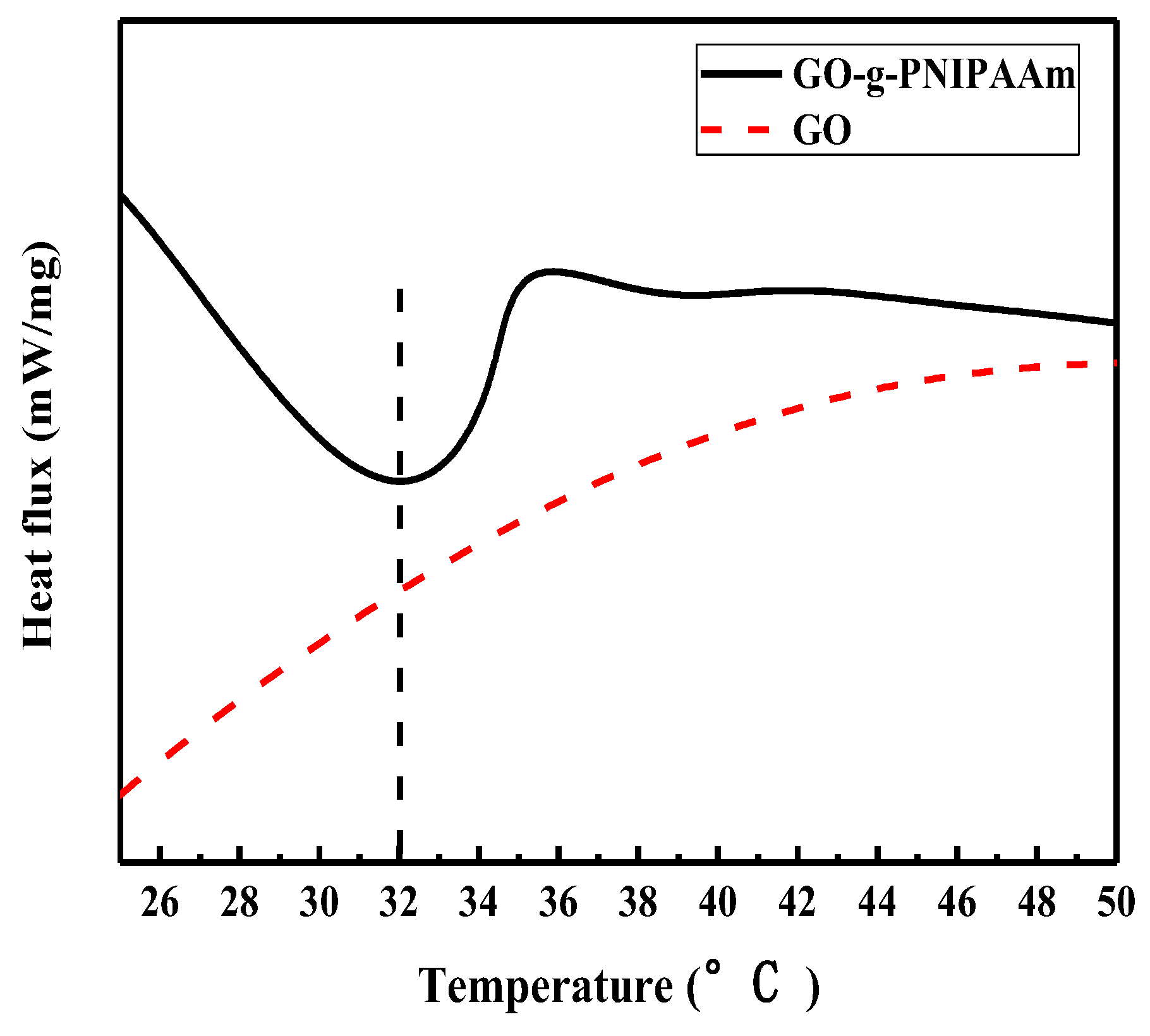

3.1. Characterizations of GO-g-PNIPAAm

3.2. Characterizations of Membrane Structures

3.3. Surface Analysis of the PVDF/GO-g-PNIPAAm Membrane by XPS

3.4. Membrane Hydrophilicity Analysis

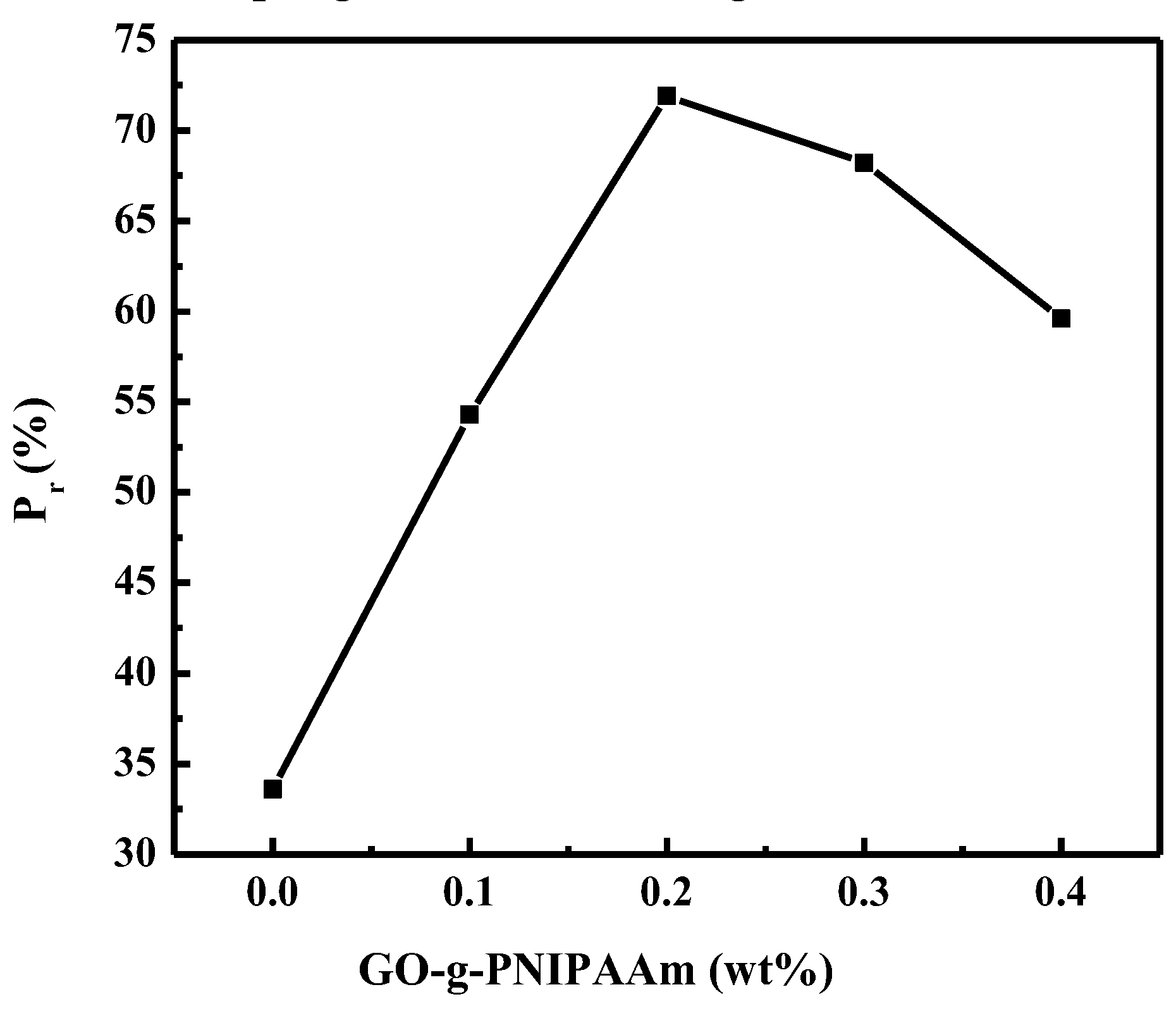

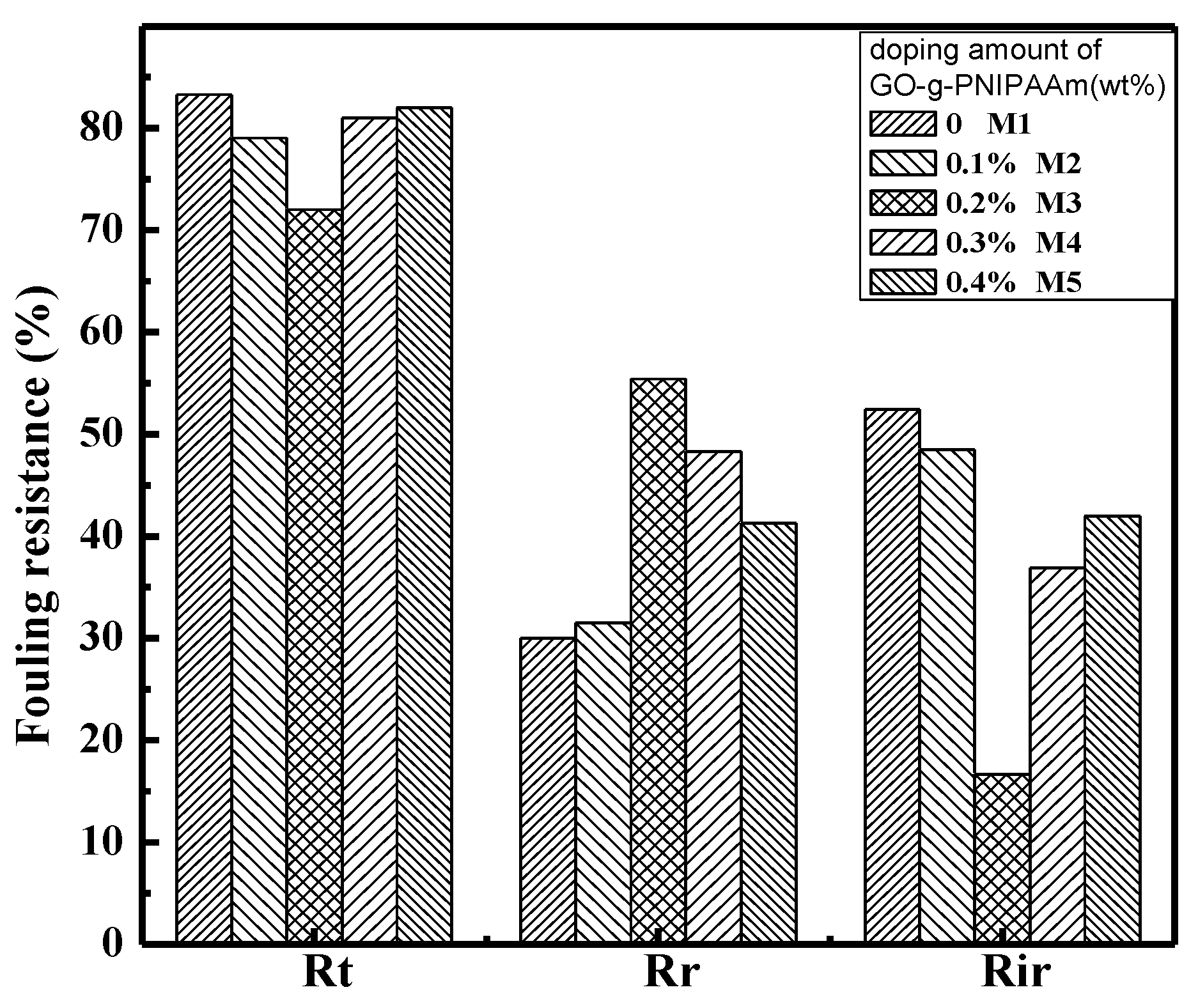

3.5. Permeability of Membranes

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hou, D.Y.; Wang, J.; Qu, D.; Luan, Z.K.; Ren, X.J. Fabrication and characterization of hydrophobic PVDF hollow fiber membranes for desalination through direct contact membrane distillation. Sep. Purif. Technol. 2009, 69, 78–86. [Google Scholar] [CrossRef] [Green Version]

- Li, J.H.; Xu, Y.Y.; Zhu, L.P.; Wang, J.H.; Du, C.H. Fabrication and characterization of a novel TiO2 nanoparticle self-assembly membrane with improved fouling resistance. J. Membr. Sci. 2009, 326, 659–666. [Google Scholar] [CrossRef]

- Hu, K.; Dickson, J.M. Development and characterization of poly(vinylidene fluoride)-poly (acrylic acid) pore-filled pH-sensitive membranes. J. Membr. Sci. 2007, 301, 19–28. [Google Scholar] [CrossRef]

- Hashim, N.A.; Liu, F.; Li, K. A simplified method for preparation of hydrophilic PVDF membranes from an amphiphilic graft copolymer. J. Membr. Sci. 2009, 345, 134–141. [Google Scholar] [CrossRef]

- Yu, J.Z.; Zhu, L.P.; Zhu, B.K.; Xu, Y.Y. Poly(N-isopropylacrylamide) grafted poly(vinylidene fluoride) copolymers for temperature-sensitive membranes. J. Membr. Sci. 2011, 366, 176–183. [Google Scholar] [CrossRef]

- Li, J.H.; Miao, J.; Shao, X.S.; Xu, Y.Y.; Zhang, Q.Q. Surface modification of PVDF porous membranes. Chin. J. Polym. Sci. 2013, 31, 994–1001. [Google Scholar] [CrossRef]

- Li, J.F.; Xu, Z.L.; Yang, H.; Yu, L.Y.; Liu, M. Effect of TiO2 nanoparticles on the surface morphology and performance of microporous PES membrane. Appl Surf. Sci. 2009, 255, 4725–4732. [Google Scholar] [CrossRef]

- Wang, Q.Q.; Wang, X.T.; Wang, Z.H.; Huang, J.; Wang, Y. PVDF membranes with simultaneously enhanced permeability and selectivity by breaking the tradeoff effect via atomic layer deposition of TiO2. J. Membr. Sci. 2013, 442, 57–64. [Google Scholar] [CrossRef]

- Liu, F.; Abed, M.R.M.; Li, K. Preparation and characterization of poly(vinylidene fluoride) (PVDF) based ultrafiltration membranes using nano gamma-Al2O3. J. Membr. Sci. 2011, 366, 97–103. [Google Scholar] [CrossRef]

- Yu, L.Y.; Xu, Z.L.; Shen, H.M.; Yang, H. Preparation and characterization of PVDF-SiO2 composite hollow fiber UF membrane by sol-gel method. J. Membr. Sci. 2009, 337, 257–265. [Google Scholar] [CrossRef]

- Xu, Z.W.; Zhang, J.G.; Shan, M.J.; Li, Y.L.; Li, B.D.; Niu, J.R.; Zhou, B.M.; Qian, X.M. Organosilane-functionalized graphene oxide for enhanced antifouling and mechanical properties of polyvinylidene fluoride ultrafiltration membranes. J. Membr. Sci. 2014, 458, 1–13. [Google Scholar] [CrossRef]

- Zhao, C.Q.; Xu, X.C.; Chen, J.; Yang, F.L. Optimization of preparation conditions of poly(vinylidene fluoride)/graphene oxide microfiltration membranes by the Taguchi experimental design. Desalination 2014, 334, 17–22. [Google Scholar] [CrossRef]

- Zinadini, S.; Zinatizadeh, A.A.; Rahimi, M.; Vatanpour, V.; Zangeneh, H. Preparation of a novel antifouling mixed matrix PES membrane by embedding graphene oxide nanoplates. J. Membr. Sci. 2014, 453, 292–301. [Google Scholar] [CrossRef]

- Subianto, S.; Pica, M.; Casciola, M.; Cojocaru, P.; Merlo, L.; Hards, G.; Jones, D.J. Physical and chemical modification routes leading to improved mechanical properties of perfluorosulfonic acid membranes for PEM fuel cells. J. Power Sources 2013, 233, 216–230. [Google Scholar] [CrossRef]

- Lv, W.P.; Qi, J.J.; Feng, W.Q.; Zhang, G.L.; Zhang, F.B.; Fan, X.B. Functionalization of carbon and gold nanomaterials using PNIPAAm grafted dextran: A general route towards robust and smart nanomaterials. J. Mater. Chem. 2012, 22, 11290–11296. [Google Scholar] [CrossRef]

- Hirata, I.; Okazaki, M.; Iwata, H. Simple method for preparation of ultra-thin poly (N-isopropylacrylamide) hydrogel layers and characterization of their thermo-responsive properties. Polymer 2004, 45, 5569–5578. [Google Scholar] [CrossRef]

- Li, Y.; Chu, L.Y.; Zhu, J.H.; Wang, H.D.; Xia, S.L.; Chen, W.M. Thermoresponsive gating characteristics of Poly(N-isopropylacrylamide)-grafted porous poly(vinylidene fluoride) membranes. Ind. Eng. Chem. Res. 2004, 43, 2643–2649. [Google Scholar] [CrossRef]

- Qu, J.B.; Chu, L.Y.; Yang, M.; Xie, R.; Hu, L.; Chen, W.M. A pH-responsive gating membrane system with pumping effects for improved controlled release. Adv. Funct. Mater. 2006, 16, 1865–1872. [Google Scholar] [CrossRef]

- Klaikherd, A.; Nagamani, C.; Thayumanavan, S. Multi-Stimuli Sensitive Amphiphilic Block Copolymer Assemblies. J. Am. Chem. Soc. 2009, 131, 4830–4838. [Google Scholar] [CrossRef] [Green Version]

- Wan, T.; Xu, M.; Chen, L.Y.; Wu, D.Q.; Cheng, W.Z.; Li, R.X.; Zou, C.Z. Synthesis and properties of a dual responsive hydrogel by inverse microemulsion polymerization. J. Chem. Sci. 2014, 126, 1623–1627. [Google Scholar] [CrossRef]

- Hervault, A.; Dunn, A.E.; Lim, M.; Boyer, C.; Mott, D.; Maenosono, S.; Thanh, N.T.K. Doxorubicin loaded dual pH- and thermo-responsive magnetic nanocarrier for combined magnetic hyperthermia and targeted controlled drug delivery applications. Nanoscale 2016, 8, 12152–12161. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Darvishmanesh, S.; Qian, X.H.; Wickramasinghe, S.R. Responsive membranes for advanced separations. Curr. Opin. Chem. Eng. 2015, 8, 98–104. [Google Scholar] [CrossRef]

- Cai, J.J.; Zhou, S.Y.; Zhao, Y.J.; Xue, A.L.; Zhang, Y.; Li, M.S.; Xing, W.H. Enhanced hydrophilicity of a thermo-responsive PVDF/palygorskite-g-PNIPAAM hybrid ultrafiltration membrane via surface segregation induced by temperature. RSC Adv. 2016, 6, 62186–62192. [Google Scholar] [CrossRef]

- Goh, P.S.; Ng, B.C.; Lau, W.J.; Ismail, A.F. Inorganic Nanomaterials in Polymeric Ultrafiltration Membranes for Water Treatment. Sep. Purif. Rev. 2015, 44, 216–249. [Google Scholar] [CrossRef]

- Vasile, C.; Nita, L.E. Novel multi-stimuli responsive sodium alginate-grafted-poly(N-isopropylacrylamide) copolymers: II. Dilute solution properties. Carbohyd. Polym. 2011, 86, 77–84. [Google Scholar] [CrossRef]

- Du, H.B.; Wickramasinghe, R.; Qian, X.H. Effects of Salt on the Lower Critical Solution Temperature of Poly (N-Isopropylacrylamide). J. Phys. Chem. B 2010, 114, 16594–16604. [Google Scholar] [CrossRef]

- Yang, H.R.; Esteves, A.C.C.; Zhu, H.J.; Wang, D.J.; Xin, J.H. In-situ study of the structure and dynamics of thermo-responsive PNIPAAm grafted on a cotton fabric. Polymer 2012, 53, 3577–3586. [Google Scholar] [CrossRef]

- Wu, C.J.; Xie, R.; Wei, H.B.; Xu, T.T.; Liu, Z.; Wang, W.; Ju, X.J.; Chu, L.Y. Fabrication of a thermo-responsive membrane with cross-linked smart gates via a ’grafting-to’ method. RSC Adv. 2016, 6, 45428–45433. [Google Scholar] [CrossRef]

- Zhou, Q.; Li, J.H.; Yan, B.F.; Wu, D.; Zhang, Q.Q. Thermo-responsive and antifouling PVDF nanocomposited membranes based on PNIPAAm modified TiO2 nanoparticles. Chin. J. Polym. Sci. 2014, 32, 892–905. [Google Scholar] [CrossRef]

- Mukherjee, R.; Bhunia, P.; De, S. Impact of graphene oxide on removal of heavy metals using mixed matrix membrane. Chem. Eng. J. 2016, 292, 284–297. [Google Scholar] [CrossRef]

- Hua, D.; Rai, R.K.; Zhang, Y.; Chung, T.S. Aldehyde functionalized graphene oxide frameworks as robust membrane materials for pervaporative alcohol dehydration. Chem. Eng. Sci. 2017, 161, 341–349. [Google Scholar] [CrossRef]

- Wang, Z.H.; Yu, H.R.; Xia, J.F.; Zhang, F.F.; Li, F.; Xia, Y.Z.; Li, Y.H. Novel GO-blended PVDF ultrafiltration membranes. Desalination 2012, 299, 50–54. [Google Scholar] [CrossRef]

- Ganesh, B.M.; Isloor, A.M.; Ismail, A.F. Enhanced hydrophilicity and salt rejection study of graphene oxide-polysulfone mixed matrix membrane. Desalination 2013, 313, 199–207. [Google Scholar] [CrossRef]

- Hwang, T.; Oh, J.S.; Yim, W.; Nam, J.D.; Bae, C.; Kim, H.I.; Kim, K.J. Ultrafiltration using graphene oxide surface-embedded polysulfone membranes. Sep. Purif. Technol. 2016, 166, 41–47. [Google Scholar] [CrossRef] [Green Version]

- Ma, J.; Guo, X.Y.; Ying, Y.P.; Liu, D.H.; Zhong, C.L. Composite ultrafiltration membrane tailored by MOF@GO with highly improved water purification performance. Chem. Eng. J. 2017, 313, 890–898. [Google Scholar] [CrossRef]

- Maity, N.; Kuila, A.; Nandi, A.K. Deciphering the Effect of Polymer-Assisted Doping on the Optoelectronic Properties of Block Copolymer-Anchored Graphene Oxide. Langmuir 2017, 33, 1460–1470. [Google Scholar] [CrossRef]

- Lee, S.H.; Dreyer, D.R.; An, J.H.; Velamakanni, A.; Piner, R.D.; Park, S.; Zhu, Y.W.; Kim, S.O.; Bielawski, C.W.; Ruoff, R.S. Polymer Brushes via Controlled, Surface-Initiated Atom Transfer Radical Polymerization (ATRP) from Graphene Oxide. Macromol. Rapid Commun. 2010, 31, 281–288. [Google Scholar] [CrossRef]

- Cao, Y.W.; Lai, Z.L.; Feng, J.C.; Wu, P.Y. Graphene oxide sheets covalently functionalized with block copolymers via click chemistry as reinforcing fillers. J. Mater. Chem. 2011, 21, 9271–9278. [Google Scholar] [CrossRef]

- Yang, H.; Paek, K.; Kim, B.J. Efficient Temperature Sensing Platform Based on Fluorescent Block Copolymer-Functionalized Graphene Oxide. Nanoscale 2013, 5, 5720–5724. [Google Scholar] [CrossRef] [PubMed]

- Kavitha, T.; Kang, I.K.; Park, S.Y. Poly(acrylic acid)-Grafted Graphene Oxide as an Intracellular Protein Carrier. Langmuir 2014, 30, 402–409. [Google Scholar] [CrossRef]

- Yang, H.F.; Li, F.H.; Shan, C.S.; Han, D.X.; Zhang, Q.X.; Niu, L.; Ivaska, A. Covalent functionalization of chemically converted graphene sheets via silane and its reinforcement. J. Mater. Chem. 2009, 19, 4632–4638. [Google Scholar] [CrossRef]

- Marcano, D.C.; Kosynkin, D.V.; Berlin, J.M.; Sinitskii, A.; Sun, Z.Z.; Slesarev, A.; Alemany, L.B.; Lu, W.; Tour, J.M. Improved Synthesis of Graphene Oxide. ACS Nano 2010, 4, 4806–4814. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, L.; Jin, Y.; Sun, L.; Chen, F.; Fan, P.; Zhong, M.; Yang, J. Graphene oxide functionalized by poly(ionic liquid)s for carbon dioxide capture. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Safarpour, M.; Khataee, A.; Vatanpour, V. Effect of reduced graphene oxide/TiO2 nanocomposite with different molar ratios on the performance of PVDF ultrafiltration membranes. Sep. Purif. Technol. 2015, 140, 32–42. [Google Scholar] [CrossRef]

| Membranes | GO-g-PNIPAAm (wt %) | PVDF (wt %) | PVP (wt %) | DMAC (wt %) |

|---|---|---|---|---|

| M1 | 0 | 20 | 3 | 77.0 |

| M2 | 0.1 | 20 | 3 | 76.9 |

| M3 | 0.2 | 20 | 3 | 76.8 |

| M4 | 0.3 | 20 | 3 | 76.7 |

| M5 | 0.4 | 20 | 3 | 76.6 |

| Element | C1s (%) | O1s (%) | N1s (%) | Cl2p (%) | |

|---|---|---|---|---|---|

| Samples | |||||

| GO | 73.18 | 26.10 | 0.64 | 0.07 | |

| GO-2 | 76.42 | 19.30 | 2.17 | 2.11 | |

| GO-g-PNIPAAm | 72.56 | 16.17 | 7.13 | 0.23 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, X.; Ji, Y.; Yu, G.; Zhai, Y. Preparation and Properties of Polyvinylidene Fluoride Nanocomposited Membranes based on Poly(N-Isopropylacrylamide) Modified Graphene Oxide Nanosheets. Polymers 2019, 11, 473. https://doi.org/10.3390/polym11030473

Meng X, Ji Y, Yu G, Zhai Y. Preparation and Properties of Polyvinylidene Fluoride Nanocomposited Membranes based on Poly(N-Isopropylacrylamide) Modified Graphene Oxide Nanosheets. Polymers. 2019; 11(3):473. https://doi.org/10.3390/polym11030473

Chicago/Turabian StyleMeng, Xiangli, Yuan Ji, Genhua Yu, and Yujia Zhai. 2019. "Preparation and Properties of Polyvinylidene Fluoride Nanocomposited Membranes based on Poly(N-Isopropylacrylamide) Modified Graphene Oxide Nanosheets" Polymers 11, no. 3: 473. https://doi.org/10.3390/polym11030473

APA StyleMeng, X., Ji, Y., Yu, G., & Zhai, Y. (2019). Preparation and Properties of Polyvinylidene Fluoride Nanocomposited Membranes based on Poly(N-Isopropylacrylamide) Modified Graphene Oxide Nanosheets. Polymers, 11(3), 473. https://doi.org/10.3390/polym11030473