Polymer-Based Device Fabrication and Applications Using Direct Laser Writing Technology

Abstract

:1. Introduction

2. Polymer-Based Optical Devices Fabricated by DLW

2.1. CYTOP POFBG by DLW

2.2. Polymer-Based Micro-Resonators by DLW

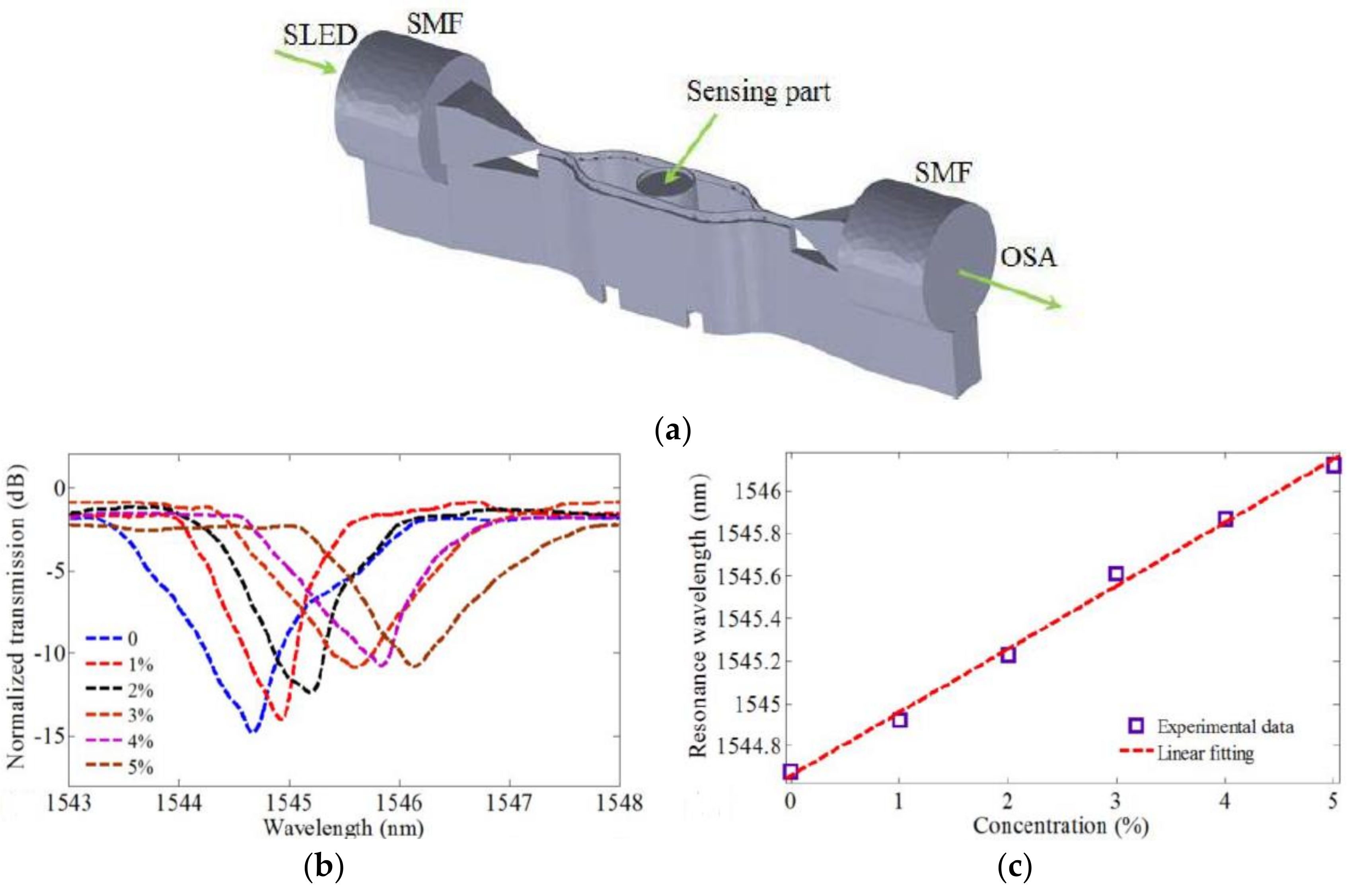

2.2.1. Micro-Resonators for Sensors

2.2.2. Micro-Resonators for Laser

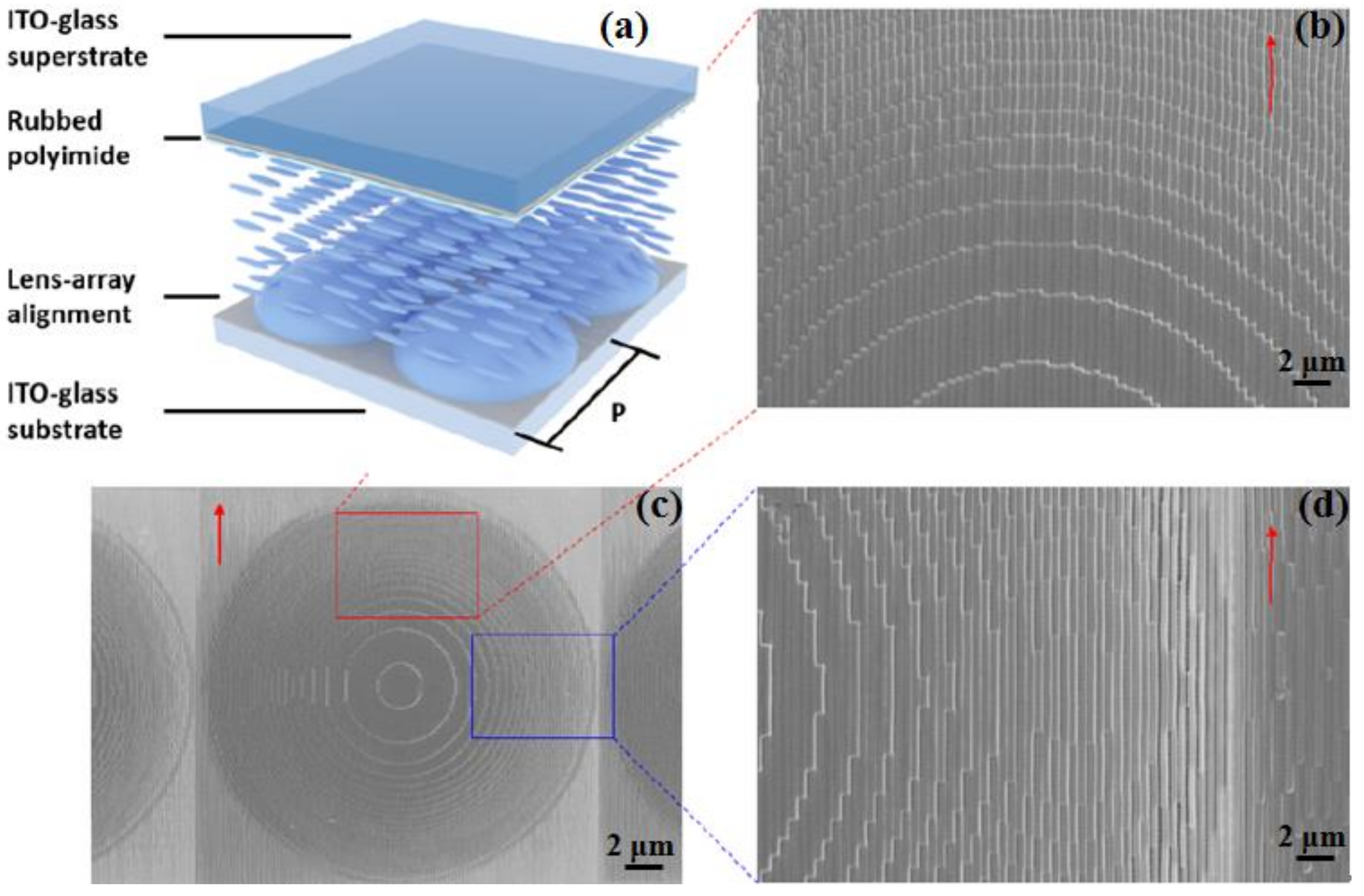

2.3. Polymer-Based Microlenses by DLW

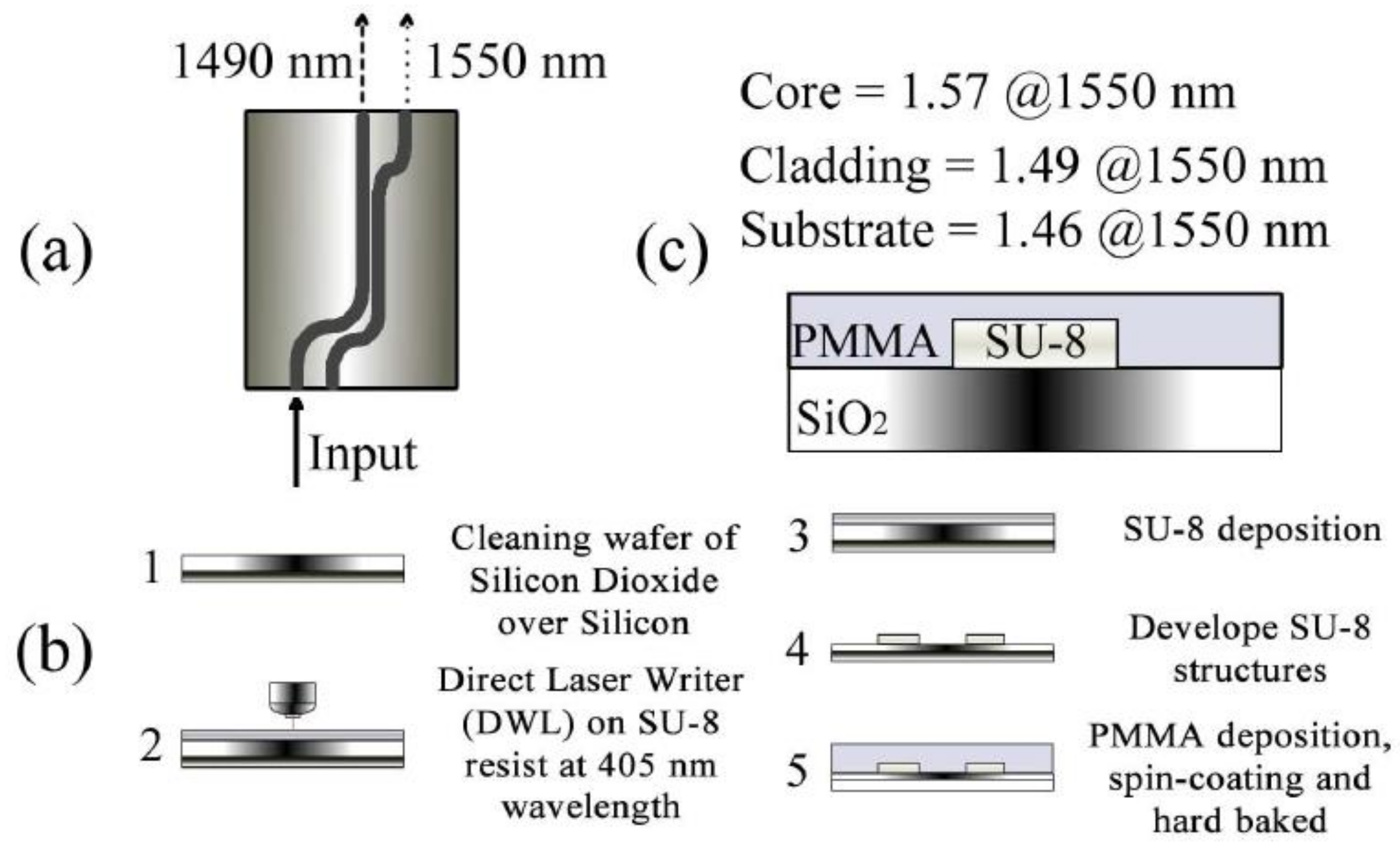

2.4. Polymer-Based Optical Waveguide Couplers by DLW

3. Polymer-Based Electro/Magnetic Devices by DLW

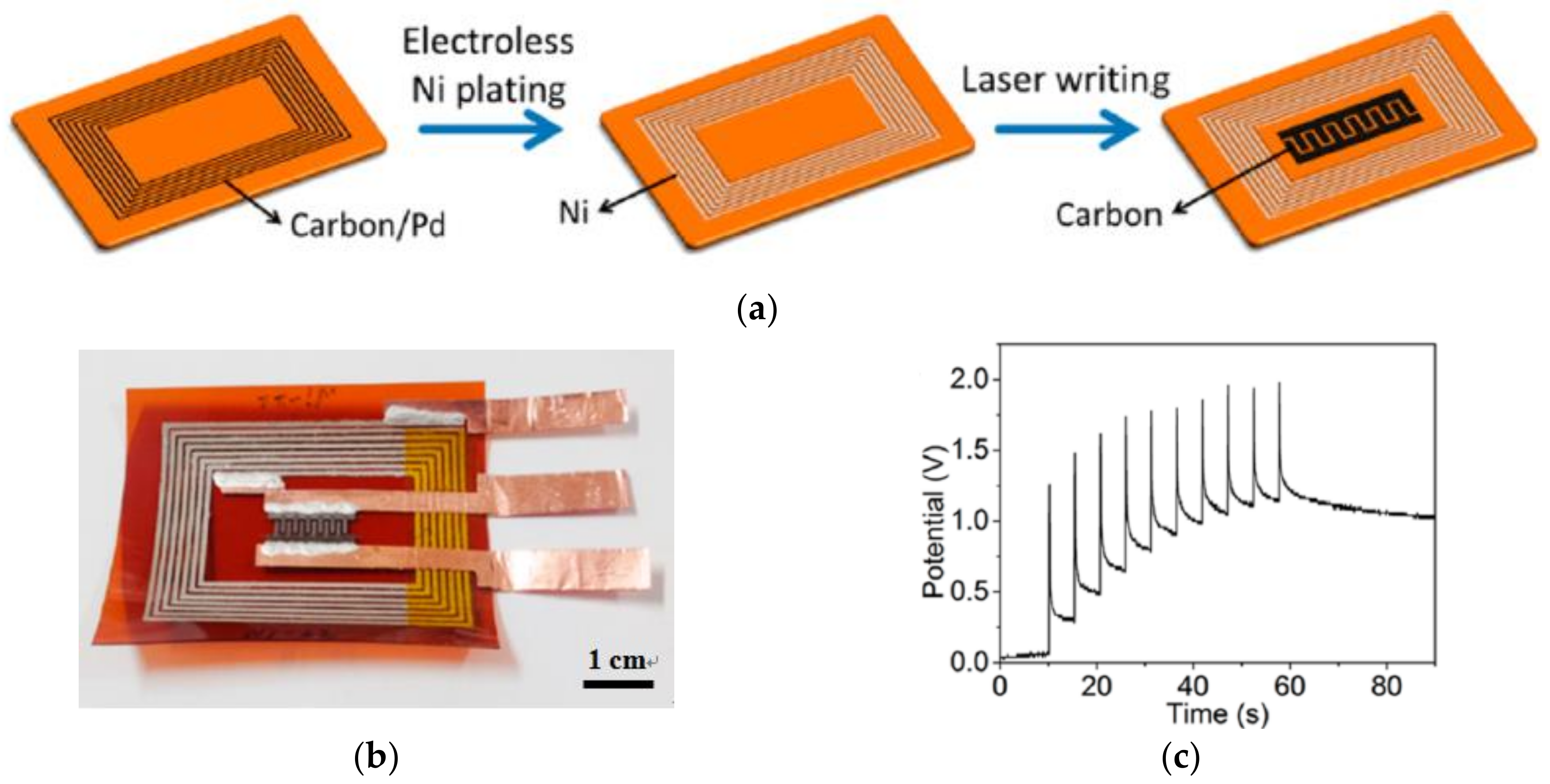

3.1. Electronic Circuits by DLW

3.2. Photonics Integrated Circuits by DLW

3.3. Micro-Supercapacitors by DLW

3.4. Electro-Optic Waveguide Modulator by DLW

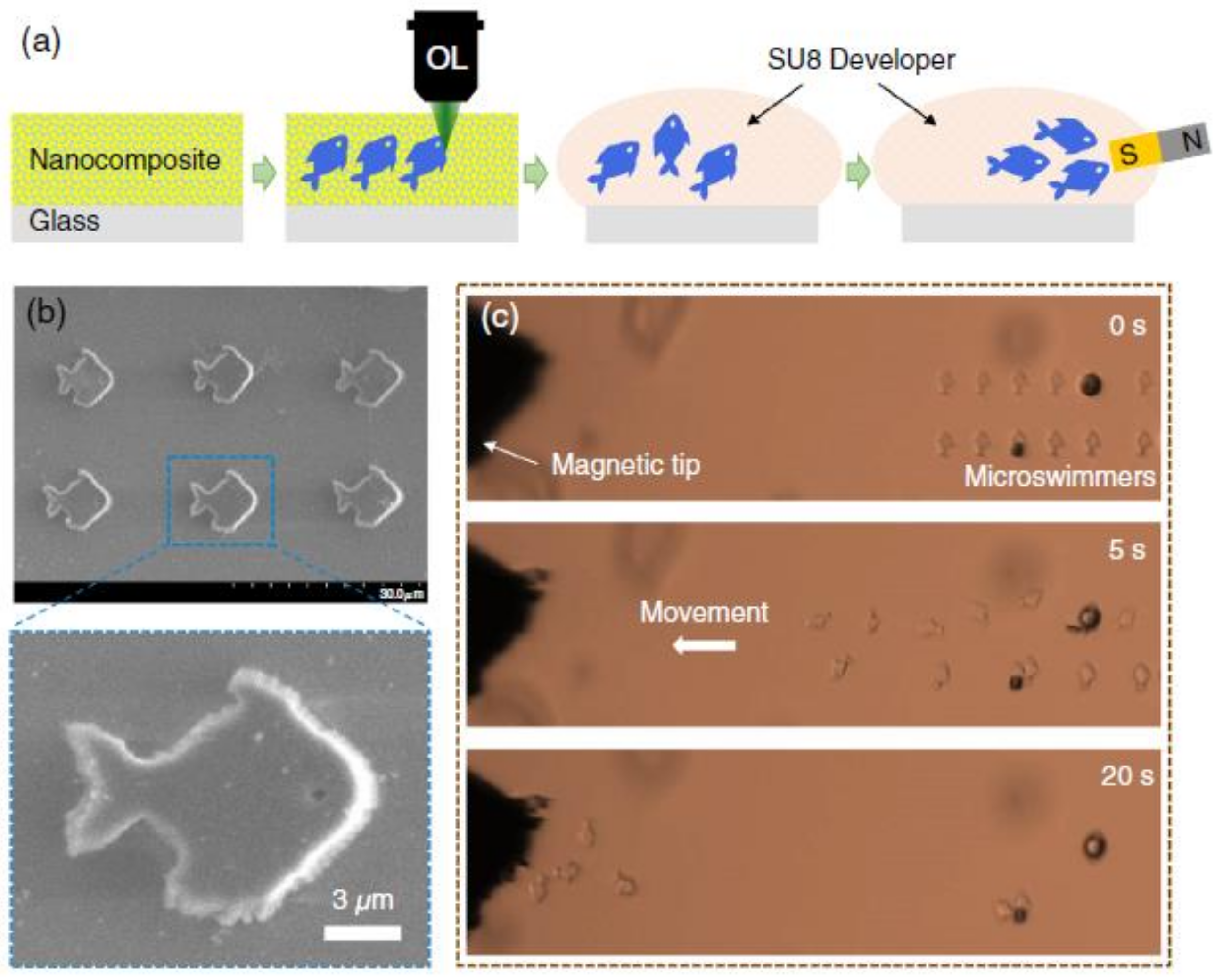

3.5. Magnetophotonic Microdevices by DLW

4. Polymer-Based Bio-Devices by DLW

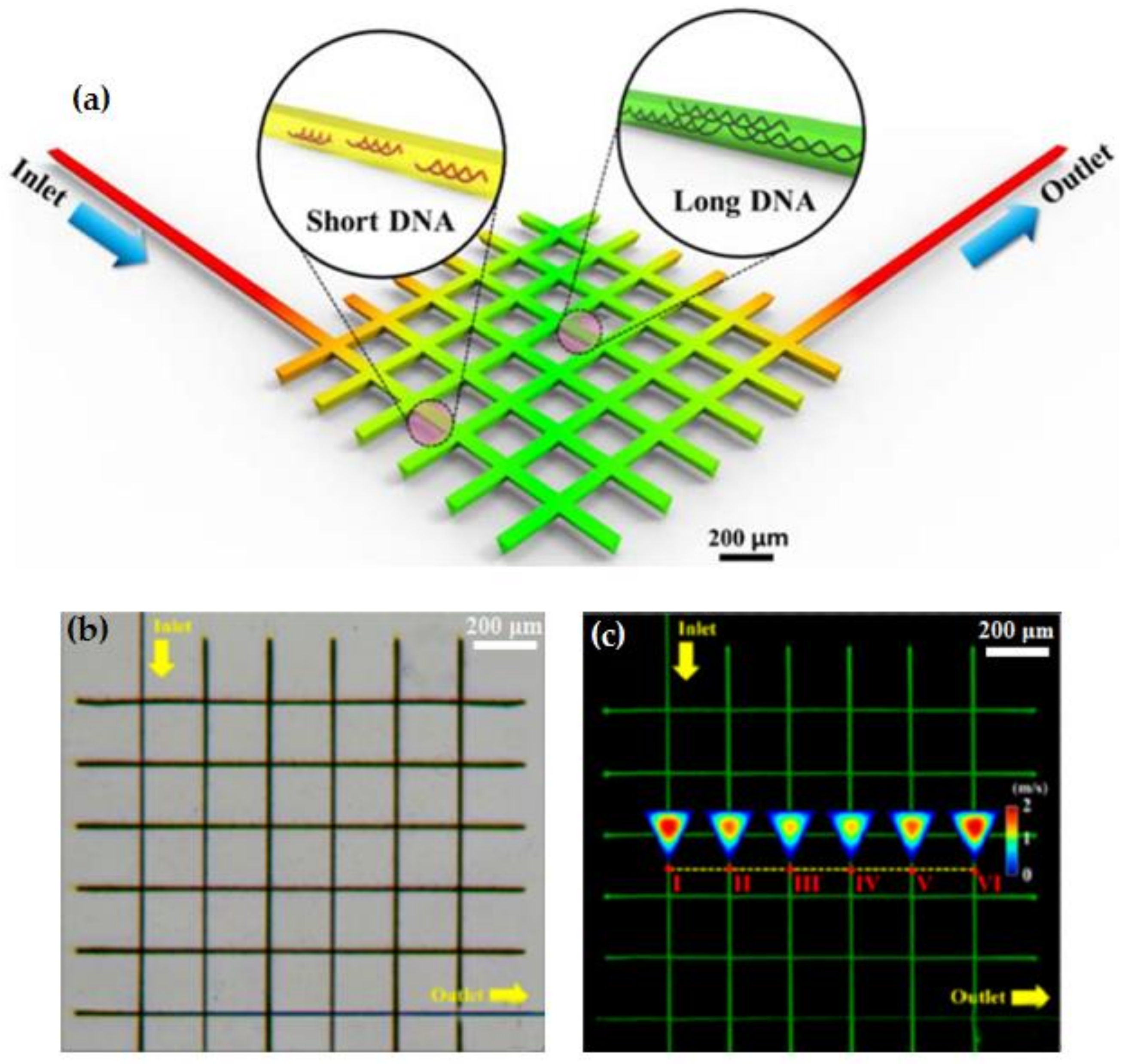

4.1. Microfluidics by DLW

4.2. Micro-Network by DLW

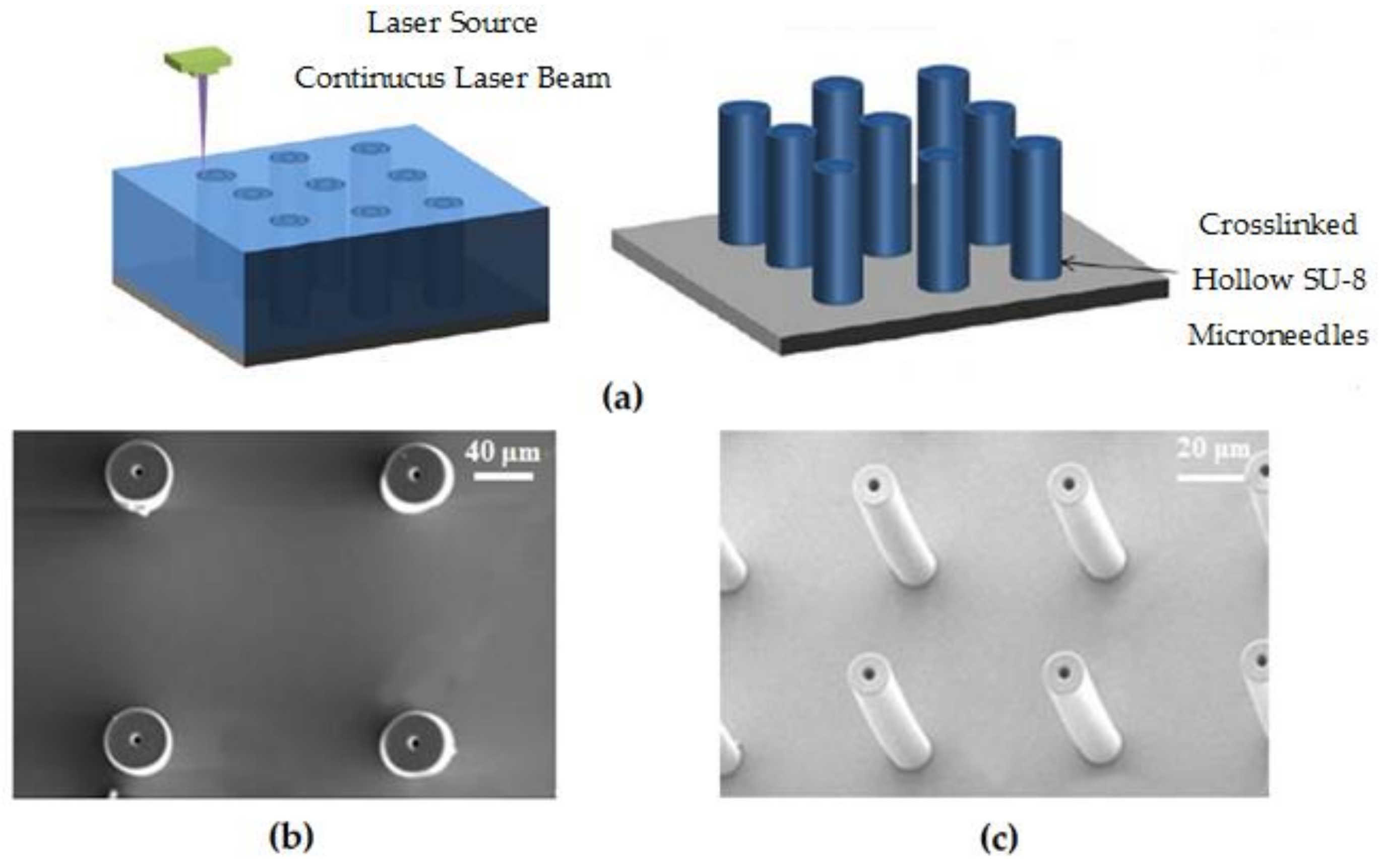

4.3. Microneedles by DLW

4.4. Bionic Actuation by DLW

5. Special Materials for DLW

6. Conclusions and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Jandura, D.; Pudis, D.; Kuzma, A. Fabrication technology for PDMS ridge waveguide using DLW. Optik Int. J. Light Electron Opt. 2016, 127, 2848–2851. [Google Scholar] [CrossRef]

- Park, R.; Kim, H.; Lone, S.; Jeon, S.; Kwon, Y.W.; Shin, B.; Hong, S.W. One-step laser patterned highly uniform reduced graphene oxide thin films for circuit-enabled tattoo and flexible humidity sensor application. Sensors 2018, 18, 1857. [Google Scholar] [CrossRef] [PubMed]

- Xia, H.; Wang, J.; Tian, Y.; Chen, Q.D.; Du, X.B.; Zhang, Y.L.; He, Y.; Sun, H.B. Ferrofluids for fabrication of remotely controllable micro-nanomachines by two-photon polymerization. Adv. Mater. 2010, 22, 3204–3207. [Google Scholar] [CrossRef] [PubMed]

- Wollhofen, R.; Axmann, M.; Freudenthaler, P.; Gabriel, C.; Röhrl, C.; Stangl, H.; Klar, T.A.; Jacak, J. Multiphoton-Polymerized 3D Protein Assay. ACS Appl. Mater. Interfaces 2018, 10, 1474–1479. [Google Scholar] [CrossRef]

- Ma, H.; Jen, A.K.-Y.; Dalton, L.R. Polymer-based optical waveguides: Materials, processing, and devices. Adv. Mater. 2002, 14, 1339–1365. [Google Scholar] [CrossRef]

- Wei, H.; Amrithanath, A.K.; Krishnaswamy, S. Three-dimensional printed polymer waveguides for whispering gallery mode sensors. IEEE Photonics Technol. Lett. 2018, 30, 451–454. [Google Scholar] [CrossRef]

- Rezem, M.; Kelb, C.; Guenther, A.; Rahlves, M.; Reithmeier, E.; Roth, B. Low-cost fabrication of optical waveguides, interconnects and sensing structures on all-polymer-based thin foils. In Proceedings of the Conference on Smart Photonic and Optoelectronic Integrated Circuits XVIII, San Francisco, CA, USA, 16–18 February 2016. [Google Scholar]

- Das, A.K. Laser direct writing polymeric single-mode waveguide devices with a rib structure. Appl. Opt. 2003, 42, 1236–1243. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, H.H.D.; Hollenbach, U.; Ostrzinski, U.; Pfeiffer, K.; Hengsbach, S.; Mohr, J. Freeform three-dimensional embedded polymer waveguides enabled by external-diffusion assisted two-photon lithography. Appl. Opt. 2016, 55, 1906–1912. [Google Scholar] [CrossRef] [PubMed]

- David, J.W. Fibre bragg grating sensors in polymer optical fibres. Meas. Sci. Technol. 2015, 26, 092004. [Google Scholar]

- Cano-Garcia, M.; Elmogi, A.; Mattelin, M.-A.; Missinne, J.; Geday, M.A.; Oton, J.M.; Van Steenberge, G.; Quintana, X. All-organic switching polarizer based on polymer waveguides and liquid crystals. Opt. Express 2018, 26, 9584–9594. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.-T.; Li, Y.-C.; Yu, J.-H.; Wang, C.Y.; Tseng, C.-W.; Jau, H.-C.; Chen, Y.-J.; Lin, T.-H. Electrically tunable high Q-factor micro-ring resonator based on blue phase liquid crystal cladding. Opt. Express 2014, 22, 17776–17781. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Chung, S.E.; Choi, S.-E.; Lee, H.; Kim, J.; Kwon, S. Programming magnetic anisotropy in polymeric microactuators. Nat. Mater. 2011, 10, 747–752. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alfadhel, A.; Li, B.; Kosel, J. Magnetic polymer nanocomposites for sensing applications. In Proceedings of the 2014 IEEE Sensors, Valencia, Spain, 2–5 November 2014. [Google Scholar]

- Ding, R.; Baehr-Jones, T.; Liu, Y.; Bojko, R.; Witzens, J.; Huang, S.; Luo, J.; Benight, S.; Sullivan, P.; Fedeli, J.-M.; et al. Demonstration of a low VπL modulator with GHz bandwidth based on electro-optic polymer-clad silicon slot waveguides. Opt. Express 2010, 18, 15618–15623. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Chung, C.J.; Hosseini, A.; Subbaraman, H.; Luo, J.; Jen, A.K.-Y.; Nelson, R.L.; Lee, C.Y.-C.; Chen, R.T. High performance optical modulator based on electro-optic polymer filled silicon slot photonic crystal waveguide. J. Lightwave Technol. 2016, 34, 2941–2951. [Google Scholar] [CrossRef]

- Wen, F.; Hao, C.; Xiang, J.; Wang, L.; Hou, H.; Su, Z.; Hu, W.; Liu, Z. Enhanced laser scribed flexible graphene-based micro-supercapacitor performance with reduction of carbon nanotubes diameter. Carbon 2014, 75, 236–243. [Google Scholar] [CrossRef]

- Farshchian, B.; Gatabi, J.R.; Bernick, S.M.; Park, S.; Lee, G.H.; Droopad, R.; Kim, N. Laser-induced superhydrophobic grid patterns on PDMS for droplet arrays formation. Appl. Surf. Sci. 2016, 396, 359–365. [Google Scholar] [CrossRef]

- Selimovic, S.; Piraino, F.; Bae, H.; Rasponi, M.; Redaelli, A.; Khademhosseini, A. Microfabricated polyester conical microwells for cell culture applications. Lab Chip 2011, 11, 2325–2332. [Google Scholar] [CrossRef]

- Mishra, R.; Maiti, T.K.; Bhattacharyya, T.K. Design and scalable fabrication of hollow SU-8 microneedles for transdermal drug delivery. IEEE Sens. J. 2018, 18, 5635–5644. [Google Scholar] [CrossRef]

- Ki-Hun, J.; Jaeyoun, K.; Lee, L.P. Biologically inspired artificial compound eyes. Science 2006, 312, 557–561. [Google Scholar]

- Gale, M.T.; Knop, K. The fabrication of fine lens arrays by laser beam writing. Opt. Acta Int. J. Opt. 1983, 398, 347–353. [Google Scholar]

- Koronkevich, V.P.; Kiriyanov, V.P.; Kokoulin, F.I.; Palchikova, I.G.; Poleshchuk, A.G.; Sedukhin, A.G.; Churin, E.G.; Shcherbachenko, A.M.; Yurlov, Y.I. Fabrication of kinoform optical-elements. Optik 1984, 67, 257–266. [Google Scholar]

- Rensch, C.; Hell, S.; Schickfus, M.V.; Hunklinger, S. Laser scanner for direct writing lithography. Appl. Opt. 1989, 28, 3754–3758. [Google Scholar] [CrossRef] [PubMed]

- Stager, B.; Gale, M.T.; Rossi, M. Replicated micro-optics for automotive applications. In Proceedings of the Conference on Photonics in the Automobile, Geneva, Switzerland, 29 November–1 December 2004. [Google Scholar]

- Behrmann, G.P.; Duignan, M.T. Excimer laser micromachining for rapid fabrication of diffractive optical elements. Appl. Opt. 1997, 36, 4666–4674. [Google Scholar] [CrossRef]

- LaFratta, C.N.; Fourkas, J.T.; Baldacchini, T.; Farrer, R.A. Multiphoton fabrication. Angew. Chem. Int. Ed. 2007, 46, 6238–6258. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Chen, Q.D.; Xia, H.; Sun, H.B. Designable 3D nanofabrication by femtosecond laser direct writing. Nano Today 2010, 5, 435–448. [Google Scholar] [CrossRef]

- Tanaka, T.; Sun, H.B.; Kawata, S. Rapid sub-diffraction-limit laser micro/nanoprocessing in a threshold material system. Appl. Phys. Lett. 2002, 80, 312–314. [Google Scholar] [CrossRef]

- Waller, E.H.; Von Freymann, G. Spatio-temporal proximity characteristics in 3D mu-printing via multi-photon absorption. Polymers 2016, 8, 297. [Google Scholar] [CrossRef]

- Klar, T.A.; Wollhofen, R.; Jacak, J. Sub-Abbe resolution: From STED microscopy to STED lithography. Phys. Scr. 2014, T162, 014049. [Google Scholar] [CrossRef]

- Fischer, J.; Von Freymann, G.; Wegener, M. The materials challenge in diffraction-unlimited direct-laser-writing optical lithography. Adv. Mater. 2010, 22, 3578–3582. [Google Scholar] [CrossRef]

- Gratton, S.E.A.; Williams, S.S.; Napier, M.E.; Pohlhaus, P.D.; Zhou, Z.; Wiles, K.B.; Maynor, B.W.; Shen, C.; Olafsen, T.; Samulski, E.T. The pursuit of a scalable nanofabrication platform for use in material and life science applications. Acc. Chem. Res. 2008, 41, 1685–1695. [Google Scholar] [CrossRef]

- Gates, B.; Xu, Q.; Stewart, M.; Ryan, D.; Willson, C.; Whitesides, G. New approaches to nanofabrication: Molding, printing, and other techniques. Chem. Rev. 2005, 105, 1171–1196. [Google Scholar] [CrossRef]

- Malinauskas, M.; Zukauskas, A.; Bickauskaite, G.; Gadonas, R.; Juodkazis, S. Mechanisms of three-dimensional structuring of photo-polymers by tightly focussed femtosecond laser pulses. Opt. Express 2010, 18, 10209–10221. [Google Scholar] [CrossRef] [PubMed]

- Kaehr, B.; Shear, J.B. Mask-directed multiphoton lithography. J. Am. Chem. Soc. 2007, 129, 1904–1905. [Google Scholar] [CrossRef] [PubMed]

- Tiawa, K.S.; Goha, S.W.; Hongb, M.; Wangb, Z.; Lanb, B.; Teoh, S.H. Laser surface modification of poly(ε-caprolactone) (PCL) membrane for tissue engineering applications. Biomaterials 2005, 26, 763–769. [Google Scholar] [CrossRef] [PubMed]

- Yong, J.; Huo, J.; Yang, Q.; Chen, F.; Fang, Y.; Wu, X.; Liu, L.; Lu, X.; Zhang, J.; Hou, X. Femtosecond laser direct writing of porous network microstructures for fabricating super-slippery surfaces with excellent liquid repellence and anti-cell proliferation. Adv. Mater. Interfaces 2018, 5, 1701479. [Google Scholar] [CrossRef]

- Hsieh, Y.K.; Chen, S.C.; Huang, W.L.; Hsu, K.P.; Gorday, K.; Wang, T.; Wang, J. Direct Micromachining of Microfluidic Channels on Biodegradable Materials Using Laser Ablation. Polymers 2017, 9, 242. [Google Scholar] [CrossRef]

- Han, W.; Kong, L.B.; Liu, M.C.; Wang, D.; Li, J.J.; Kang, L. A high performance redox-mediated electrolyte for improving properties of metal oxides based pseudocapacitive materials. Electrochim. Acta 2015, 186, 478–485. [Google Scholar] [CrossRef]

- Vilarinho, D.; Theodosiou, A.; Leitao, C.; Leal-Junior, A.G.; Domingues, M.d.F.; Kalli, K.; Andre, P.; Antunes, P.; Marques, C. POFBG-embedded cork insole for plantar pressure monitoring. Sensors 2017, 17, 2924. [Google Scholar] [CrossRef]

- Tomazio, N.B.; Boni, L.D.; Mendonca, C.R. Low threshold rhodamine-doped whispering gallery mode microlasers fabricated by direct laser writing. Sci. Rep. 2017, 7, 8559. [Google Scholar] [CrossRef]

- Zhan, X.P.; Xu, Y.X.; Xu, H.L.; Huang, Q.L.; Hou, Z.S.; Fang, W.; Chen, Q.D.; Sun, H.B. Toward on-chip unidirectional and single-mode polymer microlaser. J. Lightwave Technol. 2017, 35, 2331–2336. [Google Scholar] [CrossRef]

- Thiel, M.; Fischer, J.; Von Freymann, G.; Wegener, M. Direct laser writing of three-dimensional submicron structures using a continuous-wave laser at 532 nm. Appl. Phys. Lett. 2010, 97, 221102. [Google Scholar] [CrossRef]

- Wang, P.C.; Liu, Y.M.; Chang, C.P.; Liao, Y.Y.; Peng, Y.Y.; Ger, M.D. A laser curable palladium complex ink used for fabrication of copper pattern on polyimide substrate. J. Taiwan Inst. Chem. Eng. 2017, 80, 963–969. [Google Scholar] [CrossRef]

- Katis, I.N.; He, P.J.W.; Eason, R.W.; Sones, C.L. Improved sensitivity and limit-of-detection of lateral flow devices using spatial constrictions of the flow-path. Biosens. Bioelectron. 2018, 113, 95–100. [Google Scholar] [CrossRef] [PubMed]

- Do, M.T.; Nguyen, T.T.N.; Li, Q.; Benisty, H.; Ledoux-Rak, I.; Lai, N.D. Submicrometer 3D structures fabrication enabled by one-photon absorption direct laser writing. Opt. Express 2013, 21, 20964–20973. [Google Scholar] [CrossRef] [PubMed]

- Fan, L.; Zhang, C.; Li, H.; Wang, K.; Feng, X.; Zhao, W.; Wang, W.; Bai, J. Direct CW-laser writing sub-diffraction-limit nanopore array based on the low one-photon absorption of polymer. Rare Met. Mater. Eng. 2018, 47, 75–81. [Google Scholar]

- Malinauskas, M.; Farsari, M.; Piskarskas, A.; Juodkazis, S. Ultrafast laser nanostructuring of photopolymers: A decade of advances. Phys. Rep. 2013, 533, 1–31. [Google Scholar] [CrossRef]

- Kalli, K.; Johnson, I.P.; Urbanczyk, W.; Webb, D.J.; Kalli, K.; Large, M.C.J.; Argyros, A. Multiplexed FBG sensor recorded in multimode microstructured polymer optical fibre. In Proceedings of the Conference on Photonic Crystal Fibers IV, Brussels, Belgium, 14–16 April 2010. [Google Scholar]

- Theodosiou, A.; Lacraz, A.; Stassis, A.; Koutsides, C.; Komodromos, M.; Kalli, K. Plane-by-plane femtosecond laser inscription method for single-peak bragg gratings in multimode CYTOP polymer optical fibre. J. Lightwave Technol. 2017, 35, 5404–5410. [Google Scholar] [CrossRef]

- Yuan, W.; Khan, L.; Webb, D.J.; Kalli, K.; Rasmussen, H.K.; Stefani, A.; Bang, O. Humidity insensitive TOPAS polymer fiber Bragg grating sensor. Opt. Express 2011, 19, 19731–19739. [Google Scholar] [CrossRef]

- Yeniay, A.; Gao, R.; Takayama, K.; Gao, R.; Garito, A.F. Ultra-low-loss polymer waveguides. J. Lightwave Technol. 2004, 22, 154–158. [Google Scholar] [CrossRef]

- Lacraz, A.; Polis, M.; Theodosiou, A.; Koutsides, C.; Kalli, K. Femtosecond laser inscribed bragg gratings in low loss CYTOP polymer optical fiber. IEEE Photonics Technol. Lett. 2015, 27, 693–696. [Google Scholar] [CrossRef]

- Theodosiou, A.; Komodromos, M.; Kalli, K. Carbon cantilever beam health inspection using a polymer fibre bragg grating array. J. Lightwave Technol. 2018, 36, 986–992. [Google Scholar] [CrossRef]

- Theodosiou, A.; Hu, X.; Caucheteur, C.; Kalli, K. Bragg gratings and Fabry-Perot cavities in low-loss multimode CYTOP polymer fibre. IEEE Photonics Technol. Lett. 2018, 30, 857–860. [Google Scholar] [CrossRef]

- Ashkenazi, S.; Chao, C.Y.; Guo, L.J.; O’Donnell, M. Ultrasound detection using polymer microring optical resonator. Appl. Phys. Lett. 2004, 85, 5418–5420. [Google Scholar] [CrossRef]

- Cho, S.-Y.; Jokerst, N.M. A polymer microdisk photonic sensor integrated onto silicon. IEEE Photonics Technol. Lett. 2006, 18, 2096–2098. [Google Scholar] [CrossRef]

- Hanumegowda, N.M.; White, I.M.; Oveys, H.; Fan, X. Label-free protease sensors based on optical microsphere resonators. Sens. Lett. 2005, 3, 315–319. [Google Scholar] [CrossRef]

- Wei, H.; Krishnaswamy, S. Polymer micro-ring resonator integrated with a fiber ring laser for ultrasound detection. Opt. Lett. 2017, 42, 2655–2658. [Google Scholar] [CrossRef]

- Wei, H.; Krishnaswamy, S. Direct laser writing polymer micro-resonators for refractive index sensors. IEEE Photonics Technol. Lett. 2016, 28, 2819–2822. [Google Scholar] [CrossRef]

- Siegle, T.; Remmel, M.; Krämmer, S.; Kalt, H. Split-disk micro-lasers: Tunable whispering gallery mode cavities. APL Photonics 2017, 2, 096103. [Google Scholar] [CrossRef] [Green Version]

- Schell, A.W.; Kaschke, J.; Fischer, J.; Henze, R.; Wolters, J.; Wegener, M.; Benson, O. Three-dimensional quantum photonic elements based on single nitrogen vacancy-centres in laser-written microstructures. Sci. Rep. 2013, 3, 1577. [Google Scholar] [CrossRef]

- Cheong, Y.K.; Lim, W.H.; Lee, S.H.; Pua, C.H.; Chong, W.Y.; Ahmad, H. 405 nm laser processing of thin SU-8 polymer film. Optik 2016, 127, 1651–1655. [Google Scholar] [CrossRef]

- Lu, D.-X.; Zhang, Y.-L.; Han, D.-D.; Wang, H.; Xia, H.; Chen, Q.-D.; Ding, H.; Sun, H.-B. Solvent-tunable PDMS microlens fabricated by femtosecond laser direct writing. J. Mater. Chem. C 2015, 3, 1751–1756. [Google Scholar] [CrossRef]

- He, Z.; Lee, Y.-H.; Chanda, D.; Wu, S.-T. Adaptive liquid crystal microlens array enabled by two-photon polymerization. Opt. Express 2018, 26, 21184. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.H.; Yoshida, H.; Miura, Y.; Fujii, A.; Ozaki, M. Local liquid crystal alignment on patterned micrograting structures photofabricated by two photon excitation direct laser writing. Appl. Phys. Lett. 2008, 93, 159. [Google Scholar] [CrossRef]

- Gissibl, T.; Thiele, S.; Herkommer, A.; Giessen, H. Two-photon direct laser writing of ultracompact multi-lens objectives. Nat. Photonics 2016, 10, 554–560. [Google Scholar] [CrossRef]

- Poon, J.K.S.; Huang, Y.; Paloczi, G.T.; Yariv, A. Soft lithography replica molding of critically coupled polymer microring resonators. IEEE Photonics Technol. Lett. 2004, 16, 2496–2498. [Google Scholar] [CrossRef]

- Finardi, C.A.; Zanvettor, L.T.; Panepucci, R.R.; Nunes, R.O.; Gozzi, A.C.; Bologna, J.P. A silicon integration approach for optical front end applied to PON end-user terminal. In Proceedings of the 2013 SBMO/IEEE MTT-S International Microwave and Optoelectronics Conference (IMOC), Rio de Janeiro, Brazil, 4–7 August 2013. [Google Scholar]

- Ramirez, J.C.; Finardi, C.A.; Panepucci, R.R. SU-8 GPON diplexer based on H-line lithography by direct laser writer. IEEE Photonics Technol. Lett. 2018, 30, 205–208. [Google Scholar] [CrossRef]

- Landowski, A.; Zepp, D.; Wingerter, S.; Freymann, G.V.; Widera, A. Direct laser written polymer waveguides with out of plane couplers for optical chips. APL Photonics 2017, 2, 106102. [Google Scholar] [CrossRef]

- Lindenmann, N.; Balthasar, G.; Hillerkuss, D.; Schmogrow, R.; Jordan, M.; Leuthold, J.; Freude, W.; Koos, C. Photonic wire bonding: A novel concept for chip-scale interconnects. Opt. Express 2012, 20, 17667–17677. [Google Scholar] [CrossRef]

- Jung, Y.; Yang, Y.; Kim, S.; Kim, H.S.; Park, T.G.; Yoo, B.W. Structural and compositional effects on thermal expansion behavior in polyimide substrates of varying thicknesses. Eur. Polym. J. 2013, 49, 3642–3650. [Google Scholar] [CrossRef]

- Ratautas, K.; Gedvilas, M.; Stankevičiene, I.; Jagminienė, A.; Norkus, E.; Pira, N.L.; Sinopoli, S.; Račiukaitis, G. Laser-induced selective metallization of polypropylene doped with multiwall carbon nanotubes. Appl. Surf. Sci. 2017, 412, 319–326. [Google Scholar] [CrossRef]

- Shin, I.J.; Park, M.S. Direct conductive patterning on 3D printed structure using laser. Phys. Status Solidi A Appl. Mat. 2018, 215, 1700597. [Google Scholar] [CrossRef]

- Terzaki, K.; Vasilantonakis, N.; Gaidukeviciute, A.; Reinhardt, C.; Fotakis, C.; Vamvakaki, M.; Farsari, M. 3D conducting nanostructures fabricated using direct laser writing. Opt. Mater. Express 2011, 1, 586–597. [Google Scholar] [CrossRef]

- Waller, E.H.; Von Freymann, G. From photoinduced electron transfer to 3D metal microstructures via direct laser writing. Nanophotonics 2018, 7, 1259–1277. [Google Scholar] [CrossRef] [Green Version]

- Leuthold, J.; Koos, C.; Freude, W.; Alloatti, L.; Palmer, R.; Korn, D.; Pfeifle, J.; Lauermann, M.; Dinu, R.; Wehrli, S. Silicon-organic hybrid electro-optical devices. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 114–126. [Google Scholar] [CrossRef]

- Van Calster, A.; Cuypers, D. Reflective vertically aligned nematic liquid crystal microdisplays for projection applications. In Proceedings of the Conference on Projection Displays 2000—6th in a Series, San Jose, CA, USA, 24–25 January 2000. [Google Scholar]

- Wang, X.; Liu, Z.; Zhang, T. Flexible sensing electronics for wearable/attachable health monitoring. Small 2017, 13, 1602790. [Google Scholar] [CrossRef] [PubMed]

- Takamatsu, S.; Lonjaret, T.; Ismailova, E.; Masuda, A.; Itoh, T.; Malliaras, G.G. Wearable keyboard using conducting polymer electrodes on textiles. Adv. Mater. 2016, 28, 4485–4488. [Google Scholar] [CrossRef]

- Cai, J.; Watanabe, A.; Lv, C. Laser direct writing of carbon-based micro-supercapacitors and electronic devices. J. Laser Appl. 2018, 30, 032603. [Google Scholar] [CrossRef]

- Cai, J.; Lv, C.; Watanabe, A. Laser direct writing and selective metallization of metallic circuits for integrated wireless devices. ACS Appl. Mater. Interfaces 2018, 10, 915–924. [Google Scholar] [CrossRef]

- Heni, W.; Haffner, C.; Elder, D.L.; Tillack, A.F.; Fedoryshyn, Y.; Cottier, R.; Salamin, Y.; Hoessbacher, C.; Koch, U.; Cheng, B. Nonlinearities of organic electro-optic materials in nanoscale slots and implications for the optimum modulator design. Opt. Express 2017, 25, 2627–2653. [Google Scholar] [CrossRef]

- Nitiss, E.; Tokmakovs, A.; Pudzs, K.; Busenbergs, J.; Rutkis, M. All-organic electro-optic waveguide modulator comprising SU-8 and nonlinear optical polymer. Opt. Express 2017, 25, 31036–31044. [Google Scholar] [CrossRef]

- Norwood, R.A.; Derose, C.; Enami, Y.; Gan, H.; Greenlee, C.; Himmelhuber, R.; Kropachev, O.; Loychik, C.; Mathine, D.; Merzylak, Y. Hybrid sol-gel electro-optic polymer modulators: Beating the drive voltage/loss tradeoff. J. Nonlinear Opt. Phys. Mater. 2007, 16, 217–230. [Google Scholar] [CrossRef]

- Sun, J.; Gaidis, M.C.; O’Sullivan, E.J.; Joseph, E.A.; Hu, G.; Abraham, D.W.; Nowak, J.J.; Trouilloud, P.L.; Lu, Y.; Brown, S.L. A three terminal spin-torque driven magnetic switch. Appl. Phys. Lett. 2009, 95, 083506. [Google Scholar] [CrossRef]

- Nguyen, D.T.T.; Del Guercio, O.; Au, T.H.; Trinh, D.T.; Mai, N.P.T.; Lai, N.D. Optical lithography of three-dimensional magnetophotonic microdevices. Opt. Eng. 2018, 57, 041406. [Google Scholar] [CrossRef]

- Sun, Y.L.; Dong, W.F.; Niu, L.G.; Jiang, T.; Liu, D.X.; Zhang, L.; Wang, Y.S.; Chen, Q.D.; Kim, D.P.; Sun, H.B. Protein-based soft micro-optics fabricated by femtosecond laser direct writing. Light Sci. Appl. 2014, 3, e129. [Google Scholar] [CrossRef]

- Islam, M.M.; Loewen, A.; Allen, P.B. Simple, low-cost fabrication of acrylic based droplet microfluidics and its use to generate DNA-coated particles. Sci. Rep. 2018, 8, 8763. [Google Scholar] [CrossRef]

- Shin, H.; Kim, H.; Jang, Y.; Jung, J.; Oh, J. Femtosecond laser-inscripted direct ultrafast fabrication of a DNA distributor using microfluidics. Appl. Sci. 2017, 7, 1083. [Google Scholar] [CrossRef]

- Laib, S.; Rankl, M.; Ruckstuhl, T.; Seeger, S. Sizing of single fluorescently stained DNA fragments by scanning microscopy. Nucleic Acids Res. 2003, 31, e138. [Google Scholar] [CrossRef]

- Wu, D.; Xu, F.; Sun, B.; Fu, R.; He, H.; Matyjaszewski, K. Design and preparation of porous polymers. Chem. Rev. 2012, 112, 3959–4015. [Google Scholar] [CrossRef]

- Yang, X.-Y.; Chen, L.-H.; Li, Y.; Rooke, J.C.; Sanchez, C.; Su, B.-L. Hierarchically porous materials: Synthesis strategies and structure design. Chem. Soc. Rev. 2017, 46, 481–558. [Google Scholar] [CrossRef]

- Liu, Q.; Tang, Z.; Ou, B.; Liu, L.; Zhou, Z.; Shen, S.; Duan, Y. Design, preparation, and application of ordered porous polymer materials. Mater. Chem. Phys. 2014, 144, 213–225. [Google Scholar] [CrossRef]

- Hook, A.L.; Voelcker, N.H.; Thissen, H. Patterned and switchable surfaces for biomolecular manipulation. Acta Biomater. 2009, 5, 2350–2370. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Wang, S. Three-dimensional nano-biointerface as a new platform for guiding cell fate. Chem. Soc. Rev. 2014, 43, 2385–2401. [Google Scholar] [CrossRef] [PubMed]

- Simitzi, C.; Ranella, A.; Stratakis, E. Controlling the morphology and outgrowth of nerve and neuroglial cells: The effect of surface topography. Acta Biomater. 2017, 51, 21–52. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oliveira, S.M.; Song, W.; Alves, N.M.; Mano, J.F. Chemical modification of bioinspired superhydrophobic polystyrene surfaces to control cell attachment/proliferation. Soft Matter 2011, 7, 8932–8941. [Google Scholar] [CrossRef]

- Cheng, W.; Ding, L.; Ding, S.; Yin, Y.; Ju, H. A simple electrochemical cytosensor array for dynamic analysis of carcinoma cell surface glycans. Angew. Chem. Int. Ed. 2010, 121, 6587–6590. [Google Scholar] [CrossRef]

- Feng, W.; Li, L.; Ueda, E.; Li, J.; Heißler, S.; Welle, A.; Trapp, O.; Levkin, P.A. Surface patterning via thiol-yne click chemistry: An extremely fast and versatile approach to superhydrophilic-superhydrophobic micropatterns. Adv. Mater. Interfaces 2015, 1, 1400269. [Google Scholar] [CrossRef]

- Lee, M.R.; Phang, I.Y.; Cui, Y.; Lee, Y.H.; Ling, X.Y. Shape-shifting 3D protein microstructures with programmable directionality via quantitative nanoscale stiffness modulation. Small 2015, 11, 740–748. [Google Scholar] [CrossRef]

- Arakawa, C.K.; Badeau, B.A.; Zheng, Y.; Deforest, C.A. Multicellular vascularized engineered tissues through user-programmable biomaterial photodegradation. Adv. Mater. 2017, 29, 1703156. [Google Scholar] [CrossRef]

- Qin, X.H.; Wang, X.P.; Rottmar, M.; Nelson, B.J.; Maniura-Weber, K. Hydrogels: Near-infrared light-sensitive polyvinyl alcohol hydrogel photoresist for spatiotemporal control of cell-instructive 3D microenvironments. Adv. Mater. 2018, 30, 1705564. [Google Scholar] [CrossRef]

- Prausnitz, M.R.; Samir, M.; Robert, L. Current status and future potential of transdermal drug delivery. Nat. Rev. Drug Discov. 2004, 3, 115–124. [Google Scholar] [CrossRef]

- Ivanova, E.P.; Bazaka, K.; Crawford, R.J. New Functional Biomaterials for Medicine and Healthcare, 1st ed.; Woodhead Publishing: Sawston, UK, 2014; pp. xi–xiv. [Google Scholar]

- Nemani, K.V.; Moodie, K.L.; Brennick, J.B.; Su, A.; Gimi, B. In vitro and in vivo evaluation of SU-8 biocompatibility. Mater. Sci. Eng. C Mater. 2013, 33, 4453–4459. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hassler, C.; Boretius, T.; Stieglitz, T. Polymers for neural implants. J. Polym. Sci. Part B Polym. Phys. 2011, 49, 18–33. [Google Scholar] [CrossRef]

- Nishiguchi, A.; Mourran, A.; Zhang, H.; Moeller, M. In-gel direct laser writing for 3D-designed hydrogel composites that undergo complex self-shaping. Adv. Sci. 2018, 5, 1700038. [Google Scholar] [CrossRef] [PubMed]

- Ionov, L. Biomimetic 3D self-assembling biomicroconstructs by spontaneous deformation of thin polymer films. J. Mater. Chem. 2012, 22, 19366–19375. [Google Scholar] [CrossRef]

- Zhang, H.; Mourran, A.; Moeller, M. Dynamic switching of helical microgel ribbons. Nano Lett. 2017, 17, 2010–2014. [Google Scholar] [CrossRef] [PubMed]

- Osada, Y.; Okuzaki, H.; Hori, H. A polymer gel with electrically driven motility. Nature 1992, 355, 242–244. [Google Scholar] [CrossRef]

- He, X.; Aizenberg, M.; Kuksenok, O.; Zarzar, L.D.; Shastri, A.; Balazs, A.C.; Aizenberg, J. Synthetic homeostatic materials with chemo-mechano-chemical self-regulation. Nature 2012, 487, 214–218. [Google Scholar] [CrossRef]

- Yoshida, R. Self-oscillating gels driven by the belousov-zhabotinsky reaction as novel smart materials. Adv. Mater. 2010, 22, 3463–3483. [Google Scholar] [CrossRef]

- Hippler, M.; Blasco, E.; Qu, J.; Tanaka, M.; Barner-Kowollik, C.; Wegener, M.; Bastmeyer, M. Controlling the shape of 3D microstructures by temperature and light. Nat. Commun. 2019, 10, 232. [Google Scholar]

- Xing, J.-F.; Dong, X.-Z.; Chen, W.-Q.; Duan, X.-M.; Takeyasu, N.; Tanaka, T.; Kawata, S. Improving spatial resolution of two-photon microfabrication by using photoinitiator with high initiating efficiency. Appl. Phys. Lett. 2007, 90, 131106. [Google Scholar] [CrossRef]

- Zhou, X.; Hou, Y.; Lin, J. A review on the processing accuracy of two-photon polymerization. AIP Adv. 2015, 5, 030701. [Google Scholar] [CrossRef] [Green Version]

- Chaudhary, R.P.; Jaiswal, A.; Ummethala, G.; Hawal, S.R.; Saxena, S.; Shukla, S. Sub-wavelength lithography of complex 2D and 3D nanostructures without two-photon dyes. Addit. Manuf. 2017, 16, 30–34. [Google Scholar] [CrossRef]

- Mendonca, C.R.; Correa, D.S.; Baldacchini, T.; Tayalia, P.; Mazur, E. Two-photon absorption spectrum of the photoinitiator lucirin TPO-L. Appl. Phys. A Mater. Sci. Process. 2008, 90, 633–636. [Google Scholar] [CrossRef]

- Burroughes, J.H.; Bradley, D.D.C.; Brown, A.R.; Marks, R.N.; Mackay, K.; Friend, R.H.; Burn, P.L.; Holmes, A.B. Light-emitting-diodes based on conjugated polymers. Nature 1990, 347, 539–541. [Google Scholar] [CrossRef]

- Rothberg, L.J.; Lovinger, A.J. Status of and prospects for organic electroluminescence. J. Mater. Res. 1996, 11, 3174–3187. [Google Scholar] [CrossRef]

- Avila, O.I.; Tomazio, N.B.; Otuka, A.J.G.; Stefanelo, J.C.; Andrade, M.B.; Balogh, D.T.; Mendonca, C.R. Femtosecond laser writing of PPV-doped three-dimensional polymeric microstructures. J. Polym. Sci. Pol. Phys. 2018, 56, 479–483. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.-L.; Zhu, R.; Chen, D.-L.; Jin, G.-X.; Sun, H.-B. Femtosecond laser direct writing of ion exchangeable multifunctional microstructures. Opt. Lett. 2018, 43, 1139–1142. [Google Scholar] [CrossRef] [PubMed]

- Kumi, G.; Yanez, C.O.; Belfield, K.D.; Fourkas, J.T. High-speed multiphoton absorption polymerization: Fabrication of microfluidic channels with arbitrary cross-sections and high aspect ratios. Lab Chip 2010, 10, 1057–1060. [Google Scholar] [CrossRef]

- Hwang, D.; Choi, T.; Grigoropoulos, C. Liquid-assisted femtosecond laser drilling of straight and three-dimensional microchannels in glass. Appl. Phys. A Mater. Sci. Process. 2004, 79, 605–612. [Google Scholar] [CrossRef]

- Lee, J.-T.; George, M.C.; Moore, J.S.; Braun, P.V. Multiphoton writing of three-dimensional fluidic channels within a porous matrix. J. Am. Chem. Soc. 2009, 131, 11294–11295. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.-B.; Zhang, R.; Liu, X.-Q.; Wang, H.; Zhang, Y.-L.; Jiang, H.-B.; Wang, L.; Ma, Z.-C.; Ku, J.-F.; Xiao, F.-S. On-chip fabrication of silver microflower arrays as a catalytic microreactor for allowing in situ SERS monitoring. Chem. Commun. 2012, 48, 1680–1682. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.-B.; Zhang, R.; Wang, H.; Liu, X.-Q.; Wang, L.; Ma, Z.-C.; Chen, Q.-D.; Xiao, X.-Z.; Han, B.; Sun, H.-B. Laser patterning of conductive gold micronanostructures from nanodots. Nanoscale 2012, 4, 6955–6958. [Google Scholar] [CrossRef]

- Saha, S.K.; Oakdale, J.S.; Cuadra, J.A.; Divin, C.; Ye, J.; Forien, J.-B.; Aji, L.B.B.; Biener, J.; Smith, W.L. Radiopaque resists for two-photon lithography to enable submicron 3D imaging of polymer parts via X-ray computed tomography. ACS Appl. Mater. Interfaces 2017, 10, 1164–1172. [Google Scholar] [CrossRef] [PubMed]

- Sundaram, V.M.; Wen, S.B. An easy method to perform e-beam negative tone lift-off fabrication on dielectric material with a sandwiched conducting polymer layer. J. Micromech. Microeng. 2011, 21, 065021. [Google Scholar] [CrossRef]

- Teng, J.; Scheerlinck, S.; Zhang, H.; Jian, X.; Morthier, G.; Beats, R.; Han, X.; Zhao, M. A PSQ-L polymer microring resonator fabricated by a simple UV-based soft-lithography process. IEEE Photonics Technol. Lett. 2009, 21, 1323–1325. [Google Scholar] [CrossRef]

- Wan, L.; Zhu, N.; Zhang, R.-Y.; Mei, T. All-polymeric planar waveguide devices based on a gas-assisted thermal imprinting technique. Microsyst. Technol. 2017, 23, 5271–5279. [Google Scholar] [CrossRef]

- Lin, X.; Ling, T.; Subbaraman, H.; Guo, L.J.; Chen, R.T. Printable thermo-optic polymer switches utilizing imprinting and ink-jet printing. Opt. Express 2013, 21, 2110–2117. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.-L.; Qi, Y.-N.; Yin, X.-J.; Yang, X.; Chen, C.-M.; Yu, J.-Y.; Yu, J.-C.; Lin, Y.-M.; Hui, F.; Liu, P.-L.; et al. Polymer-Based Device Fabrication and Applications Using Direct Laser Writing Technology. Polymers 2019, 11, 553. https://doi.org/10.3390/polym11030553

Wu Z-L, Qi Y-N, Yin X-J, Yang X, Chen C-M, Yu J-Y, Yu J-C, Lin Y-M, Hui F, Liu P-L, et al. Polymer-Based Device Fabrication and Applications Using Direct Laser Writing Technology. Polymers. 2019; 11(3):553. https://doi.org/10.3390/polym11030553

Chicago/Turabian StyleWu, Zhen-Lin, Ya-Nan Qi, Xiao-Jie Yin, Xin Yang, Chang-Ming Chen, Jing-Ying Yu, Jia-Chen Yu, Yu-Meng Lin, Fang Hui, Peng-Li Liu, and et al. 2019. "Polymer-Based Device Fabrication and Applications Using Direct Laser Writing Technology" Polymers 11, no. 3: 553. https://doi.org/10.3390/polym11030553