Durability of Basalt/Hemp Hybrid Thermoplastic Composites

Abstract

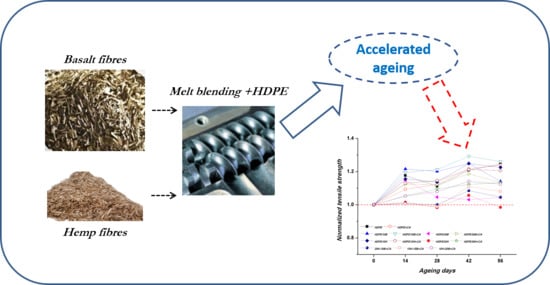

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Compounding and Processing

2.3. Water Absorption Studies

2.4. Artificial Ageing

2.5. Mechanical Characterisation of Composites

2.6. Thermal Characterisation of Composites

2.7. Morphological Characterisation

3. Results and Discussion

3.1. Water Uptake

3.2. Kinetics of Water Absorption

3.3. Effect of Water Absorption on Tensile Properties of Composites

3.4. Accelerated Ageing

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.-M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef] [PubMed]

- Bourmaud, A.; Beaugrand, J.; Shaf, D.U.; Placet, V.; Baley, C. Towards the design of high-performance plant fibre composites. Prog. Mater. Sci. 2018, 97, 347–408. [Google Scholar] [CrossRef]

- Karmaker, A.C. Effect of water absorption on dimensional stability and impact energy of jute fibre reinforced polypropylene. J. Mater. Sci. Lett. 1997, 16, 462–464. [Google Scholar] [CrossRef]

- Thwe, M.M.; Liao, K. Durability of bamboo-glass fiber reinforced polymer matrix hybrid composites. Compos. Sci. Technol. 2003, 63, 375–387. [Google Scholar] [CrossRef]

- George, J.; Bhagawan, S.S.; Thomas, S. Effects of environment on the properties of low-density polyethylene composites reinforced with pineapple-leaf fibre. Compos. Sci. Technol. 1998, 58, 1471–1485. [Google Scholar] [CrossRef]

- Stamboulis, A.; Baillie, C.A.; Garkhail, S.K.; van Melick, H.G.H.; Peijs, T. Environmental Durability of Flax Fibres and their Composites based on Polypropylene Matrix. Appl. Compos. Mater. 2000, 7, 273–294. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Arbelaiz, A.; Fernández, B.; Ramos, J.A.; Retegi, A.; Llano-Ponte, R.; Mondragon, I. Mechanical properties of short flax fibre bundle/polypropylene composites: Influence of matrix/fibre modification, fibre content, water uptake and recycling. Compos. Sci. Technol. 2005, 65, 1582–1592. [Google Scholar] [CrossRef]

- Le Duigou, A.; Davies, P.; Baley, C. Exploring durability of interfaces in flax fibre/epoxy micro-composites. Compos. Part A Appl. Sci. Manuf. 2013, 48, 121–128. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Sarasini, F.; Tirilló, J.; Calabrese, L. Salt-fog spray aging of jute-basalt reinforced hybrid structures: Flexural and low velocity impact response. Compos. Part B Eng. 2017, 116, 99–112. [Google Scholar] [CrossRef]

- Fiore, V.; Calabrese, L.; Di Bella, G.; Scalici, T.; Galtieri, G.; Valenza, A.; Proverbio, E. Effects of aging in salt spray conditions on flax and flax/basalt reinforced composites: Wettability and dynamic mechanical properties. Compos. Part B Eng. 2016, 93, 35–42. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.P.S. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Thwe, M.M.; Liao, K. Effects of environmental aging on the mechanical properties of bamboo–glass fiber reinforced polymer matrix hybrid composites. Compos. Part A Appl. Sci. Manuf. 2002, 33, 43–52. [Google Scholar] [CrossRef]

- Thwe, M.M.; Liao, K. Environmental effects on bamboo-glass/polypropylene hybrid composites. J. Mater. Sci. 2003, 38, 363–376. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. Studies on the Water Absorption Properties of Short Hemp–Glass Fiber Hybrid Polypropylene Composites. J. Compos. Mater. 2007, 41, 1871–1883. [Google Scholar] [CrossRef]

- Akil, H.M.; Santulli, C.; Sarasini, F.; Tirillò, J.; Valente, T. Environmental effects on the mechanical behaviour of pultruded jute/glass fibre-reinforced polyester hybrid composites. Compos. Sci. Technol. 2014, 94. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Sergi, C.; Seghini, M.C.; Cozzarini, L.; Graupner, N. Effect of basalt fibre hybridisation and sizing removal on mechanical and thermal properties of hemp fibre reinforced HDPE composites. Compos. Struct. 2018, 188, 394–406. [Google Scholar] [CrossRef]

- Assarar, M.; Scida, D.; El Mahi, A.; Poilâne, C.; Ayad, R. Influence of water ageing on mechanical properties and damage events of two reinforced composite materials: Flax–fibres and glass–fibres. Mater. Des. 2011, 32, 788–795. [Google Scholar] [CrossRef]

- Chilali, A.; Zouari, W.; Assarar, M.; Kebir, H.; Ayad, R. Effect of water ageing on the load-unload cyclic behaviour of flax fibre-reinforced thermoplastic and thermosetting composites. Compos. Struct. 2018, 183, 309–319. [Google Scholar] [CrossRef]

- Le Duigou, A.; Bourmaud, A.; Davies, P.; Baley, C. Long term immersion in natural seawater of Flax/PLA biocomposite. Ocean Eng. 2014, 90, 140–148. [Google Scholar] [CrossRef]

- Shen, C.-H.; Springer, G.S. Moisture absorption and desorption of composite materials. J. Compos. Mater. 1976, 10, 2–20. [Google Scholar] [CrossRef]

- Alaimo, G.; Valenza, A.; Enea, D.; Fiore, V. The durability of basalt fibres reinforced polymer (BFRP) panels for cladding. Mater. Struct. 2016, 49, 2053–2064. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Badagliacco, D.; Enea, D.; Alaimo, G.; Valenza, A. Aging resistance of bio-epoxy jute-basalt hybrid composites as novel multilayer structures for cladding. Compos. Struct. 2017, 160, 1319–1328. [Google Scholar] [CrossRef]

- Enea, D.; Bottalico, L.; de Marco, T. Service Life of Cementitious Photocatalytic Paints Newly Formulated. Adv. Mater. Res. 2013, 818, 98–103. [Google Scholar] [CrossRef]

- Wunderlich, B.; Cormier, C.M. Heat of fusion of polyethylene. J. Polym. Sci. Part A Polym. Phys. 1967, 5, 987–988. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. Injection-molded short hemp fiber/glass fiber-reinforced polypropylene hybrid composites—Mechanical, water absorption and thermal properties. J. Appl. Polym. Sci. 2007, 103, 2432–2441. [Google Scholar] [CrossRef]

- Adhikary, K.B.; Pang, S.; Staiger, M.P. Long-term moisture absorption and thickness swelling behaviour of recycled thermoplastics reinforced with Pinus radiata sawdust. Chem. Eng. J. 2008, 142, 190–198. [Google Scholar] [CrossRef]

- Gauthier, R.; Joly, C.; Coupas, A.C.; Gauthier, H.; Escoubes, M. Interfaces in polyolefin/cellulosic fiber composites: Chemical coupling, morphology, correlation with adhesion and aging in moisture. Polym. Compos. 1998, 19, 287–300. [Google Scholar] [CrossRef]

- Dhakal, H.; Zhang, Z.; Richardson, M. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Kushwaha, P.K.; Kumar, R. Studies on Water Absorption of Bamboo-Polyester Composites: Effect of Silane Treatment of Mercerized Bamboo. Polym. Plast. Technol. Eng. 2009, 49, 45–52. [Google Scholar] [CrossRef]

- Sreekala, M.S.; Kumaran, M.G.; Thomas, S. Water sorption in oil palm fiber reinforced phenol formaldehyde composites. Compos. Part A Appl. Sci. Manuf. 2002, 33, 763–777. [Google Scholar] [CrossRef]

- Espert, A.; Vilaplana, F.; Karlsson, S. Comparison of water absorption in natural cellulosic fibres from wood and one-year crops in polypropylene composites and its influence on their mechanical properties. Compos. Part A Appl. Sci. Manuf. 2004, 35, 1267–1276. [Google Scholar] [CrossRef]

- Zamri, M.H.; Akil, H.M.; Bakar, A.A.; Ishak, Z.A.M.; Cheng, L.W. Effect of water absorption on pultruded jute/glass fiber-reinforced unsaturated polyester hybrid composites. J. Compos. Mater. 2012, 46, 51–61. [Google Scholar] [CrossRef]

- Sen, I.; Aral, A.; Seki, Y.; Sarikanat, M.; Sever, K. Variations of mechanical properties of jute/polyester composite aged in various media. J. Compos. Mater. 2012, 46, 2219–2225. [Google Scholar] [CrossRef]

- Marcovich, N.; Reboredo, M.; Aranguren, M. Moisture diffusion in polyester–woodflour composites. Polymer 1999, 40, 7313–7320. [Google Scholar] [CrossRef]

- Le Duigou, A.; Davies, P.; Baley, C. Seawater ageing of flax/poly(lactic acid) biocomposites. Polym. Degrad. Stab. 2009, 94, 1151–1162. [Google Scholar] [CrossRef]

- Schmitz, G.K.; Metcalfe, A.G. Stress Corrosion of E-Glass Fibers. Ind. Eng. Chem. Prod. Res. Dev. 1966, 5, 1–8. [Google Scholar] [CrossRef]

- Gulmine, J.V.; Janissek, P.R.; Heise, H.M.; Akcelrud, L. Degradation profile of polyethylene after artificial accelerated weathering. Polym. Degrad. Stab. 2003, 79, 385–397. [Google Scholar] [CrossRef]

- Carrasco, F.; Pagès, P.; Pascual, S.; Colom, X. Artificial aging of high-density polyethylene by ultraviolet irradiation. Eur. Polym. J. 2001, 37, 1457–1464. [Google Scholar] [CrossRef]

- Wu, T.-M.; Liu, C.-Y. Poly(ethylene 2,6-naphthalate)/layered silicate nanocomposites: Fabrication, crystallization behavior and properties. Polymer 2005, 46, 5621–5629. [Google Scholar] [CrossRef]

- Pérez, C.J.; Alvarez, V.A.; Stefani, P.M.; Vázquez, A. Non-isothermal crystallization of MaterBi-Z/clay nanocomposites. J. Therm. Anal. Calorim. 2007, 88, 825–832. [Google Scholar] [CrossRef]

| Designation of Samples | HDPE (wt %) | Basalt Fibre (wt %) | Hemp Fibre (wt %) | Coupling Agent (wt %) |

|---|---|---|---|---|

| NEAT HDPE | 100 | - | - | - |

| NEAT HDPE5MA | 95 | - | - | 5 |

| HDPE10B | 90 | 10 | - | - |

| HDPE30B | 70 | 30 | - | - |

| HDPE10B5MA | 85 | 10 | - | 5 |

| HDPE30B5MA | 65 | 30 | - | 5 |

| HDPE10H | 90 | - | 10 | - |

| HDPE30H | 70 | - | 30 | - |

| HDPE10H5MA | 85 | - | 10 | 5 |

| HDPE30H5MA | 65 | - | 30 | 5 |

| HDPE10H20B | 70 | 20 | 10 | - |

| HDPE15H15B | 70 | 15 | 15 | - |

| HDPE20H10B | 70 | 10 | 20 | - |

| HDPE10H20B5MA | 65 | 20 | 10 | 5 |

| HDPE15H15B5MA | 65 | 15 | 15 | 5 |

| HDPE20H10B5MA | 65 | 10 | 20 | 5 |

| Theoretical Cycle (min) | T (°C) | RH (%) | Real Cycle (min) | |

|---|---|---|---|---|

| Phase A | ||||

| Rain | 75 | 20 | 95 | 75 |

| Transition | 8 | |||

| Cold | 40 | 2 | 50 | 32 |

| Transition | 8 | |||

| Humid climate | 115 | 35 | 87 | 107 |

| Transition | 6 | |||

| Dry climate | 70 | 50 | 56 | 64 |

| Total | 300 | 300 | ||

| Phase B | ||||

| Humid climate + UV irradiation | 120 | 35 | 87 | 120 |

| Total A + B | 420 (7 h) | 420 (7 h) | ||

| Specimen ID | Equilibrium Moisture Content (%) | Diffusion Coefficient (m2/s) | na |

|---|---|---|---|

| NEAT HDPE | 0.10 ± 0.03 | 1.41 × 10−11 | 0.21 |

| NEAT HDPE5MA | 0.12 ± 0.06 | 1.72 × 10−11 | 0.22 |

| HDPE10B | 0.06 ± 0.02 | 3.05 × 10−11 | 0.16 |

| HDPE30B | 0.05 ± 0.01 | 1.88 × 10−12 | 0.22 |

| HDPE10B5MA | 0.05 ± 0.03 | 2.66 × 10−11 | 0.12 |

| HDPE30B5MA | 0.04 ± 0.01 | 1.55 × 10−12 | 0.15 |

| HDPE10H | 2.01 ± 0.24 | 1.88 × 10−13 | 0.37 |

| HDPE30H | 7.11 ± 0.09 | 2.14 × 10−13 | 0.49 |

| HDPE10H5MA | 1.73 ± 0.14 | 1.81 × 10−13 | 0.35 |

| HDPE30H5MA | 6.36 ± 0.10 | 1.04 × 10−13 | 0.44 |

| HDPE10H20B | 1.89 ± 0.18 | 1.47 × 10−13 | 0.38 |

| HDPE15H15B | 3.35 ± 0.28 | 1.88 × 10−13 | 0.44 |

| HDPE20H10B | 4.75 ± 0.20 | 3.68 × 10−13 | 0.42 |

| HDPE10H20B5MA | 1.74 ± 0.02 | 1.06 × 10−13 | 0.35 |

| HDPE15H15B5MA | 3.09 ± 0.30 | 1.86 × 10−13 | 0.38 |

| HDPE20H10B5MA | 4.36 ± 0.42 | 2.88 × 10−13 | 0.42 |

| Specimen ID | Ageing Time (14 days) | Ageing Time (56 days) | ||||||

|---|---|---|---|---|---|---|---|---|

| Tm (°C) | Tc (°C) | ΔHm (J/g) | Xc (%) | Tm (°C) | Tc (°C) | ΔHm (J/g) | Xc (%) | |

| NEAT HDPE | 142.88 ± 2.81 | 116.34 ± 2.81 | 150.81 ± 18.36 | 55.90 ± 1.19 | 138.81 ± 0.53 | 115.80 ± 0.18 | 193.89 ± 0.03 | 66.18 ± 0.01 |

| NEAT HDPE5MA | 137.01 ± 0.48 | 113.63 ± 1.40 | 187.03 ± 3.72 | 63.83 ± 1.27 | 137.20 ± 0.22 | 115.84 ± 0.84 | 193.63 ± 9.40 | 66.09 ± 3.55 |

| HDPE10B | 137.60 ± 1.25 | 114.85 ± 2.07 | 147.52 ± 3.33 | 55.94 ± 1.26 | 135.86 ± 0.18 | 117.46 ± 0.14 | 176.22 ± 2.19 | 66.84 ± 0.47 |

| HDPE30B | 137.73 ± 1.11 | 114.38 ± 0.07 | 117.96 ± 1.04 | 57.51 ± 0.51 | 136.12 ± 0.78 | 117.09 ± 0.06 | 136.31 ± 3.90 | 66.46 ± 1.90 |

| HDPE10B5MA | 137.04 ± 0.94 | 115.41 ± 3.25 | 140.57 ± 2.88 | 53.31 ± 1.09 | 138.26 ± 1.32 | 112.87 ± 0.36 | 173.24 ± 0.69 | 65.70 ± 0.26 |

| HDPE30B5MA | 136.54 ± 2.10 | 116.02 ± 2.79 | 109.17 ± 1.54 | 53.23 ± 0.75 | 136.47 ± 1.85 | 113.62 ± 0.02 | 138.35 ± 1.34 | 67.46 ± 0.35 |

| HDPE10H | 138.27 ± 0.59 | 116.08 ± 2.06 | 143.64 ± 3.97 | 54.47 ± 1.50 | 134.95 ± 0.40 | 117.47 ± 0.38 | 175.94 ± 6.76 | 66.72 ± 2.56 |

| HDPE30H | 133.80 ± 2.91 | 114.31 ± 0.58 | 107.83 ± 3.58 | 52.57 ± 1.75 | 134.32 ± 1.79 | 117.14 ± 0.23 | 118.20 ± 4.26 | 57.63 ± 2.08 |

| HDPE10H5MA | 137.57 ± 0.92 | 116.29 ± 1.99 | 149.97 ± 12.64 | 56.87 ± 4.79 | 136.24 ± 0.60 | 114.67 ± 0.13 | 171.17 ± 9.73 | 64.91 ± 3.69 |

| HDPE30H5MA | 134.65 ± 2.30 | 115.51 ± 0.87 | 100.81 ± 7.32 | 49.15 ± 3.57 | 133.90 ± 2.74 | 114.45 ± 0.59 | 128.82 ± 5.30 | 62.81 ± 2.59 |

| HDPE10H20B | 134.92 ± 0.11 | 117.46 ± 3.30 | 120.22 ± 6.54 | 58.62 ± 3.19 | 137.48 ± 3.93 | 117.60 ± 0.65 | 129.49 ± 0.44 | 63.13 ± 0.21 |

| HDPE15H15B | 137.10 ± 0.75 | 117.24 ± 2.74 | 112.70 ± 5.18 | 54.95 ± 2.52 | 134.31 ± 0.83 | 117.88 ± 0.02 | 127.51 ± 3.24 | 62.17 ± 1.29 |

| HDPE20H10B | 137.33 ± 1.61 | 117.54 ± 2.69 | 101.57 ± 0.14 | 38.52 ± 0.05 | 133.30 ± 0.57 | 117.75 ± 0.11 | 131.09 ± 4.63 | 63.91 ± 2.26 |

| HDPE10H20B5MA | 135.68 ± 0.47 | 117.49 ± 2.55 | 98.15 ± 0.72 | 47.85 ± 0.35 | 135.23 ± 0.01 | 117.80 ± 0.42 | 122.40 ± 0.31 | 59.68 ± 0.15 |

| HDPE15H15B5MA | 136.33 ± 1.22 | 117.54 ± 2.86 | 101.61 ± 0.23 | 49.54 ± 0.11 | 135.17 ± 1.39 | 115.72 ± 0.21 | 127.01 ± 5.90 | 61.92 ± 2.88 |

| HDPE20H10B5MA | 138.14 ± 3.68 | 117.93 ± 2.59 | 110.75 ± 12.99 | 54.02 ± 4.31 | 137.55 ± 1.72 | 114.69 ± 0.59 | 138.51 ± 8.85 | 67.53 ± 4.31 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sergi, C.; Tirillò, J.; Seghini, M.C.; Sarasini, F.; Fiore, V.; Scalici, T. Durability of Basalt/Hemp Hybrid Thermoplastic Composites. Polymers 2019, 11, 603. https://doi.org/10.3390/polym11040603

Sergi C, Tirillò J, Seghini MC, Sarasini F, Fiore V, Scalici T. Durability of Basalt/Hemp Hybrid Thermoplastic Composites. Polymers. 2019; 11(4):603. https://doi.org/10.3390/polym11040603

Chicago/Turabian StyleSergi, Claudia, Jacopo Tirillò, Maria Carolina Seghini, Fabrizio Sarasini, Vincenzo Fiore, and Tommaso Scalici. 2019. "Durability of Basalt/Hemp Hybrid Thermoplastic Composites" Polymers 11, no. 4: 603. https://doi.org/10.3390/polym11040603