Effect of Mold Temperature on the Impact Behavior and Morphology of Injection Molded Foams Based on Polypropylene Polyethylene–Octene Copolymer Blends

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Methods

2.2.1. Sample Production

2.2.2. Mechanical Testing

2.2.3. Structural Characterization

3. Results

3.1. Mechanical Properties

3.2. Elastomer Phase Morphology

3.3. Crystalline Morphology

3.4. Cellular Structure

4. Discussion

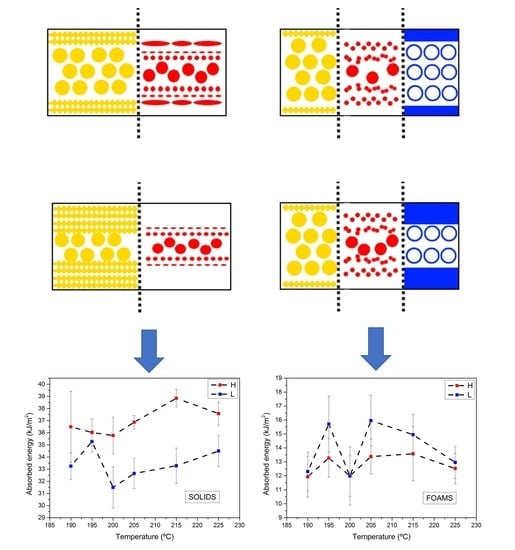

- The skin was free of elastomeric particles and the crystalline morphology was characterized by a shish-kebab structure. Spherulite morphology was predominant in core zones, allowing the inclusion of elastomer particles.

- The solid produced with a high mold temperature exhibited a zone of elongated elastomeric particles from 50 μm to 500 μm.

- On the other hand, in the solid produced with a low mold temperature, the elongated particles were only observed for distances from the skin greater than 200 μm.

- In foams, particles were less elongated in the layers nearer the mold walls and the transition from skin to the core was less abrupt than for solids. Moreover, elongated particles were observed in more internal positions that seemed to be produced by coalescence of several particles.

- Spherical particles were present in the core of solids and foams. The elastomer particles are more separated in 215 L than 215 H solids. In foams, the opposite result was observed.

- The cellular structure analysis determined that the cell size was very similar for the two conditions used, but the skin was thicker in the case of the low temperature mold foam (Table 2) (about 60% thicker).

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ma, L.F.; Wang, W.K.; Bao, R.Y.; Yang, W.; Xie, B.H.; Yang, M.B. Toughening of polypropylene with beta-nucleated thermoplastic vulcanizates based on polypropylene/ethylene-propylene-diene rubber blends. Mater. Des. 2013, 51, 536–543. [Google Scholar] [CrossRef]

- Sharma, R.; Maiti, S.N. Effects of crystallinity of PP and flexibility of SEBS-g-MA copolymer on the mechanical properties of PP/SEBS-g-MA blends. Polym. Plast. Technol. Eng. 2014, 53(3), 229–238. [Google Scholar] [CrossRef]

- Fanegas, N.; Gómez, M.A.; Jiménez, I.; Marco, C.; Garcia-Martínez, J.M.; Ellis, G. Optimizing the balance between impact strength and stiffness in polypropylene/elastomer blends by incorporation of a nucleating agent. Polym. Eng. Sci. 2008, 48, 80–87. [Google Scholar] [CrossRef]

- Karger-Kocsis, J. Polypropylene: Structure, Blends and Composites. Volume 3 Composites; Chapman & Hall: London, UK, 1994; pp. 33–84. [Google Scholar]

- Karger-Kocsis, J. Polypropylene: Structure, Blends and Composites. Volume 1 Structure and Morphology; Chapman & Hall: London, UK, 1994; pp. 2–3. [Google Scholar]

- Li, C.; Yang, S.; Wang, J.; Guo, J.; Wu, H.; Guo, S. Unique impact behavior and toughening mechanism of the polypropylene and poly (ethylene-co-octene) alternating multilayered blends with superior toughness. RSC Adv. 2014, 4, 55119–55132. [Google Scholar] [CrossRef]

- Dao, K.C. Rubber phase dispersion in polypropylene. Polymer 1984, 25, 1527–1533. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Y.; Zhang, Y. Brittle–ductile transition of PP/POE blends in both impact and high speed tensile tests. Polymer 2003, 44, 5047–5052. [Google Scholar] [CrossRef]

- Lazzeri, A.; Bucknall, C.B. Dilatational bands in rubber-toughened polymers. J. Mater. Sci. 1993, 28, 6799–6808. [Google Scholar] [CrossRef]

- Mae, H.; Omiya, M.; Kishimoto, K. Tensile behavior of polypropylene blended with bimodal distribution of styrene-ethylene-butadiene-styrene particle size. J. Appl. Polym. Sci. 2008, 107, 3520–3528. [Google Scholar] [CrossRef]

- Zebarjad, S.M.; Bagheri, R.; Reihani, S.M.; Lazzeri, A. Deformation, yield and fracture of elastomer-modified polypropylene. J. Appl. Polym. Sci. 2003, 90, 3767–3779. [Google Scholar] [CrossRef]

- Doshev, P.; Lach, R.; Lohse, G.; Heuvelsland, A.; Grellmann, W.; Radusch, H.J. Fracture characteristics and deformation behavior of heterophasic ethylene–propylene copolymers as a function of the dispersed phase composition. Polymer 2005, 46, 9411–9422. [Google Scholar] [CrossRef]

- Keskin, R.; Adanur, S. Improving toughness of polypropylene with thermoplastic elastomers in injection molding. Polym. Plast. Technol. Eng. 2011, 50, 20–28. [Google Scholar] [CrossRef]

- Lim, J.W.; Hassan, A.; Rahmat, A.R.; Wahit, M.U. Rubber-toughened polypropylene nanocomposite: Effect of polyethylene octene copolymer on mechanical properties and phase morphology. J. Appl. Polym. Sci. 2006, 99, 3441–3450. [Google Scholar] [CrossRef] [Green Version]

- Wu, S. Formation of dispersed phase in incompatible polymer blends: Interfacial and rheological effects. Polym. Eng. Sci. 1987, 27, 335–343. [Google Scholar] [CrossRef]

- Jiang, W.; Tjong, S.C.; Li, R.K.Y. Brittle–tough transition in PP/EPDM blends: effects of interparticle distance and tensile deformation speed. Polymer 2000, 41, 3479–3482. [Google Scholar] [CrossRef]

- Fasihi, M.; Mansouri, H. Effect of rubber interparticle distance distribution on toughening behavior of thermoplastic polyolefin elastomer toughened polypropylene. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Wu, S. A generalized criterion for rubber toughening: the critical matrix ligament thickness. J. Appl. Polym. Sci. 1988, 35, 549–561. [Google Scholar] [CrossRef]

- Liu, Z.H.; Li, R.K.Y.; Tjong, S.C.; Qi, Z.N.; Wang, F.S.; Choy, C.L. Influence of particle dispersion on the matrix ligament thickness of polymer blends. 1. The configuration of well-dispersed particles versus simple cubic lattice. Polymer 1998, 39, 4433–4436. [Google Scholar] [CrossRef]

- Liu, Z.H.; Zhang, X.D.; Zhu, X.G.; Qi, Z.N.; Wang, F.S. Effect of morphology on the brittle ductile transition of polymer blends: 1. A new equation for correlating morphological parameters. Polymer 1997, 38, 5267–5273. [Google Scholar] [CrossRef]

- Premphet, K.; Paecharoenchai, W. Polypropylene/metallocene ethylene-octene copolymer blends with a bimodal particle size distribution: Mechanical properties and their controlling factors. J. Appl. Polym. Sci. 2002, 85, 2412–2418. [Google Scholar] [CrossRef]

- Tokita, N. Analysis of morphology formation in elastomer blends. Rubber Chem. Technol. 1997, 50, 292–300. [Google Scholar] [CrossRef]

- Shariatpanahi, H.; Nazokdast, H.; Dabir, B.; Sadaghiani, K.; Hemmati, M. Relationship between interfacial tension and dispersed-phase particle size in polymer blends. I. PP/EPDM. J. Appl. Polym. Sci. 2002, 86, 3148–3159. [Google Scholar] [CrossRef]

- Fortelný, I.; Jůza, J.; Dimzoski, B. Coalescence in quiescent polymer blends with a high content of the dispersed phase. Eur. Polym. J. 2012, 48, 1230–1240. [Google Scholar] [CrossRef]

- Harrats, C.; Groeninckx, G.; Thomas, S. Micro-and Nanostructured Multiphase Polymer Blend Systems: Phase Morphology and Interfaces; CRC press: Boca Ratón, FL, USA, 2005. [Google Scholar]

- Pan, Y.; Liu, X.; Kaschta, J.; Liu, C.; Schubert, D.W. Reversal phenomena of molten immiscible polymer blends during creep-recovery in shear. J. Rheol. 2017, 61, 759–767. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, X.; Liu, H.; Wang, Y.; Guo, Z.; Liu, C. Multi-walled carbon nanotube in a miscible PEO/PMMA blend: Thermal and rheological behavior. Polymer Testing 2019, 75, 367–372. [Google Scholar] [CrossRef]

- Ying, J.; Xie, X.; Peng, S.; Zhou, H.; Li, D. Morphology and rheology of PP/POE blends in high shear stress field. J. Thermoplast. Compos. Mater. 2018, 31, 1263–1280. [Google Scholar] [CrossRef]

- Li, J.; Zhang, X.; Qu, C.; Zhang, Q.; Du, R.; Fu, Q. Hierarchy structure in injection molded polypropylene/ethylene–octane copolymer blends. J. Appl. Polym. Sci. 2007, 105, 2252–2259. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, Y.; Zhang, Y.; Huang, Z.; Ying, J.; Xie, X.; Zhou, H. Experimental investigation of the effects of process conditions on the morphology in injection molding of polymer blends. Adv. Polym. Tech. 2017, 36, 341–351. [Google Scholar] [CrossRef]

- Lopez-Gil, A.; Saiz-Arroyo, C.; Tirado, J.; Rodriguez-Perez, M.A. Production of non-crosslinked thermoplastic foams with a controlled density and a wide range of cellular structures. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Notario, B.; Pinto, J.; Rodríguez-Pérez, M.A. Towards a new generation of polymeric foams: PMMA nanocellular foams with enhanced physical properties. Polymer 2015, 63, 116–126. [Google Scholar] [CrossRef]

- Eaves, D. Handbook of Polymer Foams; Rapra Technology Limited: Shrewsbury, UK, 2004. [Google Scholar]

- Klempner, D.; Frisch, K.C. Handbook of Polymeric Foams and Foam Technology; Hanser: Munich, Germany, 1991. [Google Scholar]

- Throne, J.L.; Progelhof, R.C.; Kumar, S. Closed-Cell Foam Behavior Under Dynamic Loading-III. Impact Loading of High. Density Foams. J. Cell. Plast. 1985, 21, 123–140. [Google Scholar] [CrossRef]

- Tejeda, E.H.; Sahagún, C.Z.; González-Núñez, R.; Rodrigue, D. Morphology and mechanical properties of foamed polyethylene-polypropylene blends. J. Cell. Plast. 2005, 41, 417–435. [Google Scholar] [CrossRef]

- Shutov, F.A. Integral Structural Polymer Foams: Technology, Properties and Applications; Springer Science & Business Media: Berlin, Germany, 1986. [Google Scholar]

- Gong, W.; Fu, H.; Zhang, C.; Ban, D.; Yin, X.; He, Y.; Pei, X. Study on Foaming Quality and Impact Property of Foamed Polypropylene Composites. Polymers 2018, 10, 1375. [Google Scholar] [CrossRef] [PubMed]

- Pinto, J.; Solórzano, E.; Rodriguez-Perez, M.A.; de Saja, J.A. Characterization of the cellular structure based on user-interactive image analysis procedures. J. Cell. Plast. 2013, 49, 555–575. [Google Scholar] [CrossRef]

- Mi, D.; Xia, C.; Jin, M.; Wang, F.; Shen, K.; Zhang, J. Quantification of the effect of shish-kebab structure on the mechanical properties of polypropylene samples by controlling shear layer thickness. Macromolecules 2016, 49, 4571–4578. [Google Scholar] [CrossRef]

- Lee, S.M. Handbook of composite reinforcements; John Wiley & Sons: Hoboken, NJ, USA, 1992. [Google Scholar]

- Tucker, C.L., III; Moldenaers, P. Microstructural evolution in polymer blends. Annu. Rev. Fluid Mech. 2002, 34, 177–210. [Google Scholar] [CrossRef]

- Geng, C.; Su, J.; Han, S.; Wang, K.; Fu, Q. Hierarchical structure and unique impact behavior of polypropylene/ethylene-octene copolymer blends as obtained via dynamic packing injection molding. Polymer 2013, 54, 3392–3401. [Google Scholar] [CrossRef]

- Hu, X.; Geng, C.; Yang, G.; Fu, Q.; Bai, H. Synergetic effects of a matrix crystalline structure and chain mobility on the low temperature toughness of polypropylene/ethylene–octene copolymer blends. RSC Adv. 2015, 5, 54488–54496. [Google Scholar] [CrossRef]

- Du, H.; Zhang, Y.; Liu, H.; Liu, K.; Jin, M.; Li, X.; Zhang, J. Influence of phase morphology and crystalline structure on the toughness of rubber-toughened isotatic polypropylene blends. Polymer 2014, 55, 5001–5012. [Google Scholar] [CrossRef]

- Qin, X.; Thompson, M.R.; Hrymak, A.N. Rheology studies of foam flow during injection mold filling. Polym. Eng. Sci. 2007, 47, 522–529. [Google Scholar] [CrossRef]

| Sample Name | Rear (°C) | Middle (°C) | Nozzle (°C) | Mold (°C) |

|---|---|---|---|---|

| 190 L | 170 | 180 | 190 | 30 |

| 190 H | 170 | 180 | 190 | 50 |

| 195 L | 175 | 185 | 195 | 30 |

| 195 H | 175 | 185 | 195 | 50 |

| 200 L | 180 | 190 | 200 | 30 |

| 200 H | 180 | 190 | 200 | 50 |

| 205 L | 185 | 195 | 205 | 30 |

| 205 H | 185 | 195 | 205 | 50 |

| 215 L | 195 | 205 | 215 | 30 |

| 215 H | 195 | 205 | 215 | 50 |

| 225 L | 205 | 215 | 225 | 30 |

| 225 H | 205 | 215 | 225 | 50 |

| Sample | SD | Skin (%) | |

|---|---|---|---|

| 215 L | 107.96 | 46.63 | 38.20 |

| 215 H | 126.13 | 60.01 | 24.14 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muñoz-Pascual, S.; Lopez-Gonzalez, E.; Saiz-Arroyo, C.; Rodriguez-Perez, M.A. Effect of Mold Temperature on the Impact Behavior and Morphology of Injection Molded Foams Based on Polypropylene Polyethylene–Octene Copolymer Blends. Polymers 2019, 11, 894. https://doi.org/10.3390/polym11050894

Muñoz-Pascual S, Lopez-Gonzalez E, Saiz-Arroyo C, Rodriguez-Perez MA. Effect of Mold Temperature on the Impact Behavior and Morphology of Injection Molded Foams Based on Polypropylene Polyethylene–Octene Copolymer Blends. Polymers. 2019; 11(5):894. https://doi.org/10.3390/polym11050894

Chicago/Turabian StyleMuñoz-Pascual, Santiago, Eduardo Lopez-Gonzalez, Cristina Saiz-Arroyo, and Miguel Angel Rodriguez-Perez. 2019. "Effect of Mold Temperature on the Impact Behavior and Morphology of Injection Molded Foams Based on Polypropylene Polyethylene–Octene Copolymer Blends" Polymers 11, no. 5: 894. https://doi.org/10.3390/polym11050894