Investigations on the Mechanical Properties of Glass Fiber/Sisal Fiber/Chitosan Reinforced Hybrid Polymer Sandwich Composite Scaffolds for Bone Fracture Fixation Applications

Abstract

:1. Introduction

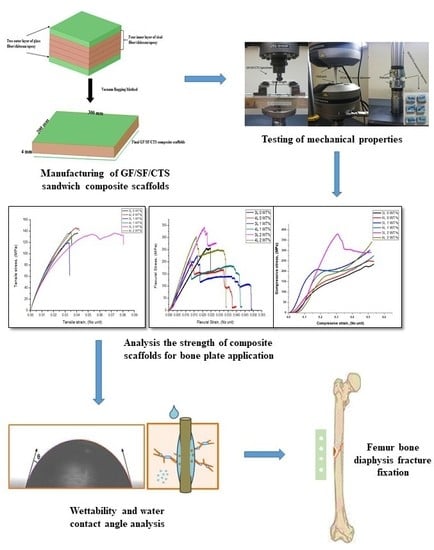

2. Materials and Methods

2.1. Materials

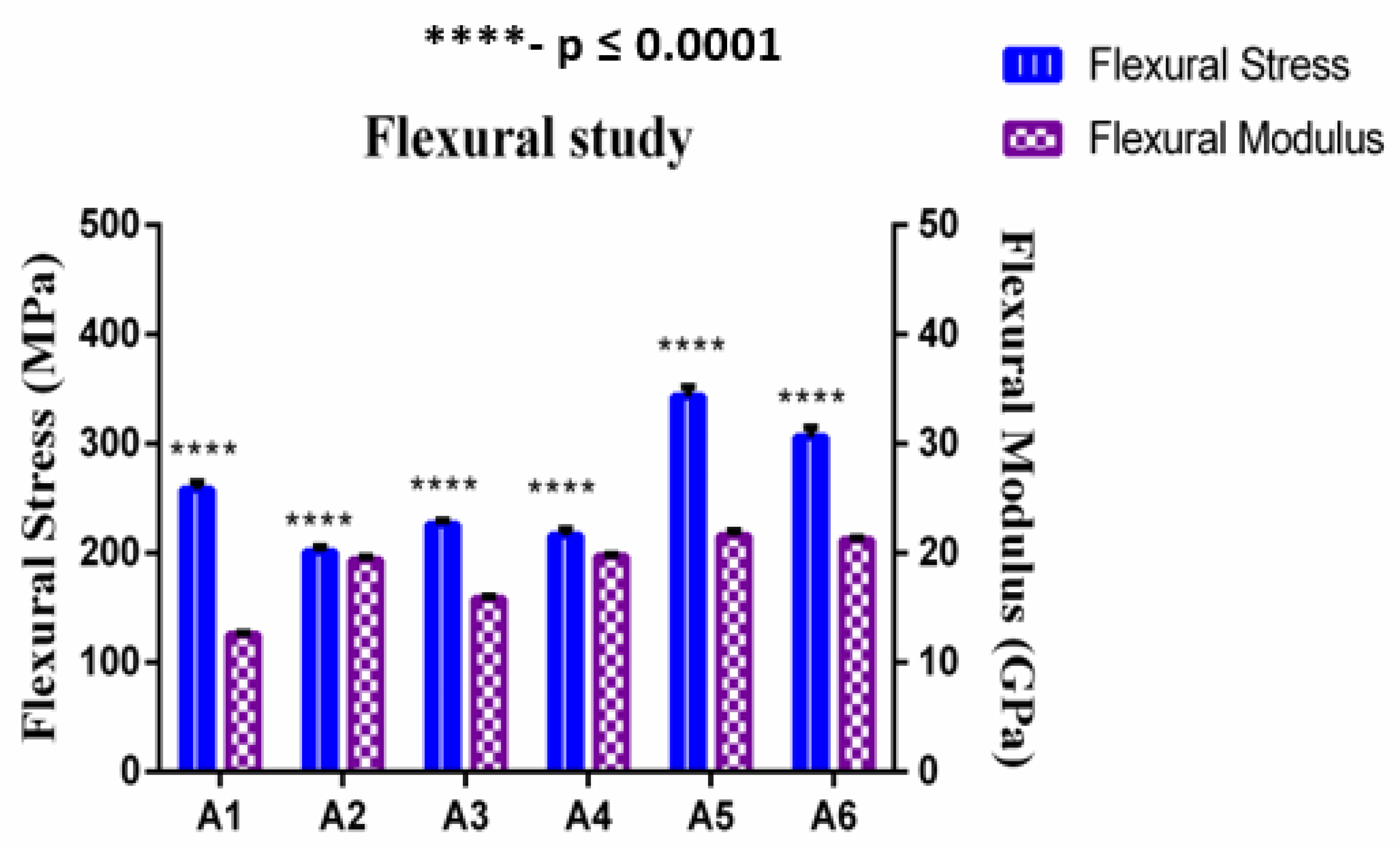

2.2. Composite Scaffold Preparation

3. Characterizations

3.1. Mechanical Properties

3.2. Micro Hardness

3.3. Scanning Electron Microscopy

3.4. Moisture Absorption and Wettability

3.5. Porosity of the Composite Scaffolds

3.6. Statistical Analysis

4. Results and Discussion

4.1. Tensile Properties of the Composite Scaffolds

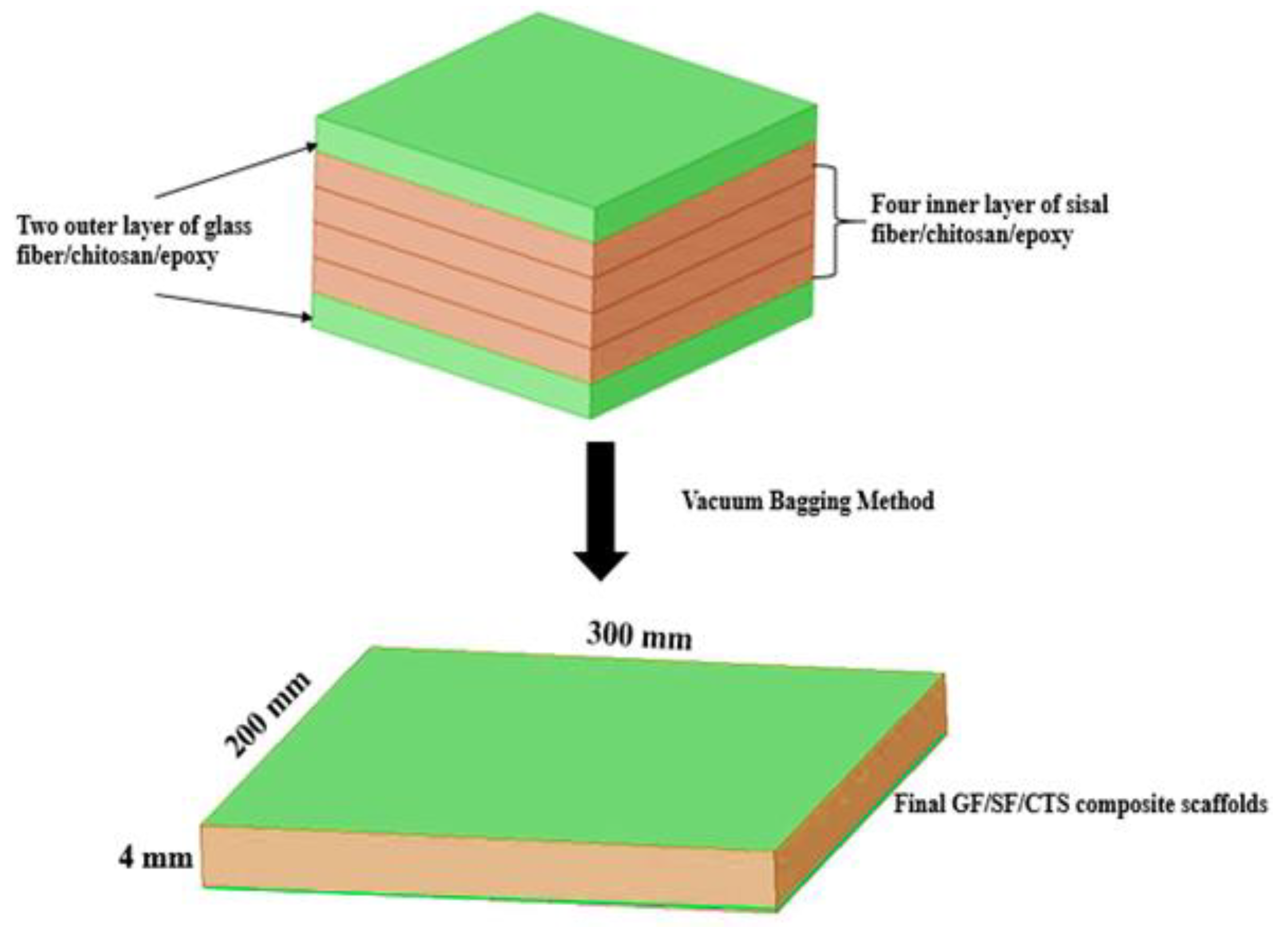

4.2. Flexural Properties of the Composite Scaffolds

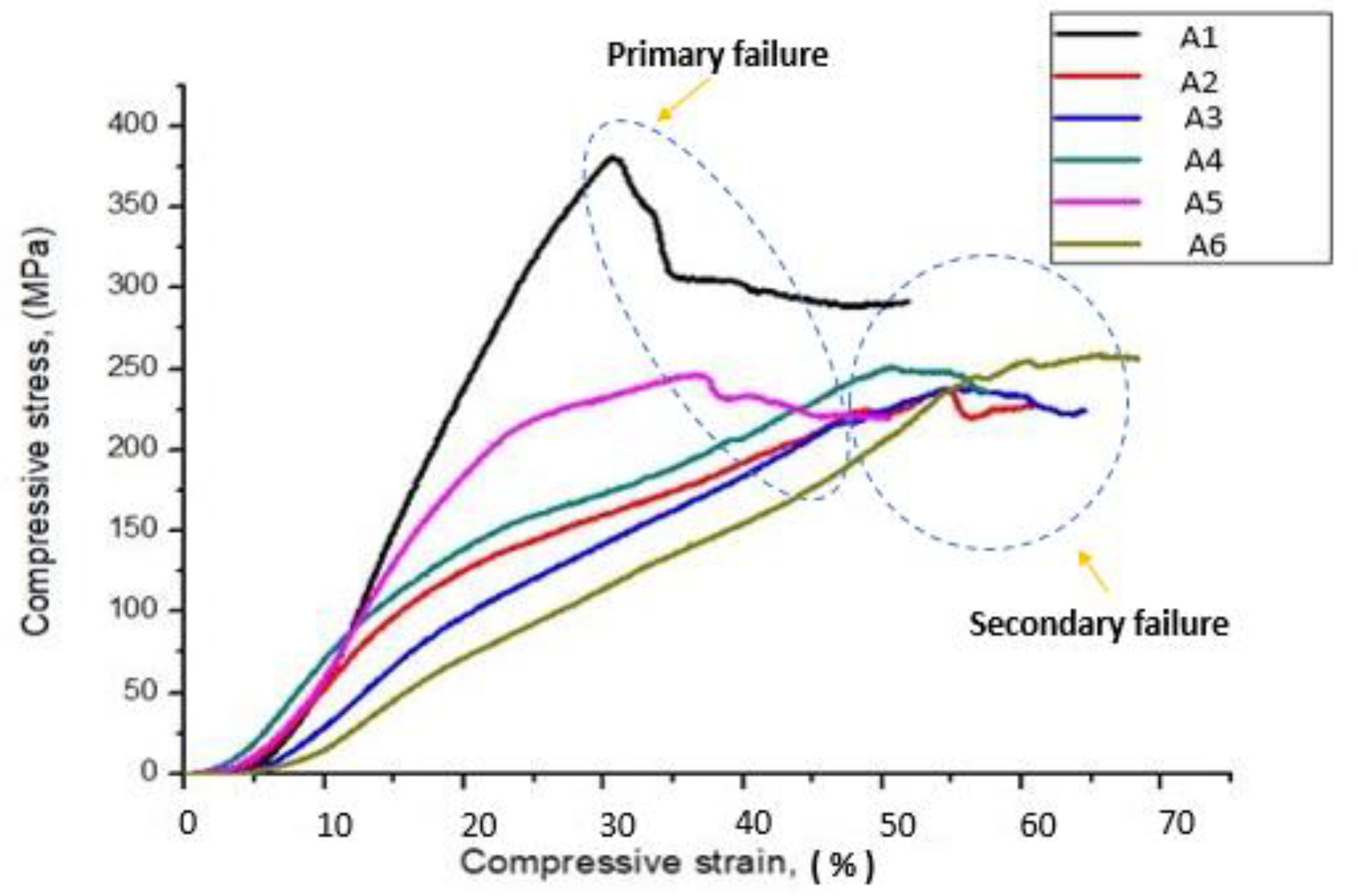

4.3. Compressive Properties of the Composite Scaffolds

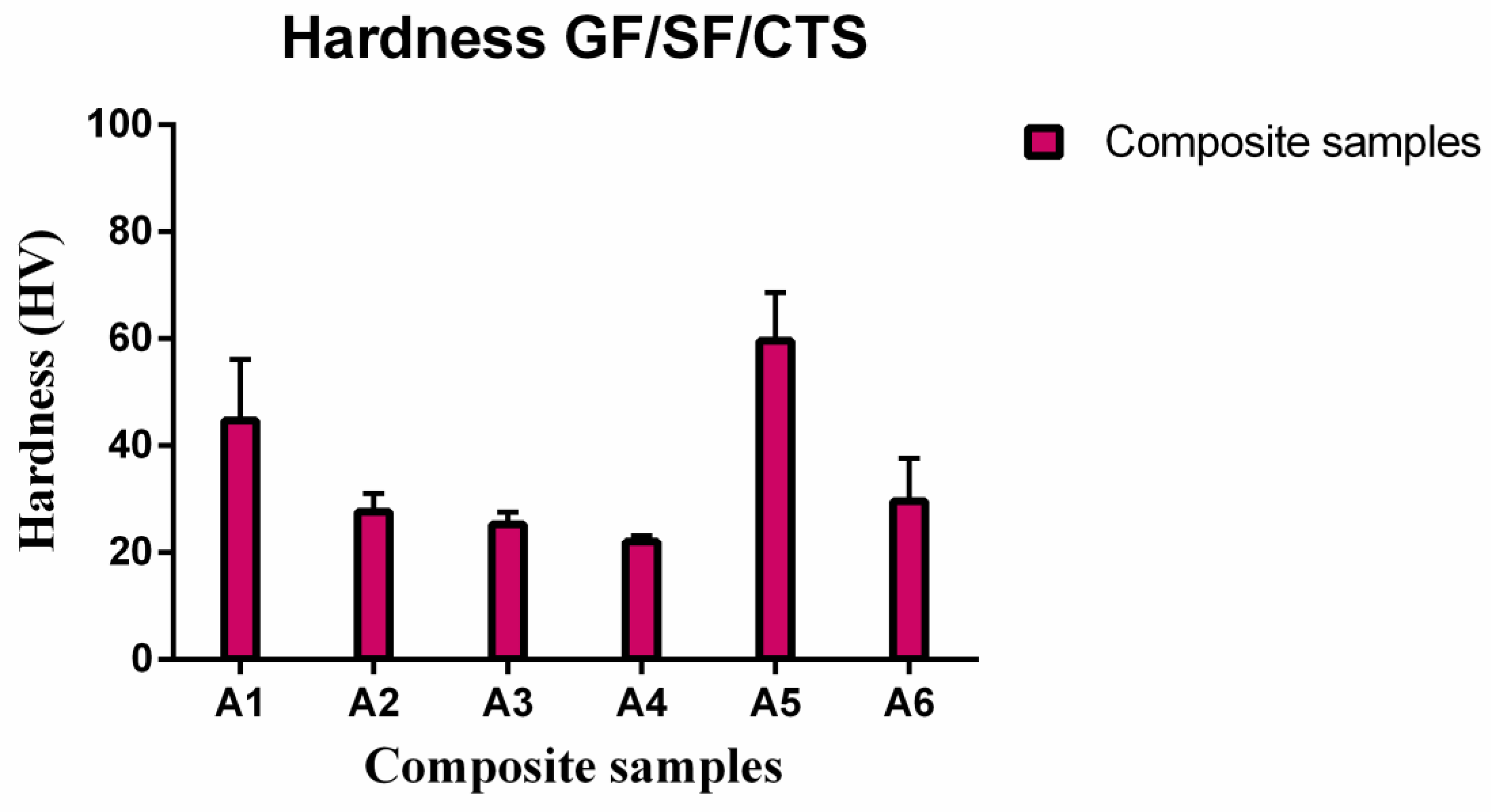

4.4. Micro Hardness Behavior of Composite Scaffolds

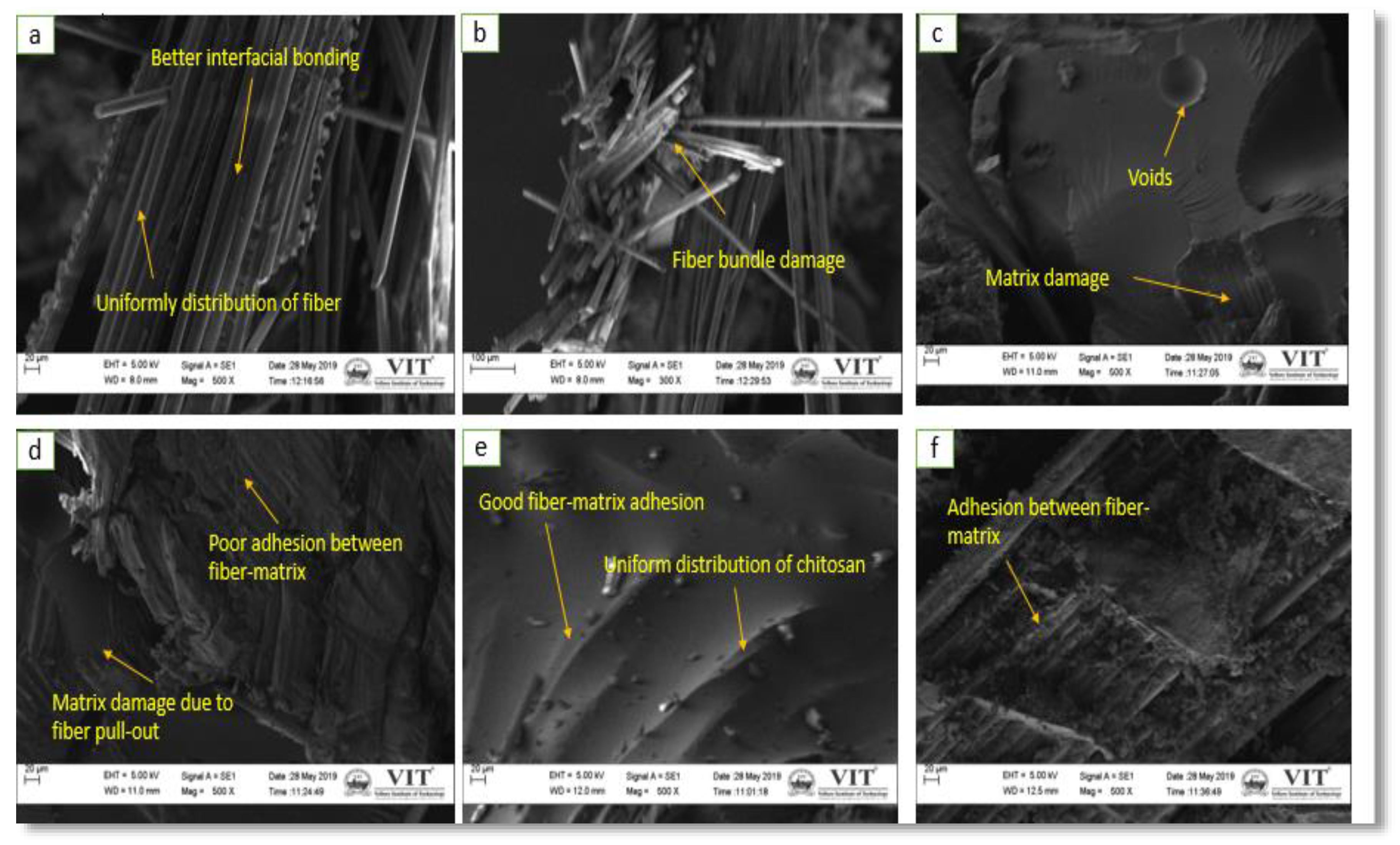

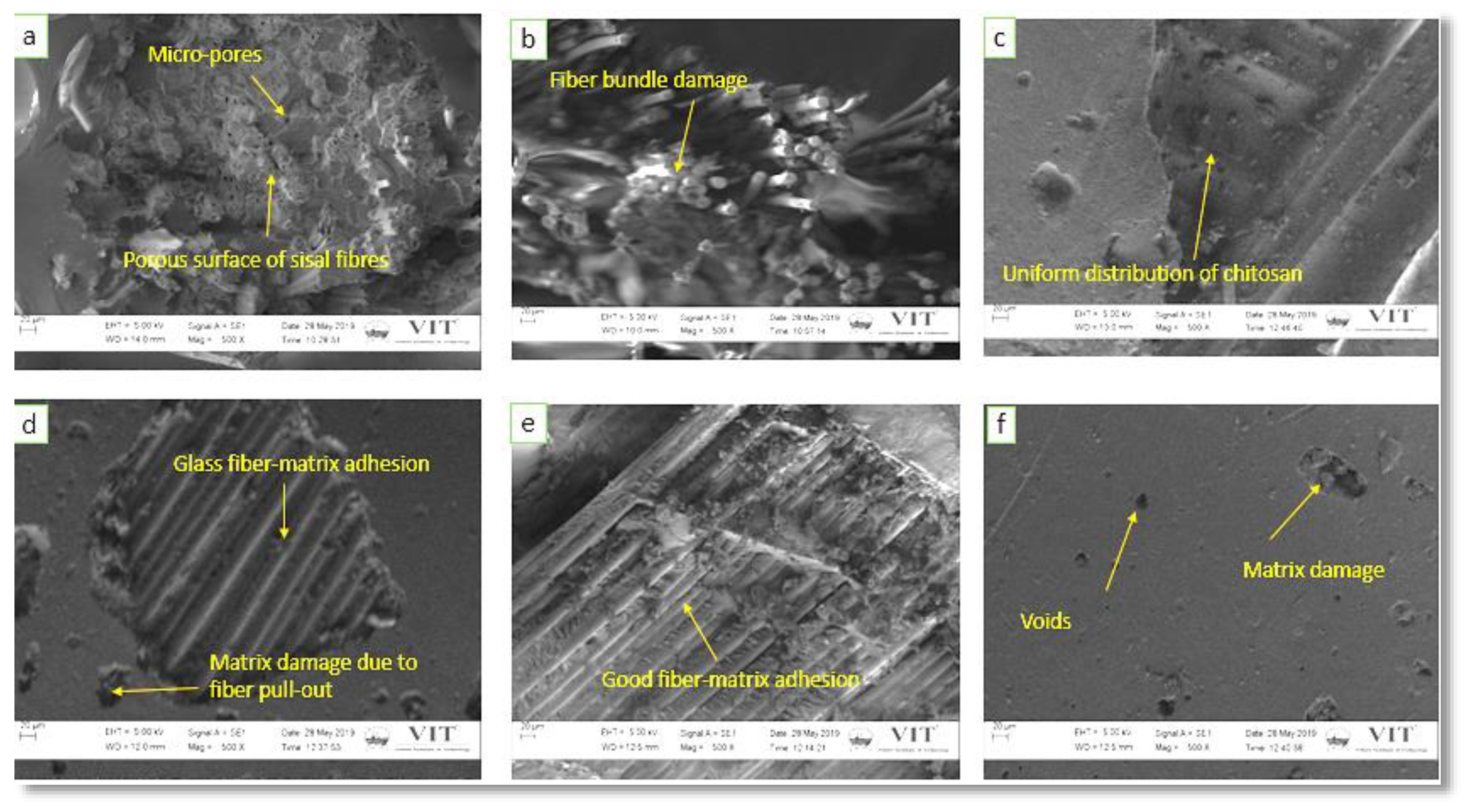

4.5. Surface Morphology Study

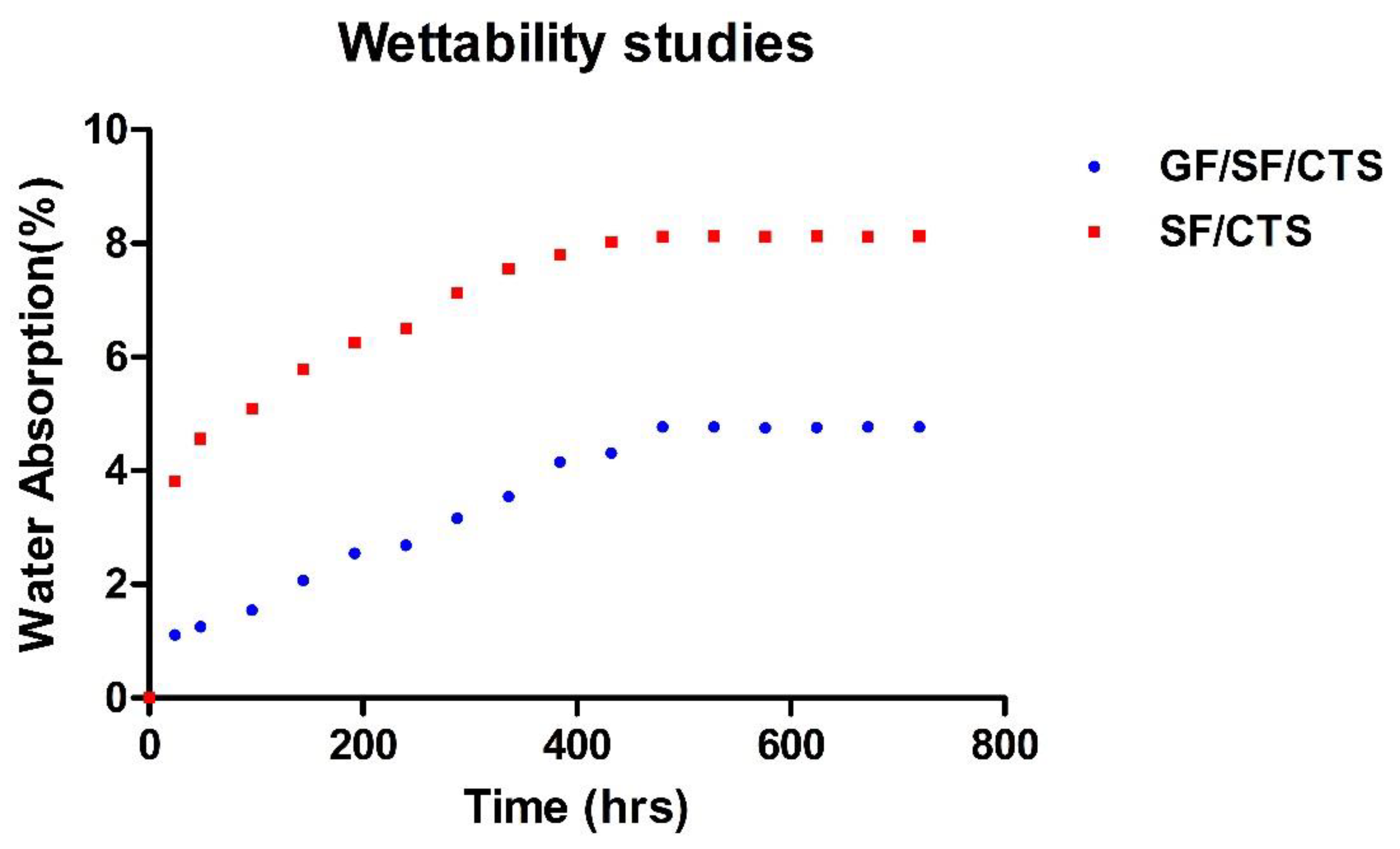

4.6. Wettability

4.7. Porosity of the Composite Scaffolds

5. Conclusions

- The mechanical properties of the GF/SF/CTS composite scaffolds reveal that the flexural stress (260 ± 6.47 MPa) and compressive stress (297 ± 5.57 MPa) were higher compared to those of the tension (134 ± 3.7 MPa).

- The hybrid GF/SF/CTS composite sample A5 showed considerable improvements in a compressive strength of 380 MPa (37.63%) and flexural strength of 343 MPa (34.11%) compared to other combinations.

- The hybrid GF/SF/CTS composite sample A5 showed maximum Vickers hardness of 59.6 ± 9.0 HV value compared to other combinations.

- The wettability study results reveal that the water CA of GF/SF/CTS composite scaffolds as 92°, exhibiting a hydrophobic nature. Whereas, the SF/CTS composite shows a hydrophilic nature at CA 57°.

- Water absorption properties show that the GF/SF/CTS composite scaffolds have less water absorption rate of 3.436% compared to the SF/CTS composites 6.953%.

- The GF/SF/CTS composite scaffolds showed considerable average porosity percentage of 3.243% using the ethanol infiltration method. The optimum value of porosity allows the growth of cells inside the scaffolds and thereby improving the mechanical stability between the composite scaffolds and natural bone.

- The statistical analysis showed that the null hypothesis is invalid and there are statistically significant differences between the mechanical properties and composite configurations.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Scholz, M.S.; Blanchfield, J.P.; Bloom, L.D. The use of composite materials in modern orthopaedic medicine and prosthetic devices: A review. Compos. Sci. Technol. 2011, 71, 1791–1803. [Google Scholar] [CrossRef]

- Ganesh, V.K.; Ramakrishna, K.; Ghista, D.N. Biomechanics of bone-fracture fixation by stiffness-graded plates in comparison with stainless-steel plates. Biomed. Eng. Online 2005, 4, 1–15. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, Z.M.; Fujihara, K. Stiffness and strength design of composite bone plates. Compos. Sci. Technol. 2005, 65, 73–85. [Google Scholar] [CrossRef]

- Ramakrishna, S.; Mayer, J.; Wintermantel, E.; Leong, K.W. Biomedical applications of polymer-composite materials: A review. Compos. Sci. Technol. 2001, 61, 1189–1224. [Google Scholar] [CrossRef]

- Rezwan, K.; Chen, Q.Z.; Blaker, J.J.; Boccaccini, A.R. Biodegradable and bioactive porous polymer/inorganic composite scaffolds for bone tissue engineering. Biomaterials 2006, 27, 3413–3431. [Google Scholar] [CrossRef] [PubMed]

- Jiang, G.; Evans, M.E.; Jones, I.A.; Rudd, C.D. Preparation of poly(epsilon-caprolactone)/continuous bioglass fibre composite using monomer transfer moulding for bone implant. Biomaterials 2005, 26, 2281–2288. [Google Scholar] [CrossRef] [PubMed]

- Gollwitzer, H.; Ibrahim, K.; Meyer, H.; Mittelmeier, W. Antibacterial poly (D, L-lactic acid) coating of medical implants using a biodegradable drug delivery technology. J. Antimicrob. Chemother. 2003, 51, 585–591. [Google Scholar] [CrossRef] [Green Version]

- Hamad, K.; Kaseem, M.; Yang, H.W.; Deri, F. Properties and medical applications of polylactic acid: A review. Express Polym. Lett. 2015, 9, 435–455. [Google Scholar] [CrossRef]

- Nair, L.S.; Laurencin, C.T. Biodegradable polymers as biomaterials. Prog. Polym. Sci. 2007, 32, 762–798. [Google Scholar] [CrossRef]

- Daniels, A.U.; Chang, M.K.; Andriano, K.P. Mechanical properties of biodegradable polymers and composites proposed for internal fixation of bone. J. Appl. Biomater. 1990, 1, 57–78. [Google Scholar] [CrossRef]

- Dhandayuthapani, B.; Yoshida, Y.; Maekawa, T.; Kumar, D.S. Polymeric Scaffolds in Tissue Engineering Application: A Review. Int. J. Polym. Sci. 2011, 2011, 290602. [Google Scholar] [CrossRef]

- Polizu, S.; Savadogo, O.; Poulin, P.; Yahia, L. Applications of carbon nanotubes-based biomaterials in biomedical nanotechnology. J. Nanosci. Nanotechnol. 2006, 6, 1883–1904. [Google Scholar] [CrossRef] [PubMed]

- Suner, S.; Bladen, C.L.; Gowland, N.; Tipper, J.L. Investigation of wear and wear particles from a UHMWPE/multi-walled carbon nanotube nanocomposite for total joint replacements. Wear 2014, 317, 163–169. [Google Scholar] [CrossRef]

- Mehboob, H.; Chang, S.H. Application of composites to orthopedic prostheses for effective bone healing: A review. Compos. Struct. 2014, 118, 328–341. [Google Scholar] [CrossRef]

- Fujihara, K.; Huang, Z.M.; Ramakrishna, S.; Satknanantham, K.; Hamada, H. Feasibility of knitted carbon/PEEK composites for orthopedic bone plates. Biomaterials 2004, 25, 3877–3885. [Google Scholar] [CrossRef]

- Li, X.; Chu, C.; Zhou, L.; Bai, J.; Guo, C.; Xue, F. Fully degradable PLA-based composite reinforced with 2D-braided Mg wires for orthopedic implants. Compos. Sci. Technol. 2017, 142, 180–188. [Google Scholar] [CrossRef]

- Zhao, C.; Wu, H.; Ni, J.; Zhang, S.; Zhang, X. Development of PLA/Mg composite for orthopedic implant: Tunable degradation and enhanced mineralization. Compos. Sci. Technol. 2017, 147, 8–15. [Google Scholar] [CrossRef]

- Wan, Y.Z.; Wang, Y.L.; He, F.; Huang, Y.; Jiang, H.J. Mechanical performance of hybrid bismaleimide composites reinforced with three-dimensional braided carbon and Kevlar fabrics. Compos. Part A Appl. Sci. Manuf. 2007, 38, 495–504. [Google Scholar] [CrossRef]

- Barua, S.; Dutta, N.; Karmakar, S.; Chattopadhyay, P.; Aidew, L.; Buragohain, A.K. Biocompatible high performance hyperbranched epoxy/clay nanocomposite as an implantable material. Biomed. Mater. 2014, 9, 025006. [Google Scholar] [CrossRef]

- Pandey, J.K.; Ahn, S.H.; Lee, C.S.; Mohanty, A.K.; Misra, M. Recent Advances in the Application of Natural Fiber Based Composites. Macromol. Mater. Eng. 2010, 295, 975–989. [Google Scholar] [CrossRef]

- Cheung, H.; Ho, M.; Lau, K.; Cardona, F.; Hui, D. Natural fibre-reinforced composites for bioengineering and environmental engineering applications. Compos. Part B Eng. 2009, 40, 655–663. [Google Scholar] [CrossRef]

- Pothan, L.A.; Mai, Y.W.; Thomas, S.; Li, R.K.Y. Tensile and Flexural Behavior of Sisal Fabric/Polyester Textile Composites Prepared by Resin Transfer Molding Technique. J. Reinf. Plast. Compos. 2008, 27, 1847–1866. [Google Scholar] [CrossRef]

- Shibata, S.; Cao, Y.; Fukumoto, I. Flexural modulus of the unidirectional and random composites made from biodegradable resin and bamboo and kenaf fibres. Compos. Part A Appl. Sci. Manuf. 2008, 39, 640–646. [Google Scholar] [CrossRef]

- Yang, J.; Gerry, L.K.; Guang, C.; Linhui, Z.; Antonios, G.M.; Fuzhai, C. A review on the exploitation of biodegradable magnesium-based composites for medical applications. Biomed. Mater. 2018, 13, 022001. [Google Scholar] [CrossRef]

- Soundhar, A.; Jayakrishna, K. Mechanical, Chemical and Morphological Analysis of Crab shell/Sisal Natural Fiber Hybrid Composites. J. Nat. Fibers 2019, 1–15. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Arpitha, G.R.; Yogesha, B. Study on Mechanical Properties of Natural-Glass Fibre Reinforced Polymer Hybrid Composites: A Review. Mater. Today Proc. 2015, 2, 2959–2967. [Google Scholar] [CrossRef]

- Noorunnisa Khanam, P.; Abdul Khalil, H.P.S.; Jawaid, M.; Ramachandra Reddy, G.; Surya Narayana, C.; Venkata Naidu, S. Sisal/Carbon Fibre Reinforced Hybrid Composites: Tensile, Flexural and Chemical Resistance Properties. J. Polym. Environ. 2010, 18, 727–733. [Google Scholar] [CrossRef]

- Rajesh, M.; Pitchaimani, J. Dynamic mechanical analysis and free vibration behavior of intra-ply woven natural fiber hybrid polymer composite. J. Reinf. Plast. Compos. 2015, 35, 228–242. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Naveen, J.; Navaneethakrishnan, P.; Satheeshkumar, S.; Rajini, N. Characterization of sisal/cotton fibre woven mat reinforced polymer hybrid composites. J. Ind. Text. 2016, 47, 429–452. [Google Scholar] [CrossRef]

- Romanzini, D.; Lavoratti, A.; Ornaghi, H.L.; Amico, S.C.; Zattera, A.J. Influence of fiber content on the mechanical and dynamic mechanical properties of glass/ramie polymer composites. Mater. Des. 2013, 47, 9–15. [Google Scholar] [CrossRef]

- Ahmed, K.S.; Vijayarangan, S. Tensile, flexural and interlaminar shear properties of woven jute and jute-glass fabric reinforced polyester composites. J. Mater. Process. Technol. 2008, 207, 330–335. [Google Scholar] [CrossRef]

- Jarukumjorn, K.; Suppakarn, N. Effect of glass fiber hybridization on properties of sisal fiber-polypropylene composites. Compos. Part B Eng. 2009, 40, 623–627. [Google Scholar] [CrossRef]

- Gouda, D.A.T.; Jagadish, S.P.; Dinesh, K.R.; Gouda, H. Characterization and Investigation of Mechanical Properties of Hybrid Natural Fiber Polymer Composite Materials Used as Orthopaedic Implants for Femur Bone Prosthesis. Iosr J. Mech. Civ. Eng. 2014, 11, 40–52. [Google Scholar] [CrossRef]

- Manteghi, S.; Mahboob, Z.; Fawaz, Z.; Bougherara, H. Investigation of the mechanical properties and failure modes of hybrid natural fiber composites for potential bone fracture fixation plates. J. Mech. Behav. Biomed. Mater. 2017, 65, 306–316. [Google Scholar] [CrossRef] [PubMed]

- Yunus, M.; Alsoufi, M.S. Experimental Investigations into the Mechanical, Tribological, and Corrosion Properties of Hybrid Polymer Matrix Composites Comprising Ceramic Reinforcement for Biomedical Applications. Int. J. Biomater. 2018, 2018, 9283291. [Google Scholar] [CrossRef] [PubMed]

- Manjubala, I.; Basu, P.; Narendrakumar, U. In situ synthesis of hydroxyapatite/carboxymethyl cellulose composites for bone regeneration applications. Colloid Polym. Sci. 2018, 296, 1729–1737. [Google Scholar] [CrossRef]

- Kong, M.; Chen, X.G.; Xing, K.; Park, H.J. Antimicrobial properties of chitosan and mode of action: A state of the art review. Int. J. Food Microbiol. 2010, 144, 51–63. [Google Scholar] [CrossRef]

- Kumar, M.R. A review of chitin and chitosan applications. React. Funct. Polym. 2000, 46, 1–27. [Google Scholar] [CrossRef]

- Amri, F.; Husseinsyah, S.; Hussin, K. Mechanical, morphological and thermal properties of chitosan filled polypropylene composites: The effect of binary modifying agents. Compos. Part A Appl. Sci. Manuf. 2013, 46, 89–95. [Google Scholar] [CrossRef]

- Li, R.; Lin, S.; Zhu, M.; Deng, Y.; Chen, X.; Wei, K.; Xu, J.; Li, G.; Bian, L. Synthetic presentation of noncanonical Wnt5a motif promotes mechanosensing-dependent differentiation of stem cells and regeneration. Sci. Adv. 2019, 5, 3896. [Google Scholar] [CrossRef] [Green Version]

- Kang, H.; Yang, B.; Zhang, K.; Pan, Q.; Yuan, W.; Li, G.; Bian, L. Immunoregulation of macrophages by dynamic ligand presentation via ligand–cation coordination. Nat. Commun. 2019, 10, 1–14. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bagheri, Z.S.; Sawi, I.; Schemitsch, E.H.; Zdero, R.; Bougherara, H. Biomechanical properties of an advanced new carbon/flax/epoxy composite material for bone plate applications. J. Mech. Behav. Biomed. Mater. 2013, 20, 398–406. [Google Scholar] [CrossRef] [PubMed]

- Soundhar, A.; Jayakrishna, K. Investigations on mechanical and morphological characterization of chitosan reinforced polymer nanocomposites. Mater. Res. Express 2019, 6, 075301. [Google Scholar] [CrossRef]

- Cheour, K.; Assarar, M.; Scida, D.; Gong, X.L. Long-term Immersion in Water of Flax-glass Fibre Hybrid Composites: Effect of Stacking Sequence on the Mechanical and Damping Properties. Fiber Polym. 2020, 21, 162–169. [Google Scholar] [CrossRef]

- Bharanichandar, J.; Chandramohan, D.; Murali, B. Natural Fiber Reinforced Polymer Composite in Synthetic Bone Grafting—A New Approach. J. Middle East Appl. Sci. Technol. 2014, 16, 588–596. [Google Scholar]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Mechanical property evaluation of sisal–jute–glass fiber reinforced polyester composites. Compos. Part B Eng. 2013, 48, 1–9. [Google Scholar] [CrossRef]

- Salman, S.D.; Hassim, W.W.; Leman, Z. Experimental Comparison between Two Types of Hybrid Composite Materials in Compression Test. Manuf. Sci. Technol. 2015, 3, 119–123. [Google Scholar]

- Yoldas, O.; Akova, T.; Uysal, H. Influence of different indentation load and dwell time on Knoop microhardness tests for composite materials. Polym. Test. 2004, 23, 343–346. [Google Scholar] [CrossRef]

- Bagheri, Z.S.; Giles, E.; El Sawi, I.; Amleh, A.; Schemitsch, E.H.; Zdero, R. Osteogenesis and cytotoxicity of a new Carbon Fiber/Flax/Epoxy composite material for bone fracture plate applications. Mater. Sci. Eng. C Mater. Biol. Appl. 2015, 46, 435–442. [Google Scholar] [CrossRef]

- Sgriccia, N.; Hawley, M.C.; Misra, M. Characterization of natural fiber surfaces and natural fiber composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1632–1637. [Google Scholar] [CrossRef]

- Kakkar, P.; Verma, S.; Manjubala, I.; Madhan, B. Development of keratin-chitosan-gelatin composite scaffold for soft tissue engineering. Mater. Sci. Eng. C Mater. Biol. Appl. 2014, 45, 343–347. [Google Scholar] [CrossRef] [PubMed]

- Ary Subagia, I.D.G.; Kim, Y.; Tijing, L.D.; Kim, C.S.; Shon, H.K. Effect of stacking sequence on the flexural properties of hybrid composites reinforced with carbon and basalt fibers. Compos. Part B Eng. 2014, 58, 251–258. [Google Scholar] [CrossRef]

- Dziadek, M.; Stodolak-Zych, E.; Cholewa-Kowalska, K. Biodegradable ceramic-polymer composites for biomedical applications: A review. Mater. Sci. Eng. C Mater. Biol. Appl. 2017, 71, 1175–1191. [Google Scholar] [CrossRef] [PubMed]

- Marcos, J.J.L.; Perrotti, V.; Iaculli, F.; Aragones, A.; Benfatti, C.A.M.; Magrin, G.L.; Piattelli, A.; Bianchini, M.A. Physical and mechanical properties of composite scaffolds with or without collagen impregnation. Appl. Sci. 2019, 9, 4296. [Google Scholar] [CrossRef] [Green Version]

| Natural/Synthetic Hybrid Fiber | Polymer Matrix | Stacking Sequence/Properties | Applications | References |

|---|---|---|---|---|

| Flax (F)/carbon fiber (C) | Epoxy | 2C-16F-2C/ high ultimate strength in both tension and flexural loading | Tissue engineering applications | Bazheri et al. (2013) [42] |

| Hemp (H)/jute (J)/sisal fiber (S) | Epoxy | SSJHJHSS/ Higher tensile, flexural and compression | Femur bone applications | Gouda et al. (2014) [33] |

| Flax (F)/glass fiber (G) | Epoxy | 2G-12F-2G/ Higher stiffness and strength in bending | Femur bone plate applications | Manteghi et al. (2017) [34] |

| Flax (F)/glass fiber (G) | Epoxy | GGFFFFGG/ Higher bending modulus and lower water absorption rate | Biomedical applications | Cheour et al. (2020) [44] |

| Sample Designation | Chitosan (wt%) | Sisal Fiber (Layer) | Glass Fiber (Layer) |

|---|---|---|---|

| A1 | 0 | 3 | 2 |

| A2 | 0 | 4 | 2 |

| A3 | 1 | 3 | 2 |

| A4 | 1 | 4 | 2 |

| A5 | 2 | 3 | 2 |

| A6 | 2 | 4 | 2 |

| Composite Samples | Tensile Stress (MPa) | Tensile Modulus (MPa) | Flexural Stress (MPa) | Flexural Modulus (GPa) | Compressive Stress (MPa) | Compressive Modulus (MPa) |

|---|---|---|---|---|---|---|

| A1 | 137 ± 7.08 | 5698 ± 194 | 258 ± 6.87 | 12.511 ± 0.18 | 237 ± 4.72 | 925 ± 25 |

| A2 | 146 ± 5.50 | 6341 ± 129 | 201 ± 4.43 | 19.373 ± 0.26 | 251 ± 3.27 | 952 ± 32 |

| A3 | 135 ± 3.01 | 5665 ± 178 | 226 ± 3.89 | 15.813 ± 0.23 | 301 ± 6.58 | 1879 ± 48 |

| A4 | 139 ± 1.33 | 6646 ± 146 | 216 ± 5.91 | 19.705 ± 0.16 | 275 ± 5.42 | 1155 ± 27 |

| A5 | 120 ± 1.09 | 6576 ± 153 | 343 ± 9.02 | 21.561 ± 0.47 | 380 ± 7.12 | 2046 ± 68 |

| A6 | 131 ± 4.42 | 6054 ± 186 | 306 ± 8.71 | 21.180 ± 0.21 | 341 ± 6.36 | 1917 ± 51 |

| Composite Samples | Vickers Micro Hardness (HV) |

|---|---|

| A1 | 44.7 ± 11.4 |

| A3 | 25.3 ± 2.2 |

| A5 | 59.6 ± 9.0 |

| A2 | 27.6 ± 3.4 |

| A4 | 22 ± 1.1 |

| A6 | 29.6 ± 8.0 |

| Composite Samples | Initial Weight (g) | Final Weight (g) | Percentage of Porosity (%) |

|---|---|---|---|

| A1 | 0.6994 | 0.7247 | 5.87 |

| A2 | 1.2798 | 1.3021 | 3.10 |

| A3 | 0.6756 | 0.6970 | 4.96 |

| A4 | 0.8510 | 0.8600 | 1.27 |

| A5 | 1.3376 | 1.3558 | 2.679 |

| A6 | 1.4679 | 1.4810 | 1.5821 |

| Material | Tensile Strength (MPa) | Bending Strength (MPa) | Compressive Strength (MPa) | References |

|---|---|---|---|---|

| Sisal/carbon fiber/polyester | 84.44–107.51 | 140.89–169.14 | - | Khanam et al. (2010) [27] |

| Sisal/banana/roselle | 60.04–72.41 | 102.41–118.51 | - | Bharanichandar et al. (2014) [45] |

| Femur bone | 43.44 ± 3.62 | 84.04 ± 9.91 | 115.29 ± 12.94 | Gouda et al. (2014) [33] |

| Current GF/SF/CTS | 120–146 * | 201–343 * | 237–380 * | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arumugam, S.; Kandasamy, J.; Md Shah, A.U.; Hameed Sultan, M.T.; Safri, S.N.A.; Abdul Majid, M.S.; Basri, A.A.; Mustapha, F. Investigations on the Mechanical Properties of Glass Fiber/Sisal Fiber/Chitosan Reinforced Hybrid Polymer Sandwich Composite Scaffolds for Bone Fracture Fixation Applications. Polymers 2020, 12, 1501. https://doi.org/10.3390/polym12071501

Arumugam S, Kandasamy J, Md Shah AU, Hameed Sultan MT, Safri SNA, Abdul Majid MS, Basri AA, Mustapha F. Investigations on the Mechanical Properties of Glass Fiber/Sisal Fiber/Chitosan Reinforced Hybrid Polymer Sandwich Composite Scaffolds for Bone Fracture Fixation Applications. Polymers. 2020; 12(7):1501. https://doi.org/10.3390/polym12071501

Chicago/Turabian StyleArumugam, Soundhar, Jayakrishna Kandasamy, Ain Umaira Md Shah, Mohamed Thariq Hameed Sultan, Syafiqah Nur Azrie Safri, Mohd Shukry Abdul Majid, Adi Azriff Basri, and Faizal Mustapha. 2020. "Investigations on the Mechanical Properties of Glass Fiber/Sisal Fiber/Chitosan Reinforced Hybrid Polymer Sandwich Composite Scaffolds for Bone Fracture Fixation Applications" Polymers 12, no. 7: 1501. https://doi.org/10.3390/polym12071501