Effect of Friction Stir Welding Techniques and Parameters on Polymers Joint Efficiency—A Critical Review

Abstract

:1. Introduction

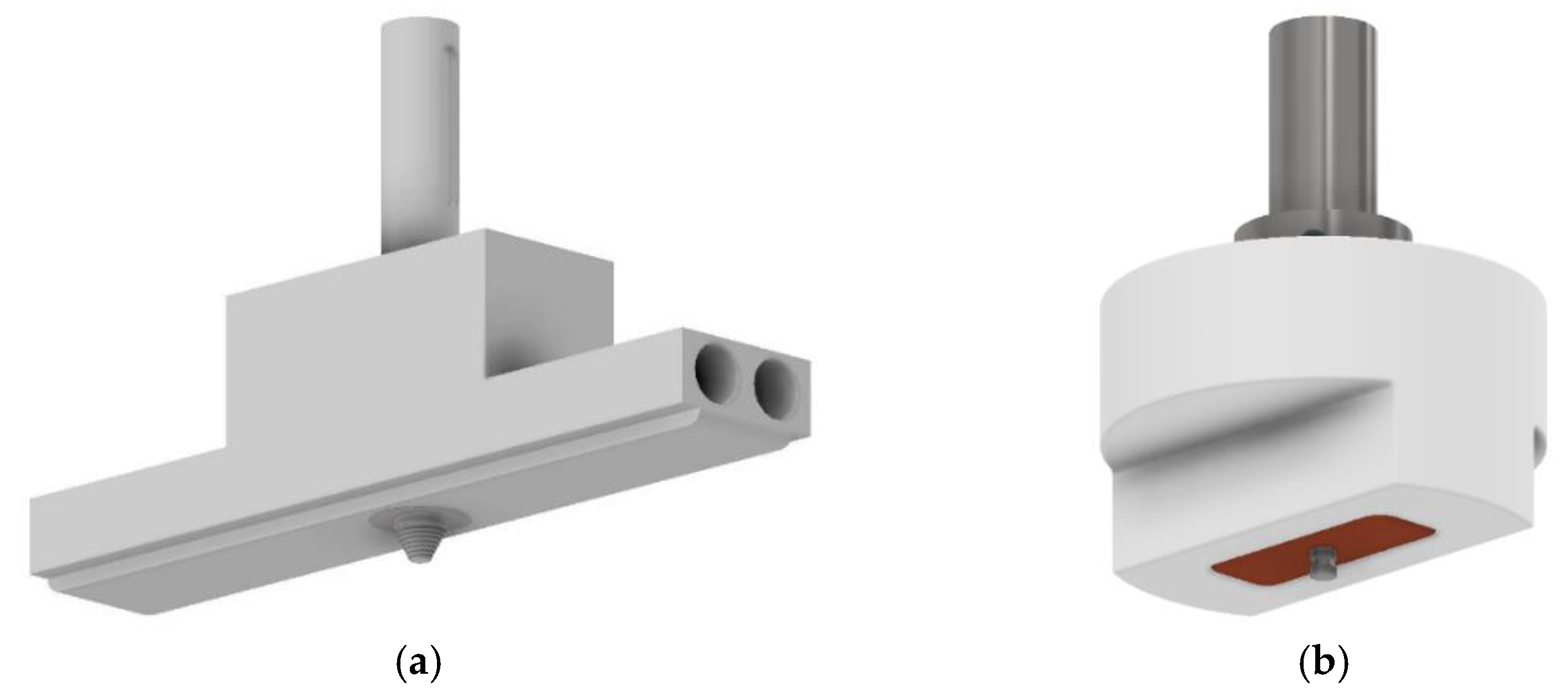

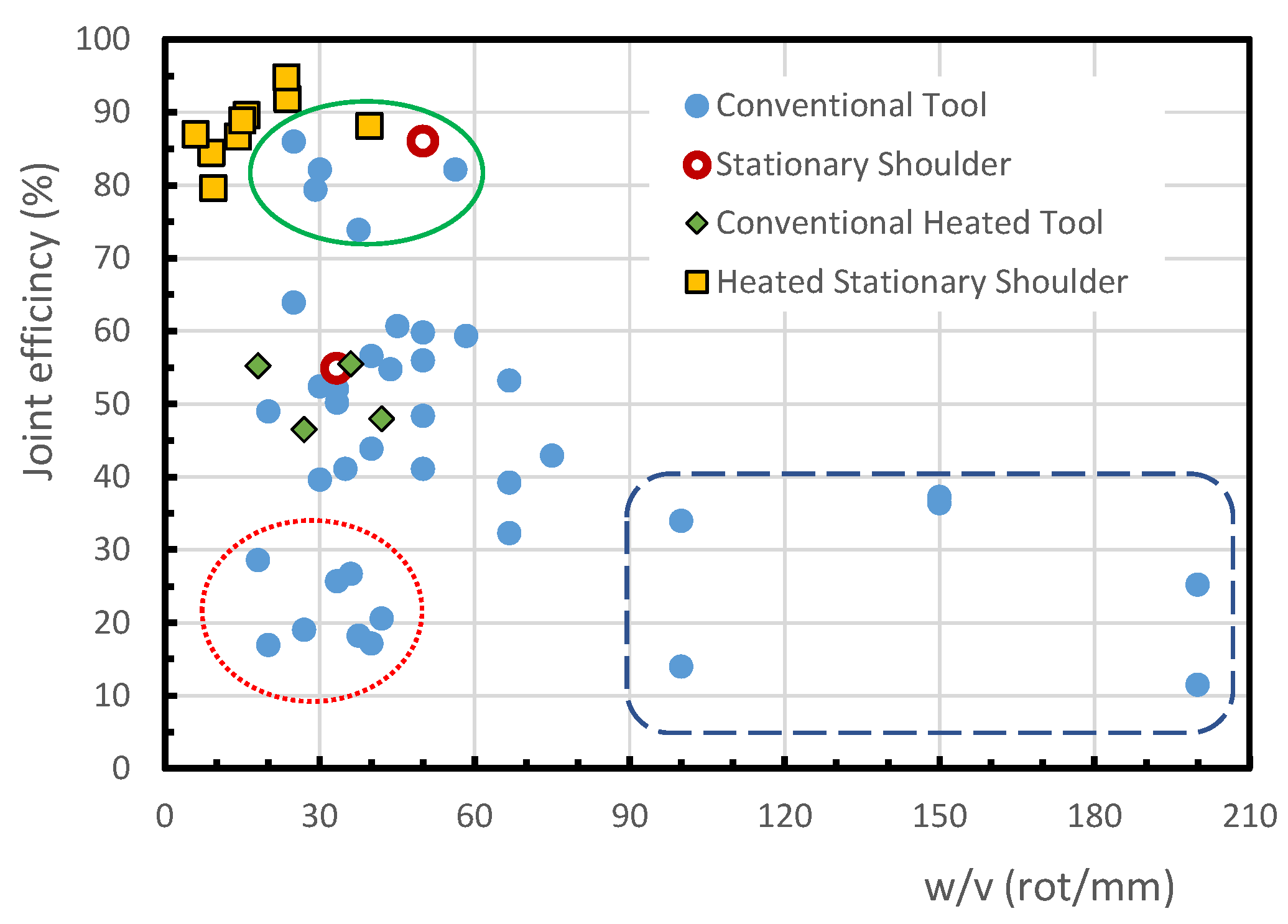

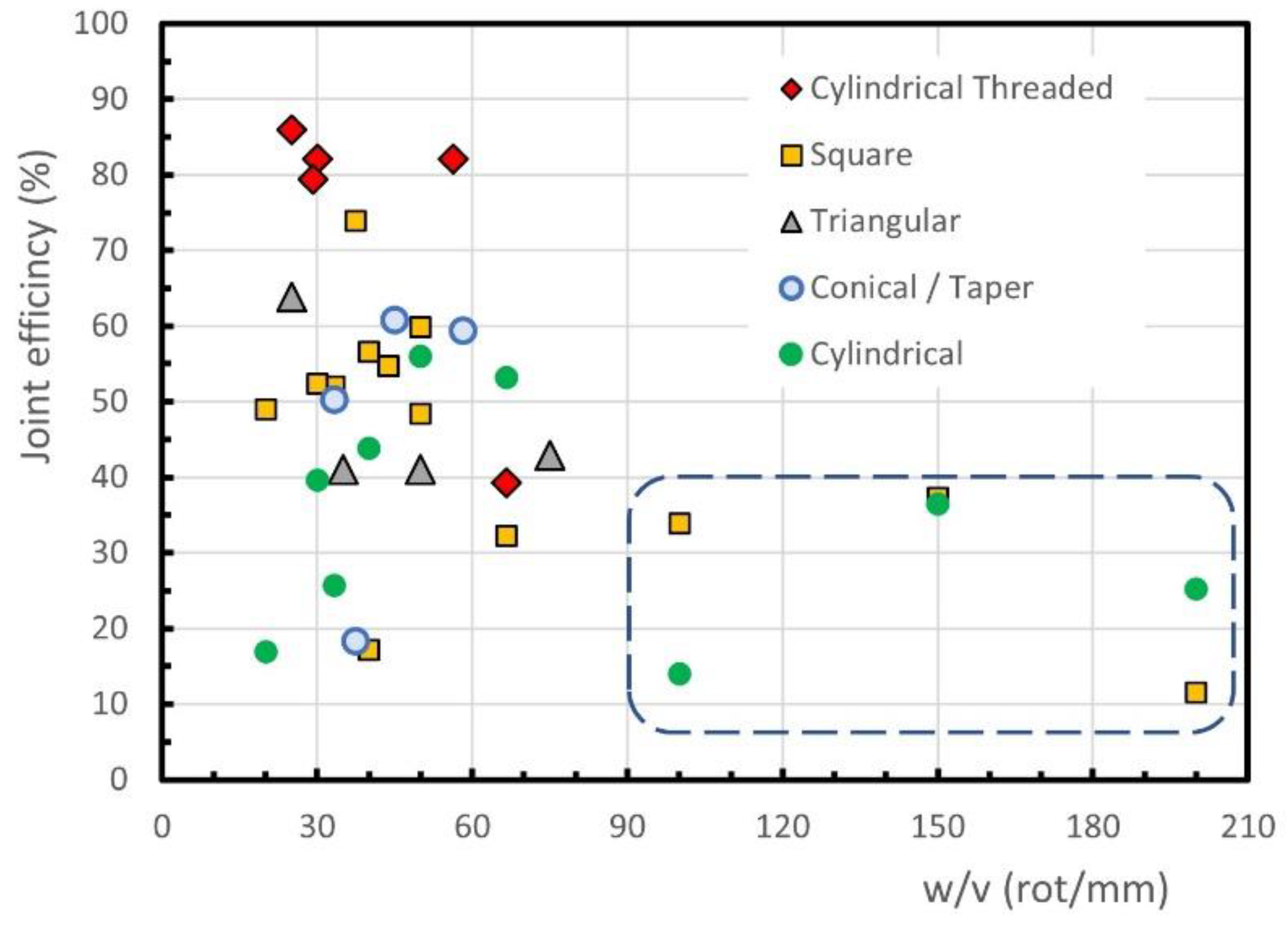

2. Graphical Presentation of Data

3. Data analysis

3.1. FSW With Conventional Tool

3.1.1. Welds in Polyethylene

3.1.2. Welds in Polypropylene

3.2. Double-Side FSW

3.3. FSW with Stationary Shoulder Tool

3.4. FSW of Preheated Polymer

3.5. FSW with Conventional Heated Tool

3.6. FSW with Tool of Heated Stationary Shoulder

3.6.1. Welds in Polyethylene

3.6.2. Welds in Polypropylene

3.7. FSW in Other Polymeric Materials

4. Discussion, Conclusions, and Future Work

- The quantification of the heat generated in the welding of polymers and the contribution of the heat added externally are still undefined.

- The effect of the plunge depth or axial force on the morphology and strength of the welds was not discussed in most of the works and needs further research.

- There are still only a few studies that analyse the microstructure and degree of crystallinity of the welds and their relationship with the welding parameters, so this aspect must be studied further.

- The relationship between the physical properties of the polymers and the optimal welding parameters needs careful analysis.

- Heated Stationary Shoulder tools are poorly adapted for welding on three-dimensional paths, so it is necessary to rethink the design of the tools for these applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Strand, S. Joining plastics—Can Friction Stir Welding compete? In Proceedings of the Electrical Insulation Conference and Electrical Manufacturing and Coil Winding Conference and Exhibition, Indianapolis, IN, USA, 25 September 2003; pp. 321–326. [Google Scholar]

- Mishra, D.; Sahu, S.K.; Mahto, R.P.; Pal, S.K.; Pal, K. Friction Stir Welding for Joining of Polymers. In Strengthening and Joining by Plastic Deformation; Dixit, U., Narayanan, R., Eds.; Springer: Singapore, 2019; pp. 123–162. [Google Scholar]

- Aydin, M. Effects of welding parameters and pre-heating on the friction stir welding of UHMW-polyethylene. Polym. Plast. Technol. Eng. 2010, 49, 595–601. [Google Scholar] [CrossRef]

- Amancio-Filho, S.T.; Dos Santos, J.F. Joining of polymers and polymer-metal hybrid structures: Recent developments and trends. Polym. Eng. Sci. 2009, 49, 1461–1476. [Google Scholar] [CrossRef]

- Awaja, F.; Gilbert, M.; Kelly, G.; Fox, B.; Pigram, P.J. Adhesion of polymers. Prog. Polym. Sci. 2009, 34, 948–968. [Google Scholar] [CrossRef]

- Amanat, N.; James, N.L.; McKenzie, D.R. Welding methods for joining thermoplastic polymers for the hermetic enclosure of medical devices. Med. Eng. Phys. 2010, 32, 690–699. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, F.A.O.; Pereira, A.B.; Guimarães, B.; Almeida, T. Laser welding of transmitting high-performance engineering thermoplastics. Polymers 2020, 12, 402. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vazquez-Martinez, J.M.; Piñero, D.; Salguero, J.; Batista, M. Evaluation of the joining response of biodegradable polylactic acid (PLA) from fused deposition modeling by infrared laser irradiation. Polymers 2020, 12, 2479. [Google Scholar] [CrossRef]

- Qiu, J.; Zhang, G.; Sakai, E.; Liu, W.; Zang, L. Thermal welding by the third phase between polymers: A review for ultrasonicweld technology developments. Polymers 2020, 12, 759. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahmed, T.J.; Stavrov, D.; Bersee, H.E.N.; Beukers, A. Induction welding of thermoplastic composites-an overview. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1638–1651. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A.; Di Ilio, A. Friction spot stir welding of polymers: Control of plunging force. Int. J. Adv. Manuf. Technol. 2017, 90, 2827–2837. [Google Scholar] [CrossRef]

- Pereira, A.B.; Fernandes, F.A.O.; de Morais, A.B.; Quintão, J. Mechanical strength of thermoplastic polyamide welded by Nd:YAG laser. Polymers 2019, 11, 1381. [Google Scholar] [CrossRef] [Green Version]

- Oliveira, P.H.F.; Amancio-Filho, S.T.; Dos Santos, J.F.; Hage, E. Preliminary study on the feasibility of friction spot welding in PMMA. Mater. Lett. 2010, 64, 2098–2101. [Google Scholar] [CrossRef] [Green Version]

- Zhu, X.; Liu, G.; Guo, Y.; Tian, Y. Study of PMMA thermal bonding. Microsyst. Technol. 2007, 13, 403–407. [Google Scholar] [CrossRef]

- Strand, S. Effects of Friction Stir Welding on Polymer Microstructure. Master’s Thesis, Brigham Young University, Provo, UT, USA, 2004. [Google Scholar]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Templesmith, P.; Dawes, C.J. Friction Stir Butt Welding. International Patent Application No. PCT/GB92/02203, 6 December 1991. [Google Scholar]

- Thomas, W.; Nicholas, E. Friction stir welding for the transportation industries. Mater. Des. 1997, 18, 269–273. [Google Scholar] [CrossRef]

- Payganeh, G.H.; Mostafa Arab, N.B.; Dadgar Asl, Y.; Ghasemi, F.A.; Saeidi Boroujeni, M. Effects of friction stir welding process parameters on appearance and strength of polypropylene composite welds. Int. J. Phys. Sci. 2011, 6, 4595–4601. [Google Scholar]

- Squeo, E.A.; Bruno, G.; Guglielmotti, A.; Quadrini, F. Friction stir welding of polyethylene sheets. Ann. DUNĂREA JOS Univ. Galati Fascicle V Technol. Mach. Build. 2009, 241–246. [Google Scholar]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Huang, Y.; Meng, X.; Wang, Y.; Xie, Y.; Zhou, L. Joining of aluminum alloy and polymer via friction stir lap welding. J. Mater. Process. Technol. 2018, 257, 148–154. [Google Scholar] [CrossRef]

- Thomas, W.M.; Johnson, K.I.; Wiesner, C.S. Friction Stir Welding—Recent Developments in Tool and Process Technologies. Adv. Eng. Mater. 2003, 5, 485–490. [Google Scholar] [CrossRef]

- Rezgui, M.A.; Ayadi, M.; Cherouat, A.; Hamrouni, K.; Zghal, A.; Bejaoui, S. Application of Taguchi approach to optimize friction stir welding parameters of polyethylene. EPJWC 2010, 6, 07003. [Google Scholar] [CrossRef] [Green Version]

- Inaniwa, S.; Kurabe, Y.; Miyashita, Y.; Hori, H. Application of friction stir welding for several plastic materials. In Proceedings of the 1st International Joint Symposium on Joining and Welding, Osaka, Japan, 6–8 November 2013; Elsevier: Amsterdam, The Netherlands, 2013; pp. 137–142. [Google Scholar]

- Bozkurt, Y. The optimization of friction stir welding process parameters to achieve maximum tensile strength in polyethylene sheets. Mater. Des. 2012, 35, 440–445. [Google Scholar] [CrossRef]

- Eslami, S.; Miranda, J.F.; Mourão, L.; Tavares, P.J.; Moreira, P.M.G.P. Polyethylene friction stir welding parameter optimization and temperature characterization. Int. J. Adv. Manuf. Technol. 2018, 99, 127–136. [Google Scholar] [CrossRef]

- Hussain, R.K.; Majeed, A.A. Thermoplastics Polymers Friction Stir Welding: Review. Int. J. Eng. Technol. 2018, 7, 4612–4616. [Google Scholar]

- Stokes, V.K. Joining methods for plastics and plastic composites: An overview. Polym. Eng. Sci. 1989, 29, 1310–1324. [Google Scholar] [CrossRef]

- Bagheri, A.; Azdast, T.; Doniavi, A. An experimental study on mechanical properties of friction stir welded ABS sheets. Mater. Des. 2013, 43, 402–409. [Google Scholar] [CrossRef]

- Mendes, N.; Loureiro, A.; Martins, C.; Neto, P.; Pires, J.N. Morphology and strength of acrylonitrile butadiene styrene welds performed by robotic friction stir welding. Mater. Des. 2014, 64, 81–90. [Google Scholar] [CrossRef]

- Mendes, N.; Loureiro, A.; Martins, C.; Neto, P.; Pires, J.N. Effect of friction stir welding parameters on morphology and strength of acrylonitrile butadiene styrene plate welds. Mater. Des. 2014, 58, 457–464. [Google Scholar] [CrossRef]

- Pirizadeh, M.; Azdast, T.; Rash Ahmadi, S.; Mamaghani Shishavan, S.; Bagheri, A. Friction stir welding of thermoplastics using a newly designed tool. Mater. Des. 2014, 54, 342–347. [Google Scholar] [CrossRef]

- Panneerselvam, K.; Lenin, K. Joining of Nylon 6 plate by friction stir welding process using threaded pin profile. Mater. Des. 2014, 53, 302–307. [Google Scholar] [CrossRef]

- Husain, I.M.; Salim, R.K.; Azdast, T.; Hasanifard, S.; Shishavan, S.M.; Lee, R.E. Mechanical properties of friction-stir-welded polyamide sheets. Int. J. Mech. Mater. Eng. 2015, 10, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Mostafapour, A.; Taghizad Asad, F. Investigations on joining of Nylon 6 plates via novel method of heat assisted friction stir welding to find the optimum process parameters. Sci. Technol. Weld. Join. 2016, 21, 660–669. [Google Scholar] [CrossRef]

- Aghajani Derazkola, H.; Simchi, A.; Lambiase, F. Friction stir welding of polycarbonate lap joints: Relationship between processing parameters and mechanical properties. Polym. Test. 2019, 79, 105999. [Google Scholar] [CrossRef]

- Lambiase, F.; Grossi, V.; Paoletti, A. Effect of tilt angle in FSW of polycarbonate sheets in butt configuration. Int. J. Adv. Manuf. Technol. 2020, 107, 489–501. [Google Scholar] [CrossRef]

- Mostafapour, A.; Azarsa, E. A study on the role of processing parameters in joining polyethylene sheets via heat assisted friction stir welding: Investigating microstructure, tensile and flexural properties. Int. J. Phys. Sci. 2012, 7, 647–654. [Google Scholar] [CrossRef]

- Saeedy, S.; Givi, M.K.B. Experimental investigation of double side friction stir welding (FSW) on high density polyethylene blanks. In American Society of Mechanical Engineers Digital Collection, Proceedings of the ASME 2010 10th Biennial Conference on Engineering Systems Design and Analysis, ESDA2010, Istanbul, Turkey, 12–14 July 2010; American Society of Mechanical Engineers, Petroleum Division: Los Angeles, CA, USA, 2010; Volume 4, pp. 845–848. [Google Scholar]

- Sharma, A.K.R.; Roy Choudhury, M.; Debnath, K. Experimental investigation of friction stir welding of PLA. Weld. World 2020, 1–11. [Google Scholar] [CrossRef]

- Aghajani Derazkola, H.; Simchi, A. Experimental and thermomechanical analysis of the effect of tool pin profile on the friction stir welding of poly(methyl methacrylate) sheets. J. Manuf. Process. 2018, 34, 412–423. [Google Scholar] [CrossRef]

- Elyasi, M.; Derazkola, H.A. Experimental and thermomechanical study on FSW of PMMA polymer T-joint. Int. J. Adv. Manuf. Technol. 2018, 97, 1445–1456. [Google Scholar] [CrossRef]

- Adibeig, M.R.; Hassanifard, S.; Vakili-Tahami, F.; Hattel, J.H. Experimental investigation of tensile strength of friction stir welded butt joints on PMMA. Mater. Today Commun. 2018, 17, 238–245. [Google Scholar] [CrossRef]

- Kiss, Z.; Czigány, T. Microscopic analysis of the morphology of seams in friction stir welded polypropylene. Express Polym. Lett. 2012, 6, 54–62. [Google Scholar] [CrossRef]

- Sharma, R.; Singh, O.P. Effect of FSW Process Parameters on Mechanical Properties of Polypropylene: An Experimental Study. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 7792–7798. [Google Scholar]

- Moochani, A.; Omidvar, H.; Ghaffarian, S.R.; Goushegir, S.M. Friction stir welding of thermoplastics with a new heat-assisted tool design: Mechanical properties and microstructure. Weld. World 2019, 63, 181–190. [Google Scholar] [CrossRef]

- Arici, A.; Sinmaz, T. Effects of double passes of the tool on friction stir welding of polyethylene. In Proceedings of the Journal of Materials Science; Springer: Heidelberg, Germany, 2005; Volume 40, pp. 3313–3316. [Google Scholar]

- Nelson, T.W.; Sorenson, C.D.; Johns, C.J. Friction Stir Welding of Polymeric Materials. U.S. Patent No. 6,811,632, 2 November 2004. [Google Scholar]

- Mendes, N.; Neto, P.; Simão, M.A.; Loureiro, A.; Pires, J.N. A novel friction stir welding robotic platform: Welding polymeric materials. Int. J. Adv. Manuf. Technol. 2016, 85, 37–46. [Google Scholar] [CrossRef]

- Lambiase, F.; Derazkola, H.A.; Simchi, A. Friction stir welding and friction spot stir welding processes of polymers-state of the art. Materials 2020, 13, 2291. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Meng, X.; Xie, Y.; Wan, L.; Lv, Z.; Cao, J.; Feng, J. Friction stir welding/processing of polymers and polymer matrix composites. Compos. Part A Appl. Sci. Manuf. 2018, 105, 235–257. [Google Scholar] [CrossRef]

- Eslami, S.; Tavares, P.J.; Moreira, P.M.G.P. Friction stir welding tooling for polymers: Review and prospects. Int. J. Adv. Manuf. Technol. 2017, 89, 1677–1690. [Google Scholar] [CrossRef]

- Mendes, N.; Neto, P.; Loureiro, A.; Moreira, A.P. Machines and control systems for friction stir welding: A review. Mater. Des. 2016, 90, 256–265. [Google Scholar] [CrossRef]

- Iftikhar, S.H.; Mourad, A.-H.I.; Sheikh-Ahmad, J.; Almaskari, F.; Vincent, S. A Comprehensive Review on Optimal Welding Conditions for Friction Stir Welding of Thermoplastic Polymers and Their Composites. Polymers 2021, 13, 1208. [Google Scholar] [CrossRef] [PubMed]

- Saeedy, S.; Givi, M.K.B. Investigation of the effects of critical process parameters of friction stir welding of polyethylene. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 1305–1310. [Google Scholar] [CrossRef]

- Saeedy, S.; Givi, M.K.B. Experimental application of friction stir welding (FSW) on thermo plastic medium density polyethylene blanks. In Proceedings of the ASME 2010 10th Biennial Conference on Engineering Systems Design and Analysis, ESDA2010, ASMEDC, Istanbul, Turkey, 12–14 July 2010; Volume 4, pp. 841–844. [Google Scholar]

- Nateghi, E.; Hosseinzadeh, M. Experimental investigation into effect of cooling of traversed weld nugget on quality of high-density polyethylene joints. Int. J. Adv. Manuf. Technol. 2016, 84, 581–594. [Google Scholar] [CrossRef]

- Azarsa, E.; Asl, A.M.; Tavakolkhah, V. Effect of process parameters and tool coating on mechanical properties and microstructure of heat assisted friction stir welded polyethylene sheets. Adv. Mater. Res. 2012, 445, 765–770. [Google Scholar] [CrossRef]

- Moreno-Moreno, M.; Macea Romero, Y.; Rodríguez Zambrano, H.; Restrepo-Zapata, N.C.; Afonso, C.R.M.; Unfried-Silgado, J. Mechanical and thermal properties of friction-stir welded joints of high density polyethylene using a non-rotational shoulder tool. Int. J. Adv. Manuf. Technol. 2018, 97, 2489–2499. [Google Scholar] [CrossRef]

- Lenin, K.; Shabeer, H.A.; Suresh Kumar, K.; Panneerselvam, K. Process Parameters Optimization for Friction Stir Welding of Polypropylene Material Using Taguchi’s Approach; NISCAIR-CSIR: New Delhi, India, 2014; Volume 73. [Google Scholar]

- Sahu, S.K.; Mishra, D.; Mahto, R.P.; Sharma, V.M.; Pal, S.K.; Pal, K.; Banerjee, S.; Dash, P. Friction stir welding of polypropylene sheet. Eng. Sci. Technol. Int. J. 2018, 21, 245–254. [Google Scholar] [CrossRef]

- Humbert, S.; Lame, O.; Vigier, G. Polyethylene yielding behaviour: What is behind the correlation between yield stress and crystallinity? Polymer 2009, 50, 3755–3761. [Google Scholar] [CrossRef]

- Arici, A.; Selale, S. Effects of tool tilt angle on tensile strength and fracture locations of friction stir welding of polyethylene. Sci. Technol. Weld. Join. 2007, 12, 536–539. [Google Scholar] [CrossRef]

- Vijendra, B.; Sharma, A. Induction heated tool assisted friction-stir welding (i-FSW): A novel hybrid process for joining of thermoplastics. J. Manuf. Process. 2015, 20, 234–244. [Google Scholar] [CrossRef]

- Banjare, P.N.; Sahlot, P.; Arora, A. An assisted heating tool design for FSW of thermoplastics. J. Mater. Process. Technol. 2017, 239, 83–91. [Google Scholar] [CrossRef]

- Dashatan, S.H.; Azdast, T.; Ahmadi, S.R.; Bagheri, A. Friction stir spot welding of dissimilar polymethyl methacrylate and acrylonitrile butadiene styrene sheets. Mater. Des. 2013, 45, 135–141. [Google Scholar] [CrossRef]

- Azarsa, E.; Mostafapour, A. Experimental investigation on flexural behavior of friction stir welded high density polyethylene sheets. J. Manuf. Process. 2014, 16, 149–155. [Google Scholar] [CrossRef]

- Zafar, A.; Awang, M.; Khan, S.R.; Emamian, S. Effect of Double Shoulder Tool Rotational Speed on Thermo-Physical Characteristics of Friction Stir Welded 16mm Thick Nylon6. Appl. Mech. Mater. 2015, 799–800, 251–255. [Google Scholar] [CrossRef]

- Aghajani Derazkola, H.; Garcia, E.; Elyasi, M. Underwater friction stir welding of PC: Experimental study and thermo-mechanical modelling. J. Manuf. Process. 2021, 65, 161–173. [Google Scholar] [CrossRef]

- Aghajani Derazkola, H.; Simchi, A. A new procedure for the fabrication of dissimilar joints through injection of colloidal nanoparticles during friction stir processing: Proof concept for AA6062/PMMA joints. J. Manuf. Process. 2020, 49, 335–343. [Google Scholar] [CrossRef]

- Zafar, A.; Awang, M.; Khan, S.R. Friction stir welding of polymers: An overview. In Lecture Notes in Mechanical Engineering, Proceedings of the 2nd International Conference on Mechanical, Manufacturing and Process Plant Engineering, Kuala Lumpur, Malaysia, 23–24 November 2016; Awang, M., Ed.; Springer: Heidelberg, Germany, 2017; pp. 19–36. [Google Scholar]

| Friction Stir Welding Technique | Joint Efficiency | Surface Finish | Material Mixing Quality | Root Defect Formation | Internal Defects Formation | Implementation |

|---|---|---|---|---|---|---|

| Conventional Tool | Satisfactory | Poor | Normal | Likely | Almost Always | Very Easy |

| Double-side Pass (Conventional tool) | Good | Poor | Normal | unlikely | Almost Always | Easy |

| Preheated Polymer | Good | Fair | Good | Reduced | Less likely | Difficult |

| Conventional Heated Tool | Good | Fair | Good | Reduced | Less likely | Easy |

| Stationary Shoulder | Very Good | Very Good | Good | Reduced | Less likely | Easy |

| Heated Stationary Shoulder | Excellent | Excellent | Very Good | Reduced | Less likely | Easy |

| i-FSW | Very Good | Fair | Good | Reduced | Less likely | Easy |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pereira, M.A.R.; Amaro, A.M.; Reis, P.N.B.; Loureiro, A. Effect of Friction Stir Welding Techniques and Parameters on Polymers Joint Efficiency—A Critical Review. Polymers 2021, 13, 2056. https://doi.org/10.3390/polym13132056

Pereira MAR, Amaro AM, Reis PNB, Loureiro A. Effect of Friction Stir Welding Techniques and Parameters on Polymers Joint Efficiency—A Critical Review. Polymers. 2021; 13(13):2056. https://doi.org/10.3390/polym13132056

Chicago/Turabian StylePereira, Miguel A. R., Ana M. Amaro, Paulo N. B. Reis, and Altino Loureiro. 2021. "Effect of Friction Stir Welding Techniques and Parameters on Polymers Joint Efficiency—A Critical Review" Polymers 13, no. 13: 2056. https://doi.org/10.3390/polym13132056