Estimating the Accuracy of Mandible Anatomical Models Manufactured Using Material Extrusion Methods

Abstract

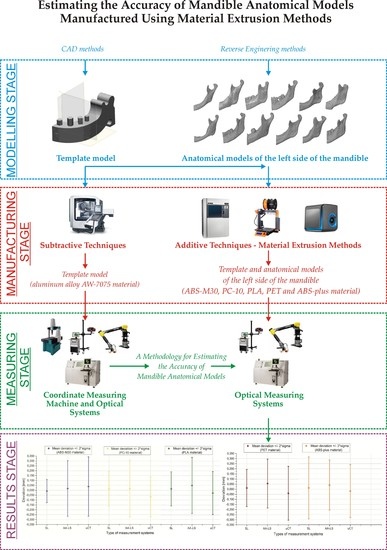

:1. Introduction

2. Materials and Methods

- Calculate the arithmetic mean (mean deviation) by Equation (8):

- Sample standard deviation—sigma (σ) by Equation (9):

- Calculate the skewness value by Equation (10):

- Calculate the kurtosis value by Equation (11):

3. Results

4. Discussion

- In the case of the Atos III Triple Scan: system errors, the adopted measurement procedure, and fitting errors of two-point clouds

- In the case of the Metris MCA II articulated arm with a laser head: system errors, the adopted measurement procedure and fitting errors of three-point clouds

- In the case of the Benchtop CT160Xi (Nikon): system errors, the adopted measurement procedure and the data processing stage (especially the segmentation and reconstruction process).

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Boboulos, M. CAD-CAM and Rapid Prototyping Application Evaluation. 2010. Available online: http://sietm.com/wp-content/uploads/2015/03/cad-cam-rapid-prototyping-application-evaluation.pdf (accessed on 19 October 2020).

- Sikorska-Czupryna, S.; Mazurkow, A. The Use of Reverse Engineering to Create FEM Model of Spiroid Gears. Adv. Manuf. Sci. Technol. 2020, 44, 71–73. [Google Scholar] [CrossRef]

- Raja, V.; Kiran, J.F. Reverse Engineering an Industrial Perspective; Springer: New York, NY, USA, 2010. [Google Scholar]

- Urbanic, R.J.; ElMaraghy, H.A.; ElMaraghy, W.H. A reverse engineering methodology for rotary components from point cloud data. Int. J. Adv. Manuf. Technol. 2008, 37, 1146–1167. [Google Scholar] [CrossRef]

- Bagci, E. Reverse engineering applications for recovery of broken or worn parts and re-manufacturing: Three case studies. Adv. Eng. Softw. 2009, 40, 407–418. [Google Scholar] [CrossRef]

- Turek, P. Automating the process of designing and manufacturing polymeric models of anatomical structures of mandible with Industry 4.0 convention. Polimery 2019, 64, 522–529. [Google Scholar] [CrossRef]

- Gdula, M.; Burek, J.; Zylka, L.; Plodzien, M. Five-axis milling of sculptured surfaces of the turbine blade. Aircr. Eng. Aerosp. Technol. 2018, 90, 146–157. [Google Scholar] [CrossRef]

- Habrat, W.; Zak, M.; Krolczyk, J.; Turek, P.; Hamrol, A.; Ciszak, O.; Legutko, S.; Jurczyk, M. Comparison of Geometrical Accuracy of a Component Manufactured Using Additive and Conventional Methods. In Proceedings of the 2nd Annual International Conference on Material, Machines and Methods for Sustainable Development (MMMS2020); Springer Science and Business Media LLC: Berlin, Germany, 2017; pp. 765–776. [Google Scholar]

- Jia, Z.-Y.; Ma, J.-W.; Song, D.-N.; Wang, F.-J.; Liu, W. A review of contouring-error reduction method in multi-axis CNC machining. Int. J. Mach. Tools Manuf. 2018, 125, 34–54. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2014. [Google Scholar]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef] [Green Version]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Bulanda, K.; Oleksy, M.; Oliwa, R.; Budzik, G.; Przeszlowski, L.; Mazurkow, A. Biodegradable polymer composites used in rapid prototyping technology by Melt Extrusion Polymers (MEP). Polimery 2020, 65, 430–436. [Google Scholar] [CrossRef]

- Turek, P.; Budzik, G.; Oleksy, M.; Bulanda, K. Polymer materials used in medicine processed by additive techniques. Polimery 2020, 65, 510–515. [Google Scholar] [CrossRef]

- Upadhyay, M.; Sivarupan, T.; El Mansori, M. 3D printing for rapid sand casting—A review. J. Manuf. Process. 2017, 29, 211–220. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Sama, S.R.; Lynch, P.C.; Manogharan, G. Design and Topology Optimization of 3D-Printed Wax Patterns for Rapid Investment Casting. Procedia Manuf. 2019, 34, 683–694. [Google Scholar] [CrossRef]

- Rokicki, P.; Budzik, G.; Kubiak, K.; Bernaczek, J.; Dziubek, T.; Magniszewski, M.; Nowotnik, A.; Sieniawski, J.; Matysiak, H.; Cygan, R.; et al. Rapid prototyping in manufacturing of core models of aircraft engine blades. Aircr. Eng. Aerosp. Technol. 2014, 86, 323–327. [Google Scholar] [CrossRef]

- Turek, P.; Budzik, G.; Sęp, J.; Oleksy, M.; Józwik, J.; Przeszłowski, Łukasz; Paszkiewicz, A.; Kochmański, Łukasz; Żelechowski, D. An Analysis of the Casting Polymer Mold Wear Manufactured Using PolyJet Method Based on the Measurement of the Surface Topography. Polymers 2020, 12, 3029. [Google Scholar] [CrossRef]

- Huang, Y.; He, K.; Wang, X. Rapid prototyping of a hybrid hierarchical polyurethane-cell/hydrogel construct for regenerative medicine. Mater. Sci. Eng. C 2013, 33, 3220–3229. [Google Scholar] [CrossRef]

- Bračun, D.; Selak, L. Optical probing for CNC machining of large parts made from fiber-reinforced polymer composite materials. Int. J. Adv. Manuf. Technol. 2018, 100, 1855–1865. [Google Scholar] [CrossRef]

- Tan, L.J.; Zhu, W.; Zhou, K. Recent Progress on Polymer Materials for Additive Manufacturing. Adv. Funct. Mater. 2020, 30, 2003062. [Google Scholar] [CrossRef]

- Ablyaz, T.; Muratov, K.; Preetkanwal, S.B.; Sarabjeet, S.S. Experimental investigation of wear resistance of copper coated electrode-tool during electrical discharge machining. IOP Conf. Ser. Mater. Sci. Eng. 2019, 510, 012001. [Google Scholar] [CrossRef]

- Yaman, K.; Çoğun, C. An experimental work on using conductive powder-filled polymer composite cast material as tool electrode in EDM. Int. J. Adv. Manuf. Technol. 2014, 73, 535–543. [Google Scholar] [CrossRef]

- Cui, S.; Wang, J.; Li, X.; Wang, Y. A Discussion on Plastic Working for Glassy Polymer Materials at Low Temperature. Polym. Mater. Sci. Eng. 2014, 10. [Google Scholar]

- Chen, P.; Cai, H.; Li, Z.; Li, M.; Wu, H.; Su, J.; Wen, S.; Zhou, Y.; Liu, J.; Wang, C.; et al. Crystallization kinetics of polyetheretherketone during high temperature-selective laser sintering. Addit. Manuf. 2020, 36, 101615. [Google Scholar] [CrossRef]

- Pilipović, A.; Brajlih, T.; Drstvenšek, I. Influence of Processing Parameters on Tensile Properties of SLS Polymer Product. Polymers 2018, 10, 1208. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Layani, M.; Wang, X.; Magdassi, S. Novel Materials for 3D Printing by Photopolymerization. Adv. Mater. 2018, 30, e1706344. [Google Scholar] [CrossRef] [PubMed]

- Patel, D.; Sakhaei, A.H.; Layani, M.; Zhang, B.; Ge, Q.; Magdassi, S. Highly Stretchable and UV Curable Elastomers for Digital Light Processing Based 3D Printing. Adv. Mater. 2017, 29, 1606000. [Google Scholar] [CrossRef] [PubMed]

- Kozior, T.; Mamun, A.; Trabelsi, M.; Sabantina, L.; Ehrmann, A. Quality of the Surface Texture and Mechanical Properties of FDM Printed Samples after Thermal and Chemical Treatment. Stroj. Vestn.-J. Mech. Eng. 2020, 66, 105–113. [Google Scholar] [CrossRef] [Green Version]

- Zanjanijam, A.R.; Major, I.; Lyons, J.G.; Lafont, U.; Devine, D.M. Fused Filament Fabrication of PEEK: A Review of Process-Structure-Property Relationships. Polymers 2020, 12, 1665. [Google Scholar] [CrossRef]

- García-Martínez, H.; Ávila-Navarro, E.; Torregrosa-Penalva, G.; Rodríguez-Martínez, A.; Blanco-Angulo, C.; de la Casa-Lillo, M.A. Low-Cost Additive Manufacturing Techniques Applied to the Design of Planar Microwave Circuits by Fused Deposition Modeling. Polymers 2020, 12, 1946. [Google Scholar] [CrossRef]

- Wiese, M.; Thiede, S.; Herrmann, C. Rapid manufacturing of automotive polymer series parts: A systematic review of processes, materials and challenges. Addit. Manuf. 2020, 36, 101582. [Google Scholar] [CrossRef]

- Vashishtha, V.K.; Makade, R.; Mehla, N. Advancement of rapid prototyping in aerospace industry-A review. Int. J. Eng. Sci. Technol. 2011, 3, 2486–2493. [Google Scholar]

- Joshi, S.C.; Sheikh, A.A. 3D printing in aerospace and its long-term sustainability. Virtual Phys. Prototyp. 2015, 10, 175–185. [Google Scholar] [CrossRef]

- Berretta, S.; Evans, K.; Ghita, O. Additive manufacture of PEEK cranial implants: Manufacturing considerations versus accuracy and mechanical performance. Mater. Des. 2018, 139, 141–152. [Google Scholar] [CrossRef]

- Faber, J.; Berto, P.M.; Quaresma, M. Rapid prototyping as a tool for diagnosis and treatment planning for maxillary canine impaction. Am. J. Orthod. Dentofac. Orthop. 2006, 129, 583–589. [Google Scholar] [CrossRef]

- Ciocca, L.; Mazzoni, S.; Fantini, M.; Persiani, F.; Baldissara, P.; Marchetti, C.; Scotti, R. A CAD/CAM-prototyped anatomical condylar prosthesis connected to a custom-made bone plate to support a fibula free flap. Med. Biol. Eng. Comput. 2012, 50, 743–749. [Google Scholar] [CrossRef] [PubMed]

- Hazeveld, A.; Slater, J.J.H.; Ren, Y. Accuracy and reproducibility of dental replica models reconstructed by different rapid prototyping techniques. Am. J. Orthod. Dentofac. Orthop. 2014, 145, 108–115. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.-Y.; Cho, J.-H.; Chang, N.-Y.; Chae, J.-M.; Kang, K.-H.; Kim, S.-C. Accuracy of three-dimensional printing for manufacturing replica teeth. Korean J. Orthod. 2015, 45, 217–225. [Google Scholar] [CrossRef] [Green Version]

- Ayoub, N.; Ghassemi, A.; Rana, M.; Gerressen, M.; Riediger, D.; Hölzle, F.; Modabber, A. Evaluation of computer-assisted mandibular reconstruction with vascularized iliac crest bone graft compared to conventional surgery: A randomized prospective clinical trial. Trials 2014, 15, 114. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.-F.; Xu, L.-W.; Zhu, H.-Y.; Liu, S.S.-Y. Technical procedures for template-guided surgery for mandibular reconstruction based on digital design and manufacturing. Biomed. Eng. Online 2014, 13, 63. [Google Scholar] [CrossRef] [Green Version]

- Modabber, A.; Ayoub, N.; Goloborodko, E.; Loberg, C.; Lethaus, B.; Ghassemi, A.; Moehlhenrich, S.; Soenmez, T.; Hoelzle, F.; Ghassemi, M. The accuracy of computer-assisted primary mandibular reconstruction with vascularized bone flaps: Iliac crest bone flap versus osteomyocutaneous fibula flap. Med. Devices Évid. Res. 2014, 7, 211–217. [Google Scholar] [CrossRef] [Green Version]

- Ren, W.; Gao, L.; Li, S.; Chen, C.; Li, F.; Wang, Q.; Zhi, Y.; Song, J.; Dou, Z.; Xue, L.; et al. Virtual Planning and 3D printing modeling for mandibular reconstruction with fibula free flap. Med. Oral Patol. Oral Cir. Bucal 2018, 98, e359–e366. [Google Scholar] [CrossRef]

- Dahake, S.W.; Kuthe, A.M.; Chawla, J.; Mawale, M.B. Rapid prototyping assisted fabrication of customized surgical guides in mandibular distraction osteogenesis: A case report. Rapid Prototyp. J. 2017, 23, 602–610. [Google Scholar] [CrossRef]

- Orabona, G.D.; Abbate, V.; Maglitto, F.; Bonavolonta, P.; Salzano, G.; Romano, A.; Reccia, A.; Committeri, U.; Iaconetta, G.; Califano, L. Low-cost, self-made CAD/CAM-guiding system for mandibular reconstruction. Surg. Oncol. 2018, 27, 200–207. [Google Scholar] [CrossRef]

- Dupret-Bories, A.; Vergez, S.; Meresse, T.; Brouillet, F.; Bertrand, G. Contribution of 3D printing to mandibular reconstruction after cancer. Eur. Ann. Otorhinolaryngol. Head Neck Dis. 2018, 135, 133–136. [Google Scholar] [CrossRef] [PubMed]

- Lethaus, B.; Poort, L.; Böckmann, R.; Smeets, R.; Tolba, R.; Kessler, P. Additive manufacturing for microvascular reconstruction of the mandible in 20 patients. J. Cranio-Maxillofac. Surg. 2012, 40, 43–46. [Google Scholar] [CrossRef] [PubMed]

- Rokicki, P.; Budzik, G.; Kubiak, K.; Dziubek, T.; Zaborniak, M.; Kozik, B.; Bernaczek, J.; Przeszlowski, L.; Nowotnik, A. The assessment of geometric accuracy of aircraft engine blades with the use of an optical coordinate scanner. Aircr. Eng. Aerosp. Technol. 2016, 88, 374–381. [Google Scholar] [CrossRef]

- Dziubek, T.; Oleksy, M. Application of ATOS II optical system in the techniques of rapid prototyping of epoxy resin-based gear models. Polimery 2017, 62, 44–52. [Google Scholar] [CrossRef]

- Kechagias, J.; Stavropoulos, P.; Koutsomichalis, A.; Ntintakis, I.; Vaxevanidis, N. Dimensional accuracy optimization of pro-totypes produced by PolyJet direct 3D printing technology. Adv. Eng. Mech. Mater. 2014, 61–65. [Google Scholar]

- Leach, R.K.; Bourell, D.; Carmignato, S.; Donmez, A.; Senin, N.; Dewulf, W. Geometrical metrology for metal additive man-ufacturing. CIRP Ann. 2019, 68, 677–700. [Google Scholar] [CrossRef]

- D’Amato, R.; Caja, J.; Maresca, P.; Gómez, E. Use of coordinate measuring machine to measure angles by geometric characterization of perpendicular planes. Estimating uncertainty. Measurement 2014, 47, 598–606. [Google Scholar] [CrossRef]

- Budzik, G.; Kubiak, K.; Bernaczek, J.; Magniszewski, M.; Matysiak, H.; Cygan, R.; Tutak, M. Hybrid Method for Rapid Prototyping of Core Models of Aircraft Engine Blades. J. KONES. Powertrain Transp. 2012, 19, 77–82. [Google Scholar] [CrossRef]

- Kawalec, A.; Magdziak, M. Usability assessment of selected methods of optimization for some measurement task in coordinate measurement technique. Measurement 2012, 45, 2330–2338. [Google Scholar] [CrossRef]

- Saqib, S.; Urbanic, J. An experimental study to determine geometric and dimensional accuracy impact factors for fused depo-sition modelled parts. In Enabling Manufacturing Competitiveness and Economic Sustainability; Springer: Berlin/Heidelberg, Germany, 2012; pp. 293–298. [Google Scholar]

- Brajlih, T.; Tasic, T.; Valentan, B.; Hadžistević, M.; Pogacar, V.; Drstvenšek, I.; Balic, J.; Acko, B. Possibilities of Using Three-Dimensional Optical Scanning in Complex Geometrical Inspection. Stroj. Vestn. J. Mech. Eng. 2011, 57, 826–833. [Google Scholar] [CrossRef] [Green Version]

- Budzik, G.; Turek, P.; Dziubek, T.; Gdula, M. Elaboration of the measuring procedure facilitating precision assessment of the geometry of mandible anatomical model manufactured using additive methods. Meas. Control. 2019, 53, 181–191. [Google Scholar] [CrossRef]

- Budzik, G.; Woźniak, J.; Paszkiewicz, A.; Przeszłowski, Ł.; Dziubek, T.; Dębski, M. Methodology for the Quality Control Process of Additive Manufacturing Products Made of Polymer Materials. Materials 2021, 14, 2202. [Google Scholar] [CrossRef] [PubMed]

- Bračun, D.; Škulj, G.; Kadiš, M. Spectral selective and difference imaging laser triangulation measurement system for on line measurement of large hot workpieces in precision open die forging. Int. J. Adv. Manuf. Technol. 2017, 90, 917–926. [Google Scholar] [CrossRef]

- Selami, Y.; Tao, W.; Gao, Q.; Yang, H.; Zhao, H. A Scheme for Enhancing Precision in 3-Dimensional Positioning for Non-Contact Measurement Systems Based on Laser Triangulation. Sensors 2018, 18, 504. [Google Scholar] [CrossRef] [Green Version]

- Warnett, J.M.; Titarenko, V.; Kiraci, E.; Attridge, A.; Lionheart, W.; Withers, P.; A Williams, M. Towards in-process x-ray CT for dimensional metrology. Meas. Sci. Technol. 2016, 27, 035401. [Google Scholar] [CrossRef]

- Turek, P.; Budzik, G.; Przeszłowski, Ł. Assessing the Radiological Density and Accuracy of Mandible Polymer Anatomical Structures Manufactured Using 3D Printing Technologies. Polymers 2020, 12, 2444. [Google Scholar] [CrossRef] [PubMed]

- Townsend, A.; Racasan, R.; Leach, R.; Senin, N.; Thompson, A.; Ramsey, A.; Bate, D.; Woolliams, P.; Brown, S.; Blunt, L. An interlaboratory comparison of X-ray computed tomography measurement for texture and dimensional characterisation of additively manufactured parts. Addit. Manuf. 2018, 23, 422–432. [Google Scholar] [CrossRef]

- VDI/VDE 2634 Blatt 3. Available online: https://www.vdi.eu/guidelines/vdivde_2634_blatt_3-optische_3_d_messsysteme_bildgebende_systeme_mit_flaechenhafter_antastung/ (accessed on 28 November 2018).

- American Society of Mechanical Engineers (ASME). B89. 4.22. Methods for Performance Evaluation of Articulated Arm Coordinate Measuring Machines (CMM); ASME: New York, NY, USA, 2004. [Google Scholar]

- VDI/VDE 2634 Blatt 2. Available online: https://www.vdi.eu/guidelines/vdivde_2634_blatt_2-optische_3_d_messsysteme_bildgebende_systeme_mit_flaechenhafter_antastung/ (accessed on 28 November 2018).

- Msallem, B.; Sharma, N.; Cao, S.; Halbeisen, F.; Zeilhofer, H.-F.; Thieringer, F.M. Evaluation of the Dimensional Accuracy of 3D-Printed Anatomical Mandibular Models Using FFF, SLA, SLS, MJ, and BJ Printing Technology. J. Clin. Med. 2020, 9, 817. [Google Scholar] [CrossRef] [Green Version]

- Gottsauner, M.; Reichert, T.; Koerdt, S.; Wieser, S.; Klingelhoeffer, C.; Kirschneck, C.; Hoffmann, J.; Ettl, T.; Ristow, O. Comparison of additive manufactured models of the mandible in accuracy and quality using six different 3D printing systems. J. Cranio-Maxillofac. Surg. 2021. [Google Scholar] [CrossRef]

- Salmi, M.; Paloheimo, K.-S.; Tuomi, J.; Wolff, J.; Mäkitie, A. Accuracy of medical models made by additive manufacturing (rapid manufacturing). J. Cranio-Maxillofac. Surg. 2013, 41, 603–609. [Google Scholar] [CrossRef] [PubMed]

- Pinto, J.M.; Arrieta, C.; Andia, M.E.; Uribe, S.; Ramos-Grez, J.; Vargas, A.; Irarrazaval, P.; Tejos, C. Sensitivity analysis of geometric errors in additive manufacturing medical models. Med. Eng. Phys. 2015, 37, 328–334. [Google Scholar] [CrossRef]

- Thomas, D.J.; Azmi, M.A.B.M.; Tehrani, Z.A. 3D additive manufacture of oral and maxillofacial surgical models for preoperative planning. Int. J. Adv. Manuf. Technol. 2014, 71, 1643–1651. [Google Scholar] [CrossRef]

- Boehm, J. Genauigkeitsuntersuchung von Sensoren basierend auf strukturierter Beleuchtung aus der Unterhaltungselektronik. Photogramm.-Fernerkund.-Geoinf. 2014, 2014, 117–127. [Google Scholar] [CrossRef] [Green Version]

- Drégelyi-Kiss, Á.; Durakbasa, N.M. Measurement Error on the Reconstruction Step in Case of Industrial Computed Tomograph. In Proceedings of the Proceedings of the International Symposium for Production Research 2018; Springer Science and Business Media LLC: Berlin, Germany, 2018; pp. 309–323. [Google Scholar]

- Mendricky, R. Impact of Applied Anti-Reflective Material on Accuracy of Optical 3D Digitisation. Mater. Sci. Forum 2018, 919, 335–344. [Google Scholar] [CrossRef]

- Boas, F.E.; Fleischmann, D. Evaluation of Two Iterative Techniques for Reducing Metal Artifacts in Computed Tomography. Radiology 2011, 259, 894–902. [Google Scholar] [CrossRef] [PubMed]

- Alsleem, H.; Davidson, R. Factors Affecting Contrast-Detail Performance in Computed Tomography: A Review. J. Med. Imaging Radiat. Sci. 2013, 44, 62–70. [Google Scholar] [CrossRef]

- Romans, L. Computed Tomography for Technologists: A Comprehensive Text; Wolters Kluwer: Baltimore, MD, USA, 2011. [Google Scholar]

- Van Eijnatten, M.; Koivisto, J.; Karhu, K.; Forouzanfar, T.; Wolff, J. The impact of manual threshold selection in medical additive manufacturing. Int. J. Comput. Assist. Radiol. Surg. 2017, 12, 607–615. [Google Scholar] [CrossRef] [Green Version]

- van Eijnatten, M.; van Dijk, R.; Dobbe, J.; Streekstra, G.; Koivisto, J.; Wolff, J. CT image segmentation methods for bone used in medical additive manufacturing. Med. Eng. Phys. 2018, 51, 6–16. [Google Scholar] [CrossRef]

| AM Technology | 3D Printer | Commercial Material Name | Generic Name | Layer Thickness |

|---|---|---|---|---|

| Fused Deposition Modeling (FDM) | Fortus 360-mc | ABS-M30 | Acrylonitrile | 0.178 mm |

| Butadiene | ||||

| Styrene | ||||

| PC-10 | Polycarbonate | 0.178 mm | ||

| Fused Filament Fabrication (FFF) | Prusa MK3s | PLA | Polylactic acid | 0.150 mm |

| PET | Polyethylene | 0.150 mm | ||

| terephthalate | ||||

| Melted and Extruded Modeling (MEM) | UP Box | ABS plus | Acrylonitrile | 0.150 mm |

| Butadiene | ||||

| Styrene |

| Atos III Triple Scan | |

|---|---|

| Acceptance test according to VDI/VDE 2634 | Measured value/Maximum permission error (2σ) |

| Probing error | ±0.003 mm/±0.006 mm |

| Sphere—spacing error | ±0.007 mm/±0.020 mm |

| Maximum error (2σ) | |

| Flatness measurement error | ±0.020 mm |

| Articulated arm coordinate measuring machine (MCA II) with a laser head (MMD × 100) | |

| Acceptance test according to ASME B89.4.22 | Measured value/Maximum permission error (2σ) |

| Effective diameter test | ±0.004 mm/±0.008 mm |

| Single point articulation test | ±0.022 mm/±0.024 mm |

| Volumetric performance test | ±0.032 mm/±0.035 mm |

| Laser head test (flat plate) | ±0.020 mm |

| Benchtop (Nikon) CT160Xi | |

| Acceptance test according to VDI/VDE 2630 Blatt 1.3 | Measured value |

| Length measuring error | ±0.006 mm |

| Probing error of size (Scanning error) | ±0.006 mm |

| Material | Coordinate Measuring Machine | Atos III Triple Scan | MCA II with Laser Head MMD × 100 | Benchtop (Nikon) CT160Xi |

|---|---|---|---|---|

| AW 7075 | −0.002 mm ± 0.015 mm | −0.008 mm ± 0.035 mm | 0.010 mm ± 0.102 mm | 0.012 mm ± 0.100 mm |

| ABS-M30 | −0.002 mm ± 0.056 mm | −0.009 mm ± 0.084 mm | 0.010 mm ± 0.208 mm | −0.032 mm ± 0.240 mm |

| PC-10 | 0.010 mm ± 0.056 mm | 0.026 mm ± 0.102 mm | 0.032 mm ± 0.220 mm | −0.020 mm ± 0.218 mm |

| PLA | −0.001 mm ± 0.084 mm | 0.010 mm ± 0.134 mm | 0.032 mm ± 0.210 mm | −0.015 mm ± 0.214 mm |

| PET | −0.010 mm ± 0.102 mm | 0.008 mm ± 0.144 mm | 0.028 mm ± 0.216 mm | −0.012 mm ± 0.250 mm |

| ABS-plus | −0.005 mm ± 0.212 mm | 0.017 mm ± 0.270 mm | 0.025 mm ± 0.204 mm | −0.008 mm ± 0.236 mm |

| Coordinate Measuring Machine | Atos III Triple Scan | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | ABS-M30 | PC-10 | PLA | PET | ABS-plus | ABS-M30 | PC-10 | PLA | PET | ABS-plus |

| Skewness | 0.202 | −0.252 | 0.152 | −0.336 | 0.342 | 0.416 | −0.694 | 0.342 | −0.235 | −0.235 |

| Kurtosis | 2.900 | 2.997 | 2.844 | 3.154 | 3.349 | 3.715 | 3.156 | 3.508 | 3.432 | 3.432 |

| MCA II with laser head MMD × 100 | Benchtop (Nikon) CT160Xi | |||||||||

| Material | ABS-M30 | PC-10 | PLA | PET | ABS-plus | ABS-M30 | PC-10 | PLA | PET | ABS-plus |

| Skewness | 0.235 | −0.250 | −0.289 | −0.329 | −0.326 | 0.532 | 0.345 | 0.225 | 0.463 | 0.254 |

| Kurtosis | 3.023 | 3.424 | 3.201 | 3.326 | 3.230 | 1.980 | 2.967 | 3.324 | 3.043 | 3.245 |

| Material | Atos III Triple Scan | MCA II with Laser Head MMD × 100 | Benchtop (Nikon) CT160Xi |

|---|---|---|---|

| ABS-M30 | −0.008 mm ± 0.118 mm | 0.018 mm ± 0.184 mm | 0.038 mm ± 0.304 mm |

| PC-10 | 0.016 mm ± 0.188 mm | 0.016 mm ± 0.290 mm | −0.067 mm ± 0.204 mm |

| PLA | 0.015 mm ± 0.174 mm | 0.050 mm ± 0.286 mm | −0.028 mm ± 0.210 mm |

| PET | 0.012 mm ± 0.182 mm | 0.056 mm ± 0.240 mm | −0.040 mm ± 0.264 mm |

| ABS-plus | 0.012 mm ± 0.308 mm | 0.040 mm ± 0.246 mm | −0.019 mm ± 0.260 mm |

| Atos III Triple Scan | MCA II with Laser Head MMD × 100 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Material | ABS-M30 | PC-10 | PLA | PET | ABS-plus | ABS-M30 | PC-10 | PLA | PET | ABS-plus |

| Skewness | 0.201 | −0.405 | 0.150 | −0.402 | 0.323 | 0.391 | −0.405 | −0.321 | −0.453 | −0.487 |

| Kurtosis | 3.432 | 3.125 | 4.089 | 3.772 | 2.585 | 2.853 | 3.125 | 3.437 | 3.743 | 3.315 |

| Benchtop (Nikon) CT160Xi | ||||||||||

| Material | ABS-M30 | PC-10 | PLA | PET | ABS-plus | |||||

| Skewness | 0.421 | 0.610 | 0.402 | 0.501 | 0.327 | |||||

| Kurtosis | 2.341 | 3.921 | 3.502 | 3.324 | 3.497 | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turek, P.; Budzik, G. Estimating the Accuracy of Mandible Anatomical Models Manufactured Using Material Extrusion Methods. Polymers 2021, 13, 2271. https://doi.org/10.3390/polym13142271

Turek P, Budzik G. Estimating the Accuracy of Mandible Anatomical Models Manufactured Using Material Extrusion Methods. Polymers. 2021; 13(14):2271. https://doi.org/10.3390/polym13142271

Chicago/Turabian StyleTurek, Paweł, and Grzegorz Budzik. 2021. "Estimating the Accuracy of Mandible Anatomical Models Manufactured Using Material Extrusion Methods" Polymers 13, no. 14: 2271. https://doi.org/10.3390/polym13142271