Biological Characterization of Polymeric Matrix and Graphene Oxide Biocomposites Filaments for Biomedical Implant Applications: A Preliminary Report

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Nanocomposites Characterization

2.3. Nanocomposites In Vivo Biocompatibility Test

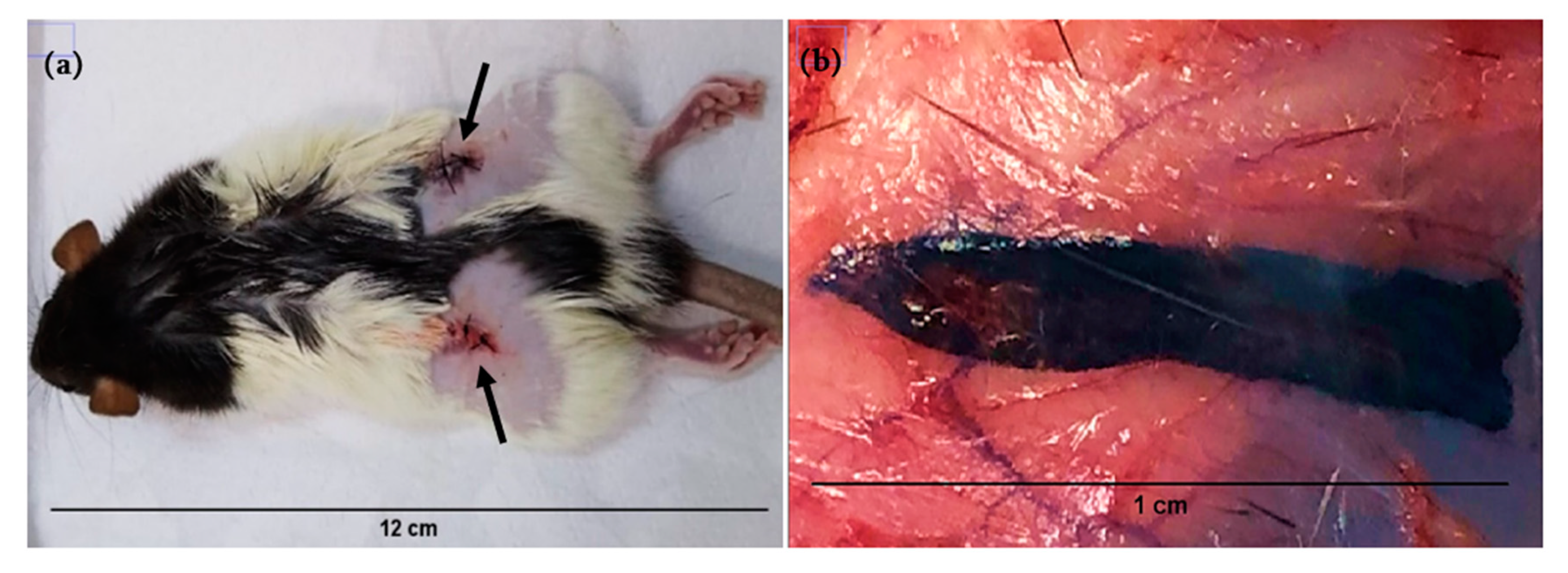

2.4. GO Nanocomposite Subcutaneous Implant

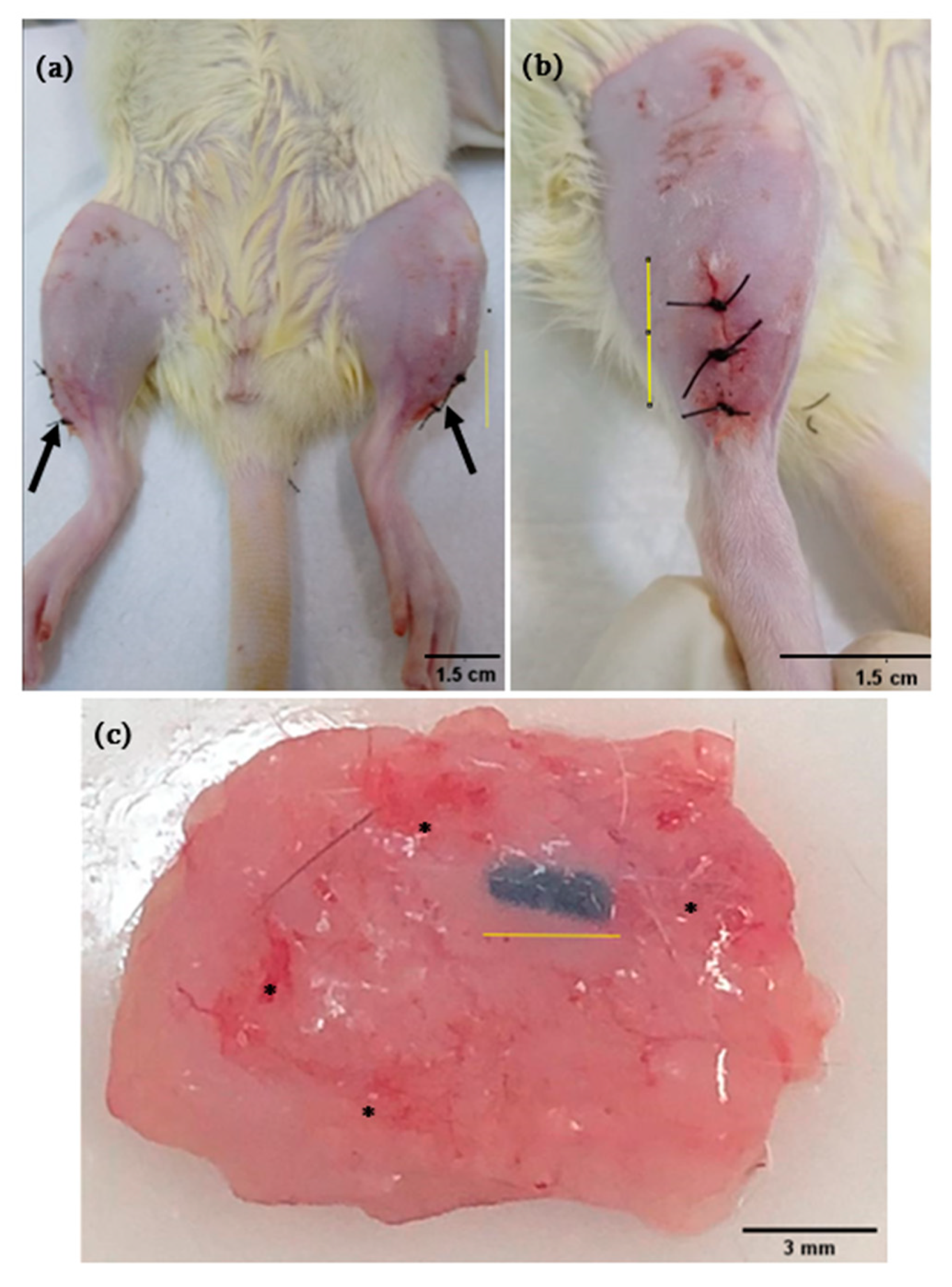

2.5. PLLA-GO Nanocomposite Intramuscular Implant

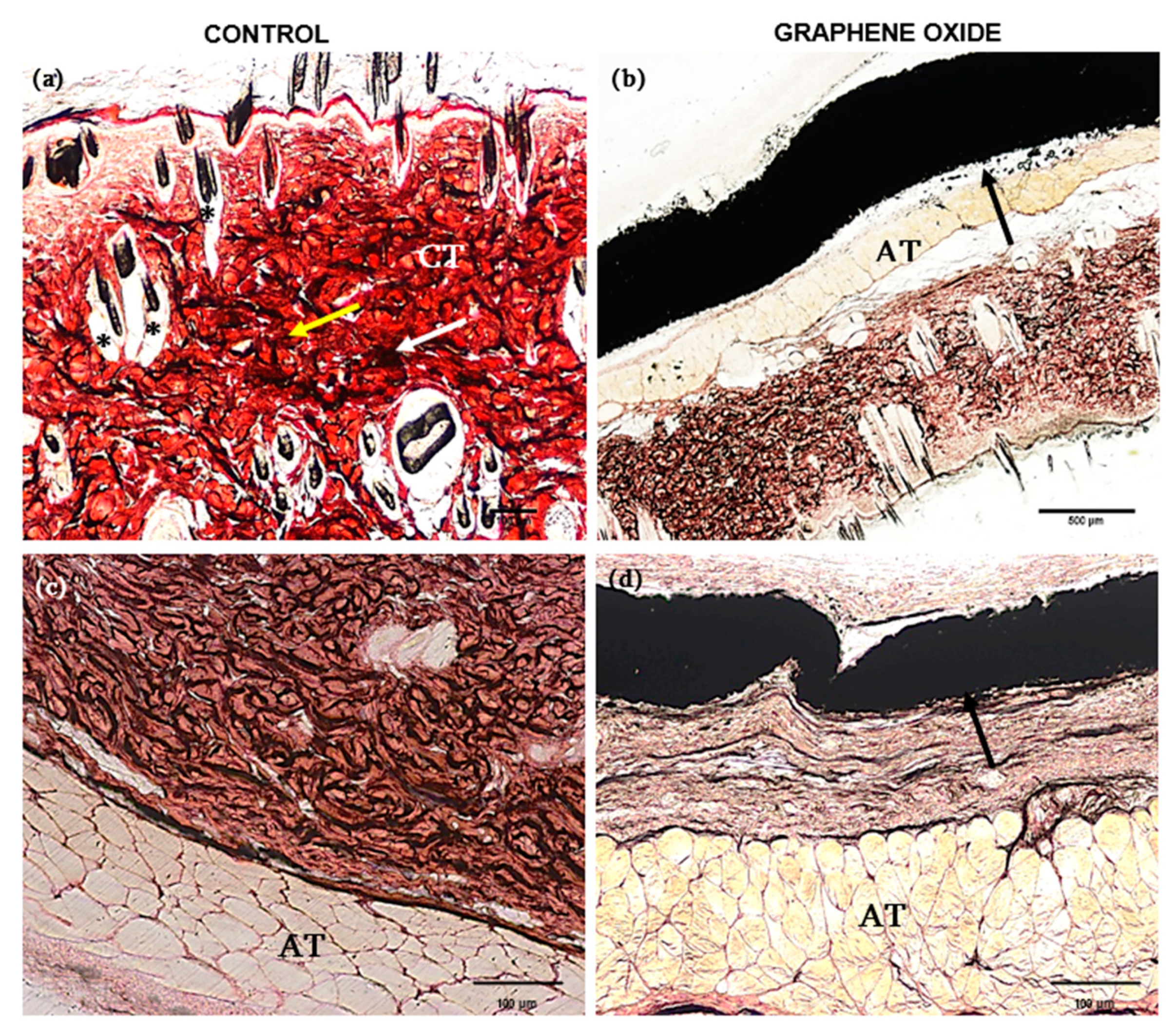

2.6. Histological Analysis

2.7. Culture of MSCs Associated with PLLA-GO Nanocomposites

2.8. Scanning Electron Microscopy (SEM)

3. Results and Discussion

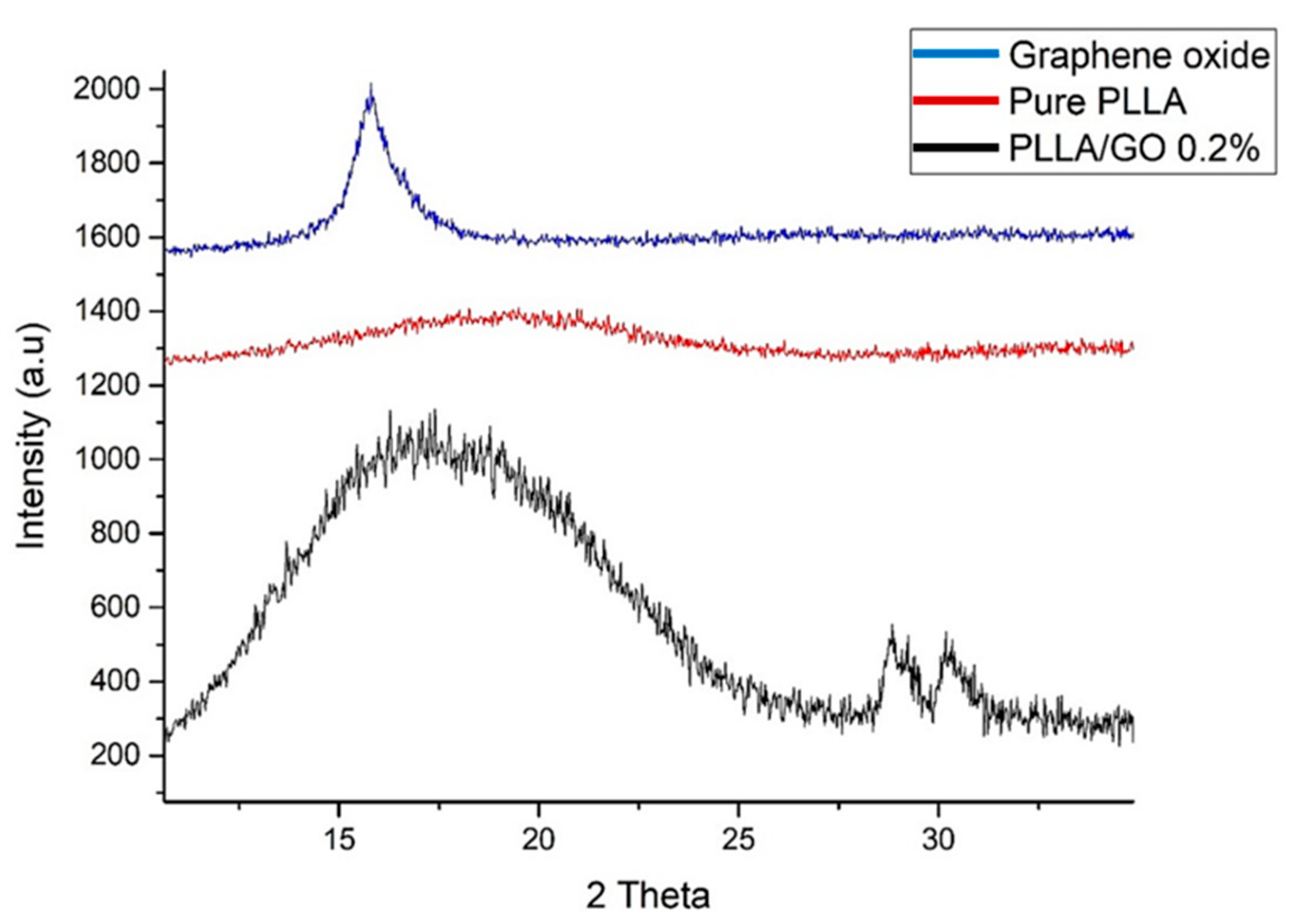

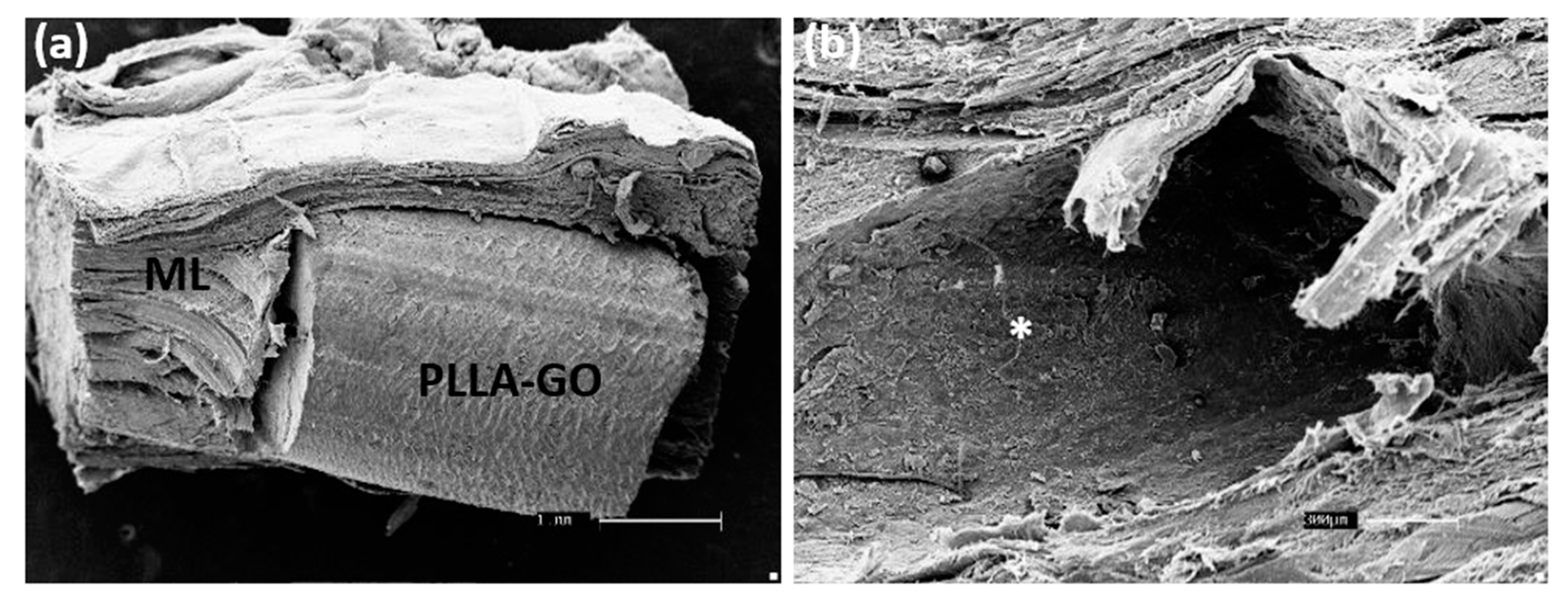

3.1. Nanocomposites’ Characterization

3.2. In Vivo Analysis

3.3. In Vitro Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, P.X. Biomimetic materials for tissue engineering. Adv. Drug Deliv. Rev. 2008, 60, 184–198. [Google Scholar] [CrossRef] [Green Version]

- Griffith, L.G. Tissue Engineering--Current Challenges and Expanding Opportunities. Science 2002, 295, 1009–1014. [Google Scholar] [CrossRef]

- Trucco, D.; Vannozzi, L.; Teblum, E.; Telkhozhayeva, M.; Nessim, G.D.; Affatato, S.; Al-Haddad, H.; Lisignoli, G.; Ricotti, L. Graphene Oxide-Doped Gellan Gum–PEGDA Bilayered Hydrogel Mimicking the Mechanical and Lubrication Properties of Articular Cartilage. Adv. Healthc. Mater. 2021, 10, 2001434. [Google Scholar] [CrossRef] [PubMed]

- Cipollaro, L.; Ciardulli, M.C.; Della Porta, G.; Peretti, G.M.; Maffulli, N. Biomechanical issues of tissue-engineered constructs for articular cartilage regeneration: In vitro and in vivo approaches. Br. Med. Bull. 2019, 132, 53–80. [Google Scholar] [CrossRef] [PubMed]

- Ng, W.L.; Chua, C.K.; Shen, Y.-F. Print Me An Organ! Why We Are Not There Yet. Prog. Polym. Sci. 2019, 97, 101145. [Google Scholar] [CrossRef]

- Shapira, A.; Dvir, T. 3D Tissue and Organ Printing—Hope and Reality. Adv. Sci. 2021, 8, 2003751. [Google Scholar] [CrossRef] [PubMed]

- Du, Z.; Wang, C.; Zhang, R.; Wang, X.; Li, X. Applications of Graphene and Its Derivatives in Bone Repair: Advantages for Promoting Bone Formation and Providing Real-Time Detection, Challenges and Future Prospects. Int. J. Nanomed. 2020, 15, 7523–7551. [Google Scholar] [CrossRef] [PubMed]

- Hoseini-Ghahfarokhi, M.; Mirkiani, S.; Mozaffari, N.; Abdolahi Sadatlu, M.A.; Ghasemi, A.; Abbaspour, S.; Akbarian, M.; Farjadain, F.; Karimi, M. Applications of Graphene and Graphene Oxide in Smart Drug/Gene Delivery: Is the World Still Flat? Int. J. Nanomed. 2020, 15, 9469–9496. [Google Scholar] [CrossRef]

- Affatato, S.; Trucco, D.; Taddei, P.; Vannozzi, L.; Ricotti, L.; Nessim, G.; Lisignoli, G. Wear Behavior Characterization of Hydrogels Constructs for Cartilage Tissue Replacement. Materials 2021, 14, 428. [Google Scholar] [CrossRef]

- More, N.; Srivastava, A.; Kapusetti, G. Graphene Oxide Reinforcement Enhances the Piezoelectric and Mechanical Properties of Poly(3-hydroxybutyrate- co -3-hydroxy valerate)-Based Nanofibrous Scaffolds for Improved Proliferation of Chondrocytes and ECM Production. ACS Appl. Bio Mater. 2020, 3, 6823–6835. [Google Scholar] [CrossRef]

- Zhao, K.; Zhang, T.; Chang, H.; Yang, Y.; Xiao, P.; Zhang, H.; Li, C.; Tiwary, C.S.; Ajayan, P.M.; Chen, Y. Super-elasticity of three-dimensionally cross-linked graphene materials all the way to deep cryogenic temperatures. Sci. Adv. 2019, 5, eaav2589. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Veetil, J.V.; Ye, K. Tailored carbon nanotubes for tissue engineering applications. Biotechnol. Prog. 2009, 25, 709–721. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Q.; Yan, J.; Yang, J.; Li, B. Nanomaterials promise better bone repair. Mater. Today 2016, 19, 451–463. [Google Scholar] [CrossRef]

- Eivazzadeh-Keihan, R.; Maleki, A.; de la Guardia, M.; Bani, M.S.; Chenab, K.K.; Pashazadeh-Panahi, P.; Baradaran, B.; Mokhtarzadeh, A.; Hamblin, M.R. Carbon based nanomaterials for tissue engineering of bone: Building new bone on small black scaffolds: A review. J. Adv. Res. 2019, 18, 185–201. [Google Scholar] [CrossRef]

- Li, G.; Zhou, T.; Lin, S.; Shi, S.; Lin, Y. Nanomaterials for Craniofacial and Dental Tissue Engineering. J. Dent. Res. 2017, 96, 725–732. [Google Scholar] [CrossRef]

- Du, Z.; Feng, X.; Cao, G.; She, Z.; Tan, R.; Aifantis, K.E.; Zhang, R.; Li, X. The effect of carbon nanotubes on osteogenic functions of adipose-derived mesenchymal stem cells in vitro and bone formation in vivo compared with that of nano-hydroxyapatite and the possible mechanism. Bioact. Mater. 2021, 6, 333–345. [Google Scholar] [CrossRef]

- Li, Z.; Fan, J.; Tong, C.; Zhou, H.; Wang, W.; Li, B.; Liu, B.; Wang, W. A smart drug-delivery nanosystem based on carboxylated graphene quantum dots for tumor-targeted chemotherapy. Nanomedicine 2019, 14, 2011–2025. [Google Scholar] [CrossRef]

- Pinto, A.M.; Gonçalves, I.C.; Magalhães, F.D. Graphene-based materials biocompatibility: A review. Colloids Surf. B Biointerfaces 2013, 111, 188–202. [Google Scholar] [CrossRef]

- Muñoz, R.; Singh, D.P.; Kumar, R.; Matsuda, A. Graphene Oxide for Drug Delivery and Cancer Therapy. In Nanostructured Polymer Composites for Biomedical Applications; Elsevier: Amsterdam, Netherlands, 2019; pp. 447–488. [Google Scholar]

- Essig, H.; Lindhorst, D.; Gander, T.; Schumann, P.; Könü, D.; Altermatt, S.; Rücker, M. Patient-specific biodegradable implant in pediatric craniofacial surgery. J. Cranio-Maxillofac. Surg. 2017, 45, 216–222. [Google Scholar] [CrossRef]

- Farjadian, F.; Abbaspour, S.; Sadatlu, M.A.A.; Mirkiani, S.; Ghasemi, A.; Hoseini-Ghahfarokhi, M.; Mozaffari, N.; Karimi, M.; Hamblin, M.R. Recent Developments in Graphene and Graphene Oxide: Properties, Synthesis, and Modifications: A Review. ChemistrySelect 2020, 5, 10200–10219. [Google Scholar] [CrossRef]

- Reddy, S.; Xu, X.; Guo, T.; Zhu, R.; He, L.; Ramakrishana, S. Allotropic carbon (graphene oxide and reduced graphene oxide) based biomaterials for neural regeneration. Curr. Opin. Biomed. Eng. 2018, 6, 120–129. [Google Scholar] [CrossRef]

- Kadota, J.; Pavlović, D.; Desvergne, J.-P.; Bibal, B.; Peruch, F.; Deffieux, A. Ring-Opening Polymerization of l-Lactide Catalyzed by an Organocatalytic System Combining Acidic and Basic Sites. Macromolecules 2010, 43, 8874–8879. [Google Scholar] [CrossRef]

- Schmack, G.; Jehnichen, D.; Vogel, R.; Tändler, B.; Beyreuther, R.; Jacobsen, S.; Fritz, H.-G. Biodegradable fibres spun from poly(lactide) generated by reactive extrusion. J. Biotechnol. 2001, 86, 151–160. [Google Scholar] [CrossRef]

- Nejati, E.; Mirzadeh, H.; Zandi, M. Synthesis and characterization of nano-hydroxyapatite rods/poly(l-lactide acid) composite scaffolds for bone tissue engineering. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1589–1596. [Google Scholar] [CrossRef]

- Navarro, M.; Michiardi, A.; Castaño, O.; Planell, J. Biomaterials in orthopaedics. J. R. Soc. Interface 2008, 5, 1137–1158. [Google Scholar] [CrossRef] [Green Version]

- Hummers, W.S.; Offeman, R.E. Preparation of Graphitic Oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Prado, C.; Fratini, P.; de Sá Schiavo Matias, G.; Bocabello, R.Z.; Monteiro, J.; dos Santos, C.J.; Joaquim, J.G.F.; Giglio, R.F.; Possebon, F.S.; Sakata, S.H.; et al. Combination of stem cells from deciduous teeth and electroacupuncture for therapy in dogs with chronic spinal cord injury: A pilot study. Res. Vet. Sci. 2019, 123, 247–251. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; He, C. Synthesis and Stereocomplex Crystallization of Poly(lactide)–Graphene Oxide Nanocomposites. ACS Macro Lett. 2012, 1, 709–713. [Google Scholar] [CrossRef]

- Wang, D.-Y.; Leuteritz, A.; Kutlu, B.; der Landwehr, M.A.; Jehnichen, D.; Wagenknecht, U.; Heinrich, G. Preparation and investigation of the combustion behavior of polypropylene/organomodified MgAl-LDH micro-nanocomposite. J. Alloy. Compd. 2011, 509, 3497–3501. [Google Scholar] [CrossRef]

- Wang, H.; Qiu, Z. Crystallization behaviors of biodegradable poly(l-lactic acid)/graphene oxide nanocomposites from the amorphous state. Thermochim. Acta 2011, 526, 229–236. [Google Scholar] [CrossRef]

- Rhazouani, A.; Gamrani, H.; El Achaby, M.; Aziz, K.; Gebrati, L.; Uddin, M.S.; AZIZ, F. Synthesis and Toxicity of Graphene Oxide Nanoparticles: A Literature Review of In Vitro and In Vivo Studies. BioMed Res. Int. 2021, 2021, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Análise Da Célula Inflamatória (macrófago), Em Uma Lesão Músculo Esquelética Sob Crioterapia. Estudo Em Grupos Controle E Não Controle. Available online: https://www.efdeportes.com/efd136/lesao-musculo-esqueletica-sob-crioterapia.htm (accessed on 27 July 2021).

- Dias, G.C.; Cellet, T.S.; Santos, M.C.; Carvalho, C.L.; Malmonge, L.F. A Caracterização Morfológica de Óxido de Grafeno Preparados Pelo Método de Hummers Modificado. Rev. Tecnológica 2020, 29, 199–216. [Google Scholar] [CrossRef] [Green Version]

- Yang, K.; Feng, L.; Liu, Z. Stimuli responsive drug delivery systems based on nano-graphene for cancer therapy. Adv. Drug Deliv. Rev. 2016, 105, 228–241. [Google Scholar] [CrossRef]

- Sun, X.; Liu, Z.; Welsher, K.; Robinson, J.T.; Goodwin, A.; Zaric, S.; Dai, H. Nano-graphene oxide for cellular imaging and drug delivery. Nano Res. 2008, 1, 203–212. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Xia, J.; Zhao, Q.; Liu, L.; Zhang, Z. Functional Graphene Oxide as a Nanocarrier for Controlled Loading and Targeted Delivery of Mixed Anticancer Drugs. Small 2010, 6, 537–544. [Google Scholar] [CrossRef]

- Balbino, C.A.; Pereira, L.M.; Curi, R. Mecanismos envolvidos na cicatrização: Uma revisão. Rev. Bras. Ciências Farm. 2005, 41, 27–51. [Google Scholar] [CrossRef]

- Lobato, R. EEfeitos Bioquímicos Da Exposição Ao Nanomaterial Óxido de Grafeno Em Diferentes Tecidos Do Camarão Branco (Litopenaeus Vannamei; Crustacea, Decapoda), Através Da Suplementação Na Ração. Master’s Thesis, Federal University of Rio Grande, Rio Grande, Brazil, 2013. [Google Scholar]

- Liu, S.; Zeng, T.H.; Hofmann, M.; Burcombe, E.; Wei, J.; Jiang, R.; Kong, J.; Chen, Y. Antibacterial Activity of Graphite, Graphite Oxide, Graphene Oxide, and Reduced Graphene Oxide: Membrane and Oxidative Stress. ACS Nano 2011, 5, 6971–6980. [Google Scholar] [CrossRef]

- Bianco, A.; Kostarelos, K.; Prato, M. Applications of carbon nanotubes in drug delivery. Curr. Opin. Chem. Biol. 2005, 9, 674–679. [Google Scholar] [CrossRef] [PubMed]

- Pan, C.; Xie, Q.; Hu, Z.; Yang, M.; Zhu, L. Mechanical and biological properties of silk fibroin/carbon nanotube nanocomposite films. Fibers Polym. 2015, 16, 1781–1787. [Google Scholar] [CrossRef]

- Willander, M.; Nur, O.; Zaman, S.; Zainelabdin, A.; Bano, N.; Hussain, I. Zinc oxide nanorods/polymer hybrid heterojunctions for white light emitting diodes. J. Phys. D Appl. Phys. 2011, 44, 224017. [Google Scholar] [CrossRef] [Green Version]

- Wahid, F.; Khan, T.; Shehzad, A.; Ul-Islam, M.; Kim, Y.Y. Interaction of Nanomaterials with Cells and Their Medical Applications. J. Nanosci. Nanotechnol. 2014, 14, 744–754. [Google Scholar] [CrossRef]

- Simsikova, M.; Sikola, T. Interaction of Graphene Oxide with Proteins and Applications of their Conjugates. J. Nanomed. Res. 2017, 5, 00109. [Google Scholar] [CrossRef]

- Vuppaladadium, S.S.R.; Agarwal, T.; Kulanthaivel, S.; Mohanty, B.; Barik, C.S.; Maiti, T.K.; Pal, S.; Pal, K.; Banerjee, I. Silanization improves biocompatibility of graphene oxide. Mater. Sci. Eng. C 2020, 110, 110647. [Google Scholar] [CrossRef]

- Jeevanandam, J.; Barhoum, A.; Chan, Y.S.; Dufresne, A.; Danquah, M.K. Review on nanoparticles and nanostructured materials: History, sources, toxicity and regulations. Beilstein J. Nanotechnol. 2018, 9, 1050–1074. [Google Scholar] [CrossRef] [Green Version]

- Navarro, E.; Baun, A.; Behra, R.; Hartmann, N.B.; Filser, J.; Miao, A.-J.; Quigg, A.; Santschi, P.H.; Sigg, L. Environmental behavior and ecotoxicity of engineered nanoparticles to algae, plants, and fungi. Ecotoxicology 2008, 17, 372–386. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dreyer, D.R.; Park, S.; Bielawski, C.W.; Ruoff, R.S. The chemistry of graphene oxide. Chem. Soc. Rev. 2010, 39, 228–240. [Google Scholar] [CrossRef] [PubMed]

- Dong, R.; Ma, P.X.; Guo, B. Conductive biomaterials for muscle tissue engineering. Biomaterials 2020, 229, 119584. [Google Scholar] [CrossRef]

- Kuo, I.Y.; Ehrlich, B.E. Signaling in Muscle Contraction. Cold Spring Harb. Perspect. Biol. 2015, 7, a006023. [Google Scholar] [CrossRef]

- Guo, B.; Qu, J.; Zhao, X.; Zhang, M. Degradable conductive self-healing hydrogels based on dextran-graft-tetraaniline and N-carboxyethyl chitosan as injectable carriers for myoblast cell therapy and muscle regeneration. Acta Biomater. 2019, 84, 180–193. [Google Scholar] [CrossRef]

- Lee, J.; Ko, S.; Kwon, C.H.; Lima, M.D.; Baughman, R.H.; Kim, S.J. Carbon Nanotube Yarn-Based Glucose Sensing Artificial Muscle. Small 2016, 12, 2085–2091. [Google Scholar] [CrossRef]

- Shevach, M.; Fleischer, S.; Shapira, A.; Dvir, T. Gold Nanoparticle-Decellularized Matrix Hybrids for Cardiac Tissue Engineering. Nano Lett. 2014, 14, 5792–5796. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, G.A.B. Nanocompósitos de Pmma/Ha/Grafeno Para Aplicações Biomédicas. Ph.D. Thesis, University of Aveiro, Aveiro, Portugal, 2012. [Google Scholar]

- Unagolla, J.M.; Jayasuriya, A.C. Enhanced cell functions on graphene oxide incorporated 3D printed polycaprolactone scaffolds. Mater. Sci. Eng. C 2019, 102, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Vlček, J.; Lapčík, L.; Havrdová, M.; Poláková, K.; Lapčíková, B.; Opletal, T.; Froning, J.P.; Otyepka, M. Flow induced HeLa cell detachment kinetics show that oxygen-containing functional groups in graphene oxide are potent cell adhesion enhancers. Nanoscale 2019, 11, 3222–3228. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Ruan, J.; Song, H.; Zhang, J.; Wo, Y.; Guo, S.; Cui, D. Biocompatibility of Graphene Oxide. Nanoscale Res. Lett. 2010, 6, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Song, K.; Ji, L.; Zhang, J.; Wang, H.; Jiao, Z.; Mayasari, L.; Fu, X.; Liu, T. Fabrication and Cell Responsive Behavior of Macroporous PLLA/Gelatin Composite Scaffold with Hierarchical Micro-Nano Pore Structure. Nanomaterials 2015, 5, 415. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lech, A.; Butruk-Raszeja, B.A.; Ciach, T.; Lawniczak-Jablonska, K.; Kuzmiuk, P.; Bartnik, A.; Wachulak, P.; Fiedorowicz, H. Surface modification of plla, ptfe and pvdf with extreme ultraviolet (Euv) to enhance cell adhesion. Int. J. Mol. Sci. 2020, 21, 9679. [Google Scholar] [CrossRef]

- Yanagida, H.; Okada, M.; Masuda, M.; Ueki, M.; Narama, I.; Kitao, S.; Koyama, Y.; Furuzono, T.; Takakuda, K. Cell adhesion and tissue response to hydroxyapatite nanocrystal-coated poly(l-lactic acid) fabric. J. Biosci. Bioeng. 2009, 108, 235–243. [Google Scholar] [CrossRef]

| DIE | Zone 8 | Zone 7 | Zone 6 | Zone 5 | Zone 4 | Zone 3 | Zone 2 |

|---|---|---|---|---|---|---|---|

| 220 °C | 220 °C | 215 °C | 210 °C | 210 °C | 210 °C | 210 °C | 200 °C |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos Silva, T.; Melo Soares, M.; Oliveira Carreira, A.C.; de Sá Schiavo Matias, G.; Coming Tegon, C.; Massi, M.; de Aguiar Oliveira, A.; da Silva Júnior, L.N.; Costa de Carvalho, H.J.; Doná Rodrigues Almeida, G.H.; et al. Biological Characterization of Polymeric Matrix and Graphene Oxide Biocomposites Filaments for Biomedical Implant Applications: A Preliminary Report. Polymers 2021, 13, 3382. https://doi.org/10.3390/polym13193382

Santos Silva T, Melo Soares M, Oliveira Carreira AC, de Sá Schiavo Matias G, Coming Tegon C, Massi M, de Aguiar Oliveira A, da Silva Júnior LN, Costa de Carvalho HJ, Doná Rodrigues Almeida GH, et al. Biological Characterization of Polymeric Matrix and Graphene Oxide Biocomposites Filaments for Biomedical Implant Applications: A Preliminary Report. Polymers. 2021; 13(19):3382. https://doi.org/10.3390/polym13193382

Chicago/Turabian StyleSantos Silva, Thamires, Marcelo Melo Soares, Ana Claudia Oliveira Carreira, Gustavo de Sá Schiavo Matias, Carolina Coming Tegon, Marcos Massi, Andressa de Aguiar Oliveira, Leandro Norberto da Silva Júnior, Hianka Jasmyne Costa de Carvalho, Gustavo Henrique Doná Rodrigues Almeida, and et al. 2021. "Biological Characterization of Polymeric Matrix and Graphene Oxide Biocomposites Filaments for Biomedical Implant Applications: A Preliminary Report" Polymers 13, no. 19: 3382. https://doi.org/10.3390/polym13193382