Fabrication of Highly Microporous Structure Activated Carbon via Surface Modification with Sodium Hydroxide

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of Activated Carbon

2.2. Surface Modification with NaOH

2.3. Evaluation

2.3.1. Mass Yield

2.3.2. Ash Content

2.3.3. Methylene Blue Adsorption

2.3.4. Iodine Adsorption Number

2.3.5. Surface Characteristic

2.3.6. Surface Morphology

2.3.7. FTIR

2.4. Statistical Analysis

3. Results and Discussion

3.1. Physiochemical Properties of the Activated Carbon

3.2. Adsorption Properties of the Activated Carbon

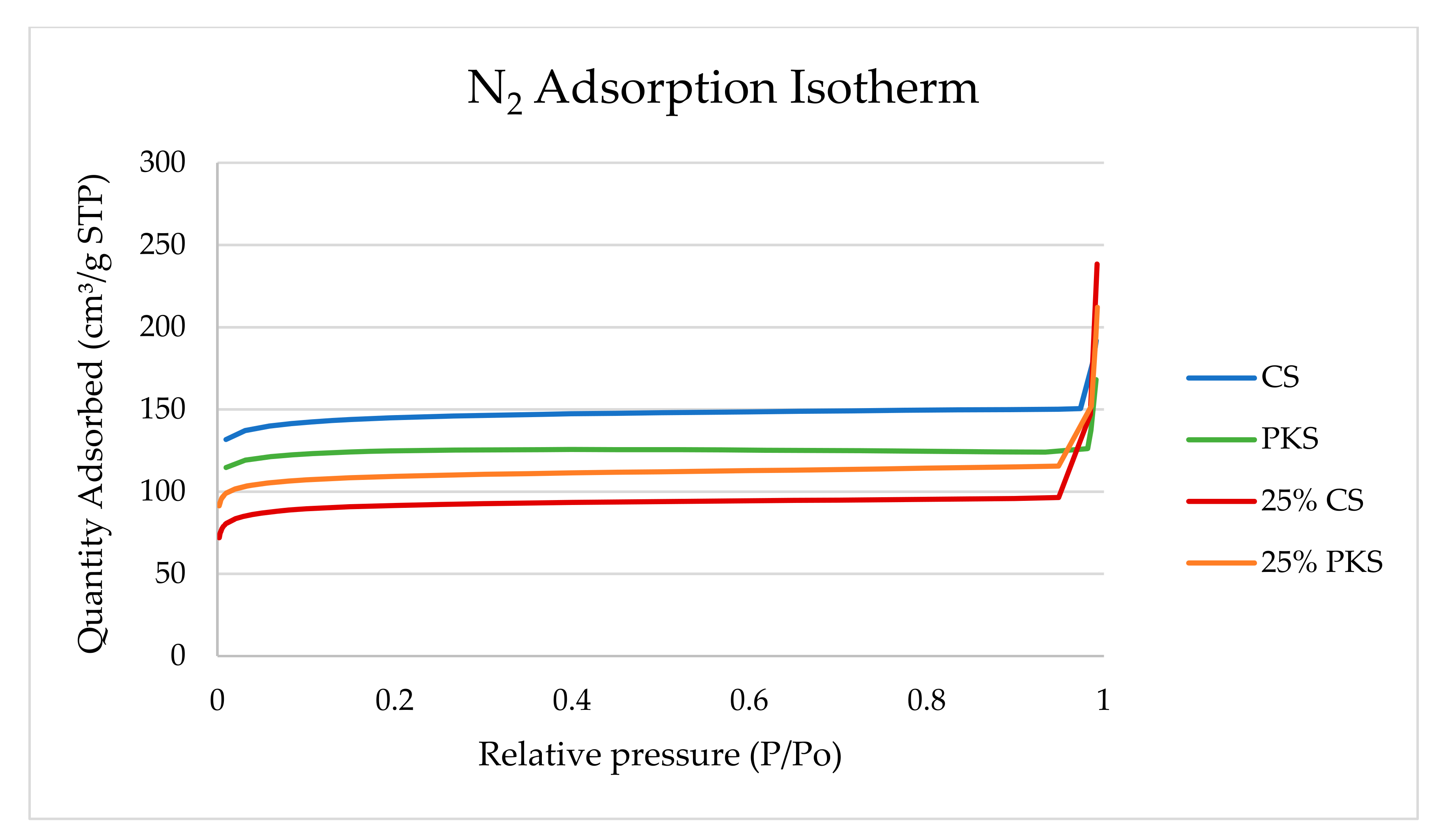

3.3. Surface Characteristic of Activated Carbon

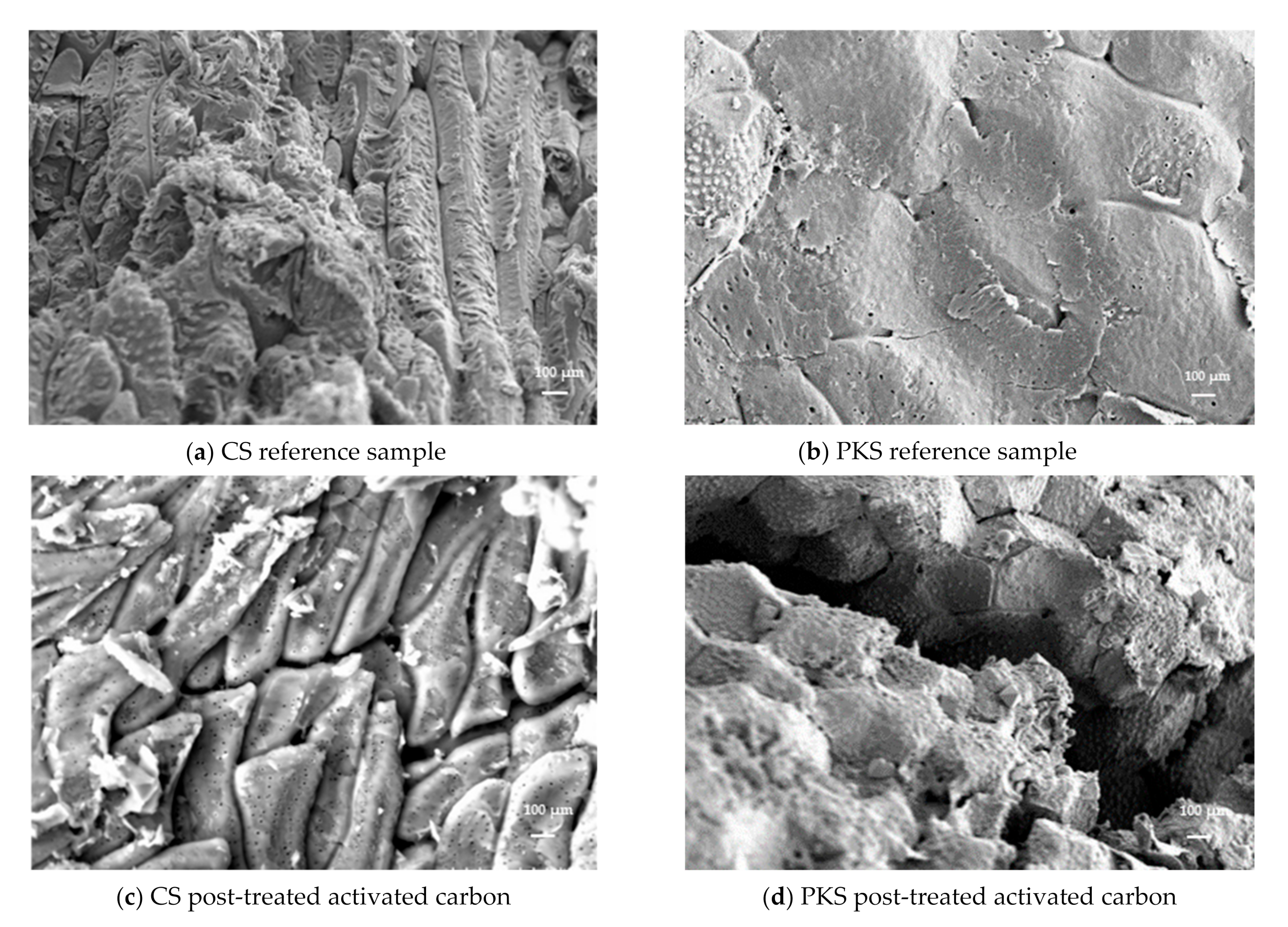

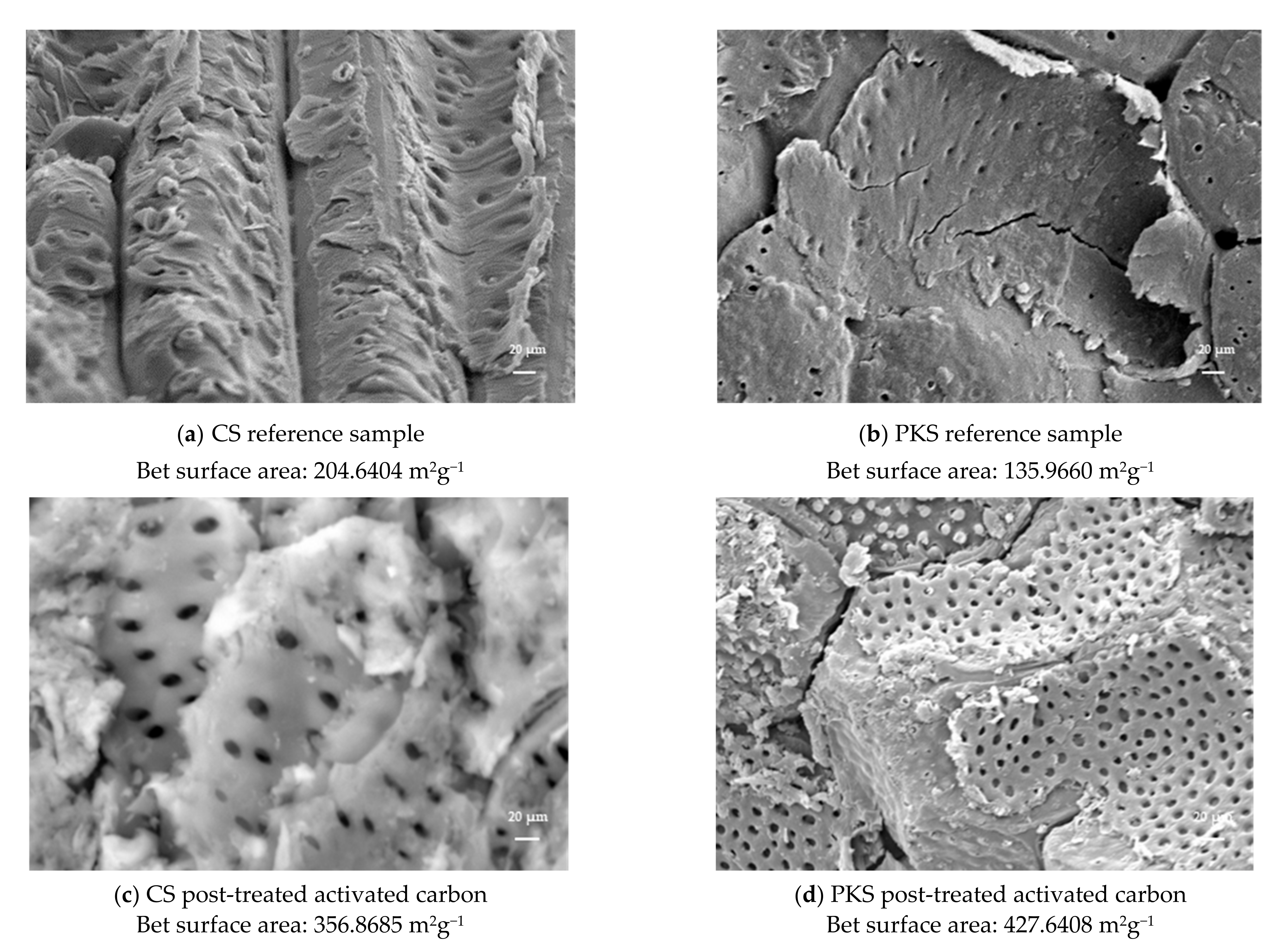

3.4. Surface Morphology of Activated Carbon

3.5. Surface Chemical Characteristics of Activated Carbon

3.6. Correlation of Surface Area and Micropore

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Goi, C.L. The river water quality before and during the Movement Control Order (MCO) in Malaysia. Case Stud. Chem. Environ. Eng. 2020, 2, 100027. [Google Scholar] [CrossRef]

- Najah, A.; Teo, F.Y.; Chow, M.F.; Huang, Y.F.; Latif, S.D.; Abdullah, S.; Ismail, M.; El-Shafie, A. Surface water quality status and prediction during movement control operation order under COVID-19 pandemic: Case studies in Malaysia. Int. J. Environ. Sci. Technol. 2021, 18, 1009–1018. [Google Scholar] [CrossRef]

- Jasim, N.A. The design for wastewater treatment plant (WWTP) with GPS X modelling. Cogent Eng. 2020, 7, 1723782. [Google Scholar] [CrossRef]

- Musa, M.; Idrus, S. Physical and Biological Treatment Technologies of Slaughterhouse Wastewater: A Review. Sustainability 2021, 13, 4656. [Google Scholar] [CrossRef]

- Dash, R.R.; Mohanty, S. Removal of organic matters and nutrients by using bio-balls and corn cobs as bio-film carrier in MBBR technology. In Water Security and Sustainability; Springer: Singapore, 2021; pp. 227–237. [Google Scholar]

- Fröhlich, A.C.; Foletto, E.L.; Dotto, G.L. Preparation and characterization of NiFe2O4/activated carbon composite as potential magnetic adsorbent for removal of ibuprofen and ketoprofen pharmaceuticals from aqueous solutions. J. Clean. Prod. 2019, 229, 828–837. [Google Scholar] [CrossRef]

- Saad, M.J.; Chia, C.; Zakaria, S.; Sajab, M.S.; Misran, S. Malaysia rice wastes for activated carbon production. In Proceedings of the 9th Kuala Lumpur International Agriculture, Forestry and Plantation Conference, Bangi, Malaysia, 21–22 September 2020; pp. 20–26. [Google Scholar]

- Bhatnagar, A. (Ed.) Application of Adsorbents for Water Pollution Control; Bentham Science Publishers: Sharjah, United Arab Emirates, 2012. [Google Scholar]

- Mahanim, S.M.A.; Asma, I.W.; Rafidah, J.; Puad, E.; Shaharuddin, H. Production of activated carbon from industrial bamboo wastes. J. Trop. For. Sci. 2011, 23, 417–424. [Google Scholar]

- Anwar, Z.; Gulfraz, M.; Irshad, M. Agro-industrial lignocellulosic biomass a key to unlock the future bio-energy: A brief review. J. Radiat. Res. Appl. Sci. 2014, 7, 163–173. [Google Scholar] [CrossRef]

- Lee, C.L.; H’Ng, P.S.; Paridah, T.; Chin, K.L.; Rashid, U.; Maminski, M.; Go, W.Z.; Nazrin, R.A.R.; Rosli, S.N.A.; Khoo, P.S. Production of bioadsorbent from phosphoric acid pretreated palm kernel shell and coconut shell by two-stage continuous physical activation via N2 and air. R. Soc. Open Sci. 2018, 5, 180775. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bădescu, I.S.; Bulgariu, D.; Ahmad, I.; Bulgariu, L. Valorisation possibilities of exhausted biosorbents loaded with metal ions—A review. J. Environ. Manag. 2018, 224, 288–297. [Google Scholar] [CrossRef]

- Manyangadze, M.; Chikuruwo, N.; Narsaiah, T.; Chakra, C.; Radhakumari, M.; Danha, G. Enhancing adsorption capacity of nano-adsorbents via surface modification: A review. S. Afr. J. Chem. Eng. 2020, 31, 25–32. [Google Scholar] [CrossRef]

- Ambaye, T.G.; Vaccari, M.; van Hullebusch, E.D.; Amrane, A.; Rtimi, S. Mechanisms and adsorption capacities of biochar for the removal of organic and inorganic pollutants from industrial wastewater. Int. J. Environ. Sci. Technol. 2021, 18, 3273–3294. [Google Scholar] [CrossRef]

- Chin, K.L.; Lee, C.L.; H’ng, P.S.; Rashid, U.; Paridah, M.T.; Khoo, P.S.; Maminski, M. Refining micropore capacity of activated carbon derived from coconut shell via deashing post-treatment. Bioresource 2020, 15, 7749–7769. [Google Scholar] [CrossRef]

- Zhang, Y.; Song, X.; Xu, Y.; Shen, H.; Kong, X.; Xu, H. Utilization of wheat bran for producing activated carbon with high specific surface area via NaOH activation using industrial furnace. J. Clean. Prod. 2019, 210, 366–375. [Google Scholar] [CrossRef]

- Xu, B.; Chen, Y.; Wei, G.; Cao, G.; Zhang, H.; Yang, Y. Activated carbon with high capacitance prepared by NaOH activation for supercapacitors. Mater. Chem. Phys. 2010, 124, 504–509. [Google Scholar] [CrossRef]

- Lee, C.L.; H’ng, P.S.; Paridah, M.T.; Chin, K.L.; Khoo, P.S.; Nazrin, R.A.R.; Asyikin, S.N.; Mariusz, M. Effect of reaction time and temperature on the properties of carbon black made from palm kernel and coconut shell. Asian J. Sci. Res. 2017, 10, 24–33. [Google Scholar] [CrossRef] [Green Version]

- Liew, R.K.; Azwar, E.; Yek, P.N.Y.; Lim, X.Y.; Cheng, C.K.; Ng, J.-H.; Jusoh, A.; Lam, W.-H.; Ibrahim, M.D.; Ma, N.L.; et al. Microwave pyrolysis with KOH/NaOH mixture activation: A new approach to produce micro-mesoporous activated carbon for textile dye adsorption. Bioresour. Technol. 2018, 266, 1–10. [Google Scholar] [CrossRef]

- Liu, Z.; Niu, W.; Chu, H.; Zhou, T.; Niu, Z. Effect of the Carbonization Temperature on the Properties of Biochar Produced from the Pyrolysis of Crop Residues. Bioresource 2018, 13, 3429–3446. [Google Scholar] [CrossRef] [Green Version]

- Cao, J.; Xiao, G.; Xu, X.; Shen, D.; Jin, B. Study on carbonization of lignin by TG-FTIR and high-temperature carbonization reactor. Fuel Process. Technol. 2013, 106, 41–47. [Google Scholar] [CrossRef]

- Cazetta, A.L.; Vargas, A.; Nogami, E.M.; Kunita, M.H.; Guilherme, M.R.; Martins, A.C.; Silva, T.L.; Moraes, J.C.; Almeida, V.C. NaOH-activated carbon of high surface area produced from coconut shell: Kinetics and equilibrium studies from the methylene blue adsorption. Chem. Eng. J. 2011, 174, 117–125. [Google Scholar] [CrossRef]

- Kumar, R.H.S.M. Removal of Ash from Indian Assam Coking Coal Using Sodium Hydroxide and Acid Solutions. Energy Sources 2000, 22, 187–196. [Google Scholar] [CrossRef]

- Emara, M.M.; Farag, R.S.; Mubarak, M.F.; Ali, S.K. Synthesis of core–shell activated carbon/CaO composite from Ficus Nitida leaves, as an efficient adsorbent for removal of methylene blue. Nanotechnol. Environ. Eng. 2020, 5, 1–14. [Google Scholar] [CrossRef]

- Lee, C.L.; H’Ng, P.S.; Chin, K.L.; Paridah, T.; Rashid, U.; Go, W.Z. Characterization of bioadsorbent produced using incorporated treatment of chemical and carbonization procedures. R. Soc. Open Sci. 2019, 6, 190667. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mojoudi, N.; Mirghaffari, N.; Soleimani, M.; Shariatmadari, H.; Belver, C.; Bedia, J. Phenol adsorption on high microporous activated carbons prepared from oily sludge: Equilibrium, kinetic and thermodynamic studies. Sci. Rep. 2019, 9, 1–12. [Google Scholar] [CrossRef]

- Saad, M.J.; Chia, C.H.; Misran, S.; Zakaria, S.; Sajab, M.S.; Rahman, M.H.A. Rice Husk Activated Carbon with NaOH Activation: Physical and Chemical Properties. Sains Malays. 2020, 49, 2261–2267. [Google Scholar] [CrossRef]

- Shi, J.; Lu, Y.; Zhang, Y.; Cai, L.; Shi, S.Q. Effect of thermal treatment with water, H2SO4 and NaOH aqueous solution on color, cell wall and chemical structure of poplar wood. Sci. Rep. 2018, 8, 17735. [Google Scholar] [CrossRef]

- Heidarinejad, Z.; Dehghani, M.H.; Heidari, M.; Javedan, G.; Ali, D.I.; Sillanpää, M. Methods for preparation and activation of activated carbon: A review. Environ. Chem. Lett. 2020, 18, 393–415. [Google Scholar] [CrossRef]

- Owais, M.; Zhao, J.; Imani, A.; Wang, G.; Zhang, H.; Zhang, Z. Synergetic effect of hybrid fillers of boron nitride, graphene nanoplatelets, and short carbon fibers for enhanced thermal conductivity and electrical resistivity of epoxy nanocomposites. Compos. Part A Appl. Sci. Manuf. 2019, 117, 11–22. [Google Scholar] [CrossRef]

- Syabaniah, N.F.; Syarif, N.; Rohendi, D.; Wandasari, M.; Rengga, W.D. The Light Transmittance and Electrical Conductivity Properties of Gelam Wood Carbon Nanosheet and Its Derivatives. Indones. J. Fundam. Appl. Chem. 2019, 4, 126–131. [Google Scholar] [CrossRef]

- Syabania, N.F.; Sudarsono, W.; Rohendi, D.; Syarif, N. Functionality Analysis of Carbon Nanosheet, Oxidized Carbon Nanosheet and Reduced Carbon Nanosheet Oxide by Using Fourier Transform Infra Red and Boehm Titration Method. J. Phys. Conf. Ser. 2018, 1095, 012028. [Google Scholar] [CrossRef]

- Derdour, K.; Bouchelta, C.; Naser-Eddine, A.K.; Medjram, M.S.; Magri, P. Removal of Cr(VI) from aqueous solutions by using activated carbon supported iron catalysts as efficient adsorbents. World J. Eng. 2018, 15, 3–13. [Google Scholar] [CrossRef]

- Ren, Q.; Shen, X.; Zhang, J.; Liu, J. Simultaneous Reduction and Covalent Combining of Tetraethylenepentamine on Graphene Oxide. IOP Conf. Ser. Mater. Sci. Eng. 2019, 472, 012096. [Google Scholar] [CrossRef] [Green Version]

- Alsbaiee, A.; Smith, B.J.; Xiao, L.; Ling, Y.; Helbling, D.E.; Dichtel, W. Rapid removal of organic micropollutants from water by a porous β-cyclodextrin polymer. Nat. Cell Biol. 2016, 529, 190–194. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Liu, J.; Zhang, Y.; Zhang, H.; Chen, W.-Y.; Norris, P.; Pan, W.-P. Use of a non-thermal plasma technique to increase the number of chlorine active sites on biochar for improved mercury removal. Chem. Eng. J. 2018, 331, 536–544. [Google Scholar] [CrossRef]

- Jin, W.; Xu, W.; Liang, H.; Li, Y.; Liu, S.; Li, B. Nanoemulsions for Food: Properties, Production, Characterization, and Applications; Elsevier BV: Amsterdam, The Netherlands, 2016; pp. 1–36. [Google Scholar]

- Kerr, R.; Garvin, J.; Heaton, N.; Boyle, E. Emotional intelligence and leadership effectiveness. Leadersh. Organ. Dev. J. 2006, 27, 265–279. [Google Scholar] [CrossRef]

- Nishi, Y.; Inagaki, M. Gas Adsorption/Desorption Isotherm for Pore Structure Characterization. Mater. Sci. Eng. Carbon 2016, 11, 227–247. [Google Scholar] [CrossRef]

- Gottipati, R. Preparation and Characterization of Microporous Activated Carbon from Biomass and Its Application in the Removal of Chromium (Vi) from Aqueous Phase; National Institute of Technology: Rourkela, India, 2012. [Google Scholar]

| Carbonization Temperature (°C) | Mass Yield (%) | Ash Content (%) | Methylene Blue (mg/g) | Iodine Adsorption (mg/g) | ||||

|---|---|---|---|---|---|---|---|---|

| CS | PKS | CS | PKS | CS | PKS | CS | PKS | |

| 500 | 36.23 | 37.08 | 24.34 | 24.23 | 86.128 | 115.350 | 308.693 | 305.901 |

| 600 | 26.93 | 27.04 | 35.51 | 34.39 | 264.792 | 212.757 | 406.430 | 372.920 |

| 700 | 27.44 | 27.26 | 35.50 | 31.08 | 280.429 | 212.757 | 441.800 | 402.710 |

| Carbonization Temperature (°C) | NaOH Concentration (%) | Mass Yield (%) | Ash Content (%) | ||

|---|---|---|---|---|---|

| CS | PKS | CS | PKS | ||

| 500 | 6.25 | 36.19 a | 36.84 a | 24.16 a | 24.10 a |

| 500 | 12.5 | 35.42 b | 35.54 b | 25.31 b | 25.30 b |

| 500 | 25 | 33.75 e | 33.92 d | 27.01 d | 26.72 d |

| 500 | 50 | 32.82 f | 33.39 e | 27.20 e | 27.30 f |

| 600 | 6.25 | 35.31 c | 34.84 c | 26.30 c | 25.25 b |

| 600 | 12.5 | 34.53 b | 33.93 d | 27.01 d | 27.09 e |

| 600 | 25 | 28.12 i | 33.11 f | 29.51 g | 28.12 g |

| 600 | 50 | 27.63 j | 32.08 g | 31.10 i | 28.90 h |

| 700 | 6.25 | 30.91 g | 33.2 e f | 26.30 c | 26.01 c |

| 700 | 12.5 | 29.96 h | 31.08 h | 28.38 f | 29.50 i |

| 700 | 25 | 27.36 k | 29.65 i | 30.81 h | 31.16 j |

| 700 | 50 | 27.02 l | 28.20 j | 32.01 j | 32.49 k |

| p-value | <0.001 | <0.001 | <0.001 | <0.001 | |

| Carbonization Temperature (°C) | NaOH Concentration (%) | Methylene Blue (mg/g) | Iodine Adsorption (mg/g) | ||

|---|---|---|---|---|---|

| CS | PKS | CS | PKS | ||

| 500 | 6.25 | 108.685 j | 173.025 j | 327.310 i | 314.279 k |

| 500 | 12.5 | 208.399 g | 208.912 g h | 336.618 h | 333.826 i |

| 500 | 25 | 187.380 h | 192.763 h i | 358.958 j | 353.373 h |

| 500 | 50 | 177.126 i | 185.842 h i | 309.625 j | 375.713 g |

| 600 | 6.25 | 350.408 d | 302.217 d | 307.763 j | 476.241 f |

| 600 | 12.5 | 400.905 a | 331.952 c | 414.807 e | 504.166 c |

| 600 | 25 | 395.266 b | 261.204 e | 442.732 d | 543.260 b |

| 600 | 50 | 388.345 c | 218.909f g | 361.751 g | 318.002 j |

| 700 | 6.25 | 296.321 e | 238.903 e f | 479.965 c | 487.411 e |

| 700 | 12.5 | 226.855 f | 409.877 a | 499.512 b | 543.260 b |

| 700 | 25 | 110.480 j | 376.297 b | 527.436 a | 627.034 a |

| 700 | 50 | 72.799 k | 257.871 e | 401.776 f | 495.789 d |

| p-value | <0.001 | <0.001 | <0.001 | <0.001 | |

| Correlation | Micropore Surface Area | Total Surface Area | |

|---|---|---|---|

| Micropore surface area | Pearson Correlation | 1 | 0.858 ** |

| Sig. (2-tailed) | 0.000 | ||

| N | 18 | 18 | |

| Total surface area | Pearson Correlation | 0.858 ** | 1 |

| Sig. (2-tailed) | 0.000 | ||

| N | 18 | 18 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hafizuddin, M.S.; Lee, C.L.; Chin, K.L.; H’ng, P.S.; Khoo, P.S.; Rashid, U. Fabrication of Highly Microporous Structure Activated Carbon via Surface Modification with Sodium Hydroxide. Polymers 2021, 13, 3954. https://doi.org/10.3390/polym13223954

Hafizuddin MS, Lee CL, Chin KL, H’ng PS, Khoo PS, Rashid U. Fabrication of Highly Microporous Structure Activated Carbon via Surface Modification with Sodium Hydroxide. Polymers. 2021; 13(22):3954. https://doi.org/10.3390/polym13223954

Chicago/Turabian StyleHafizuddin, Mohd Sahfani, Chuan Li Lee, Kit Ling Chin, Paik San H’ng, Pui San Khoo, and Umer Rashid. 2021. "Fabrication of Highly Microporous Structure Activated Carbon via Surface Modification with Sodium Hydroxide" Polymers 13, no. 22: 3954. https://doi.org/10.3390/polym13223954