Polybenzoxazine Resins with Cellulose Phosphide: Preparation, Flame Retardancy and Mechanisms

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

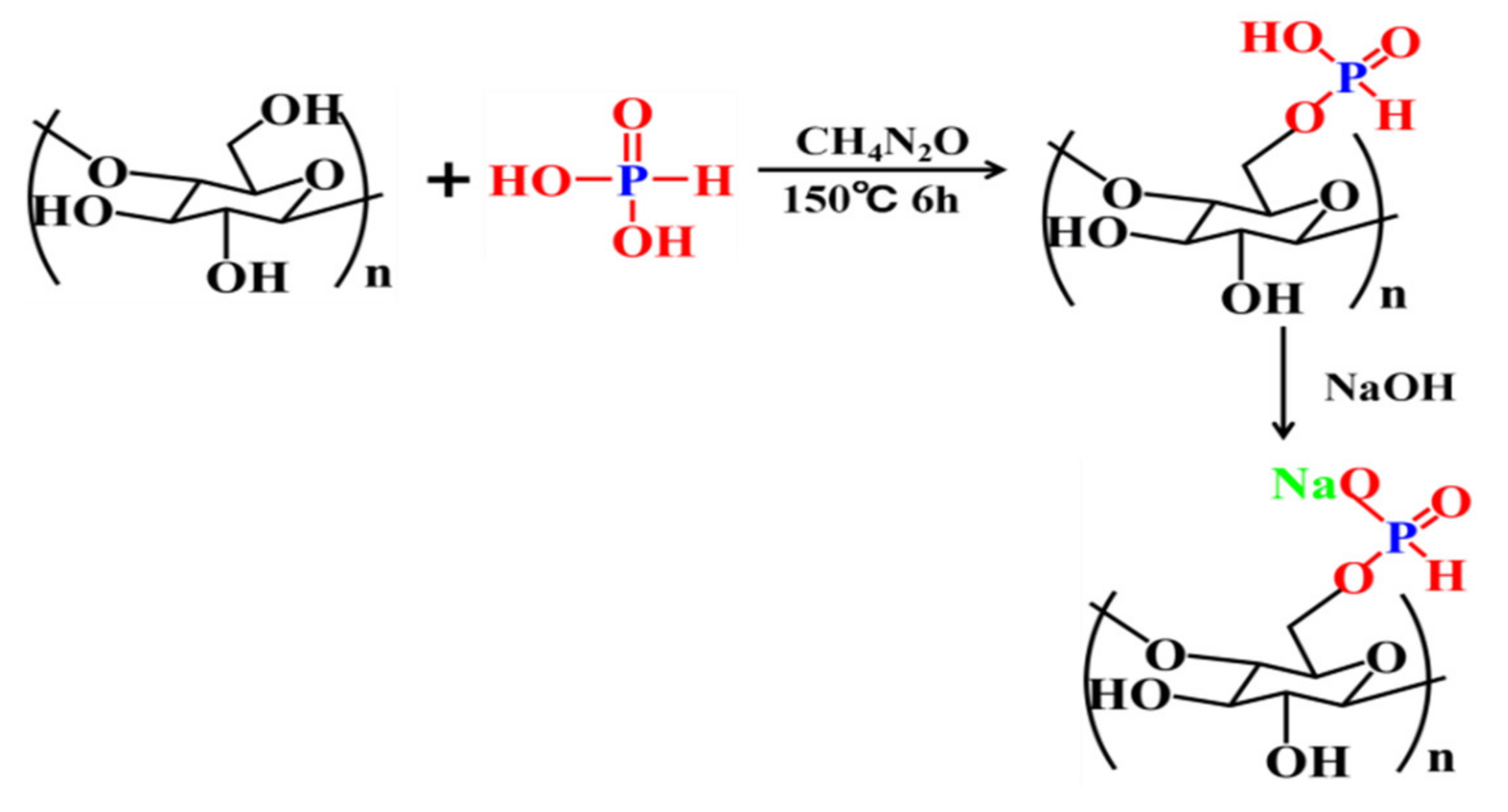

2.2. Phosphorylation of α-Cellulose

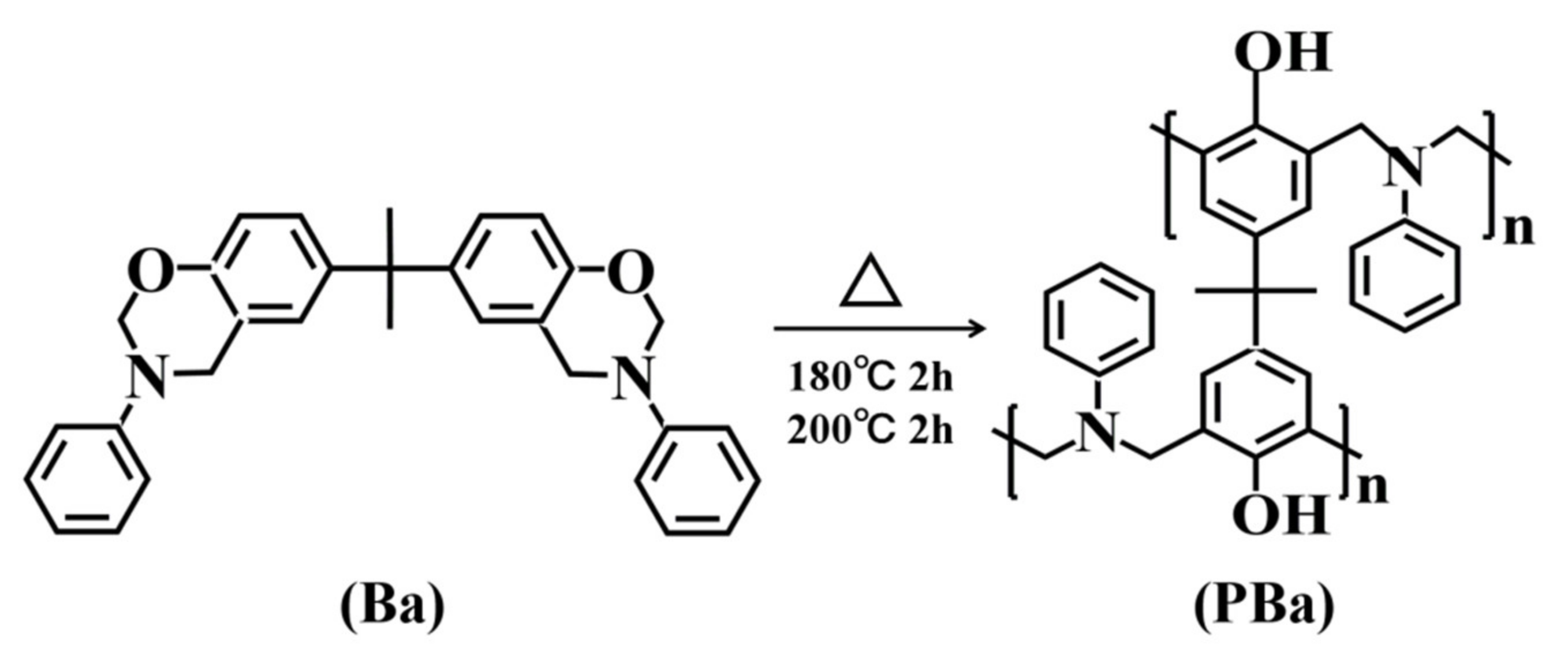

2.3. Preparation of PBa/PCF Composites

2.4. Characterization

3. Results and Discussion

3.1. Characterization of PCF

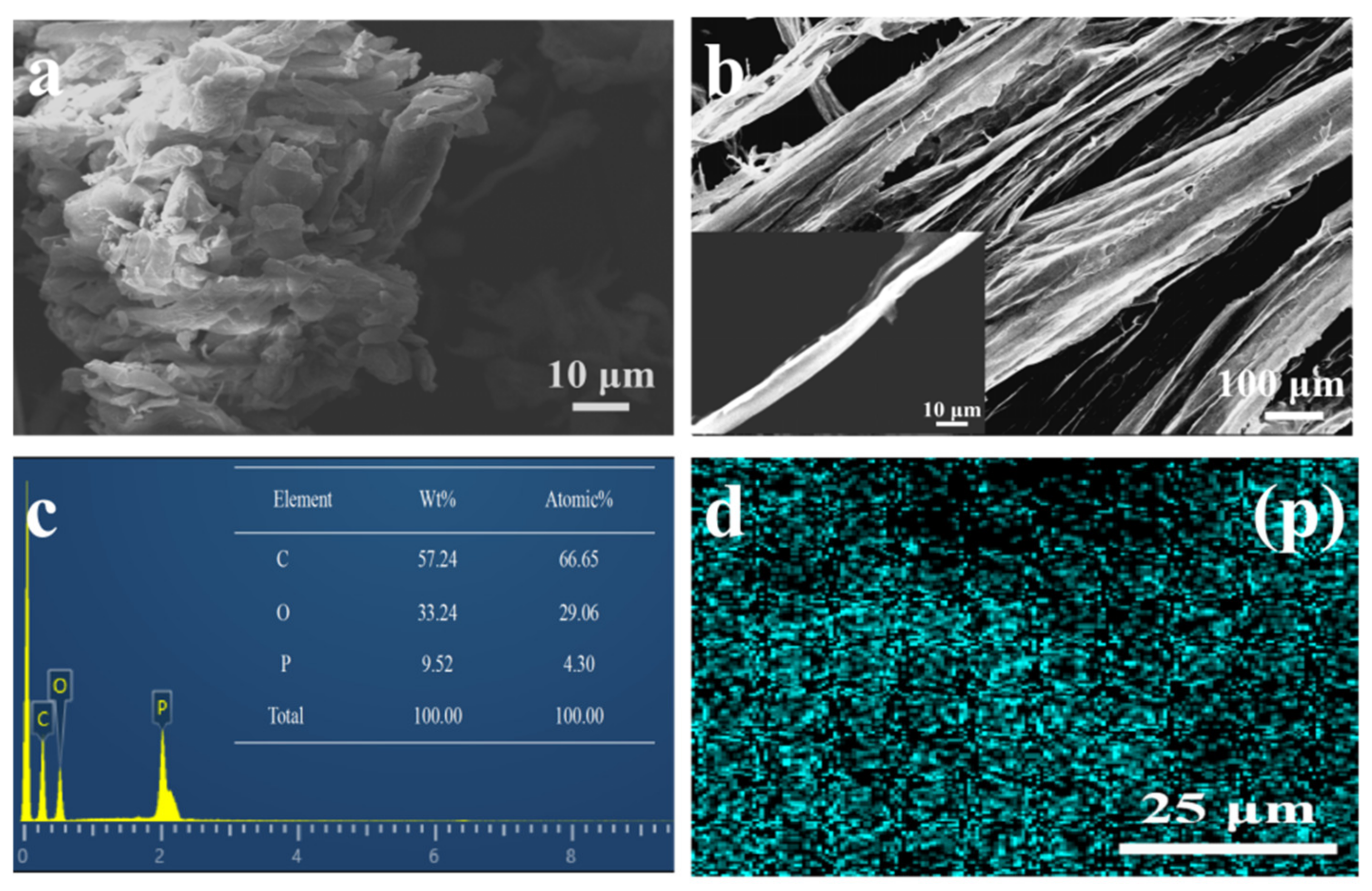

3.2. Morphology of Cellulose and PCF

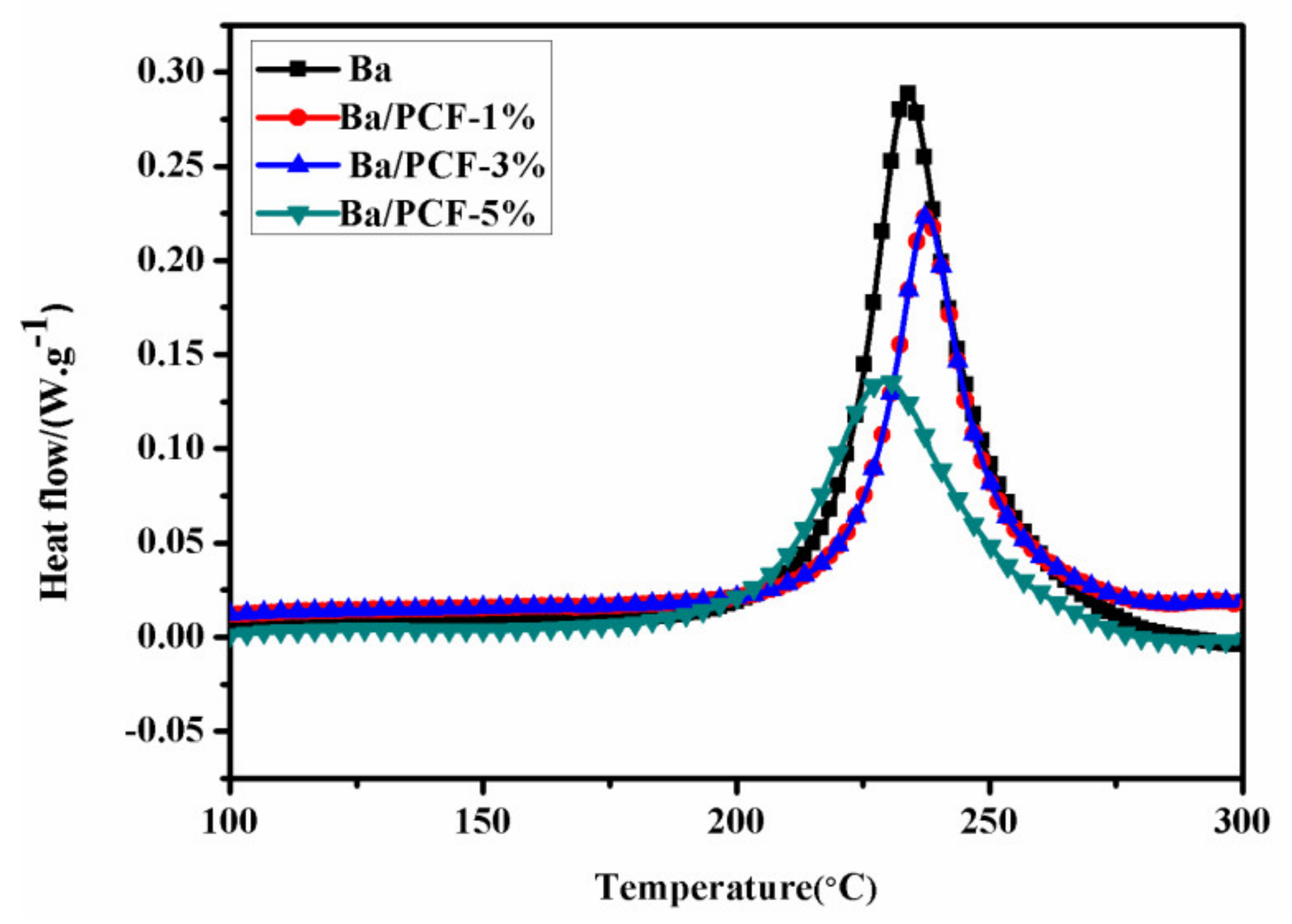

3.3. Curing Temperature of Ba and Ba/PCF Systems

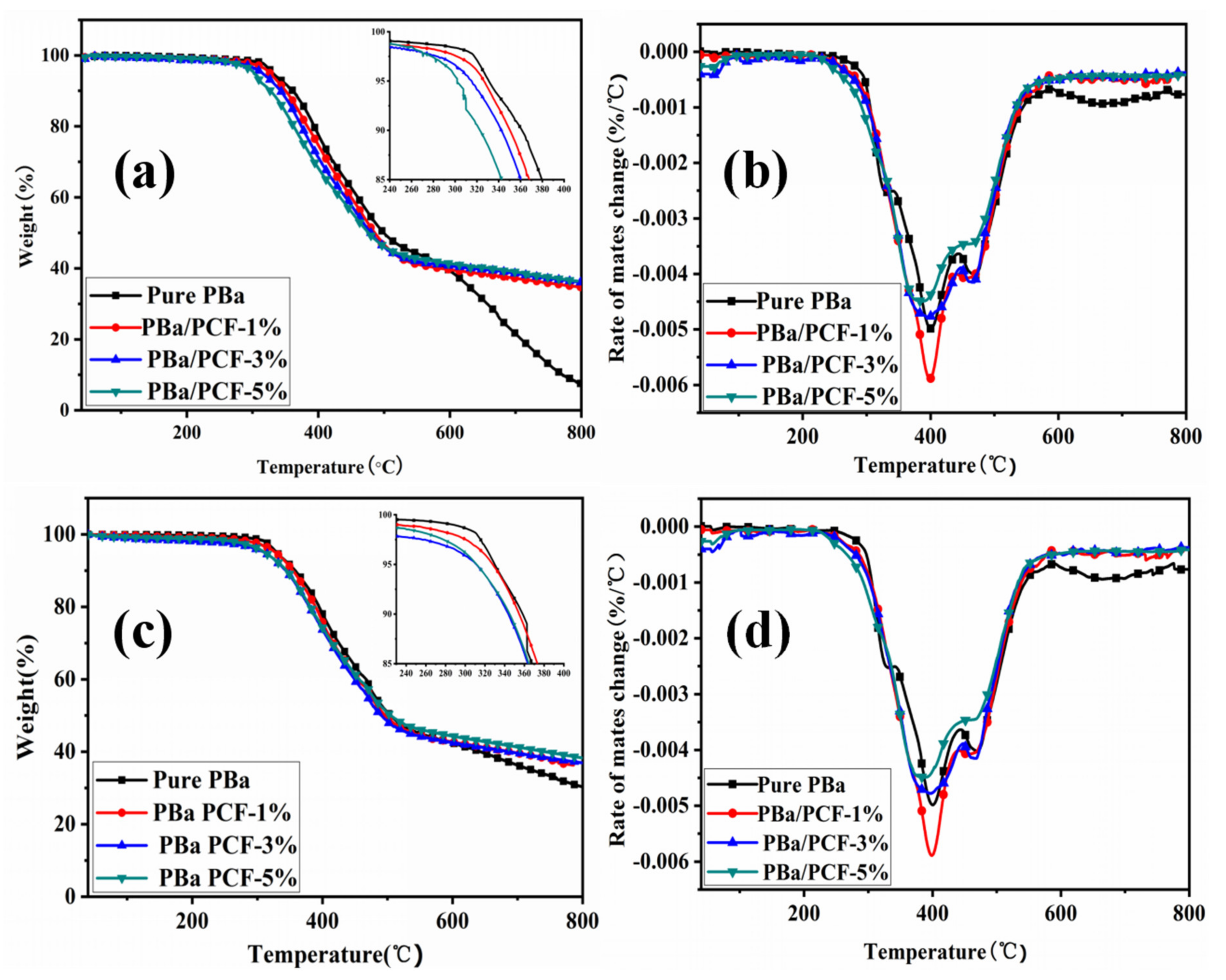

3.4. Thermal Stability

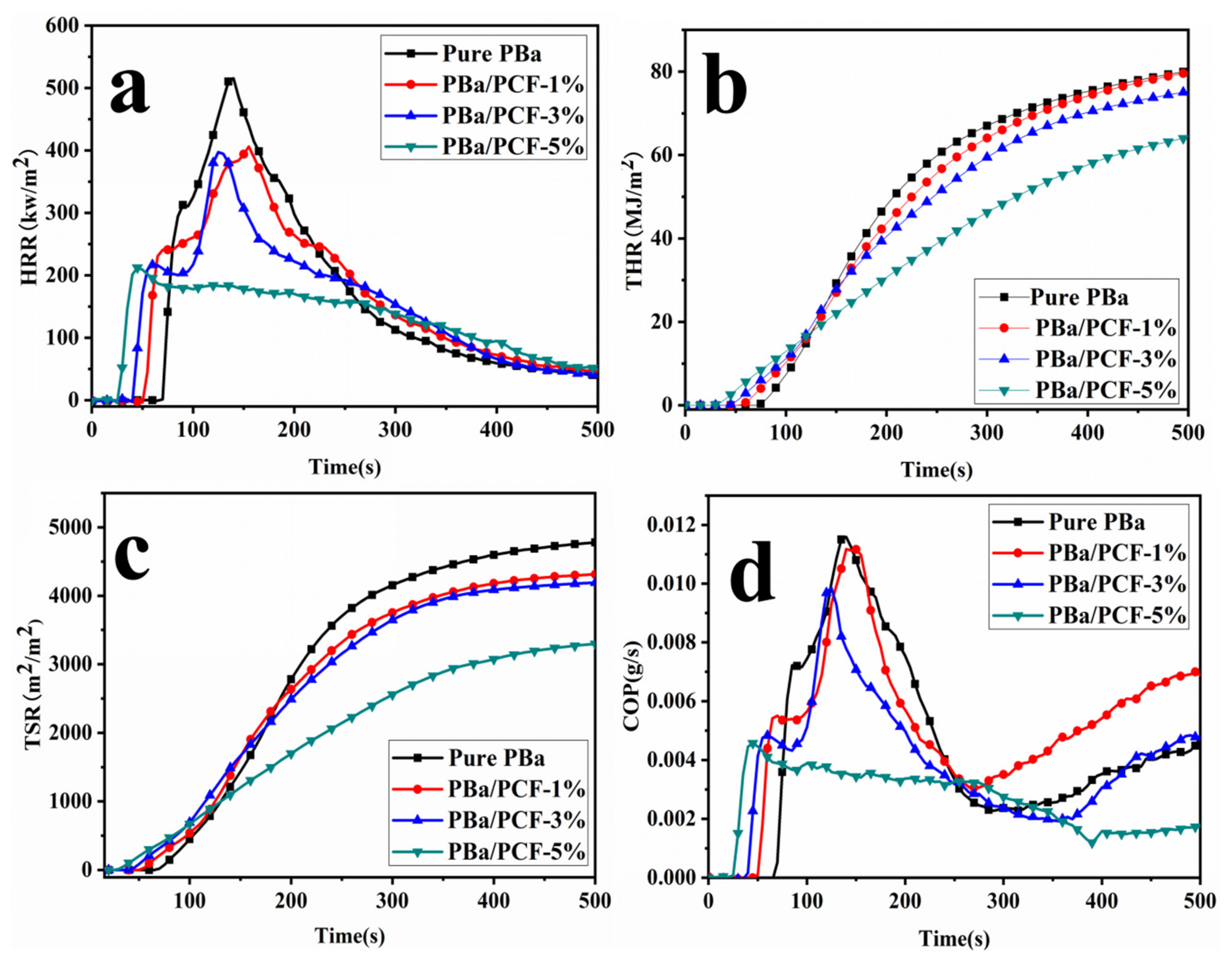

3.5. Flammability Performance of PBa and Its Composites

3.6. Analysis of Flame Retardancy Mechanism

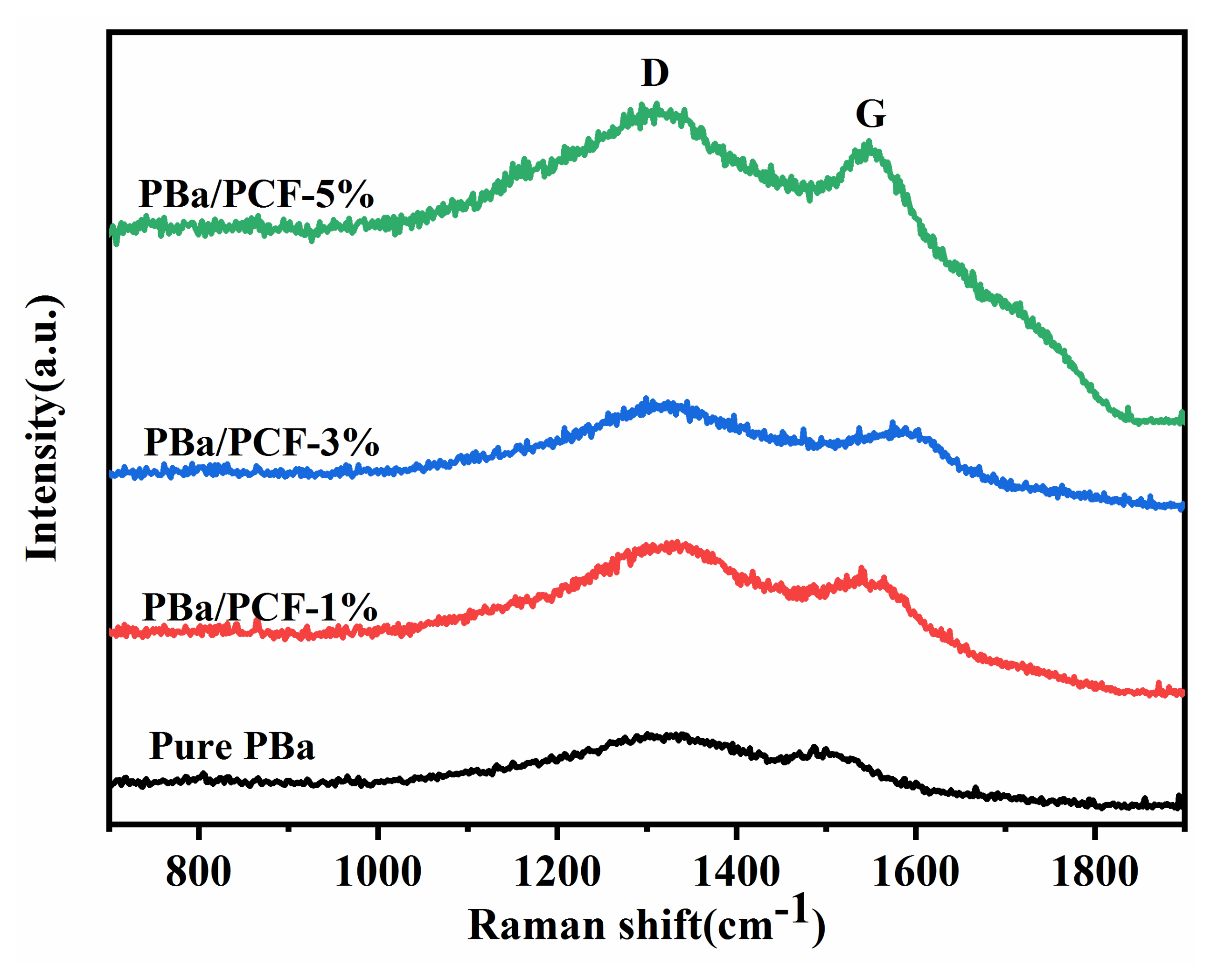

3.6.1. Condensed Phase Analysis

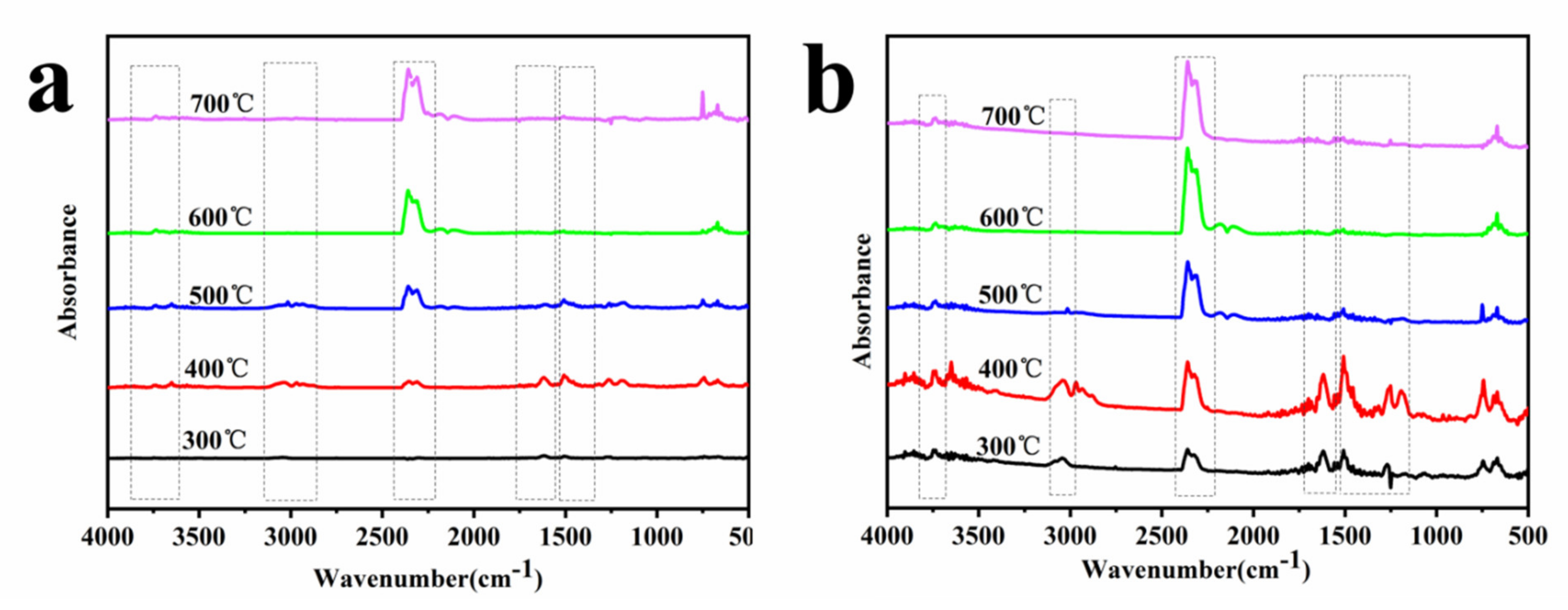

3.6.2. Gas Phase Analysis

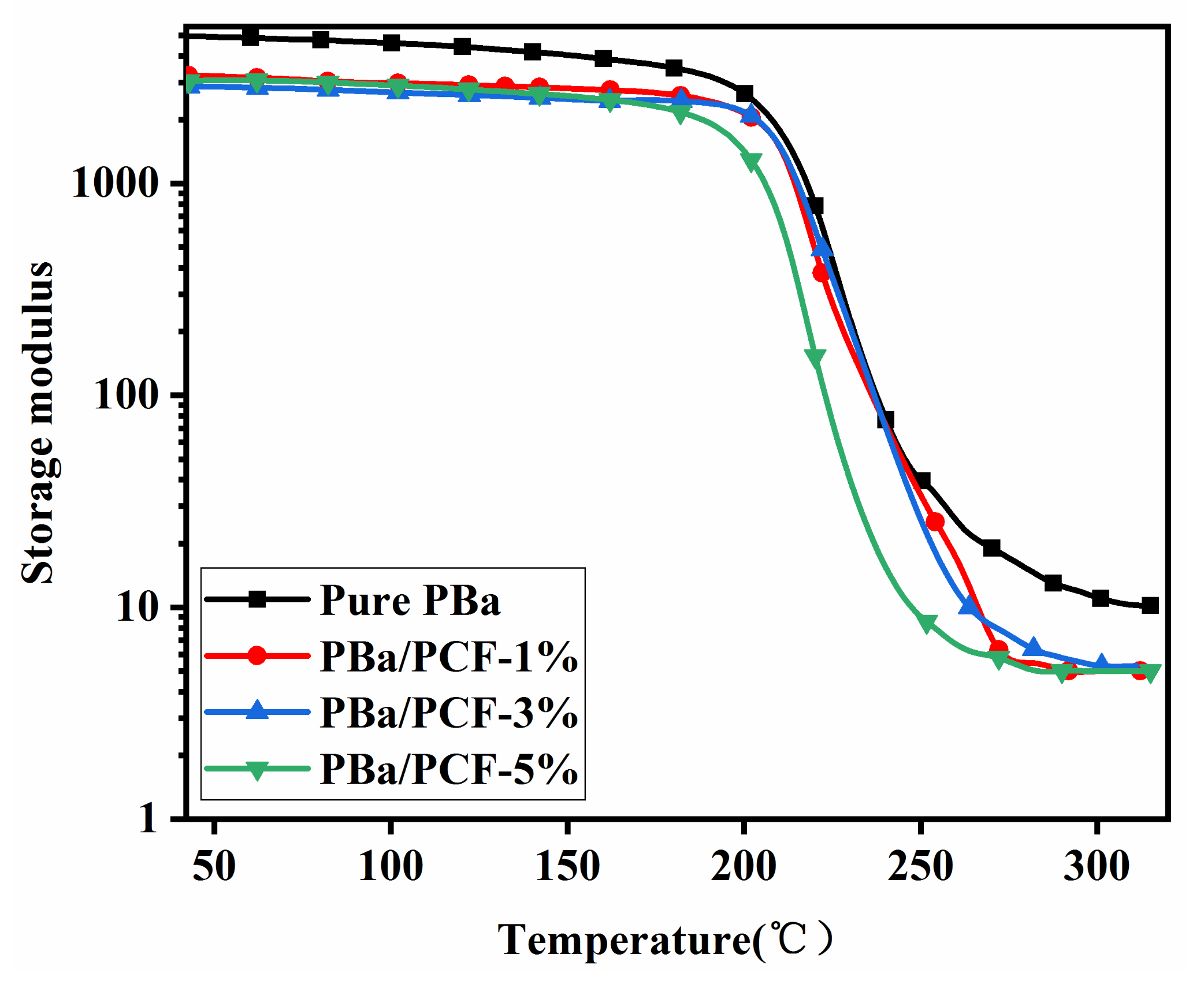

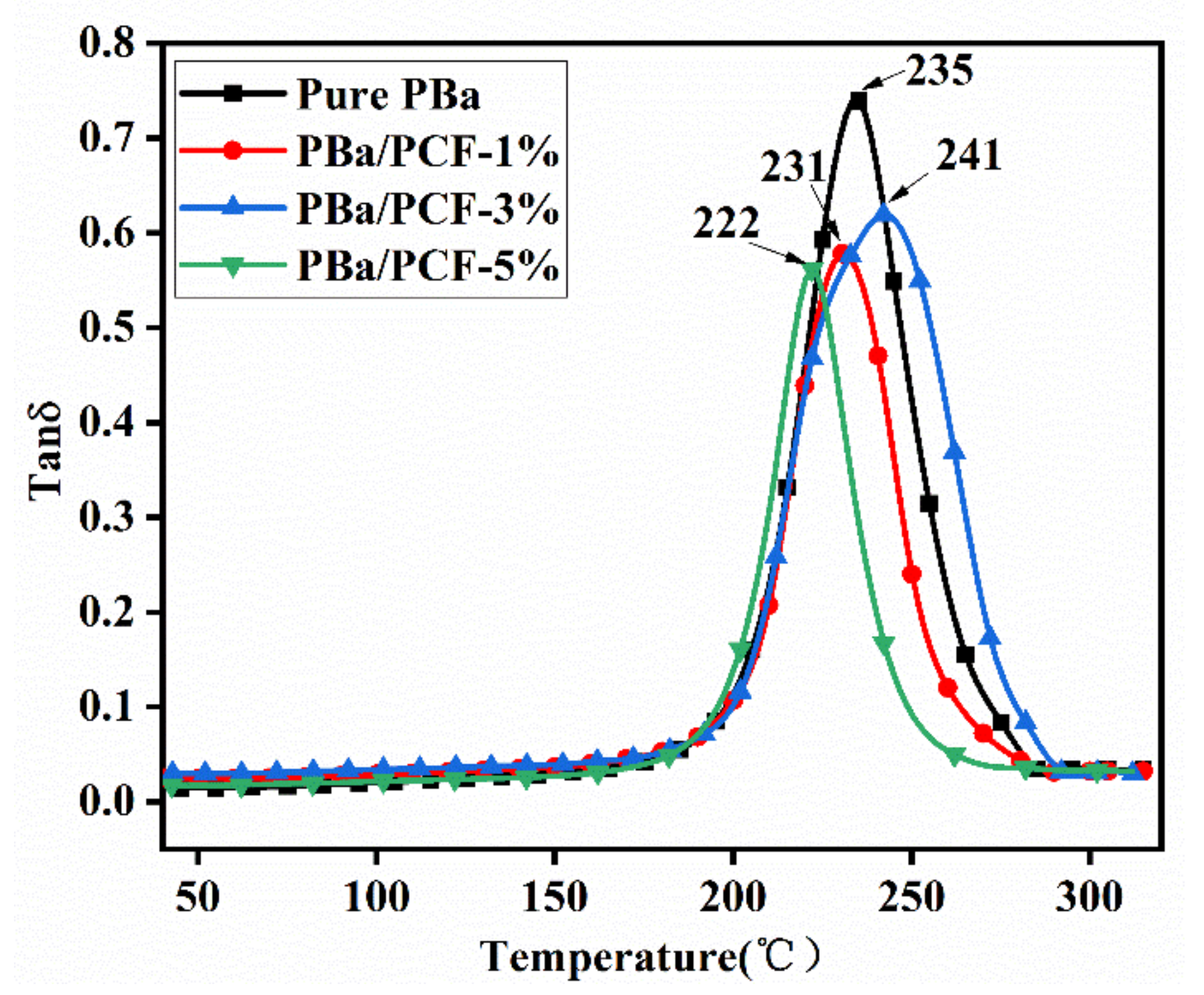

3.7. Dynamic Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ghosh, N.; Kiskan, B.; Yagci, Y. Polybenzoxazines—New high performance thermosetting resins: Synthesis and properties. Prog. Polym. Sci. 2007, 32, 1344–1391. [Google Scholar] [CrossRef]

- Nair, C.P.R. Advances in addition-cure phenolic resins. Prog. Polym. Sci. 2004, 29, 401–498. [Google Scholar] [CrossRef]

- Takeichi, T.; Agag, T. High performance polybenzoxazines as novel thermosets. High Perform. Polym. 2006, 18, 777–797. [Google Scholar] [CrossRef]

- Jubsilp, C.; Taewattana, R.; Takeichi, T.; Rimdusit, S. Investigation on rubber-modified polybenzoxazine composites for lubricating material applications. J. Mater. Eng. Perform. 2015, 24, 3958–3968. [Google Scholar] [CrossRef]

- Wang, D.Y.; Liu, Y.; Wang, Y.Z.; Artiles, C.P.; Hull, T.R.; Price, D. Fire retardancy of a reactively extruded intumescent flame retardant polyethylene system enhanced by metal chelates. Polym. Degrad. Stab. 2017, 92, 1592–1598. [Google Scholar] [CrossRef]

- Liu, Y.; Ran, Q.; Gu, Y. Preparation and properties of benzoxazine blends with intumescent flame retardancy. Polym. Degrad. Stab. 2019, 163, 15–24. [Google Scholar] [CrossRef]

- Xu, Y.; Dai, J.; Ran, Q.; Gu, Y. Greatly improved thermal properties of polybenzoxazine via modification by acetylene/aldehyde groups. Polymer 2017, 123, 232–239. [Google Scholar] [CrossRef]

- Jubsilp, C.; Singto, J.; Yamo, W.; Rimdusit, S. Effect of graphite particles size on tribological and mechanical properties of polybenzoxazine composites. Chem. Eng. Transac. 2017, 57, 1351–1356. [Google Scholar]

- Wan, L.; Wang, J.; Xie, L.; Sun, Y.; Li, K. Nitrogen-enriched hierarchically porous carbons prepared from polybenzoxazine for high-performance supercapacitors. ACS Appl. Mater. Interfaces 2014, 6, 15583–15596. [Google Scholar] [CrossRef] [PubMed]

- Sha, X.L.; Yuan, L.; Liang, G.Z.; Gu, A.J. Development and mechanism of high-performance fully biobased shape memory benzoxazine resins with a green strategy. ACS Sustain. Chem. Eng. 2020, 8, 18696–18705. [Google Scholar] [CrossRef]

- Zhang, K.; Han, M.; Liu, Y.; Froimowicz, P. Design and synthesis of bio-based high-performance trioxazine benzoxazine resin via natural renewable resources. ACS Sustain. Chem. Eng. 2019, 7, 9399–9407. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, Y.; Chen, Y.; Lu, H. Cardanol-capped main-chain benzoxazine oli-gomers for resin transfer molding. Eur. Polym. J. 2017, 93, 284–293. [Google Scholar] [CrossRef]

- Su, Y.C.; Chang, F.C. Synthesis and characterization of fluorinated polybenzoxazine material with low dielectric constant. Polymer 2013, 44, 7989–7996. [Google Scholar] [CrossRef]

- Zhu, Y.F.; Jiang, Y.H.; Lin, R.S.; Yu, S.J. Research on thermal degradation process of p-nitrophenol-based polybenzoxazine. Polym. Degrad. Stab. 2017, 141, 1–10. [Google Scholar] [CrossRef]

- Lin, C.H.; Huang, S.J.; Wang, P.J.; Lin, H.T.; Dai, S.A. Mis-cibility, microstructure, and thermal and dielectric properties of reactive blends of dicyanate ester and diamine-based benzoxazine. Macromolecules 2012, 45, 7461–7466. [Google Scholar] [CrossRef]

- Chen, M.J.; Shao, Z.B.; Wang, X.L.; Chen, L.; Wang, Y.Z. Halogen-free flame-retardant flexible polyurethane foam with a novel nitrogen–phosphorus flame retardant. Ind. Eng. Chem. Res. 2012, 51, 9769–9776. [Google Scholar] [CrossRef]

- Marset, D.; Dolza, C.; Fages, E.; Gonga, E.; Gutiérrez, O.; Gomez-Caturla, J.; Ivorra-Martinez, J.; Sanchez-Nacher, L.; Quiles-Carrillo, L. The Effect of Halloysite Nanotubes on the Fire Retardancy Properties of Partially Biobased Polyamide 610. Polymers 2020, 12, 3050. [Google Scholar] [CrossRef]

- Demir, K.D.; Tasdelen, M.A.; Uyar, T.; Kawaguchi, A.W.; Sudo, A.; Endo, T.; Yagci, Y. Synthesis of polybenzoxazine/clay nanocomposites by in situ thermal ring-opening polymerization using intercalated monomer. J. Polym. Sci. Part A Polym Chem. 2011, 49, 4213–4220. [Google Scholar] [CrossRef]

- Zhao, C.X.; Li, P.; He, D.; Li, Y.T.; Lei, F.; Sue, H.J. Flame retardation behavior of polybenzoxazine/a-ZrP nanocomposites. RSC Adv. 2016, 6, 73485–73495. [Google Scholar] [CrossRef]

- Zhao, L.; Zhao, C.X.; Guo, C.Y.; Li, Y.T.; Li, S.L.; Sun, L.Y.; Li, H.; Xiang, D. Polybenzoxazine resins with polyphosphazene microspheres: Synthesis, flame retardancy, mechanisms, and applications. ACS Omega 2019, 4, 20275–20284. [Google Scholar] [CrossRef]

- Shao, Z.B.; Zhang, M.X.; Li, Y.; Han, Y.; Ren, L.; Deng, C. A novel multi-functional polymeric curing agent: Synthesis, characterization, and its epoxy resin with simultaneous excellent flame retardance and transparency. Chem. Eng. J. 2018, 345, 471–482. [Google Scholar] [CrossRef]

- Chen, H.; Deng, C.; Zhao, Z.Y.; Wan, L.; Wang, Y.Z. Novel piperazine-containing oligomer as flame retardant and crystallization induction additive for thermoplastics polyurethane. Chem. Eng. J. 2020, 400, 125941–125954. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, X.; Jin, X.; Li, H.; Sun, J.; Gu, X. The novel application of chitosan: Effects of cross-linked chitosan on the fire performance of thermoplastic polyurethane. Carbohydr. Polym. 2018, 189, 313–321. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Gu, X.; Sun, J.; Zhang, S. Preparation and characterization of chitosan derivatives and their application as flame retardants in thermoplastic polyurethane. Carbohydr. Polym. 2017, 167, 356–364. [Google Scholar] [CrossRef] [PubMed]

- Jian, R.K.; Ai, Y.F.; Xia, L.; Zhang, Z.P.; Wang, D.Y. Organophosphorus heteroaromatic compound towards mechanically reinforced and low-flammability epoxy resin. Composites 2019, 168, 458–466. [Google Scholar] [CrossRef]

- Jiang, Z.; Li, H.; He, Y.; Liu, Y.; Dong, C.; Zhu, P. Flame retardancy and thermal behavior of cotton fabrics based on a novel phosphorus-containing siloxane. Appl. Surf. Sci. 2019, 479, 765–775. [Google Scholar] [CrossRef]

- Cao, Z.J.; Wang, L.; Wang, S.X.; Zhao, H.B.; Wang, Y.Z. Polyurethane foams with functionalized graphene towards high fire-resistance, low smoke release, superior thermal insulation. Chem. Eng. J. 2019, 361, 1245–1254. [Google Scholar] [CrossRef]

- Zhan, Y.; Wu, X.; Wang, S.S.; Yuan, B.H.; Fang, Q.; Shang, S.; Chao, C.; Chen, G.Q. Synthesis of a bio-based flame retardant via a facile strategy and its synergistic effect with ammonium polyphosphate on the flame retardancy of polylactic acid. Polym. Degrad. Stab. 2021, 191, 109684–109697. [Google Scholar] [CrossRef]

- Réti, C.; Casetta, M.; Duquesne, S.; Bourbigot, S.; Delobel, R. Flammability properties of intumescent PLA including starch and lignin. Polym. Adv. Technol. 2010, 19, 628–635. [Google Scholar] [CrossRef]

- Feng, J.X.; Su, S.P.; Zhu, J. An intumescent flame retardant system using β-cyclodextrin as a carbon source in polylactic acid (PLA). Polym. Adv. Technol. 2011, 22, 1115–1122. [Google Scholar] [CrossRef]

- Jing, J.; Zhang, Y.; Tang, X.; Fang, Z.P. Synthesis of a highly efficient phosphorus-containing flame retardant utilizing plant-derived diphenolic acids and its application in polylactic acid. RSC Adv. 2016, 6, 49019–49027. [Google Scholar] [CrossRef]

- Thirukumaran, P.; Parveen, A.S.; Shanmugam, M.; Kim, S.C. Development of sustainable and antimicrobial film based on polybenzoxazine and cellulose. Int. J. Biol. Macromol. 2020, 170, 664–673. [Google Scholar]

- Dana, M.S.; Gabrielle, C.C.; Valentin, I.P. Phosphorylation of polysaccharides: New results on synthesis and characterisation of phosphorylated cellulose. React. Funct. Polym. 2006, 66, 1240–1249. [Google Scholar]

- Maryam, G.; Federico, C.; Tomas, L.P.; Lars, W. Phosphorylated cellulose nanofibrils: A renewable nanomaterial for the preparation of intrinsically flame-retardant materials. Biomacromolecules 2015, 16, 3399–3410. [Google Scholar]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef] [PubMed]

- Sander, M.; Steininger, E. Chapter 5: Phosphorylation of Polymers. J. Macromol. Sci. C 1968, 2, 57–72. [Google Scholar] [CrossRef]

- Chen, H.B.; Wang, W.Z.; Sanchez-Soto, M.; Schiraldi, D.A. Low flammability, foam-like materials based on ammonium alginate and sodium montmorillonite clay. Polymer 2012, 53, 825–831. [Google Scholar] [CrossRef]

- Kotzebue, L.R.V.; Ribeiro, F.W.M.; Sombra, V.G.; Feitosa, J.P.A.; Mele, G.; Mazzetto, S.E.; Lomonaco, D. Spectral and thermal studies on the synthesis and catalyzed oligomerization of novel cardanol-based benzoxazines. Polymer 2016, 92, 189–200. [Google Scholar] [CrossRef]

- Chutayothin, P.; Ishida, H. Cationic ring-opening polymerization of 1,3-benzoxazines: Mechanistic study using model compounds. Macromolecules 2010, 43, 4562–4572. [Google Scholar] [CrossRef]

- Ran, Q.C.; Zhang, D.X.; Zhu, R.Q.; Gu, Y. The structural transformation during polymerization of benzoxazine/FeCl3 and the effect on the thermal stability. Polymer 2012, 53, 4119–4127. [Google Scholar] [CrossRef]

- Lin, R.S.; Zhu, Y.F.; Wang, L.M.; Yu, S.J. Pyrogallol-based benzoxazines with latent catalytic characteristics: The temperature-dependent effect of hydrogen bonds on ring-opening polymerization. Chem. Eng. J. 2018, 102, 141–150. [Google Scholar] [CrossRef]

- Hu, Z.; Chen, L.; Zhao, B.; Luo, Y.; Wang, D.Y.; Wang, Y.Z. A novel efficient halogen-free flame retardant system for polycarbonate. Polym. Degrad. Stab. 2011, 96, 320–327. [Google Scholar] [CrossRef]

- Wei, J.X.; Zhao, C.X.; Li, Y.C.; Li, Y.T.; Sun, Z.M.; Xiang, D.; Li, H. A simple and green strategy for preparing poly(vinyl alcohol)/phosphate cellulose aerogel with enhanced flame-retardant properties. Polym. Eng. Sci. 2021, 61, 693–705. [Google Scholar]

- Yu, L.; Chen, L.; Dong, L.P.; Li, L.J.; Wang, Y.Z. Organic-inorganic hybrid flame retardant: Preparation, characterization and application in EVA. RSC Adv. 2014, 4, 17812–17821. [Google Scholar] [CrossRef]

- Wang, X.; Romero, M.Q.; Zhang, X.Q.; Wang, R.; Wang, D.Y. Intumescent multilayer hybrid coating for flame retardant cotton fabrics based on layer-by-layer assembly and sol-gel process. RSC Adv. 2015, 5, 10647–10655. [Google Scholar] [CrossRef] [Green Version]

- Sun, D.C.; Yao, Y.W. Synthesis of three novel phosphorus-containing flame retardants and their application in epoxy resins. Polym. Degrad. Stab. 2011, 96, 1720–1724. [Google Scholar] [CrossRef]

- Qian, X.D.; Song, L.; Yuan, B.H.; Yu, B.; Shi, Y.Q.; Hu, Y.; Yuen, R.K.K. Organic/inorganic flame retardants containing phosphorus, nitrogen and silicon: Preparation and their performance on the flame retardancy of epoxy resins as a novel intumescent flame retardant system. Mater. Chem. Phys. 2014, 143, 1243–1252. [Google Scholar] [CrossRef]

- Qian, X.D.; Song, L.; Hu, Y.; Yuen, R.K.K.; Chen, Y.L.; Guo, Y.Q.; Hong, N.N.; Jiang, S.H. Combustion and thermal degradation mechanism of a novel intumescent flame retardant for epoxy acrylate containing phosphorus and nitrogen. Ind. Eng. Chem. Res. 2011, 50, 266–270. [Google Scholar] [CrossRef]

| Samples | Ti (°C) | Tp (°C) | Tf (°C) |

|---|---|---|---|

| Ba | 215 | 234 | 280 |

| Ba/PCF-1% | 199 | 239 | 277 |

| Ba/PCF-3% | 194 | 236 | 273 |

| Ba/PCF-5% | 186 | 229 | 268 |

| Sample | Tonset (°C) | Tmax (°C) | Char Residue (%) | |||||

|---|---|---|---|---|---|---|---|---|

| 700 °C | 800 °C | |||||||

| Air | N2 | Air | N2 | Air | N2 | Air | N2 | |

| PBa | 331 | 334 | 410 | 418 | 26 | 34 | 7 | 30 |

| PBa/PCF-1% | 326 | 323 | 400 | 404 | 37 | 35 | 34 | 34 |

| PBa/PCF-3% | 315 | 329 | 394 | 390 | 38 | 36 | 36 | 36 |

| PBa/PCF-5% | 302 | 316 | 380 | 379 | 39 | 41 | 37 | 38 |

| Sample | TTI(S) | PHRR((kW/m2) | AvHRR(kW/m2) | Mass Loss(%) | LOI(%) | UL-94 |

|---|---|---|---|---|---|---|

| Pure PBa | 66 | 515.6 | 158.3 | 74.5% | 21 | NO |

| PBa/PCF-1% | 50 | 406.1 | 152.8 | 75.9% | 24 | V-1 |

| PBa/PCF-3% | 39 | 397.2 | 163.6 | 68.9% | 28 | V-1 |

| PBa/PCF-5% | 23 | 212.3 | 110.3 | 65.9% | 31 | V0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Sun, Z.; Zhao, C.; Li, Y.; Xiang, D.; Wu, Y.; Wei, J.; Que, Y. Polybenzoxazine Resins with Cellulose Phosphide: Preparation, Flame Retardancy and Mechanisms. Polymers 2021, 13, 4288. https://doi.org/10.3390/polym13244288

Li H, Sun Z, Zhao C, Li Y, Xiang D, Wu Y, Wei J, Que Y. Polybenzoxazine Resins with Cellulose Phosphide: Preparation, Flame Retardancy and Mechanisms. Polymers. 2021; 13(24):4288. https://doi.org/10.3390/polym13244288

Chicago/Turabian StyleLi, Hui, Zhangmei Sun, Chunxia Zhao, Yuntao Li, Dong Xiang, Yuanpeng Wu, Jixuan Wei, and Yusheng Que. 2021. "Polybenzoxazine Resins with Cellulose Phosphide: Preparation, Flame Retardancy and Mechanisms" Polymers 13, no. 24: 4288. https://doi.org/10.3390/polym13244288