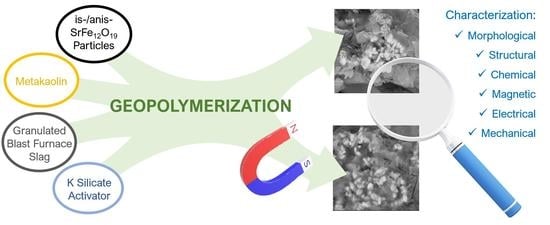

Novel Magnetic Inorganic Composites: Synthesis and Characterization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Samples

2.3. Characterization Techniques

2.3.1. Chemical, Structural, and Morphological Characterization

2.3.2. Magnetic Characterization

2.3.3. Electrical Characterization

2.3.4. Mechanical Characterization

3. Results and Discussion

3.1. Characterization of the SrFe12O19 Particles

3.2. Characterization of the G1 and G2 Matrices

3.3. Structural and Morphological Study of the Magnetic Inorganic Composites

3.3.1. Morphology and Thermal Behavior

3.3.2. FTIR, Raman and XRD Characterization of the Magnetic Geopolymers

3.3.3. Magnetic Characterization

3.3.4. Electrical Characterization

3.4. Mechanical Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Magment: Concretes Wireless Power. Available online: https://www.magment.de (accessed on 12 March 2021).

- Mansouri, I.; Nejat, M.; Shahbazi, S.; Karami, A. Effect of magnetite nanoparticles (ferroferric oxide) on discrete concrete properties. Constr. Mater. 2019, 172, 95–102. [Google Scholar] [CrossRef]

- He, Y.; Lu, L.; Sun, K.; Wang, F.; Hu, S. Electromagnetic wave absorbing cement-based composite using Nano-Fe3O4 magnetic fluid as absorber. Cem. Concr. Compos. 2018, 92, 1–6. [Google Scholar] [CrossRef]

- Wang, D.; Yang, P.; Hou, P.; Zhang, L.; Zhang, X.; Zhou, Z.; Xie, N.; Huang, S.; Cheng, X. Cement-based composites endowed with novel functions through controlling interface microstructure from Fe3O4@SiO2 nanoparticles. Cem. Concr. Compos. 2017, 80, 268–276. [Google Scholar] [CrossRef]

- Zhang, Y.; Hao, W.; Li, B.; Duan, Y.; Liu, S. Electromagnetic wave absorbing properties of double-layer cement composite and theory analysis. Asian J. Chem. 2014, 17, 5563–5566. [Google Scholar] [CrossRef]

- Aygun, B.; Sakar, E.; Korkut, T.; Sayyed, M.I.; Karabulut, A. New high temperature resistant heavy concretes for fast neutron and gamma radiation shielding. Radiochim. Acta 2019, 107, 359–367. [Google Scholar] [CrossRef]

- Valizadeh, A.; Aslani, F.; Asif, Z.; Roso, M. Development of heavyweight self-compacting concrete and ambient-cured heavyweight geopolymer concrete using magnetite aggregates. Materials 2019, 12, 1035–1060. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sikora, P.; Elrahman, M.A.; Horszczaruk, E.; Brzozowski, P.; Stephan, D. Incorporation of magnetite powder as a cement additive for improving thermal resistance and gamma-ray shielding properties of cement-based composites. Constr. Build. Mater. 2019, 204, 113–121. [Google Scholar] [CrossRef]

- Florez, R.; Colorado, H.A.; Alajo, A.; Giraldo, C.H.C. The material characterization and gamma attenuation of Portland cement-Fe3O4 composites for potential dry cask applications. Prog. Nucl. Energy 2019, 111, 65–73. [Google Scholar] [CrossRef]

- Lou, Z.; Wang, Q.; Zhang, Y.; Zhou, X.; Li, R.; Liu, J.; Li, J. In-situ formation of low-dimensional, magnetic core-shell nanocrystal for electromagnetic dissipation. Compos. Part B 2021, 214, 108744. [Google Scholar] [CrossRef]

- Jia, C.; Xia, T.; Ma, Y.; He, N.; Yu, Z.; Lou, Z.; Li, Y. Fe3O4/α-Fe decorated porous car-bon-based composites with adjustable electromagnetic wave absorption: Impedance matching and loading rate. J. Alloy. Compd. 2021, 858, 157706. [Google Scholar] [CrossRef]

- Lou, Z.; Li, R.; Wang, P.; Zhang, Y.; Che, B.; Huang, C.; Wang, C.; Han, H.; Li, Y. Phenolic foam-derived magnetic carbon foams (MCFs) with tunable electromagnetic wave ad-sorption behavior. Chem. Eng. J. 2020, 391, 123571. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications, 5th ed.; Institut Géopolymère: Saint-Quentin, France, 2008. [Google Scholar]

- Mugahed Amran, Y.H.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete: A review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Provis, J.L.; van Deventer, J.S.J. Geopolymers: Structures, Processing, Properties and Industrial Applications, 1st ed.; Woodhead Publishing Limited: Cambridge, UK, 2009. [Google Scholar]

- Xie, T.; Visintin, P.; Zhao, X.; Gravina, R. Mix design and mechanical properties of geopolymer and alkali activated concrete: Review of the state-of-the-art and the development of a new unified approach. Constr. Build. Mater. 2020, 256, 119380. [Google Scholar] [CrossRef]

- Wang, Y.S.; Alrefaei, Y.; Dai, J.G. Silico-aluminophosphate and alkali-aluminosilicate geopolymers: A comparative review. Front. Mater. 2019, 6, 106. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.; Zhu, Z. Utilization of fly ash to enhance ground waste concrete-based geopolymer. Adv. Mater. Sci. Eng. 2018, 4793917. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.; Liu, C.; Wang, L.; Zuo, L.; Zhu, Q.; Ma, W. Physical and mechanical properties and micro characteristics of fly ash-based geopolymers incorporating soda residue. Cem. Concr. Compos. 2019, 98, 125–136. [Google Scholar] [CrossRef]

- Sumesh, M.; Johnson Alengaram, U.; Jumaat, M.Z.; Mo, K.H.; Alnahhal, M.F. Incorporation of nano-materials in cement composite and geopolymer based paste and mortar—A review. Constr. Build. Mater. 2017, 148, 62–84. [Google Scholar] [CrossRef]

- Hua, P.; Sellaoui, L.; Franco, D.; Netto, M.S.; Dotto, G.L.; Bajahzar, A.; Belmabrouk, H.; Bonilla-Petriciolet, A.; Li, Z. Adsorption of acid green and procion red on a magnetic geopolymer based adsorbent: Experiments, characterization and theoretical treatment. Chem. Eng. J. 2020, 383, 123113. [Google Scholar] [CrossRef]

- Rossatto, D.I.; Netto, M.S.; Jahn, S.L.; Mallmann, E.S.; Dotto, G.I.; Foletto, E.L. Highly efficient adsorption performance of a novel magnetic geopolymer/Fe3O4 composite towards removal of aqueous acid green 16 dye. J. Environ. Chem. Eng. 2020, 8, 103804. [Google Scholar] [CrossRef]

- Hernandez-Flores, H.; Pariona, N.; Herrera-Trejo, M.; Hdz-Garcia, H.M.; Mtz-Enriquez, A.I. Concrete/maghemite nanocomposites as novel adsorbents for arsenic removal. J. Mol. Struct. 2018, 1171, 9–16. [Google Scholar] [CrossRef]

- Maleki, A.; Hajizadeh, Z.; Sharifi, V.; Emdadi, Z. A green, porous, and eco-friendly magnetic geopolymer adsorbent for heavy metals removal from aqueous solutions. J. Clean. Prod. 2019, 215, 1233–1245. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Han, Z.C.; He, P.Y.; Chen, H. Geopolymer-based catalyst for cost-effective environmental governance: A review based on source control and end-of-pipe treatment. J. Clean. Prod. 2020, 263, 121556. [Google Scholar] [CrossRef]

- Hajizadeh, Z.; Radinekiyan, F.; Eivazzadeh-keihan, R.; Maleki, A. Development of novel and green NiFe2O4/geopolymer nanocatalyst based on bentonite for synthesis of imidazole heterocycles by ultrasonic irradiation. Sci. Rep. 2020, 10, 11671. [Google Scholar] [CrossRef]

- Xiao, T.D.; Ma, X.Q.; Zhang, H.; Reisner, D.E.; Raj, P.M.; Wan, L.; Tummala, R. Magnetic nanocomposite paste: An ideal high-μ, k and Q nanomaterial for embedded inductors in high frequency electronic applications. In Proceedings of the 9th World Multi-Conference on Systemics, Cybernetics and Informatic, Orlando, FL, USA, 10–13 July 2005. [Google Scholar]

- Raj, P.M.; Muthana, P.; Xiao, T.D.; Wan, L.; Balaraman, D.; Abothu, I.R.; Bhattacharya, S.; Swaminathan, M.; Tummala, R. Magnetic nanocomposites for organic compatible miniaturized antennas and inductors. In Proceedings of the International Symposium on Advanced Packaging Materials: Processes, Properties and Interfaces, Irvine, CA, USA, 16–18 March 2005. [Google Scholar]

- Komlev, A.A.; Almjashev, V.I.; Bechta, S.V.; Khabensky, V.B.; Granovsky, V.S.; Gusarov, V.V. New sacrificial material for ex-vessel core catcher. J. Nucl. Mater. 2015, 467, 778–784. [Google Scholar] [CrossRef]

- Cantarel, V.; Motooka, T.; Yamagishi, I. Geopolymers and their potential applications in the nuclear waste management field—A bibliographic study. JAEA Rev. 2017, 014. [Google Scholar] [CrossRef]

- Fathi, M.; Mehdipour, M.; Shokrollahi, H. Microwave adsorption properties of nanostructure composite particles based on SrFe12O19. J. Aust. Ceram. Soc. 2020, 56, 251–256. [Google Scholar] [CrossRef]

- Karahroudi, Z.H.; Hedayati, K.; Goodarzi, M. Green synthesis and characterization of hexaferrite strontium-perovskite strontium photocatalyst nanocomposites. Main Group Met. Chem. 2020, 43, 26–42. [Google Scholar] [CrossRef]

- Mishra, D.D.; Tan, G. Visible photocatalytic degradation of methylene blue on magnetic SrFe12O19. J. Phys. Chem. Solids 2018, 123, 157–161. [Google Scholar] [CrossRef]

- Bavarsiha, F.; Rajabi, M.; Montazeri-Pour, M. Synthesis of SrFe12O19/SiO2/TiO2 composites with core/shell/shell nano-structure and evaluation of their photo-catalytic efficiency for degradation of methylene blue. J. Mater. Sci. Mater. Electron. 2018, 29, 1877–1887. [Google Scholar] [CrossRef]

- Ziarani, G.M.; Asl, Z.K.; Gholamzadeh, P.; Badiei, A.; Afshar, M. The use of SrFe12O19 magnetic nanoparticles as an efficient catalyst in the modified Niementowski reaction. Appl. Organomet. Chem. 2017, 31, e3830. [Google Scholar] [CrossRef]

- Panpan, J.; Jinlu, D.; Jianbo, W.; Jinwu, W.; Lining, P.; Jianan, L.; Qingfang, L. Width-controlled M-type hexagonal strontium ferrite (SrFe12O19) nanoribbons with high saturation magnetization and superior coercivity synthesized by electrospinning. Sci. Rep. 2015, 5, 15089. [Google Scholar] [CrossRef]

- Ketov, S.V.; Yagodkin, Y.D.; Menushenkov, V.P. Structure and magnetic properties of strontium ferrite anisotropic powder with nanocrystalline structure. J. Alloy. Compd. 2011, 509, 1065–1068. [Google Scholar] [CrossRef]

- Italian Version of EN 206: 2013 + A1(2016). Concrete Specification, Performance, Production and Conformity; European Committee for Standardization CEN-CENELEC Management Centre: Brussels, Belgium, 2016.

- Massiot, D.; Fayon, F.; Capron, M.; King, I.; Le Calvé, S.; Alonso, B.; Durand, J.O.; Bujoli, B.; Gan, Z.; Hoatson, G. Modelling one- and two-dimensional solid state NMR spectra. Magn. Reson. Chem. 2020, 40, 70–76. [Google Scholar] [CrossRef]

- Patrakeev, M.V.; Leonidov, I.A.; Kozhevnikov, V.L.; Kharton, V.V. Ion-electron transport in strontium ferrites: Relationship. Solid State Sci. 2004, 6, 907–913. [Google Scholar] [CrossRef]

- Eikeland, A.Z.; Stingaciu, M.; Mamakhel, A.H.; Saura-Muzquiz, M.; Christensen, M. Enhancement of magnetic properties through morphology control of SrFe12O19 nanocrystallites. Sci. Rep. 2018, 8, 7325–7333. [Google Scholar] [CrossRef] [Green Version]

- Stingaciu, M.; Eikeland, A.Z.; Gjorup, F.H.; Deledda, S.; Christensen, M. Optimization of magnetic properties in fast consolidated SrFe12O19 nanocrystallites. Rcs Adv. 2019, 9, 12698–12976. [Google Scholar] [CrossRef] [Green Version]

- Sun, R.; Li, X.; Xia, A.; Su, S.; Jin, C. Hexagonal SrFe12O19 ferrite with high saturation magnetization. Ceram. Int. 2018, 44, 13551–13555. [Google Scholar] [CrossRef]

- Margarette, S.J.; Venkateswara Rao, A.; Vemuri, R.; Murali, N.; Ramakrishna, Y.; Veeraiah, V.; Devi, M.J. Synthesis, structural and magnetic properties of SeFe12O19 hexaferrites. Int. J. Sci. Technol. Res. 2019, 8, 1585–1589. [Google Scholar]

- Zhang, T.; Peng, X.; Li, J.; Yang, Y.; Xu, J.; Wang, P.; Jin, D.; Jin, H.; Hong, B.; Wang, X.; et al. Platelet-like hexagonal SrFe12O19 particles: Hydrothermal synthesis and their orientation in a magnetic field. J. Magn. Magn. Mater. 2016, 412, 102–196. [Google Scholar] [CrossRef]

- Cullity, B.D.; Graham, C.D. Introduction to Magnetic Materials, 2nd ed.; Wiley-IEEE Press: Piscataway, NJ, USA, 2009. [Google Scholar]

- Roberts, A.P.; Cui, Y.; Verosub, K.L. Wasp-waisted hysteresis loops: Mineral magnetic characteristics and discrimination of components in mixed magnetic systems. J. Geophys. Res. 1995, 100, 17909–17924. [Google Scholar] [CrossRef]

- Bennett, L.H.; Della Torre, E. Analysis of wasp-waist hysteresis loops. J. Appl. Phys. 2005, 97, 10E502. [Google Scholar] [CrossRef]

- Spizzo, F.; Sgarbossa, P.; Sieni, E.; Semenzato, A.; Dughiero, F.; Forzan, M.; Bertani, R.; Del Bianco, L. Synthesis of ferrofluids made of iron oxide nanoflowers: Interplay between carrier fluid and magnetic properties. Nanomaterials 2017, 7, 373. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Coduri, M.; Masala, P.; Del Bianco, L.; Spizzo, F.; Ceresoli, D.; Castellano, C.; Cappelli, S.; Oliva, C.; Checchia, S.; Allieta, M.; et al. Local structure and magnetism of Fe2O3 maghemite nanocrystals: The role of crystal dimension. Nanomaterials 2020, 10, 867. [Google Scholar] [CrossRef]

- Remya, K.P.; Prabhu, D.; Amirthapandian, S.; Viswanathan, C.; Ponpandian, N. Exchange spring magnetic behavior in BaFe12O19/Fe3O4 nanocomposites. J. Magn. Magn. Mater. 2016, 406, 233–238. [Google Scholar] [CrossRef]

- Algarou, N.A.; Slimani, Y.; Almessiere, M.A.; Alahmari, F.S.; Vakhitov, M.G.; Klygach, D.S.; Trukhanov, S.V.; Trukhanov, A.V.; Baykal, A. Magnetic and microwave properties of SrFe12O19/MCe0.04Fe1.96O4 (M = Cu, Ni, Mn, Co and Zn) hard/soft nanocomposites. J. Mater. Res. Technol. 2020, 9, 5858–5870. [Google Scholar] [CrossRef]

- Jacobo, S.E.; Bercoff, P.G.; Herme, C.A.; Vives, L.A. Sr hexaferrite/Ni ferrite nanocomposites: Magnetic behavior and microwave absorbing properties in the X-band. Mater. Chem. Phys. 2015, 157, 124–129. [Google Scholar] [CrossRef]

- Ovejero, J.G.; Spizzo, F.; Morales, M.P.; Del Bianco, L. Mixing iron oxide nanoparticles with different shape and size for tunable magneto-heating performance. Nanoscale 2021, 13, 5714–5729. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.C.; Mikulec, F.V.; Pelaez, J.M.; Koo, B.; Korgel, B.A. Synthesis and magnetic properties of silica-coated FePt nanocrystals. J. Phys. Chem. B 2006, 110, 11160–11166. [Google Scholar] [CrossRef] [PubMed]

- Magno De Lima Alves, T.; Amorim, B.F.; Morales Torres, M.A.; Bezerra, C.G.; De Medeiros, S.N.; Gastelois, P.L.; Fernandez Outon, L.E.; De Almeida Macedo, W.A. Wasp-waisted behavior in magnetic hysteresis curves of CoFe2O4 nanopowder at a low temperature: Experimental evidence and theoretical approach. Rsc Adv. 2017, 7, 22187–22196. [Google Scholar] [CrossRef] [Green Version]

- Stoner, E.C.; Wohlfarth, E.P. A mechanism of magnetic hysteresis in heterogeneous alloys. IEEE Trans. Magn. 1991, 27, 3475–3518. [Google Scholar] [CrossRef]

- Kechrakos, D.; Trohidou, K. Magnetic properties of dipolar interacting single-domain particles. Phys. Rev. B Condens. Matter Mater. Phys. 1998, 58, 12169–12177. [Google Scholar] [CrossRef] [Green Version]

- Schrefl, T.; Schmidts, H.F.; Fidler, J.; Kronmüller, H. The role of exchange and dipolar coupling at grain boundaries in hard magnetic materials. J. Magn. Magn. Mater. 1993, 124, 251–261. [Google Scholar] [CrossRef]

- Zeng, H.; Sun, S.; Vedantam, T.S.; Liu, J.P.; Dai, Z.R.; Wang, Z.L. Exchange-coupled FePt nanoparticle assembly. Appl. Phys. Lett. 2002, 80, 2583–2585. [Google Scholar] [CrossRef]

- Lee, W.K.W.; van Deventer, J.S.J. Use of infrared spectroscopy to study geopolymerization of heterogeneous amorphous aluminosilicates. Langmuir 2003, 19, 8726–8734. [Google Scholar] [CrossRef]

- Valcke, S.L.A.; Pipilikaki, P.; Fischer, H.R.; Verkuijlen, M.H.W.; van Eck, E.R.H. FT-IR and 29Si NMR for evaluating aluminum-silicate precursors for geopolymers. Mater. Struct. 2015, 48, 557–569. [Google Scholar] [CrossRef]

- Mikhailova, O.; del Campo, A.; Rovnanik, P.; Fernandez, J.F.; Torres-Carrasco, M. In situ characterization of main reaction propducts in alkali-activated slag materials by Confocal Raman Microscopy. Cem. Concr. Compos. 2019, 99, 32–39. [Google Scholar] [CrossRef]

- Walkey, B.; Provis, J.I. Solid-state nuclear magnetic resonance spectroscopy of cements. Mater. Today Adv. 2019, 1, 100007. [Google Scholar] [CrossRef]

- Dupuy, C.; Gharzouni, A.; Sobrados, I.; Texier-Mandoki, N.; Bourbon, X.; Rossignol, S. 29Si, 27Al, 31P and 11B magic angle spinning nuclear magnetic resonance study of the structural evolutions induced by the use of phosphor- and boron-based additives in geopolymer mixtures. J. Non Cryst. Solids 2019, 521, 119541. [Google Scholar] [CrossRef]

- Autef, A.; Joussein, E.; Gasgnier, G.; Pronier, S.; Sobrados, I.; Sanz, J.; Rossignol, S. Role of metakaolin dehydroxylation in geopolymer synthesis. Powder Technol. 2013, 250, 33–39. [Google Scholar] [CrossRef]

- Buchwald, A.; Hilbig, H.; Kaps, C. Alkali-activated metakaolin-slag blends performance and structure in dependence of their composition. J. Mater. Sci. 2007, 42, 3024–3032. [Google Scholar] [CrossRef]

- Ferone, C.; Colangelo, F.; Roviello, G.; Asprone, D.; Menna, D.; Balsamo, A.; Prota, A.; Cioffi, R.; Manfredi, G. Application-oriented chemical optimization of a metakaolin based geopolymer. Materials 2013, 6, 1920–1939. [Google Scholar] [CrossRef] [Green Version]

- Subaer, J.; van Riessen, A. Thermo-mechanical and microstructural characterization of sodium-poly(sialate-siloxo) (Na-PSS) geopolymers. J. Mater. Sci. 2007, 42, 3117–3123. [Google Scholar] [CrossRef]

- Rosas-Casarez, C.A.; Arredondo-Rea, S.P.; Gomez-Soberon, J.M.; Alamaral-Sanchez, J.L.; Corral-Higuera, R.; Chinchillas-Chinchillas, M.J.; Acuna-Aguero, O.H. Experimental study of XRD, FTIR and TGA techniques in geopolymeric materials. Int. J. Adv. Comput. Sci. Appl. 2014, 4, 221–225. [Google Scholar]

- Iwahiro, T.; Nakamura, Y.; Komatsu, R.; Ikeda, K. Crystallization behavior and characteristics of mullites formed from alumina–silica gels prepared by the geopolymer technique in acidic conditions. J. Eur. Ceram. Soc. 2001, 21, 2515–2519. [Google Scholar] [CrossRef]

- Erb, R.M.; Martin, J.J.; Soheilian, R.; Pan, C.; Barber, J.R. Actuating soft matter with magnetic torque. Adv. Funct. Mater. 2016, 26, 3859–3880. [Google Scholar] [CrossRef]

- McCarter, W.J.; Taha, H.M.; Suryanto, B.; Starrs, G. Two-poin concrete resistivity measurements: Interfacial phenomena at the electrode-concrete contact zone. Meas. Sci. Technol. 2015, 26, 085007. [Google Scholar] [CrossRef]

- Zeng, S.; Wang, J. Characterization of mechanical and electric properties of geopolymers synthesized using four locally available fly ashes. Constr. Build. Mater. 2016, 121, 386–399. [Google Scholar] [CrossRef] [Green Version]

- Hu, X.; Shi, C.; Liu, X.; Zhang, J.; Schutter, G. A review on microstructural characterization of cement-based materials by AC impedances specttroscopy. Cem. Concr. Compos. 2019, 100, 1–14. [Google Scholar] [CrossRef]

- Hu, X.; Shi, C.; Liu, X.; Zhang, Z. Study of the effect of alkali dosage on microstructure development of alkali-activated slag pastes by electrical impedance spectroscopy (EIS). Constr. Build. Mater. 2020, 261, 119982. [Google Scholar] [CrossRef]

- Song, Q.; Wang, J.; Dong, T.; He, L.; Lu, S. Study of the alkali activated geopolymer by AC impedances spectroscopy. IOP Conf. Ser. Earth Environ. Sci. 2019, 267, 022001. [Google Scholar] [CrossRef] [Green Version]

- Cui, X.-M.; Zheng, G.J.; Han, Y.C.; Su, F.; Zhou, J. A study of electrical conductivity of chemosynthetic Al2O3-2SiO2 geopolymer materials. J. Powder Sources 2008, 184, 652–656. [Google Scholar] [CrossRef]

- Chuewangkam, N.; Pinitsoontorn, S.; Chindaprasirt, P. Properties of NdFeB magnetic cement. Cem. Concr. Compos. 2019, 103, 204–212. [Google Scholar] [CrossRef]

| Sample | MK | Slag | Activator | Quartz Aggregates | Water % w/w on Total Wet Amount |

|---|---|---|---|---|---|

| G1 | 1 | 1 | K 1.3, 45% | none | ca. 10 |

| G2 | 1 | 1 | K 1.3, 45% | I84 1; 3.2 | 7.2 |

| Sample | Magnetic Particles (% Dry Weight) | Extra Water (% Wet Weight) | Density (g/cm3) 1 |

|---|---|---|---|

| anis-SrFe12O19 | 100 | - | - |

| is-SrFe12O19 | 100 | - | - |

| G1 | 0 | 10 | 2.02 |

| G2 | 0 | 7.2 | 2.19 |

| G1anis_6 | 6 | 10.2 | 2.19 |

| G1is_6 | 6 | 10.2 | 2.21 |

| G1anis_6DENSE | 6 | 3.3 | 2.22 |

| G1is_6DENSE | 6 | 2.3 | 2.24 |

| G1anis_11 | 11.2 | 9.8 | 2.19 |

| G1anisM_11 | 11.2 | 9.8 | 2.18 |

| G1is_11 | 10.2 | 9.8 | 2.21 |

| G1isM_11 | 10.2 | 9.9 | 2.30 |

| G2anis_6 | 6 | 6.4 | 2.29 |

| G2anisM_6 | 5.9 | 6.4 | 2.32 |

| G2is_6 | 6 | 5.9 | 2.25 |

| G2isM_6 | 5.9 | 5.9 | 2.40 |

| G2anis_11 | 11.2 | 8.3 | 2.34 |

| G2is_11 | 11.2 | 8.3 | 2.36 |

| Sample | Formulation |

|---|---|

| G1_matrix | MK:slag:Ksil = 1:1:1.33, extra water = 0 |

| G1is_6_norm | MK:slag:Ksil = 1:1:1.30, is-SrFe12O19 = 5.99%, extra water = 0 |

| G1is_6_highW | MK:slag:Ksil = 1:1:1.30, is-SrFe12O19 = 6.11%, extra water = 4.36% |

| G1is_6_highK | MK:slag:Ksil = 1:1:2, is-SrFe12O19 = 5.37%, extra water = 0 |

| Element | is-SrFe12O19 | anis-SrFe12O19 | ||

|---|---|---|---|---|

| w/w % | Atomic % | w/w % | Atomic % | |

| O | 18.4 | 44.2 | 22.2 | 51.3 |

| Sr | 5.7 | 4.4 | 4.5 | 1.9 |

| Ba | 1.9 | 0.6 | 4.8 | 1.3 |

| Fe | 74.0 | 50.8 | 68.5 | 45.5 |

| Sample | 300 K | 20 K | ||||

|---|---|---|---|---|---|---|

| MS (emu/g) ± 2% | HC (kOe) ± 1% | MR ± 2% | MS (emu/g) ± 2% | HC (kOe) ± 1% | MR ± 2% | |

| is-SrFe12O19 | 69 | 0.95 | 0.48 | 97 | 1.51 | 0.44 |

| anis-SrFe12O19 | 75 | 2.11 | 0.70 | 107 | 2.97 | 0.71 |

| Sample | Element Atomic % | |||||

|---|---|---|---|---|---|---|

| O | Mg | Al | Si | K | Ca | |

| G1 | 66.1 | 1.1 | 7.7 | 12.9 | 5.4 | 6.8 |

| G2 | 66.7 | 0.6 | 5.5 | 21.2 | 3.2 | 2.8 |

| Sample | MS (emu/g) 1 T = 300 K ± 2% | MS (emu/g) 2 T = 20 K ± 2% | Magnetic Particles (% weight) ± 3% | HC (kOe) 3 T = 300 K ± 1% | MR 4 T = 300 K ± 2% |

|---|---|---|---|---|---|

| G2anis_6 | 4.4 | 6.5 | 5.9 | 2.82 | 0.45 |

| G2is_6 | 4.3 | 6.1 | 6.2 | 2.83 | 0.45 |

| G1anis_11 | 7.8 | 11.6 | 10.4 | 3.68 | 0.45 |

| G1is_11 | 7.0 | 10.3 | 10.1 | 2.90 | 0.44 |

| Sample | HC (kOe) 1 ± 1% | MR 2 ± 2% |

|---|---|---|

| G2anisM_6 | 2.42 | 0.59 |

| G2isM_6 | 2.40 | 0.60 |

| G1anisM_11 | 4.10 | 0.84 |

| G1isM_11 | 2.47 | 0.59 |

| Sample | Compressive Strength (MPa) | Sample | Compressive Strength (MPa) |

|---|---|---|---|

| G1 | 58.5 ± 5.7 | G1anis_11 | 33.9 ± 1.4 |

| G2 | 46.8 ± 0.5 | G1is_11 | 36.2 ± 2.7 |

| G1anis_6 | 38.3 ± 5.1 | G2anis_6 | 49.9 ± 3.3 |

| G1is_6 | 44.8 ± 1.5 | G2is_6 | 56.4 ± 1.0 |

| G1anis_6DENSE | 57.55 ± 1.87 | G2anis_11 | 36.8 ± 0.3 |

| G1is_6DENSE | 61.5 ± 2.6 | G2is_11 | 47.7 ± 2.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Natali, M.; Tamburini, S.; Bertani, R.; Desideri, D.; Mozzon, M.; Pavarin, D.; Spizzo, F.; Del Bianco, L.; Zorzi, F.; Sgarbossa, P. Novel Magnetic Inorganic Composites: Synthesis and Characterization. Polymers 2021, 13, 1284. https://doi.org/10.3390/polym13081284

Natali M, Tamburini S, Bertani R, Desideri D, Mozzon M, Pavarin D, Spizzo F, Del Bianco L, Zorzi F, Sgarbossa P. Novel Magnetic Inorganic Composites: Synthesis and Characterization. Polymers. 2021; 13(8):1284. https://doi.org/10.3390/polym13081284

Chicago/Turabian StyleNatali, Marco, Sergio Tamburini, Roberta Bertani, Daniele Desideri, Mirto Mozzon, Daniele Pavarin, Federico Spizzo, Lucia Del Bianco, Federico Zorzi, and Paolo Sgarbossa. 2021. "Novel Magnetic Inorganic Composites: Synthesis and Characterization" Polymers 13, no. 8: 1284. https://doi.org/10.3390/polym13081284