Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications

Abstract

:1. Introduction

2. Natural Fibre

Chemical Treatment of Natural Fibres

3. Polylactic Acid (PLA)

4. Composite

5. Natural Fibre Reinforced PLA Composite

5.1. Brief on PLA Composite

5.2. Development of Natural Fibres/PLA Biocomposite

5.2.1. Brief Study on PLA Biocomposite

5.2.2. Non-Wood Natural Fibre/PLA Composite

Leaf

Bast

Seed/fruit

Grass

Straw fibre

5.2.3. Wood Natural Fibre/PLA Composite

5.2.4. Natural Mineral Fibre/PLA Biocomposites

5.3. Processing Method Developments of Natural Fibre/PLA Composite

| Polymer | Natural Fibre | Effect of Reinforcement | Mechanical Strength | Reference | ||

|---|---|---|---|---|---|---|

| Tensile (MPa) | Flexural (MPa) | Impact (kJ/m2) | ||||

| PLA | Bamboo fibre | -Increased mechanical properties -Bamboo fibre was the most effective in increasing tensile strength | 54 | - | - | [133] |

| PLA | Wood fibre | -Improved the fibre adhesion with the PLA, | 73.8 | - | 21.5 | [122] |

| PLA | Hard wood high yield pulp | -The incorporation of pulp fibres significantly increased the composite storage moduli and elasticity | 90 | - | - | [124] |

| PLA | Soft wood high yield pulp | -The incorporation of pulp fibres significantly increased the composite storage moduli and elasticity | 110 | - | - | [124] |

| PLA | Kraft | -Suggesting the fibre–fibre bond also positively contributed to the composites’ strengths | 121 | - | - | [124] |

| PLA | Wood fibre | -Improved mechanical and thermal properties of composites | 23.0 | - | - | [123] |

| PLA | Vetiver fibre | -Increased mechanical properties -Bamboo fibre was the most effective in increasing tensile strength | 48 | - | - | [133] |

| PLA | Coconut fibre | -Increased mechanical properties -Bamboo fibre was the most effective in increasing tensile strength | 50 | - | - | [133] |

| PLA | Kenaf fibre | -Comparable mechanical and physical properties to glass-fibre composite -Safe for environment | - | - | - | [107] |

| PLA | Jute fibre | -Elephant grass fibre had higher tensile strength and flexural strength than treated Jute/PLA composite and plain PLA -Untreated composite with elephant grass, jute, and sisal fibre had higher impact strength than plain PLA | 65 | 112 | 5.3 | [114] |

| PLA | Sisal fibre | -Elephant grass fibre had higher tensile strength and flexural strength than treated Jute/PLA composite and plain PLA -Untreated composite with elephant grass, jute, and sisal fibre had higher impact strength than plain PLA | 62 | 110 | 5.3 | [114] |

| PLA | Elephant grass | -Elephant grass fibre had higher tensile strength and flexural strength than treated Jute/PLA composite and plain PLA -Untreated composite with elephant grass, jute, and sisal fibre had higher impact strength than plain PLA | 55 | 86 | 3.0 | [114] |

| PLA | Flax fibre | -Showed high Limiting Oxygen Index (LOI) of 26.1% -Achieved V-2 rating | 59.1 | - | - | [109] |

| PLA | Wheat straw | -Excellent tensile mechanical properties | 62 | 98 | 27 | [116] |

| PLA | Rice straw fibre | -Increased the shear modulus and impact strength | 50 | - | - | [117] |

| PLA | Corn straw fibre | -Shorter curing time and enhanced mechanical properties. | 24.38 | - | - | [119] |

| PLA | Abutilon fibre | -Increased the shear modulus and impact strength | 53 | - | 1.7 | [121] |

| PLA | Woven jute fibre | -Increased mechanical properties | 81 | 82 | 16.4 | [128] |

| PLA | Hemp fibre | -Improved mechanical properties | 54.6 | 112.7 | - | [134] |

| PLA | Jute fibre | -Water absorption during ageing caused fibre/matrix bonding failure | 60 | - | - | [104] |

| PLA | Jute fibre | -Increased the shear modulus and impact strength | 52 | 100 | 9 | [105] |

| PLA | Ramie fibre | -Shorter curing time and enhanced mechanical properties. | 48 | 105 | 10 | [105] |

| PLA | Flax fibre | -Optimised mechanical properties of composites for automotive applications | 53 | - | 12 | [18] |

| PLA | Ramie fibre | -The composites had better mechanical properties than pure PLA | 72 | - | 11 | [135] |

| PLA | Hemp fibre | -Improved tensile, impact, and flexural properties | 45 | 60 | 9.7 | [136] |

| PLA | Hemp-lyocell fibre | -Improved tensile, impact, and flexural properties | 60 | 102 | 21.7 | [136] |

| PLA | Lyocell fibre | -Improved tensile, impact, and flexural properties | 80 | 121 | 26 | [136] |

| PLA | Flax fibre | -Flame retardant flax/PLA samples achieved V0 rating -All flame retardant reduced the mechanical properties | 80 | 40 | - | [110] |

| PLA | Basalt fibre | -PLA/KBF exhibited comparable tensile properties and superior flexural properties | 79.5 | 128 | 5.6 | [126] |

| PLA | Grewia optiva fibre | -Tensile strength of the composite increased by 75% of the neat polymer -Microwave joining was better than adhesive bonding | - | - | - | [137] |

| PLA | Palm fibre | -Increased mechanical strength | 35 | - | - | [138] |

| PLA | Kenaf fibre | -Increased mechanical strength | 27 | - | - | [138] |

| PLA | Manicaria Saccifera palm fibre | -Tensile strength, elastic modulus, and impact resistance were improved by 26%, 51% and 56%, respectively | 68.45 | 133.12 | 26.62 | [139] |

| PLA | Cordenka rayon fibres | --Mechanical properties improved | 58 | - | 72 | [140] |

| PLA | Kenaf fibre | -Very high tensile strength and Young’s modulus values | 52.9 | - | 9 | [103] |

| PLA | Jute fibres | -Increased tensile stiffness and strength significantly -Different improvements of the mechanical parameters | 81.9 | - | 3 | [141] |

| PLA | Keratin-based fibre | -Green and safe environment -Joints and bone fixtures to alleviate pain for patients | - | - | - | [142] |

| PLA | Flax fibre | -Mechanical properties improved -Tensile properties were in the same range | 253.7 | - | - | [143] |

| PLA | Flax fibre | -Tensile properties improved -Tensile strength and modulus of flax fibre/PLLA composite close to glass fibres | 100 | - | - | [144] |

| PLA | Ramie, flax and cotton fibres | -Difference intrinsic viscosity and melt flow index | - | - | - | [145] |

| PLA | Kenaf fibre | -Excellent tensile mechanical properties | 52.88 | - | 8.97 | [10] |

| PLA | Kenaf fibres | -Perfectly improved features of the polymers -Suitable for construction materials application | - | - | - | [146] |

| PLA | Hemp fibres | -Increased PLA transcrystallinity -Improved chemical bonding | - | - | - | [147] |

| PLA | Plant fibres | -Susceptibility to chemical degradation | - | - | - | [148] |

| PLA | Woven flax and jute fabrics | -Flax fibre resulted in composites with better mechanical strength than the woven jute fibre composites | - | - | - | [149] |

| PLA | Abaca fibre | -No weight loss observed for neat PLA and PLA/AA-abaca composite, meanwhile the PLA/untreated abaca composite showed ca. 10% weight loss | - | - | - | [150] |

| PLA | Banana/sisal fibre | -Mechanical properties were enhanced | 80 | 125 | 48 | [101] |

| PLA | Lyocell fibre | -Very high tensile strength and Young’s modulus values -Good impact characteristics | 81.8 | - | 39.7 | [103] |

| PLA | Abaca fibres | -Increased tensile stiffness and strength significantly -Different improvements of the mechanical parameters | 74 | - | 5 | [141] |

| PLA | Coir, sisal and jutes fibres | -Can be used to replace petroleum-based polymer -High specific strength | 16.17 | 29.26 | 46.17 | [151] |

| PLA | Coconut fibre | -Improved mechanical and thermal properties of composites | 23.5 | - | - | [123] |

| PLA | Bamboo fibre | -Improved mechanical and thermal properties of composites | 22.5 | - | - | [123] |

| PLA | Bamboo fibre | -Tensile strength was comparable with ordinary glass fibre-reinforced plastics laminate -Three times higher specific strength than mild steel | 210 | - | - | [112] |

| PLA | Coconut fibre | -Excellent tensile mechanical properties | 65 | - | - | [111] |

| PLA | Bamboo fibre | -Thermal conductivity of the natural composite was lower than that of synthetic composites | - | - | - | [152] |

| PLA | Cotton fibre | -Very high tensile strength and Young’s modulus values -Good impact characteristics | 41.2 | - | 28.7 | [103] |

| PLA | Cotton fibre | -Increased stiffness, tensile strength, elongation at break, and impact strength | 41.20 | - | 28.71 | [10] |

| PLA | Bamboo fibre, vetiver grass fibre and coconut fibre | -Impact of strength decreased | - | - | 1.8 | [153] |

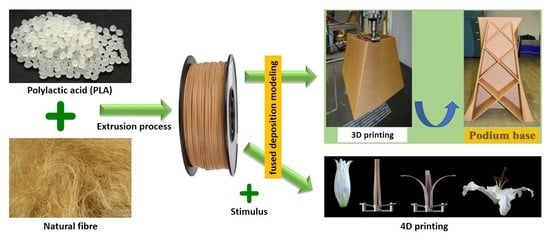

6. 3D and 4D Printings of PLA Biocomposite

7. Potential Applications of Natural Fibre Reinforced PLA Composite

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Plackett, D.; Andersen, T.L.; Pedersen, W.B.; Nielsen, L. Biodegradable composites based on L-polylactide and jute fibres. Compos. Sci. Technol. 2003, 63, 1287–1296. [Google Scholar] [CrossRef]

- Harussani, M.M.; Sapuan, S.M.; Khalina, A.; Ilyas, R.A.; Hazrol, M.D. Review on Green Technology Pyrolysis for Plastic Wastes. In Proceedings of the 7th Postgraduate Seminar on Natural Fibre Reinforced Polymer Composites 2020; Sapuan, S.M., Ilyas, R.A., Eds.; Institute of Tropical Forestry and Forest Products (INTROP), Universiti Putra Malaysia: Serdang, Selangor, 2020; pp. 50–53. [Google Scholar]

- Syafiq, R.; Sapuan, S.M.; Zuhri, M.Y.M.; Ilyas, R.A.; Nazrin, A.; Sherwani, S.F.K.; Khalina, A. Antimicrobial activities of starch-based biopolymers and biocomposites incorporated with plant essential oils: A review. Polymers 2020, 12, 2403. [Google Scholar] [CrossRef] [PubMed]

- Atikah, M.S.N.; Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S.; Ibrahim, R.; Atiqah, A.; Ansari, M.N.M.; Jumaidin, R. Degradation and physical properties of sugar palm starch/sugar palm nanofibrillated cellulose bionanocomposite. Polimery 2019, 64, 27–36. [Google Scholar] [CrossRef] [Green Version]

- Drumright, R.E.; Gruber, P.R.; Henton, D.E. Polylactic acid technology. Adv. Mater. 2000, 12, 1841–1846. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Harussani, M.M.; Zulaikha, N.D.S.; Norhana, A.H.; Syakir, M.I.; Norli, A. Composites based on conductive polymer with carbon nanotubes in DMMP gas sensors—An overview. Polimery 2021, 66, 85–97. [Google Scholar] [CrossRef]

- Ali, S.S.S.; Razman, M.R.; Awang, A. The nexus of population, GDP growth, electricity generation, electricity consumption and carbon emissions output in Malaysia. Int. J. Energy Econ. Policy 2020, 10, 84–89. [Google Scholar] [CrossRef]

- Nazrin, A.; Sapuan, S.M.; Zuhri, M.Y.M.; Ilyas, R.A.; Syafiq, R.; Sherwani, S.F.K. Nanocellulose Reinforced Thermoplastic Starch (TPS), Polylactic Acid (PLA), and Polybutylene Succinate (PBS) for Food Packaging Applications. Front. Chem. 2020, 8, 1–12. [Google Scholar] [CrossRef]

- Oksman, K.; Skrifvars, M.; Selin, J.-F. Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Graupner, N. Application of lignin as natural adhesion promoter in cotton fibre-reinforced poly(lactic acid) (PLA) composites. J. Mater. Sci. 2008, 43, 5222–5229. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Rafiqah, S.A.; Aisyah, H.A.; Nurazzi, N.M.; Norrrahim, M.N.F. Effect of hydrolysis time on the morphological, physical, chemical, and thermal behavior of sugar palm nanocrystalline cellulose (Arenga pinnata (Wurmb.) Merr). Text. Res. J. 2020, 004051752093239. [Google Scholar] [CrossRef]

- Sabaruddin, F.A.; Paridah, M.T.; Sapuan, S.M.; Ilyas, R.A.; Lee, S.H.; Abdan, K.; Mazlan, N.; Roseley, A.S.M.; Abdul Khalil, H.P.S. The effects of unbleached and bleached nanocellulose on the thermal and flammability of polypropylene-reinforced kenaf core hybrid polymer bionanocomposites. Polymers 2020, 13, 116. [Google Scholar] [CrossRef]

- Ayu, R.S.; Khalina, A.; Harmaen, A.S.; Zaman, K.; Isma, T.; Liu, Q.; Ilyas, R.A.; Lee, C.H. Characterization Study of Empty Fruit Bunch (EFB) Fibers Reinforcement in Poly(Butylene) Succinate (PBS)/Starch/Glycerol Composite Sheet. Polymers 2020, 12, 1571. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibres: Can they replace glass in fibre reinforced plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Comparison of Static and Long-term Creep Behaviors between Balau Wood and Glass Fiber Reinforced Polymer Composite for Cross-arm Application. Fibers Polym. 2021, 22. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Influence of Additional Bracing Arms as Reinforcement Members in Wooden Timber Cross-Arms on Their Long-Term Creep Responses and Properties. Appl. Sci. 2021, 11, 2061. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A. Woods and composites cantilever beam: A comprehensive review of experimental and numerical creep methodologies. J. Mater. Res. Technol. 2020. [Google Scholar] [CrossRef]

- Suriani, M.J.; Radzi, F.S.M.; Ilyas, R.A.; Petrů, M.; Sapuan, S.M.; Ruzaidi, C.M. Flammability, Tensile, and Morphological Properties of Oil Palm Empty Fruit Bunches Fiber/Pet Yarn-Reinforced Epoxy Fire Retardant Hybrid Polymer Composites. Polymers 2021, 13, 1282. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Rafidah, M.; Azrina, A.; Razman, M.R. Dynamic mechanical behaviour of kenaf cellulosic fibre biocomposites: A comprehensive review on chemical treatments. Cellulose 2021. [Google Scholar] [CrossRef]

- Jumaidin, R.; Ilyas, R.A.; Saiful, M.; Hussin, F.; Mastura, M.T. Water Transport and Physical Properties of Sugarcane Bagasse Fibre Reinforced Thermoplastic Potato Starch Biocomposite. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 61, 273–281. [Google Scholar]

- Ilyas, R.A.; Sapuan, S.M. The Preparation Methods and Processing of Natural Fibre Bio-polymer Composites. Curr. Org. Synth. 2020, 16, 1068–1070. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Asyraf, M.R.M.; Khalina, A.; Abdullah, N.; Aisyah, H.A.; Rafiqah, S.A.; Sabaruddin, F.A.; Kamarudin, S.H.; Norrrahim, M.N.F.; Ilyas, R.A.; et al. A Review on Natural Fiber Reinforced Polymer Composite for Bullet Proof and Ballistic Applications. Polymers 2021, 13, 646. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Rafidah, M.; Ishak, M.R.; Sapuan, S.M.; Ilyas, R.A.; Razman, M.R. Integration of TRIZ, Morphological Chart and ANP method for development of FRP composite portable fire extinguisher. Polym. Compos. 2020, 1–6. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Khalina, A.; Sapuan, S.M.; Ilyas, R.A.; Rafiqah, S.A.; Hanafee, Z.M. Thermal properties of treated sugar palm yarn/glass fiber reinforced unsaturated polyester hybrid composites. J. Mater. Res. Technol. 2020, 9, 1606–1618. [Google Scholar] [CrossRef]

- Aisyah, H.A.; Paridah, M.T.; Sapuan, S.M.; Khalina, A.; Berkalp, O.B.; Lee, S.H.; Lee, C.H.; Nurazzi, N.M.; Ramli, N.; Wahab, M.S.; et al. Thermal Properties of Woven Kenaf/Carbon Fibre-Reinforced Epoxy Hybrid Composite Panels. Int. J. Polym. Sci. 2019, 2019, 5258621. [Google Scholar] [CrossRef] [Green Version]

- Norizan, M.N.; Abdan, K.; Ilyas, R.A.; Biofibers, S.P. Effect of fiber orientation and fiber loading on the mechanical and thermal properties of sugar palm yarn fiber reinforced unsaturated polyester resin composites. Polimery 2020, 65, 34–43. [Google Scholar] [CrossRef]

- Sapuan, S.M.; Aulia, H.S.; Ilyas, R.A.; Atiqah, A.; Dele-Afolabi, T.T.; Nurazzi, M.N.; Supian, A.B.M.; Atikah, M.S.N. Mechanical properties of longitudinal basalt/woven-glass-fiber-reinforced unsaturated polyester-resin hybrid composites. Polymers 2020, 12, 2211. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Evaluation of Design and Simulation of Creep Test Rig for Full-Scale Crossarm Structure. Adv. Civ. Eng. 2020, 2020. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Conceptual design of multi-operation outdoor flexural creep test rig using hybrid concurrent engineering approach. J. Mater. Res. Technol. 2020, 9, 2357–2368. [Google Scholar] [CrossRef]

- Syafri, E.; Yulianti, E.; Asrofi, M.; Abral, H.; Sapuan, S.; Ilyas, R.; Fudholi, A. Effect of sonication time on the thermal stability, moisture absorption, and biodegradation of water hyacinth (Eichhornia crassipes) nanocellulose-filled bengkuang (Pachyrhizus erosus) starch biocomposites. J. Mater. Res. Technol. 2019, 8, 6223–6231. [Google Scholar] [CrossRef]

- Abral, H.; Atmajaya, A.; Mahardika, M.; Hafizulhaq, F.; Kadriadi; Handayani, D.; Sapuan, S.M.; Ilyas, R.A. Effect of ultrasonication duration of polyvinyl alcohol (PVA) gel on characterizations of PVA film. J. Mater. Res. Technol. 2020, 9, 2477–2486. [Google Scholar] [CrossRef]

- Jumaidin, R.; Saidi, Z.A.S.; Ilyas, R.A.; Ahmad, M.N.; Wahid, M.K.; Yaakob, M.Y.; Maidin, N.A.; Rahman, M.H.A.; Osman, M.H. Characteristics of Cogon Grass Fibre Reinforced Thermoplastic Cassava Starch Biocomposite: Water Absorption and Physical Properties. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 62, 43–52. [Google Scholar]

- Rozilah, A.; Jaafar, C.N.A.; Sapuan, S.M.; Zainol, I.; Ilyas, R.A. The Effects of Silver Nanoparticles Compositions on the Mechanical, Physiochemical, Antibacterial, and Morphology Properties of Sugar Palm Starch Biocomposites for Antibacterial Coating. Polymers 2020, 12, 2605. [Google Scholar] [CrossRef] [PubMed]

- Mazani, N.; Sapuan, S.M.; Sanyang, M.L.; Atiqah, A.; Ilyas, R.A. Design and Fabrication of a Shoe Shelf From Kenaf Fiber Reinforced Unsaturated Polyester Composites. In Lignocellulose for Future Bioeconomy; Ariffin, H., Sapuan, S.M., Hassan, M.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 315–332. ISBN 9780128163542. [Google Scholar]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Potential Application of Green Composites for Cross Arm Component in Transmission Tower: A Brief Review. Int. J. Polym. Sci. 2020, 2020, 8878300. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Conceptual design of creep testing rig for full-scale cross arm using TRIZ-Morphological chart-analytic network process technique. J. Mater. Res. Technol. 2019, 8, 5647–5658. [Google Scholar] [CrossRef]

- Alam, M.M.; Maniruzzaman, M.; Morshed, M.M. Application and Advances in Microprocessing of Natural Fiber (Jute)–Based Composites. In Comprehensive Materials Processing; Hashmi, S., Batalha, G.F., Van Tyne, C.J., Eds.; Elsevier: London, UK, 2014; pp. 243–260. [Google Scholar]

- Chemiefaser, I. Worldwide Production Volume of Chemical and Textile Fibers from 1975 to 2018. Available online: https://www.statista.com/statistics/263154/worldwide-production-volume-of-textile-fibers-since-1975/ (accessed on 2 December 2019).

- Migneault, S.; Koubaa, A.; Erchiqui, F.; Chaala, A.; Englund, K.; Krause, C.; Wolcott, M. Effect of fiber length on processing and properties of extruded wood-fiber/HDPE composites. J. Appl. Polym. Sci. 2008, 110, 1085–1092. [Google Scholar] [CrossRef] [Green Version]

- Mukherjee, T.; Kao, N. PLA Based Biopolymer Reinforced with Natural Fibre: A Review. J. Polym. Environ. 2011, 19, 714–725. [Google Scholar] [CrossRef]

- Cosgrove, D.J. Growth of the plant cell wall. Nat. Rev. Mol. Cell Biol. 2005, 6, 850–861. [Google Scholar] [CrossRef]

- Martins, M.A.; Kiyohara, P.K.; Joekes, I. Scanning electron microscopy study of raw and chemically modified sisal fibers. J. Appl. Polym. Sci. 2004, 94, 2333–2340. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Sanyang, M.L.; Ishak, M.R.; Zainudin, E.S. Nanocrystalline cellulose as reinforcement for polymeric matrix nanocomposites and its potential applications: A Review. Curr. Anal. Chem. 2018, 14, 203–225. [Google Scholar] [CrossRef]

- Ferreira, F.V.; Mariano, M.; Rabelo, S.C.; Gouveia, R.F.; Lona, L.M.F. Isolation and surface modification of cellulose nanocrystals from sugarcane bagasse waste: From a micro- to a nano-scale view. Appl. Surf. Sci. 2018, 436, 1113–1122. [Google Scholar] [CrossRef]

- Abral, H.; Ariksa, J.; Mahardika, M.; Handayani, D.; Aminah, I.; Sandrawati, N.; Pratama, A.B.; Fajri, N.; Sapuan, S.M.; Ilyas, R.A. Transparent and antimicrobial cellulose film from ginger nanofiber. Food Hydrocoll. 2020, 98, 105266. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R. Isolation and characterization of nanocrystalline cellulose from sugar palm fibres (Arenga Pinnata). Carbohydr. Polym. 2018, 181, 1038–1051. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Sugar palm nanofibrillated cellulose (Arenga pinnata (Wurmb.) Merr): Effect of cycles on their yield, physic-chemical, morphological and thermal behavior. Int. J. Biol. Macromol. 2019, 123, 379–388. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Effect of delignification on the physical, thermal, chemical, and structural properties of sugar palm fibre. BioResources 2017, 12, 8734–8754. [Google Scholar] [CrossRef]

- Ahmad Ilyas, R.; Mohd Sapuan, S.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Asrofi, M.; Siti Nur Atikah, M.; Muhammad Huzaifah, M.R.; Radzi, M.A.; et al. Sugar palm (Arenga pinnata (Wurmb.) Merr) cellulosic fibre hierarchy: A comprehensiveapproach from macro to nano scale. J. Mater. Res. Technol. 2019, 8, 2753–2766. [Google Scholar] [CrossRef]

- Alemdar, A.; Sain, M. Isolation and characterization of nanofibers from agricultural residues—Wheat straw and soy hulls. Bioresour. Technol. 2008, 99, 1664–1671. [Google Scholar] [CrossRef] [PubMed]

- Julie Chandra, C.S.; George, N.; Narayanankutty, S.K. Isolation and characterization of cellulose nanofibrils from arecanut husk fibre. Carbohydr. Polym. 2016, 142, 158–166. [Google Scholar] [CrossRef]

- Chirayil, C.J.; Joy, J.; Mathew, L.; Mozetic, M.; Koetz, J.; Thomas, S. Isolation and characterization of cellulose nanofibrils from Helicteres isora plant. Ind. Crops Prod. 2014, 59, 27–34. [Google Scholar] [CrossRef]

- Cherian, B.M.; Leão, A.L.; de Souza, S.F.; Thomas, S.; Pothan, L.A.; Kottaisamy, M. Isolation of nanocellulose from pineapple leaf fibres by steam explosion. Carbohydr. Polym. 2010, 81, 720–725. [Google Scholar] [CrossRef]

- Syafri, E.; Kasim, A.; Abral, H.; Asben, A. Cellulose nanofibers isolation and characterization from ramie using a chemical-ultrasonic treatment. J. Nat. Fibers 2018, 1145–1155. [Google Scholar] [CrossRef]

- Megashah, L.N.; Ariffin, H.; Zakaria, M.R.; Hassan, M.A. Properties of Cellulose Extract from Different Types of Oil Palm Biomass. IOP Conf. Ser. Mater. Sci. Eng. 2018, 368. [Google Scholar] [CrossRef]

- Jonoobi, M.; Khazaeian, A.; Tahir, P.M.; Azry, S.S.; Oksman, K. Characteristics of cellulose nanofibers isolated from rubberwood and empty fruit bunches of oil palm using chemo-mechanical process. Cellulose 2011, 18, 1085–1095. [Google Scholar] [CrossRef]

- Corrêa, A.C.; de Morais Teixeira, E.; Pessan, L.A.; Mattoso, L.H.C. Cellulose nanofibers from curaua fibers. Cellulose 2010, 17, 1183–1192. [Google Scholar] [CrossRef]

- Tibolla, H.; Pelissari, F.M.; Menegalli, F.C. Cellulose nanofibers produced from banana peel by chemical and enzymatic treatment. LWT Food Sci. Technol. 2014, 59, 1311–1318. [Google Scholar] [CrossRef]

- de Morais Teixeira, E.; Bondancia, T.J.; Teodoro, K.B.R.; Corrêa, A.C.; Marconcini, J.M.; Mattoso, L.H.C. Sugarcane bagasse whiskers: Extraction and characterizations. Ind. Crops Prod. 2011, 33, 63–66. [Google Scholar] [CrossRef]

- Jonoobi, M.; Harun, J.; Shakeri, A.; Misra, M.; Oksmand, K. Chemical composition, crystallinity, and thermal degradation of bleached and unbleached kenaf bast (Hibiscus cannabinus) pulp and nanofibers. BioResources 2009, 4, 626–639. [Google Scholar] [CrossRef]

- Bendahou, A.; Habibi, Y.; Kaddami, H.; Dufresne, A. Physico-chemical characterization of palm from Phoenix Dactylifera-L, preparation of cellulose whiskers and natural rubber-based nanocomposites. J. Biobased Mater. Bioenergy 2009, 3, 81–90. [Google Scholar] [CrossRef]

- Chan, C.H.; Chia, C.H.; Zakaria, S.; Ahmad, I.; Dufresne, A. Production and characterisation of cellulose and nano-crystalline cellulose from kenaf core wood. BioResources 2013, 8, 785–794. [Google Scholar] [CrossRef] [Green Version]

- Abral, H.; Dalimunthe, M.H.; Hartono, J.; Efendi, R.P.; Asrofi, M.; Sugiarti, E.; Sapuan, S.M.; Park, J.W.; Kim, H.J. Characterization of Tapioca Starch Biopolymer Composites Reinforced with Micro Scale Water Hyacinth Fibers. Starch Staerke 2018, 70, 1–8. [Google Scholar] [CrossRef]

- Alemdar, A.; Sain, M. Biocomposites from wheat straw nanofibers: Morphology, thermal and mechanical properties. Compos. Sci. Technol. 2008, 68, 557–565. [Google Scholar] [CrossRef]

- Li, M.; Wang, L.J.; Li, D.; Cheng, Y.L.; Adhikari, B. Preparation and characterization of cellulose nanofibers from de-pectinated sugar beet pulp. Carbohydr. Polym. 2014, 102, 136–143. [Google Scholar] [CrossRef] [PubMed]

- Sheltami, R.M.; Abdullah, I.; Ahmad, I.; Dufresne, A.; Kargarzadeh, H. Extraction of cellulose nanocrystals from mengkuang leaves (Pandanus tectorius). Carbohydr. Polym. 2012, 88, 772–779. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Dreal, L.T. Surface modifications of natural fibres and peformance of the resulting biocomposite. Compos. Interfaces 2001, 8, 313–343. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Improvement of mechanical performance of industrial hemp fibre reinforced polylactide biocomposites. Compos. Part A Appl. Sci. Manuf. 2011. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Hazrol, M.D.; Sapuan, S.M.; Zuhri, M.Y.M.; Zainudin, E.S.; Wahab, N.I.A.; Ilyas, R.A.; Harussani, M.M.; Jamal, T.; Nazrin, A.; Syafiq, R. Effect of sorbitol and glycerol plasticizer and concentration on physical properties of corn starch (Zea mays) biodegradable films. In Proceedings of the 7th Postgraduate Seminar on Natural Fibre Reinforced Polymer Composites 2020; Sapuan, S.M., Ilyas, R.A., Eds.; Institute of Tropical Forestry and Forest Products (INTROP), Universiti Putra Malaysia: Serdang, Selangor, 2020; pp. 1–10. [Google Scholar]

- Kandemir, N.; Yemeniciogwlu, A.; Mecitogwlu, Ç.; Elmaci, Z.S.; Arslanogwlu, A.; Göksungur, Y.; Baysal, T. Production of antimicrobial films by incorporation of partially purified lysozyme into biodegradable films of crude exopolysaccharides obtained from Aureobasidium pullulans fermentation. Food Technol. Biotechnol. 2005, 43, 343–350. [Google Scholar]

- Södergård, A.; Stolt, M. Industrial Production of High Molecular Weight Poly(Lactic Acid). In Poly(Lactic Acid); Auras, R., Lim, L., Selke, S.E.M., Tsuji, H., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; pp. 27–41. ISBN 9780470293669. [Google Scholar]

- Lim, L.T.; Auras, R.; Rubino, M. Processing technologies for poly(lactic acid). Prog. Polym. Sci. 2008, 33, 820–852. [Google Scholar] [CrossRef]

- Rasal, R.M.; Janorkar, A.V.; Hirt, D.E. Poly(lactic acid) modifications. Prog. Polym. Sci. 2010, 35, 338–356. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; Aldas, M.; López, J. On the use of PLA-PHB blends for sustainable food packaging applications. Materials 2017, 10, 1008. [Google Scholar] [CrossRef]

- Devaux, E.; Aubry, C.; Campagne, C.; Rochery, M. PLA/carbon nanotubes multifilament yarns for relative humidity textile sensor. J. Eng. Fiber. Fabr. 2011, 6, 155892501100600300. [Google Scholar] [CrossRef] [Green Version]

- Tanase, C.E.; Spiridon, I. PLA/chitosan/keratin composites for biomedical applications. Mater. Sci. Eng. C 2014, 40, 242–247. [Google Scholar] [CrossRef]

- Pozo Morales, A.; Güemes, A.; Fernandez-Lopez, A.; Carcelen Valero, V.; De La Rosa Llano, S. Bamboo–polylactic acid (PLA) composite material for structural applications. Materials 2017, 10, 1286. [Google Scholar] [CrossRef] [Green Version]

- Pickering, K.L.; Efendy, M.G.A. Preparation and mechanical properties of novel bio-composite made of dynamically sheet formed discontinuous harakeke and hemp fibre mat reinforced PLA composites for structural applications. Ind. Crops Prod. 2016, 84, 139–150. [Google Scholar] [CrossRef]

- Kumar, N.; Das, D. Fibrous biocomposites from nettle (Girardinia diversifolia) and poly (lactic acid) fibers for automotive dashboard panel application. Compos. Part B Eng. 2017, 130, 54–63. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 24, 1–24. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Khalina, A.; Sapuan, S.M.; Ilyas, R.A. Mechanical properties of sugar palm yarn/woven glass fiber reinforced unsaturated polyester composites: Effect of fiber loadings and alkaline treatment. Polimery 2019, 64, 12–22. [Google Scholar] [CrossRef]

- Abral, H.; Ariksa, J.; Mahardika, M.; Handayani, D.; Aminah, I.; Sandrawati, N.; Sapuan, S.M.; Ilyas, R.A. Highly transparent and antimicrobial PVA based bionanocomposites reinforced by ginger nanofiber. Polym. Test. 2019, 106186. [Google Scholar] [CrossRef]

- Jumaidin, R.; Khiruddin, M.A.A.; Asyul Sutan Saidi, Z.; Salit, M.S.; Ilyas, R.A. Effect of cogon grass fibre on the thermal, mechanical and biodegradation properties of thermoplastic cassava starch biocomposite. Int. J. Biol. Macromol. 2020, 146, 746–755. [Google Scholar] [CrossRef]

- İşmal, Ö.E.; Paul, R. Composite textiles used in high-performance apparel. In High-Performance Apparel: Materials, Development, and Applications; McLoughlin, J., Sabir, T., Eds.; Woodhead Publishing: Cambridge, UK, 2017; pp. 377–420. ISBN 9780081009048. [Google Scholar]

- Mohd Nurazzi, N.; Muhammad Asyraf, M.R.; Khalina, A.; Abdullah, N.; Sabaruddin, F.A.; Kamarudin, S.H.; Ahmad, S.; Mahat, A.M.; Lee, C.L.; Aisyah, H.A.; et al. Fabrication, Functionalization, and Application of Carbon Nanotube-Reinforced Polymer Composite: An Overview. Polymers 2021, 13, 1047. [Google Scholar] [CrossRef]

- Sari, N.H.; Pruncu, C.I.; Sapuan, S.M.; Ilyas, R.A.; Catur, A.D.; Suteja, S.; Sutaryono, Y.A.; Pullen, G. The effect of water immersion and fibre content on properties of corn husk fibres reinforced thermoset polyester composite. Polym. Test. 2020, 91, 106751. [Google Scholar] [CrossRef]

- Amir, S.M.M.; Sultan, M.T.H.; Jawaid, M.; Ariffin, A.H.; Mohd, S.; Salleh, K.A.M.; Ishak, M.R.; Md Shah, A.U. Nondestructive testing method for Kevlar and natural fiber and their hybrid composites. Durab. Life Predict. Biocompos. Fibre Reinf. Compos. Hybrid Compos. 2018, 367–388. [Google Scholar] [CrossRef]

- Ogin, S.L.; Brøndsted, P.; Zangenberg, J. Composite materials: Constituents, architecture, and generic damage. In Modeling Damage, Fatigue and Failure of Composite Materials; Talreja, R., Varna, J., Eds.; Elsevier Ltd.: London, UK, 2016; pp. 3–23. ISBN 9781782422860. [Google Scholar]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef] [Green Version]

- Jem, K.J.; Tan, B. The development and challenges of poly (lactic acid) and poly (glycolic acid). Adv. Ind. Eng. Polym. Res. 2020, 3, 60–70. [Google Scholar] [CrossRef]

- Jiménez-Gómez, C.P.; Cecilia, J.A. Chitosan: A Natural Biopolymer with a Wide and Varied Range of Applications. Molecules 2020, 25, 3981. [Google Scholar] [CrossRef] [PubMed]

- Saratale, R.G.; Cho, S.-K.; Saratale, G.D.; Kadam, A.A.; Ghodake, G.S.; Kumar, M.; Bharagava, R.N.; Kumar, G.; Kim, D.S.; Mulla, S.I. A comprehensive overview and recent advances on polyhydroxyalkanoates (PHA) production using various organic waste streams. Bioresour. Technol. 2021, 325, 124685. [Google Scholar] [CrossRef] [PubMed]

- Siakeng, R.; Jawaid, M.; Ariffin, H.; Sapuan, S.M.; Asim, M.; Saba, N. Natural fiber reinforced polylactic acid composites: A review. Polym. Compos. 2019, 40, 446–463. [Google Scholar] [CrossRef]

- Hinchcliffe, S.A.; Hess, K.M.; Srubar, W.V. Experimental and theoretical investigation of prestressed natural fiber-reinforced polylactic acid (PLA) composite materials. Compos. Part B Eng. 2016, 95, 346–354. [Google Scholar] [CrossRef] [Green Version]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. Jom 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Dunne, R.; Desai, D.; Sadiku, R.; Jayaramudu, J. A review of natural fibres, their sustainability and automotive applications. J. Reinf. Plast. Compos. 2016, 35, 1041–1050. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Herrera-Franco, P.J.; Valadez-González, A. Mechanical properties of continuous natural fibre-reinforced polymer composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 339–345. [Google Scholar] [CrossRef]

- Alkbir, M.F.M.; Sapuan, S.M.; Nuraini, A.A.; Ishak, M.R. Fibre properties and crashworthiness parameters of natural fibre-reinforced composite structure: A literature review. Compos. Struct. 2016, 148, 59–73. [Google Scholar] [CrossRef]

- Asaithambi, B.; Ganesan, G.; Ananda Kumar, S. Bio-composites: Development and mechanical characterization of banana/sisal fibre reinforced poly lactic acid (PLA) hybrid composites. Fibers Polym. 2014, 15, 847–854. [Google Scholar] [CrossRef]

- Bajpai, P.K.; Singh, I.; Madaan, J. Tribological behavior of natural fiber reinforced PLA composites. Wear 2013, 297, 829–840. [Google Scholar] [CrossRef]

- Graupner, N.; Herrmann, A.S.; Müssig, J. Natural and man-made cellulose fibre-reinforced poly(lactic acid) (PLA) composites: An overview about mechanical characteristics and application areas. Compos. Part A Appl. Sci. Manuf. 2009, 40, 810–821. [Google Scholar] [CrossRef]

- Jiang, N.; Yu, T.; Li, Y.; Pirzada, T.J.; Marrow, T.J. Hygrothermal aging and structural damage of a jute/poly (lactic acid) (PLA) composite observed by X-ray tomography. Compos. Sci. Technol. 2019. [Google Scholar] [CrossRef]

- Yu, T.; Li, Y.; Ren, J. Preparation and properties of short natural fiber reinforced poly(lactic acid) composites. Trans. Nonferrous Met. Soc. China Engl. Ed. 2009, 19, s651–s655. [Google Scholar] [CrossRef]

- Oksman, K.; Selin, J.-F. Plastics and Composites from Polylactic Acid. In Natural Fibers, Plastics and Composites; Wallenberger, F.T., Weston, N.E., Eds.; Springer: Boston, MA, USA, 2004; pp. 149–165. [Google Scholar]

- Omar, M.F.; Jaya, H.; Zulkepli, N.N. Kenaf Fiber Reinforced Composite in the Automotive Industry. Encycl. Renew. Sustain. Mater. 2020, 5, 95–101. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Atikah, M.S.N.; Ibrahim, R.; Hazrol, M.D.; Sherwani, S.F.K.; Harussani, M.M.; Jamal, T.; Nazrin, A.; Syafiq, R. Natural fibre: A promising source for the production of nanocellulose. In Proceedings of the 7th Postgraduate Seminar on Natural Fibre Reinforced Polymer Composites 2020; Sapuan, S.M., Ilyas, R.A., Eds.; Institute of Tropical Forestry and Forest Products (INTROP), Universiti Putra Malaysia: Serdang, Selangor, 2020; pp. 2–9. [Google Scholar]

- Zhang, L.; Li, Z.; Pan, Y.T.; Yáñez, A.P.; Hu, S.; Zhang, X.Q.; Wang, R.; Wang, D.Y. Polydopamine induced natural fiber surface functionalization: A way towards flame retardancy of flax/poly(lactic acid) biocomposites. Compos. Part B Eng. 2018, 154, 56–63. [Google Scholar] [CrossRef]

- Pornwannachai, W.; Ebdon, J.R.; Kandola, B.K. Fire-resistant natural fibre-reinforced composites from flame retarded textiles. Polym. Degrad. Stab. 2018, 154, 115–123. [Google Scholar] [CrossRef]

- Jang, J.Y.; Jeong, T.K.; Oh, H.J.; Youn, J.R.; Song, Y.S. Thermal stability and flammability of coconut fiber reinforced poly(lactic acid) composites. Compos. Part B Eng. 2012, 43, 2434–2438. [Google Scholar] [CrossRef]

- Sukmawan, R.; Takagi, H.; Nakagaito, A.N. Strength evaluation of cross-ply green composite laminates reinforced by bamboo fiber. Compos. Part B Eng. 2016, 84, 9–16. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Bhat, I.U.H.; Jawaid, M.; Zaidon, A.; Hermawan, D.; Hadi, Y.S. Bamboo fibre reinforced biocomposites: A review. Mater. Des. 2012, 42, 353–368. [Google Scholar] [CrossRef]

- Gunti, R.; Ratna Prasad, A.V.; Gupta, A.V.S.S.K.S. Mechanical and degradation properties of natural fiber-reinforced PLA composites: Jute, sisal, and elephant grass. Polym. Compos. 2018, 39, 1125–1136. [Google Scholar] [CrossRef]

- Elmessiry, M.; Deeb, E. Analysis of the wheat straw/flax fiber reinforced polymer hybrid composites. J. App. Mech. Eng 2016, 5, 1–5. [Google Scholar]

- Nyambo, C.; Mohanty, A.K.; Misra, M. Effect of maleated compatibilizer on performance of PLA/wheat Straw-Based green composites. Macromol. Mater. Eng. 2011, 296, 710–718. [Google Scholar] [CrossRef]

- Mat Zubir, N.H.; Sam, S.T.; Santiagoo, R.; Noimam, N.Z.; Wang, J. Tensile properties of rice straw fiber reinforced poly (lactic acid) biocomposites. In Advanced Materials Research; Trans Tech Publications Ltd.: Bäch, Switzerland, 2016; Volume 1133, pp. 598–602. [Google Scholar]

- Ismail, M.R.; Yassen, A.A.M.; Afify, M.S. Mechanical properties of rice straw fiber-reinforced polymer composites. Fibers Polym. 2011, 12, 648. [Google Scholar] [CrossRef]

- Ding, F. Mechanical properties and degradation characteristics of corn straw fibers/polylactic acid composite materials. J. Agric. Resour. Environ. 2018, 35, 455–458. [Google Scholar]

- Pradhan, R.; Misra, M.; Erickson, L.; Mohanty, A. Compostability and biodegradation study of PLA–wheat straw and PLA–soy straw based green composites in simulated composting bioreactor. Bioresour. Technol. 2010, 101, 8489–8491. [Google Scholar] [CrossRef]

- Wang, H.; Hassan, E.; Memon, H.; Elagib, T.; Abad AllaIdris, F. Characterization of natural composites fabricated from Abutilon-fiber-reinforced Poly (Lactic Acid). Processes 2019, 7, 583. [Google Scholar] [CrossRef] [Green Version]

- Ozyhar, T.; Baradel, F.; Zoppe, J. Effect of functional mineral additive on processability and material properties of wood-fiber reinforced poly(lactic acid) (PLA) composites. Compos. Part A Appl. Sci. Manuf. 2020, 132, 105827. [Google Scholar] [CrossRef]

- Zhang, Q.; Shi, L.; Nie, J.; Wang, H.; Yang, D. Study on poly(lactic acid)/natural fibers composites. J. Appl. Polym. Sci. 2012, 125, E526–E533. [Google Scholar] [CrossRef]

- Du, Y.; Wu, T.; Yan, N.; Kortschot, M.T.; Farnood, R. Fabrication and characterization of fully biodegradable natural fiber-reinforced poly(lactic acid) composites. Compos. Part B Eng. 2014, 56, 717–723. [Google Scholar] [CrossRef]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.-J.; Hui, D. A short review on basalt fiber reinforced polymer composites. Compos. Part B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Sang, L.; Han, S.; Li, Z.; Yang, X.; Hou, W. Development of short basalt fiber reinforced polylactide composites and their feasible evaluation for 3D printing applications. Compos. Part B Eng. 2019, 164, 629–639. [Google Scholar] [CrossRef]

- Kurniawan, D.; Kim, B.S.; Lee, H.Y.; Lim, J.Y. Atmospheric pressure glow discharge plasma polymerization for surface treatment on sized basalt fiber/polylactic acid composites. Compos. Part B Eng. 2012, 43, 1010–1014. [Google Scholar] [CrossRef]

- Khan, G.M.A.; Terano, M.; Gafur, M.A.; Alam, M.S. Studies on the mechanical properties of woven jute fabric reinforced poly(L-lactic acid) composites. J. King Saud Univ. Eng. Sci. 2016, 28, 69–74. [Google Scholar] [CrossRef] [Green Version]

- Bergeret, A.; Benezet, J.C. Natural fibre-reinforced biofoams. Int. J. Polym. Sci. 2011, 2011, 569871. [Google Scholar] [CrossRef]

- Jauhari, N.; Mishra, R.; Thakur, H. Natural Fibre Reinforced Composite Laminates—A Review. Mater. Today Proc. 2015, 2, 2868–2877. [Google Scholar] [CrossRef]

- Nechwatal, A.; Mieck, K.-P.; Reußmann, T. Developments in the characterization of natural fibre properties and in the use of natural fibres for composites. Compos. Sci. Technol. 2003, 63, 1273–1279. [Google Scholar] [CrossRef]

- Van De Velde, K.; Kiekens, P. Thermoplastic pultrusion of natural fibre reinforced composites. Compos. Struct. 2001, 54, 355–360. [Google Scholar] [CrossRef]

- Sujaritjun, W.; Uawongsuwan, P.; Pivsa-Art, W.; Hamada, H. Mechanical property of surface modified natural fiber reinforced PLA biocomposites. Energy Procedia 2013, 34, 664–672. [Google Scholar] [CrossRef] [Green Version]

- Hu, R.; Lim, J.K. Fabrication and mechanical properties of completely biodegradable hemp fiber reinforced polylactic acid composites. J. Compos. Mater. 2007, 41, 1655–1669. [Google Scholar] [CrossRef]

- Choi, H.Y.; Lee, J.S. Effects of surface treatment of ramie fibers in a ramie/poly(lactic acid) composite. Fibers Polym. 2012, 13, 217–223. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M.; Rissanen, M.; Ramamoorthy, S.K. Mechanical and thermal characterization of compression moulded polylactic acid natural fiber composites reinforced with hemp and lyocell fibers. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Singh, I.; Bajpai, P.K.; Malik, D.; Madaan, J.; Bhatnagar, N. Microwave Joining of Natural Fiber Reinforced Green Composites. Adv. Mater. Res. 2011, 410, 102–105. [Google Scholar] [CrossRef]

- Neoh, K.W.; Tshai, K.Y.; Khiew, P.S.; Chia, C.H. Micro Palm and Kenaf Fibers Reinforced PLA Composite: Effect of Volume Fraction on Tensile Strength. Appl. Mech. Mater. 2011, 145, 1–5. [Google Scholar] [CrossRef]

- Porras, A.; Maranon, A.; Ashcroft, I.A. Thermo-mechanical characterization of Manicaria Saccifera natural fabric reinforced poly-lactic acid composite lamina. Compos. Part A Appl. Sci. Manuf. 2016, 81, 105–110. [Google Scholar] [CrossRef]

- Bax, B.; Müssig, J. Impact and tensile properties of PLA/Cordenka and PLA/flax composites. Compos. Sci. Technol. 2008, 68, 1601–1607. [Google Scholar] [CrossRef] [Green Version]

- Bledzki, A.K.; Jaszkiewicz, A. Mechanical performance of biocomposites based on PLA and PHBV reinforced with natural fibres—A comparative study to PP. Compos. Sci. Technol. 2010, 70, 1687–1696. [Google Scholar] [CrossRef] [Green Version]

- Cheung, H.; Ho, M.; Lau, K.; Cardona, F.; Hui, D. Natural fibre-reinforced composites for bioengineering and environmental engineering applications. Compos. Part B Eng. 2009, 40, 655–663. [Google Scholar] [CrossRef]

- Le Duigou, A.; Barbé, A.; Guillou, E.; Castro, M. 3D printing of continuous flax fibre reinforced biocomposites for structural applications. Mater. Des. 2019, 180, 107884. [Google Scholar] [CrossRef]

- Bodros, E.; Pillin, I.; Montrelay, N.; Baley, C. Could biopolymers reinforced by randomly scattered flax fibre be used in structural applications? Compos. Sci. Technol. 2007, 67, 462–470. [Google Scholar] [CrossRef]

- Van Den Oever, M.J.A.; Beck, B.; Müssig, J. Agrofibre reinforced poly(lactic acid) composites: Effect of moisture on degradation and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1628–1635. [Google Scholar] [CrossRef]

- Saba, N.; Paridah, M.T.; Jawaid, M. Mechanical properties of kenaf fibre reinforced polymer composite: A review. Constr. Build. Mater. 2015, 76, 87–96. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Effect of fibre treatments on interfacial shear strength of hemp fibre reinforced polylactide and unsaturated polyester composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1189–1196. [Google Scholar] [CrossRef] [Green Version]

- Hughes, M. Defects in natural fibres: Their origin, characteristics and implications for natural fibre-reinforced composites. J. Mater. Sci. 2012, 47, 599–609. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Zhang, W.; Chate, A. Natural-fibre-reinforced polyurethane microfoams. Compos. Sci. Technol. 2001, 61, 2405–2411. [Google Scholar] [CrossRef]

- Teramoto, N.; Urata, K.; Ozawa, K.; Shibata, M. Biodegradation of aliphatic polyester composites reinforced by abaca fiber. Polym. Degrad. Stab. 2004, 86, 401–409. [Google Scholar] [CrossRef]

- Verma, D.; Gope, P.C.; Shandilya, A.; Gupta, A.; Maheshwari, M.K. Coir fibre reinforcement and application in polymer composites: A review. J. Mater. Environ. Sci. 2013, 4, 263–276. [Google Scholar]

- Takagi, H.; Kako, S.; Kusano, K.; Ousaka, A. Thermal conductivity of PLA-bamboo fiber composites. Adv. Compos. Mater. Off. J. Japan Soc. Compos. Mater. 2007, 16, 377–384. [Google Scholar] [CrossRef]

- Nuthong, W.; Uawongsuwan, P.; Pivsa-Art, W.; Hamada, H. Impact property of flexible epoxy treated natural fiber reinforced PLA composites. Energy Procedia 2013, 34, 839–847. [Google Scholar] [CrossRef] [Green Version]

- Azlin, M.N.M.; Sapuan, S.M.; Zainudin, E.S.; Zuhri, M.Y.M.; Ilyas, R.A. Natural Polylactic Acid-Based Fiber Composites: A Review. In Advanced Processing, Properties, and Applications of Starch and Other Bio-Based Polymers; Al-Oqla, F.M., Sapuan, S.M., Eds.; Elsevier: Oxford, UK, 2020; pp. 21–34. ISBN 9780128196618. [Google Scholar]

- Chia, H.N.; Wu, B.M. High-resolution direct 3D printed PLGA scaffolds: Print and shrink. Biofabrication 2014, 7, 015002. [Google Scholar] [CrossRef] [PubMed]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of their Mechanical Properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jamshidian, M.; Tehrany, E.A.; Imran, M.; Jacquot, M.; Desobry, S. Poly-Lactic Acid: Production, Applications, Nanocomposites, and Release Studies. Compr. Rev. Food Sci. Food Saf. 2010, 9, 552–571. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M. Biopolymers and biocomposites: Chemistry and technology. Curr. Anal. Chem. 2020, 16, 500–503. [Google Scholar] [CrossRef]

- Le Duigou, A.; Castro, M.; Bevan, R.; Martin, N. 3D printing of wood fibre biocomposites: From mechanical to actuation functionality. Mater. Des. 2016, 96, 106–114. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kariz, M.; Kwon, J.H.; Kitek Kuzman, M. Effect of printing layer thickness on water absorption and mechanical properties of 3D-printed wood/PLA composite materials. Int. J. Adv. Manuf. Technol. 2019, 102, 2195–2200. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.-K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef]

- Zhao, X.; Tekinalp, H.; Meng, X.; Ker, D.; Benson, B.; Pu, Y.; Ragauskas, A.J.; Wang, Y.; Li, K.; Webb, E.; et al. Poplar as Biofiber Reinforcement in Composites for Large-Scale 3D Printing. ACS Appl. Bio Mater. 2019, 2, 4557–4570. [Google Scholar] [CrossRef]

- Champeau, M.; Heinze, D.A.; Viana, T.N.; de Souza, E.R.; Chinellato, A.C.; Titotto, S. 4D Printing of Hydrogels: A Review. Adv. Funct. Mater. 2020, 30, 1910606. [Google Scholar] [CrossRef]

- Spiegel, C.A.; Hippler, M.; Münchinger, A.; Bastmeyer, M.; Barner-Kowollik, C.; Wegener, M.; Blasco, E. 4D Printing at the Microscale. Adv. Funct. Mater. 2020, 30, 1907615. [Google Scholar] [CrossRef] [Green Version]

- Zolfagharian, A.; Kaynak, A.; Kouzani, A. Closed-loop 4D-printed soft robots. Mater. Des. 2020, 188, 108411. [Google Scholar] [CrossRef]

- Quanjin, M.; Rejab, M.R.M.; Idris, M.S.; Kumar, N.M.; Abdullah, M.H.; Reddy, G.R. Recent 3D and 4D intelligent printing technologies: A comparative review and future perspective. Procedia Comput. Sci. 2020, 167, 1210–1219. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, Y.; Wang, M.; Liang, Y.; Ren, L.; Ren, L. Recent progress in 4D printing of stimuli-responsive polymeric materials. Sci. China Technol. Sci. 2020, 63, 532–544. [Google Scholar] [CrossRef]

- Subash, A.; Kandasubramanian, B. 4D printing of shape memory polymers. Eur. Polym. J. 2020, 134, 109771. [Google Scholar] [CrossRef]

- Zafar, M.Q.; Zhao, H. 4D Printing: Future Insight in Additive Manufacturing. Met. Mater. Int. 2020, 26, 564–585. [Google Scholar] [CrossRef]

- Chu, H.; Yang, W.; Sun, L.; Cai, S.; Yang, R.; Liang, W.; Yu, H.; Liu, L. 4D Printing: A Review on Recent Progresses. Micromachines 2020, 11, 796. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Kaynak, A.; Bodaghi, M.; Kouzani, A.Z.; Gharaie, S.; Nahavandi, S. Control-Based 4D Printing: Adaptive 4D-Printed Systems. Appl. Sci. 2020, 10, 3020. [Google Scholar] [CrossRef]

- Yang, J.; Bai, R.; Chen, B.; Suo, Z. Hydrogel Adhesion: A Supramolecular Synergy of Chemistry, Topology, and Mechanics. Adv. Funct. Mater. 2020, 30, 1901693. [Google Scholar] [CrossRef]

- Nautiyal, U.; Sahu, N.; Gupta, D. Hydrogel: Preparation, Characterization and Applications. Asian Pacific J. Nurs. Health Sci. 2020, 3. [Google Scholar] [CrossRef]

- Zheng, Y.; Chen, Z.; Jiang, Q.; Feng, J.; Wu, S.; del Campo, A. Near-infrared-light regulated angiogenesis in a 4D hydrogel. Nanoscale 2020, 12, 13654–13661. [Google Scholar] [CrossRef] [PubMed]

- Le Duigou, A.; Requile, S.; Beaugrand, J.; Scarpa, F.; Castro, M. Natural fibres actuators for smart bio-inspired hygromorph biocomposites. Smart Mater. Struct. 2017, 26, 125009. [Google Scholar] [CrossRef] [Green Version]

- Poppinga, S.; Correa, D.; Bruchmann, B.; Menges, A.; Speck, T. Plant Movements as Concept Generators for the Development of Biomimetic Compliant Mechanisms. Integr. Comp. Biol. 2020, 60, 886–895. [Google Scholar] [CrossRef]

- Alief, N.A.; Supriadi, S.; Whulanza, Y. Modelling the shape memory properties of 4D printed polylactic acid (PLA) for application of disk spacer in minimally invasive spinal fusion. AIP Conf. Proc. 2019, 2092, 020005. [Google Scholar] [CrossRef]

- Martins, S.S.; Evangelista, A.C.J.; Hammad, A.W.A.; Tam, V.W.Y.; Haddad, A. Evaluation of 4D BIM tools applicability in construction planning efficiency. Int. J. Constr. Manag. 2020, 1–14. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Mahmud, M.A.P.; Gharaie, S.; Bodaghi, M.; Kouzani, A.Z.; Kaynak, A. 3D/4D-printed bending-type soft pneumatic actuators: Fabrication, modelling, and control. Virtual Phys. Prototyp. 2020, 15, 373–402. [Google Scholar] [CrossRef]

- Miao, S.; Cui, H.; Esworthy, T.; Mahadik, B.; Lee, S.; Zhou, X.; Hann, S.Y.; Fisher, J.P.; Zhang, L.G. 4D Self-Morphing Culture Substrate for Modulating Cell Differentiation. Adv. Sci. 2020, 7, 1902403. [Google Scholar] [CrossRef] [Green Version]

- Le Fer, G.; Becker, M.L. 4D Printing of Resorbable Complex Shape-Memory Poly(propylene fumarate) Star Scaffolds. ACS Appl. Mater. Interfaces 2020, 12, 22444–22452. [Google Scholar] [CrossRef]

- Durga Prasad Reddy, R.; Sharma, V. Additive manufacturing in drug delivery applications: A review. Int. J. Pharm. 2020, 589, 119820. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Leng, J.; Du, S. 4D printing of shape memory polymers and their composites: Research status and application progress. Harbin Gongye Daxue Xuebao J. Harbin Inst. Technol. 2020. [Google Scholar] [CrossRef]

- Saravana Bavan, D.; Mohan Kumar, G.C. Potential use of natural fiber composite materials in India. J. Reinf. Plast. Compos. 2010, 29, 3600–3613. [Google Scholar] [CrossRef]

- Furtado, S.C.R.; Araújo, A.L.; Silva, A.; Alves, C.; Ribeiro, A.M.R. Natural fibre-reinforced composite parts for automotive applications. Int. J. Automot. Compos. 2014, 1, 18. [Google Scholar] [CrossRef]

- Barkoula, N.M.; Alcock, B.; Cabrera, N.O.; Peijs, T. Flame-Retardancy Properties of Intumescent Ammonium Poly(Phosphate) and Mineral Filler Magnesium Hydroxide in Combination with Graphene. Polym. Polym. Compos. 2008, 16, 101–113. [Google Scholar] [CrossRef]

| Fibres | Holocellulose (wt%) | Lignin (wt%) | Ash (wt%) | Extractives (wt%) | Crystallinity (%) | Ref. | |

|---|---|---|---|---|---|---|---|

| Cellulose (wt%) | Hemicellulose (wt%) | ||||||

| Sugar palm fibre | 43.88 | 7.24 | 33.24 | 1.01 | 2.73 | 55.8 | [46] |

| Wheat straw fibre | 43.2 ± 0.15 | 34.1 ± 1.2 | 22.0 ± 3.1 | - | - | 57.5 | [50] |

| Soy hull fibre | 56.4 ± 0.92 | 12.5 ± 0.72 | 18.0 ± 2.5 | - | - | 59.8 | [50] |

| Arecanut husk fibre | 34.18 | 20.83 | 31.60 | 2.34 | - | 37 | [51] |

| Helicteres isora plant | 71 ± 2.6 | 3.1 ± 0.5 | 21 ± 0.9 | - | - | 38 | [52] |

| Pineapple leaf fibre | 81.27 ± 2.45 | 12.31 ± 1.35 | 3.46 ± 0.58 | - | - | 35.97 | [53] |

| Ramie fibre | 69.83 | 9.63 | 3.98 | - | - | 55.48 | [54] |

| Oil palm mesocarp fibre (OPMF) | 28.2 ± 0.8 | 32.7 ± 4.8 | 32.4 ± 4.0 | - | 6.5 ± 0.1 | 34.3 | [55] |

| Oil palm empty fruit bunch (OPEFB) | 37.1 ± 4.4 | 39.9 ± 0.75 | 18.6 ± 1.3 | - | 3.1 ± 3.4 | 45.0 | [55] |

| Oil palm frond (OPF) | 45.0 ± 0.6 | 32.0 ± 1.4 | 16.9 ± 0.4 | - | 2.3 ± 1.0 | 54.5 | [55] |

| Oil palm empty fruit bunch (OPEFB) fibre | 40 ± 2 | 23 ± 2 | 21 ± 1 | - | 2.0 ± 0.2 | 40 | [56] |

| Rubber wood | 45 ± 3 | 20 ± 2 | 29 ± 2 | - | 2.5 ± 0.5 | 46 | [56] |

| Curauna fibre | 70.2 ± 0.7 | 18.3 ± 0.8 | 9.3 ± 0.9 | - | - | 64 | [57] |

| Banana fibre | 7.5 | 74.9 | 7.9 | 0.01 | 9.6 | 15.0 | [58] |

| Sugarcane bagasse | 43.6 | 27.7 | 27.7 | - | - | 76 | [59] |

| Kenaf bast | 63.5 ± 0.5 | 17.6 ± 1.4 | 12.7 ± 1.5 | 2.2 ± 0.8 | 4.0 ± 1.0 | 48.2 | [60] |

| Phoenix dactylifera palm leaflet | 33.5 | 26.0 | 27.0 | 6.5 | - | 50 | [61] |

| Phoenix dactylifera palm rachis | 44.0 | 28.0 | 14.0 | 2.5 | - | 55 | [61] |

| Kenaf core powder | 80.26 | 23.58 | - | - | 48.1 | [62] | |

| Water hyacinth fibre | 42.8 | 20.6 | 4.1 | - | - | 59.56 | [63] |

| Wheat straw | 43.2 ± 0.15 | 34.1 ± 1.2 | 22.0 ± 3.1 | - | - | 57.5 | [64] |

| Sugar beet fibre | 44.95 ± 0.09 | 25.40 ± 2.06 | 11.23 ± 1.66 | 17.67 ± 1.54 | - | 35.67 | [65] |

| Mengkuang leaves | 37.3 ± 0.6 | 34.4 ± 0.2 | 24 ± 0.8 | 2.5 ± 0.02 | 55.1 | [66] | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ilyas, R.A.; Sapuan, S.M.; Harussani, M.M.; Hakimi, M.Y.A.Y.; Haziq, M.Z.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Nurazzi, N.M.; et al. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymers 2021, 13, 1326. https://doi.org/10.3390/polym13081326

Ilyas RA, Sapuan SM, Harussani MM, Hakimi MYAY, Haziq MZM, Atikah MSN, Asyraf MRM, Ishak MR, Razman MR, Nurazzi NM, et al. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymers. 2021; 13(8):1326. https://doi.org/10.3390/polym13081326

Chicago/Turabian StyleIlyas, R.A., S.M. Sapuan, M.M. Harussani, M.Y.A.Y. Hakimi, M.Z.M. Haziq, M.S.N. Atikah, M.R.M. Asyraf, M.R. Ishak, M.R. Razman, N.M. Nurazzi, and et al. 2021. "Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications" Polymers 13, no. 8: 1326. https://doi.org/10.3390/polym13081326