4th Generation Biomaterials Based on PVDF-Hydroxyapatite Composites Produced by Electrospinning: Processing and Characterization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

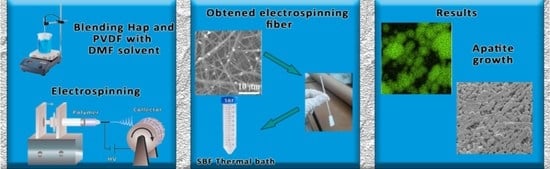

2.2. Scaffolding Processing

2.3. Electrospinning Parameters

2.4. Characterizations

2.5. Cytotoxicity Test

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Heath, D.E.; Cooper, S.L. Biomaterials Science: An Introduction to Materials in Medicine; Academic Press: Oxford, UK, 2013. [Google Scholar]

- Park, J.B.; Lakes, R.S. Biomaterials: An Introduction; Springer: New York, NY, USA, 2007. [Google Scholar]

- Ratner, B.D.; Hoffman, A.S.; Schoen, F.J.; Lemons, J.E. Introduction-Biomaterials Science: An Evolving, Multidisciplinary Endeavor. In Biomaterials Science, 3rd ed.; Ratner, B.D., Hoffman, A.S., Schoen, F.J., Lemons, J.E., Eds.; Academic Press: Cambridge, MA, USA, 2013; pp. xxv–xxxix. [Google Scholar] [CrossRef]

- Levin, M. Molecular bioelectricity: How endogenous voltage potentials control cell behavior and instruct pattern regulation in vivo. Mol. Biol. Cell 2014, 24, 3835–3850. [Google Scholar]

- Watson, J. The electrical stimulation of bone healing. Proc. IEEE 1979, 67, 1339–1352. [Google Scholar] [CrossRef]

- Ning, C.; Zhou, Z.; Tan, G.; Zhu, Y.; Mao, C. Electroactive polymers for tissue regeneration: Developments and perspectives. Prog. Polym. Sci. 2018, 81, 144–162. [Google Scholar] [CrossRef] [PubMed]

- Ning, C.; Zhou, L.; Tan, G. Fourth-generation biomedical materials. Mater. Today 2016, 19, 2–3. [Google Scholar] [CrossRef]

- Jacob, J.; More, N.; Kalia, K.; Kapusetti, G. Piezoelectric smart biomaterials for bone and cartilage tissue engineering. Inflamm. Regen. 2018, 38, 1–11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Curie, P.; Curie, J. Dévelopment, par pression, de l’électricité polaire dans les cristaux hémièdres à faces inclinées. Comptes Rendus l’Académie Sci. 1880, 91, 294–295. [Google Scholar]

- Madorsky, S.L. Thermal Degradation of Organic Polymers Fluorocarbon and Chlorocarbon Polymers; John Wiley & Sons Inc.: Hoboken, NJ, USA, 1964; pp. 130–172. [Google Scholar]

- Saxena, P.; Shukla, P. A comprehensive review on fundamental properties and applications of poly(vinylidene fluoride) (PVDF). Adv. Compos. Hybrid Mater. 2021, 4, 1–19. [Google Scholar] [CrossRef]

- Lovinger, A.J. Developments in Crystalline Polymers-1; Applied Science Publishers: London, UK, 1982; p. 195. [Google Scholar]

- Eisenmenger, W.; Schmidt, H.; Dehlen, B. Space charge and dipoles in polyvinylidenefluoride. Braz. J. Phys. 1999, 29, 295–305. [Google Scholar] [CrossRef]

- Sajkiewicz, P.; Wasiak, A.; Goclowski, Z. Phase transition during stretching of poly (vinylidene fluoride). Eur. Polym. J. 1999, 35, 423–429. [Google Scholar] [CrossRef]

- He, T.; Wang, J.; Huang, P.; Zeng, B.; Li, H.; Cao, Q.; Zhang, S.; Luo, Z.; Deng, D.Y.B.; et al. Electrospinning polyvinylidene fluoride fibrous membranes containing anti-bacterial drugs used as wound dressing. Colloids Surf. B Biointerfaces 2015, 130, 278–286. [Google Scholar]

- Varma, H.K.; Yokogawa, Y.; Espinosa, F.F.; Kawamoto, Y.; Nishizawa, K.; Nagata, F.; Kameyama, T. In-vitro Calcium Phosphate Growth Over Functionalized Cotton Fibers. J. Mater. Sci. Mater. Med. 1999, 10, 395–400. [Google Scholar] [CrossRef] [PubMed]

- Gomes, D.S.; Santos, A.M.C.; Neves, G.A.; Menezes, R.R. A brief review on hydroxyapatite production and use in biomedicine. Cerâmica 2019, 65, 282–302. [Google Scholar] [CrossRef]

- Bernardo, M.P.; Silva, B.C.R.D.; Hamouda, A.E.I.; Schalla, C.; Zenke, M.; Sechi, A. PLA/Hydroxyapatite scaffolds exhibit in vitro immunological inertness and promote robust osteogenic differentiation of human mesenchymal stem cells without osteogenic stimuli. Sci. Rep. 2022, 12, 2333. [Google Scholar] [CrossRef] [PubMed]

- Tandon, B.; Kamble, P.; Olsson, R.T.; Blaker, J.J.; Cartmell, S.H. Fabrication and Characterization of Stimuli Responsive Piezoelectric PVDF and Hydroxyapatite-Filled PVDF Fibrous Membranes. Molecules 2019, 24, 1903. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahmed, M.K.; Ramadan, R.; El-Dek, S.I.; Uskoković, V. Complex relationship between alumina and selenium-doped carbonated hydroxyapatite as the ceramic additives to electrospun polycaprolactone scaffolds for tissue engineering applications. J. Alloy. Compd. 2019, 801, 70–81. [Google Scholar] [CrossRef]

- Ullah, S.; Hashmi, M.; Kim, I.S. Electrospun Composite Nanofibers for Functional Applications. Polymers 2022, 14, 2290. [Google Scholar] [CrossRef]

- Xu, L.; Liu, Y.; Zhou, W.; Yu, D. Electrospun Medical Sutures for Wound Healing: A Review. Polymers 2022, 14, 1637. [Google Scholar] [CrossRef]

- Chou, Y.L.; Wen, H.Y.; Weng, Y.Q.; Liu, Y.C.; Wu, C.W.; Hsu, H.C.; Chiang, C.C. A U-Shaped Optical Fiber Temperature Sensor Coated with Electrospinning Polyvinyl Alcohol Nanofibers: Simulation and Experiment. Polymers 2022, 14, 2110. [Google Scholar] [CrossRef]

- Li, Y.L.; Chen, C.Y. Near-Infrared Light-Remote Localized Drug Delivery Systems Based on Zwitterionic Polymer Nanofibers for Combination Therapy. Polymers 2022, 14, 1860. [Google Scholar] [CrossRef]

- Wang, M.; Wang, K.; Yang, Y.; Liu, Y.; Yu, D.G. Electrospun Environment Remediation Nanofibers Using Unspinnable Liquids as the Sheath Fluids: A Review. Polymers 2020, 12, 103. [Google Scholar] [CrossRef] [Green Version]

- Lv, H.; Guo, S.; Zhang, G.; He, W.; Wu, Y.; Yu, D.G. Electrospun Structural Hybrids of Acyclovir-Polyacrylonitrile at Acyclovir for Modifying Drug Release. Polymers 2021, 13, 4286. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Zhang, F.; Wang, M.; Lv, H.; Yu, D.G.; Liu, X.; Shen, H. Electrospun hierarchical structural films for effective wound healing. Biomater. Adv. 2022, 136, 212795. [Google Scholar] [CrossRef] [PubMed]

- Zhao, K.; Lu, Z.H.; Zhao, P.; Kang, S.X.; Yang, Y.Y.; Yu, D.G. Modified tri–axial electrospun functional core–shell nanofibrous membranes for natural photodegradation of antibiotics. Chem. Eng. J. 2021, 425, 131455. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, W.; Yang, Z.; Chen, X.; Yu, D.G.; Shao, J. Hybrid Films Prepared from a Combination of Electrospinning and Casting for Offering a Dual-Phase Drug Release. Polymers 2022, 14, 2132. [Google Scholar] [CrossRef]

- Nasution, H.; Yahya, E.B.; Abdul Khalil, H.P.S.; Shaah, M.A.; Suriani, A.B.; Mohamed, A.; Alfatah, T.; Abdullah, C.K. Extraction and Isolation of Cellulose Nanofibers from Carpet Wastes Using Supercritical Carbon Dioxide Approach. Polymers 2022, 14, 326. [Google Scholar] [CrossRef]

- Chaudhari, A.A.; Vig, K.; Baganizi, D.R.; Sahu, R.; Dixit, S.; Dennis, V.; Singh, S.R.; Pillai, S.R. Future Prospects for Scaffolding Methods and Biomaterials in Skin Tissue Engineering: A Review. International Journal of Molecular Sciences. Int. J. Mol. Sci. 2016, 17, 1974. [Google Scholar] [CrossRef] [PubMed]

- Ramachandran, K.; Gouma, P.I. Electrospinning for bone tissue engineering. Recent Patents Nanotechnol. 2008, 2, 1–7. [Google Scholar]

- Miyahara, R.Y.; Gouvêa, D.; Toffoli, S.M. Obtenção e caracterização de cinza de ossos bovinos visando à fabricação de porcelana de ossos-bone china. Cerâmica 2007, 53, 234–239. [Google Scholar] [CrossRef]

- ImageJ—Image Processing and Analysis in Java. 2012. Available online: https://www.researchgate.net/publication/258729119_ImageJ_-_Image_Processing_and_Analysis_in_Jav (accessed on 26 September 2022).

- Cai, X.; Lei, T.; Sun, D.; Lin, L. A critical analysis of the α, β and γ phases in poly(vinylidene fluoride) using FTIR. RSC Adv. 2017, 7, 15382–15389. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.M.; Miyaji, F.; Kokubo, T.; Ohtsuki, C.; Nakamura, T.; Yamamuro, T. Bioactivity of Na2O-CaO-SiO2 Glasses. J. Am. Ceram. Soc. 1995, 78, 2405–2411. [Google Scholar] [CrossRef]

- Kim, H.M.; Miyaji, F.; Kokubo, T.; Ohtsuki, C.; Nakamura, T. Bioactivity of M2O-TiO2-SiO2 (M = Na, K) Glasses: An In vitro Evaluation. Bull. Chem. Soc. Jpn. 1996, 69, 2387–2394. [Google Scholar] [CrossRef]

- Uchida, M.; Kim, H.M.; Kokubo, T.; Miyaji, F.; Nakamura, T. Bonelike apatite formation induced on zirconia gel in a simulated body fluid and its modified solutions. J. Am. Ceram. Soc. 2001, 84, 2041–2044. [Google Scholar] [CrossRef]

- Abe, Y.; Kawashita, M.; Kokubo, T.; Nakamura, T. Effect of solution on apatite formation on substrate in biomimetic method. J. Ceram. Soc. Jpn. 2001, 109, 106–109. [Google Scholar] [CrossRef]

- Ohtsuki, C.; Kokubo, T.; Yamamura, T. Mechanism of apatite formation on CaO-SiO2-P205 glasses in a simulated body fluid. J. Non-Cryst. Solids 1992, 143, 80556–80559. [Google Scholar] [CrossRef]

- Li, P.; Ohtsuki, C.; Kokubo, T.; Nakanishi, K.; Soga, N.; Nakamura, T.; Yamamuro, T. Apatite formation induced by silica gel in a simulated body fluid. J. Am. Ceram. Soc. 1992, 75, 2094–2097. [Google Scholar] [CrossRef]

- Li, P.; Ohtsuki, C.; Kokubo, T.; Nakanishi, K.; Soga, N.; Groot, A. The role of hydrated silica, titania, and alumina in inducing apatite on implants. J. Biomed. Mater. Res. 1994, 28, 7–15. [Google Scholar] [CrossRef]

- Deliormanli, A.M.; Konyali, R. Bioactive glass/hydroxyapatite-containing electrospun poly(ε-caprolactone) composite nanofibers for bone tissue engineering. J. Aust. Ceram. Soc. 2019, 55, 247–256. [Google Scholar] [CrossRef]

- Bružauskaitė, I.; Bironaitė, D.; Bagdonas, E.; Bernotienė, E. Scaffolds and cells for tissue regeneration: Different scaffold pore sizes—Different cell effects. Cytotechnology 2016, 68, 355–369. [Google Scholar] [CrossRef] [Green Version]

- Brunengo, E.; Luciano, G.; Canu, G.; Canetti, M.; Conzatti, L.; Castellano, M.; Stagnaro, P. Double-step moulding: An effective method to induce the formation of β-phase in PVDF. Polymer 2020, 193, 122345. [Google Scholar] [CrossRef]

- Mokhtari, F.; Latifi, M.; Shamshirsaz, M. Electrospinnig/electrospray of polyvinylidene fluoride (PVDF): Piezoelectric nanofibers. J. Text. Inst. 2015, 107, 1037–1055. [Google Scholar]

- Andrew, J.S.; Clark, D.R. Effect of Electrospinning on the Ferroelectric Phase Content of Polyvinylidene Difluoride Fibers. Langmuir 2008, 24, 670–672. [Google Scholar] [CrossRef] [PubMed]

- Bormashenko, Y.; Pogreb, R.; Stanevsky, O.; Bormashenko, E. Vibrational spectrum of PVDF and its interpretation. Polym. Test. 2004, 23, 791–796. [Google Scholar] [CrossRef]

- Silva, L.M.; Bonadio, T.G.M.; Rosso, J.M.; Dias, G.S.; Cótica, L.F.; Weinand, W.R.; Miyahara, R.Y.; Santos, I.A.; Freitas, V.F. On the synthesis and characterization of (bio)ferroelectrically active PVDF-BCP composites. Ferroelectrics 2018, 533, 63–71. [Google Scholar] [CrossRef]

- Ince-Gunduz, B.S.; Alpern, R.; Amare, D.; Crawford, J.; Dolan, B.; Jones, S.; Kobylarz, R.; Reveley, M.; Cebe, P. Impact of nanosilicates on poly(vinylidene fluoride) crystal polymorphism: Part 1. Melt-crystallization at high supercooling. Polymer 2010, 52, 1485–1493. [Google Scholar] [CrossRef]

- Arami, H.; Mohajerani, M.; Mazloumi, M.; Khalifehzadeh, R.; Lak, A.; Sadrnezhaad, S.K. Rapid formation of hydroxyapatite nanostrips via microwave irradiation. J. Alloy. Compd. 2009, 469, 391–394. [Google Scholar] [CrossRef]

- Guo, H.F.; Li, Z.S.; Dong, S.W.; Chen, W.J.; Deng, L.; Wang, Y.F.; Ying, D.J. Piezoelectric PU/PVDF electrospun scaffolds for wound healing applications. Colloids Surf. B Biointerfaces 2012, 96, 29–36. [Google Scholar] [CrossRef]

- Braga, F.J.C.; Rogero, S.O.; Couto, A.A.; Marques, R.F.C.; Ribeiro, A.A.; Campos, J.S.C. Characterization of PVDF/HAP composites for medical applications. Mater. Res. 2007, 10, 247–251. [Google Scholar] [CrossRef] [Green Version]

- Damaraju, S.M.; Wu, S.; Jaffe, M.; Arinzeh, T.L. Structural changes in PVDF fibers due to electrospinning and its effect on biological function. Biomed. Mater. 2013, 8, 045007. [Google Scholar] [CrossRef] [PubMed]

- Szewczyk, P.K.; Gradys, A.; Kim, S.K.; Persano, L.; Marzec, M.; Kryshtal, A.; Busolo, T.; Toncelli, A.; Pisignano, D.; Bernasik, A.; et al. Enhanced Piezoelectricity of Electrospun Polyvinylidene Fluoride Fibers for Energy Harvesting. ACS Appl. Mater. Interfaces 2020, 12, 13575–13583. [Google Scholar] [CrossRef]

| Sample | Percentage of HA | Percentage of Phase |

|---|---|---|

| (%) | (%) | |

| PVDF (Powder) | 0 | 32.6 |

| P14 | 0 | 90.0 |

| P14-H10 | 10 | 83.7 |

| P14-H15 | 15 | 86.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

dos Santos, G.G.; Malherbi, M.S.; de Souza, N.S.; César, G.B.; Tominaga, T.T.; Miyahara, R.Y.; de Mendonça, P.d.S.B.; Faria, D.R.; Rosso, J.M.; Freitas, V.F.; et al. 4th Generation Biomaterials Based on PVDF-Hydroxyapatite Composites Produced by Electrospinning: Processing and Characterization. Polymers 2022, 14, 4190. https://doi.org/10.3390/polym14194190

dos Santos GG, Malherbi MS, de Souza NS, César GB, Tominaga TT, Miyahara RY, de Mendonça PdSB, Faria DR, Rosso JM, Freitas VF, et al. 4th Generation Biomaterials Based on PVDF-Hydroxyapatite Composites Produced by Electrospinning: Processing and Characterization. Polymers. 2022; 14(19):4190. https://doi.org/10.3390/polym14194190

Chicago/Turabian Styledos Santos, Gabriel Grube, Milena Schroeder Malherbi, Natália Silva de Souza, Gabriel Batista César, Tania Toyomi Tominaga, Ricardo Yoshimitsu Miyahara, Patrícia de Souza Bonfim de Mendonça, Daniela Renata Faria, Jaciele Márcia Rosso, Valdirlei Fernandes Freitas, and et al. 2022. "4th Generation Biomaterials Based on PVDF-Hydroxyapatite Composites Produced by Electrospinning: Processing and Characterization" Polymers 14, no. 19: 4190. https://doi.org/10.3390/polym14194190