Low-Density Geopolymer Composites for the Construction Industry

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Mechanical Strength Tests

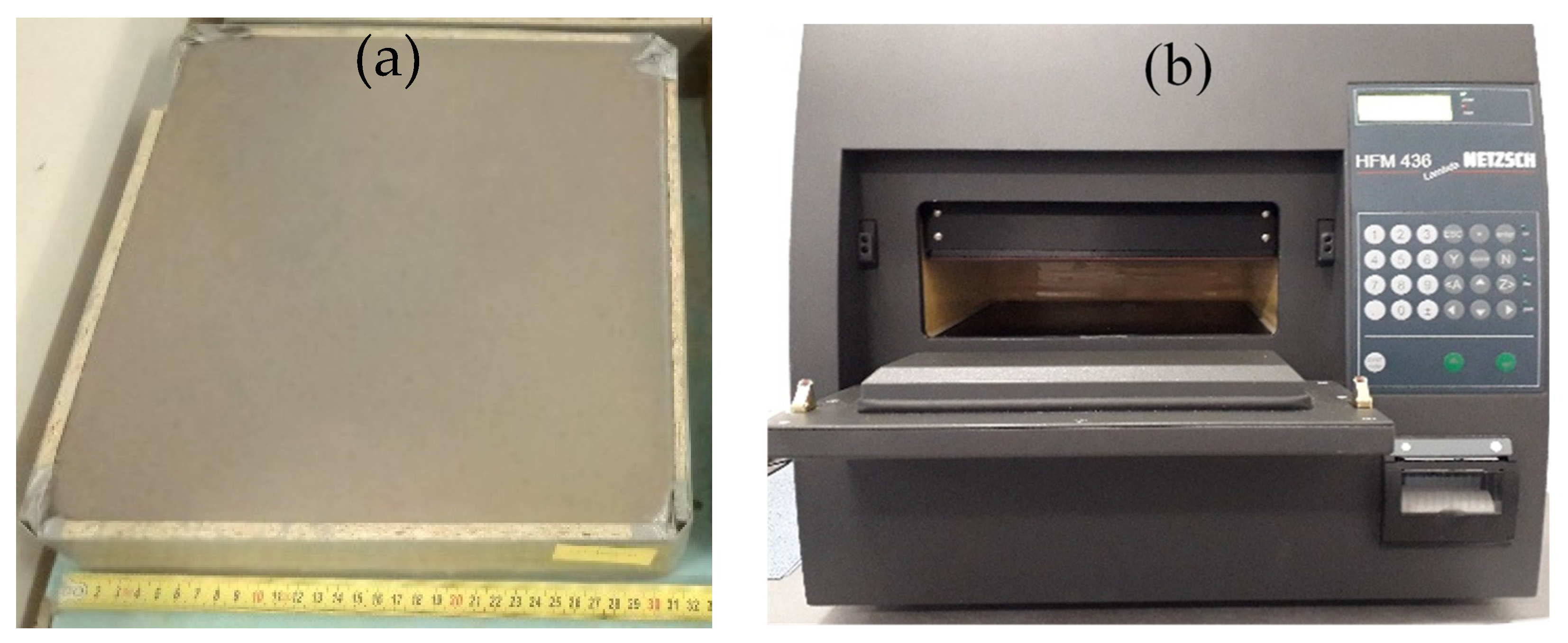

2.4. Physical Properties Measurements

2.5. Electromagnetic Shielding Measurements

3. Results

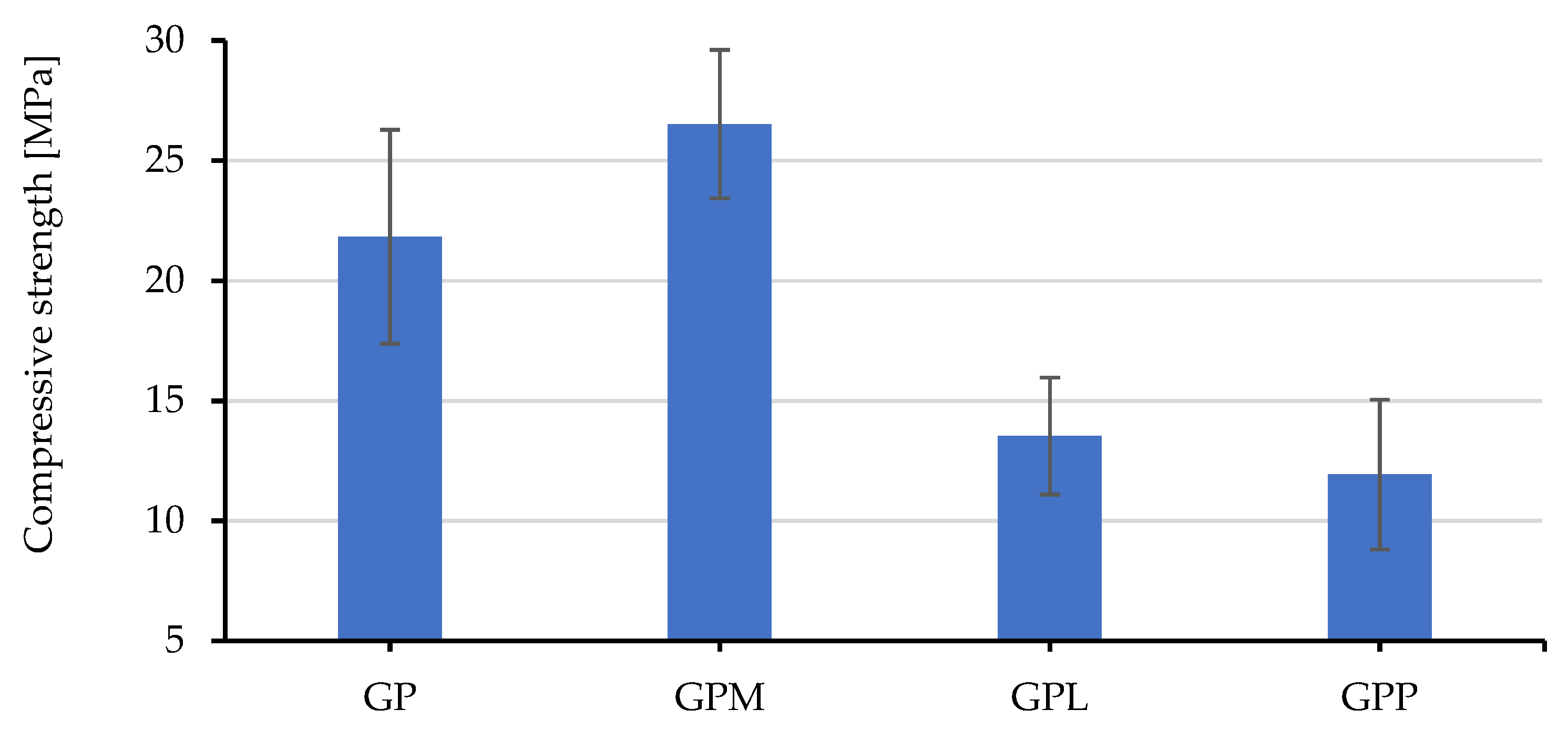

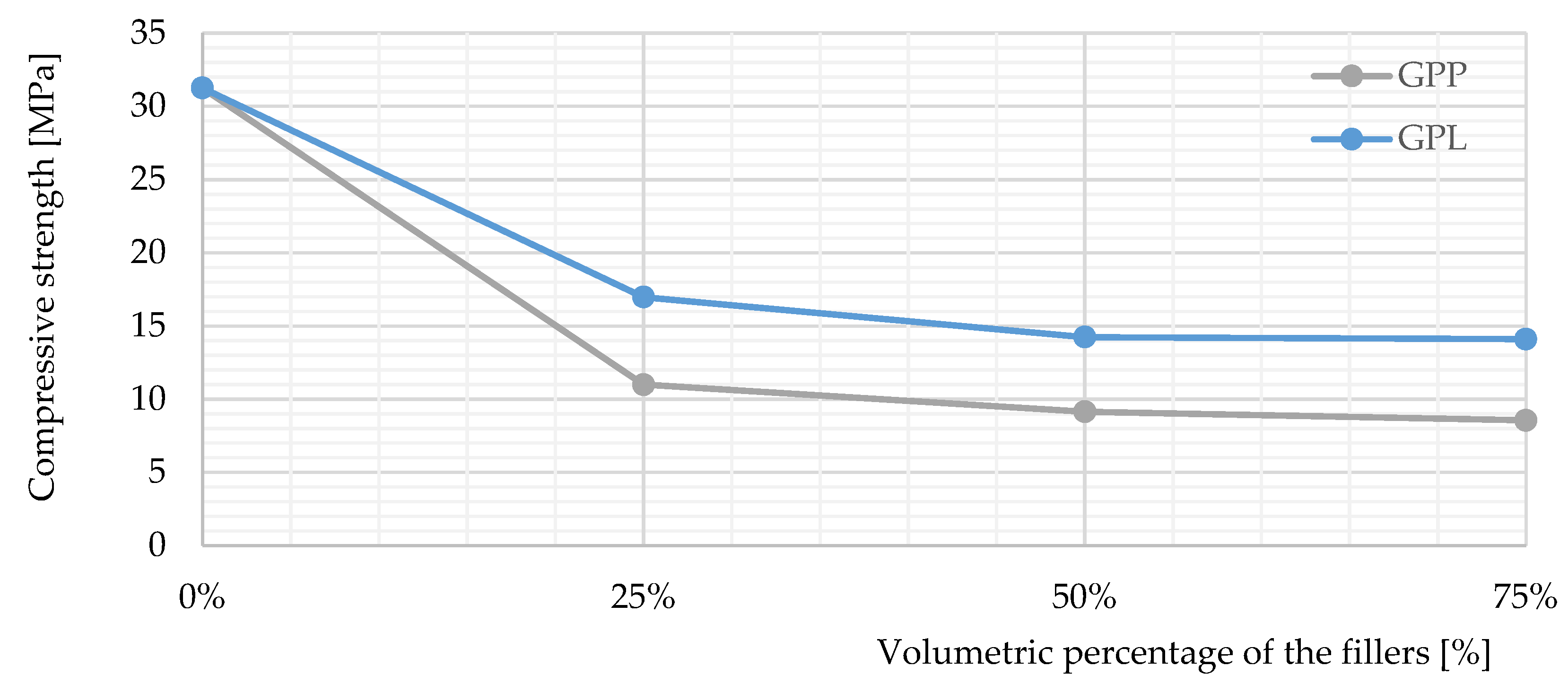

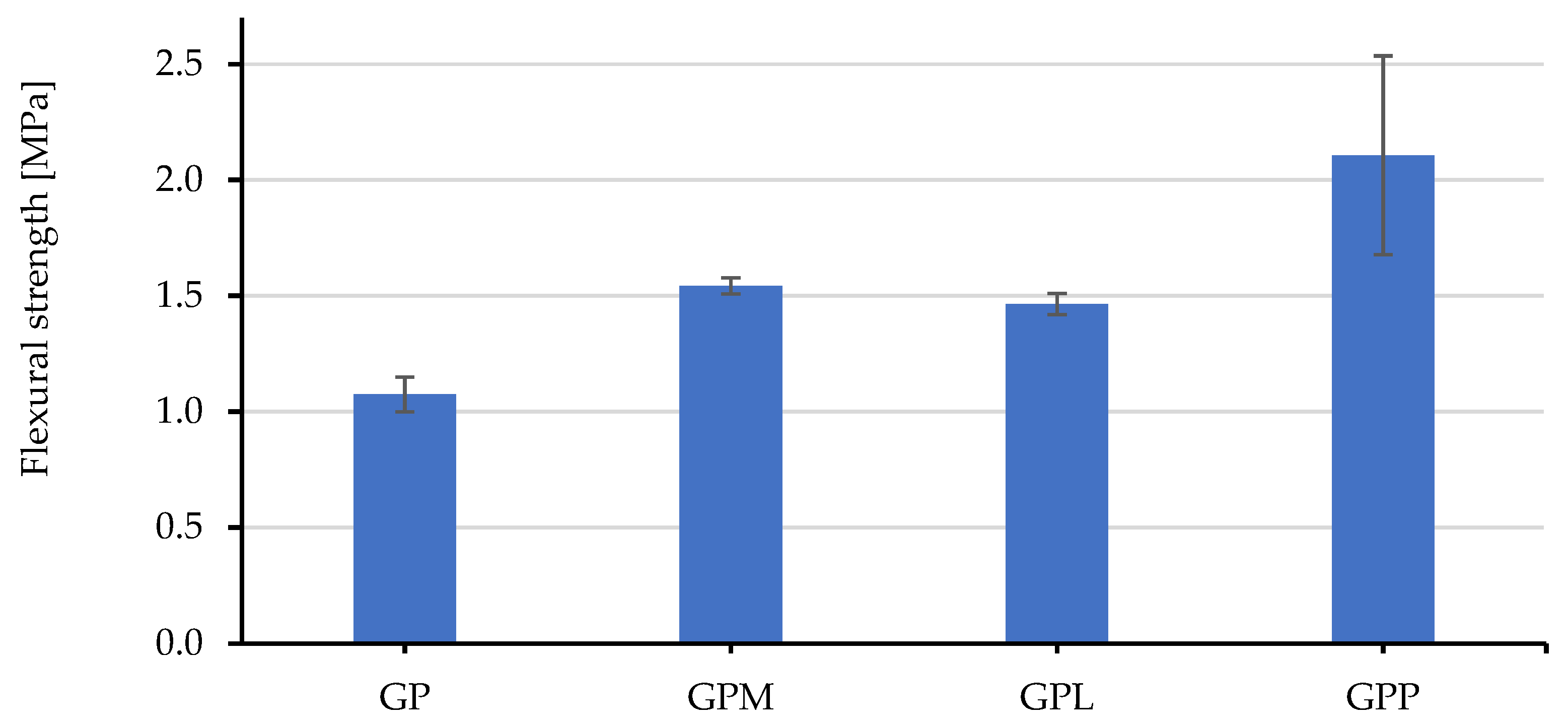

3.1. Mechanical Properties

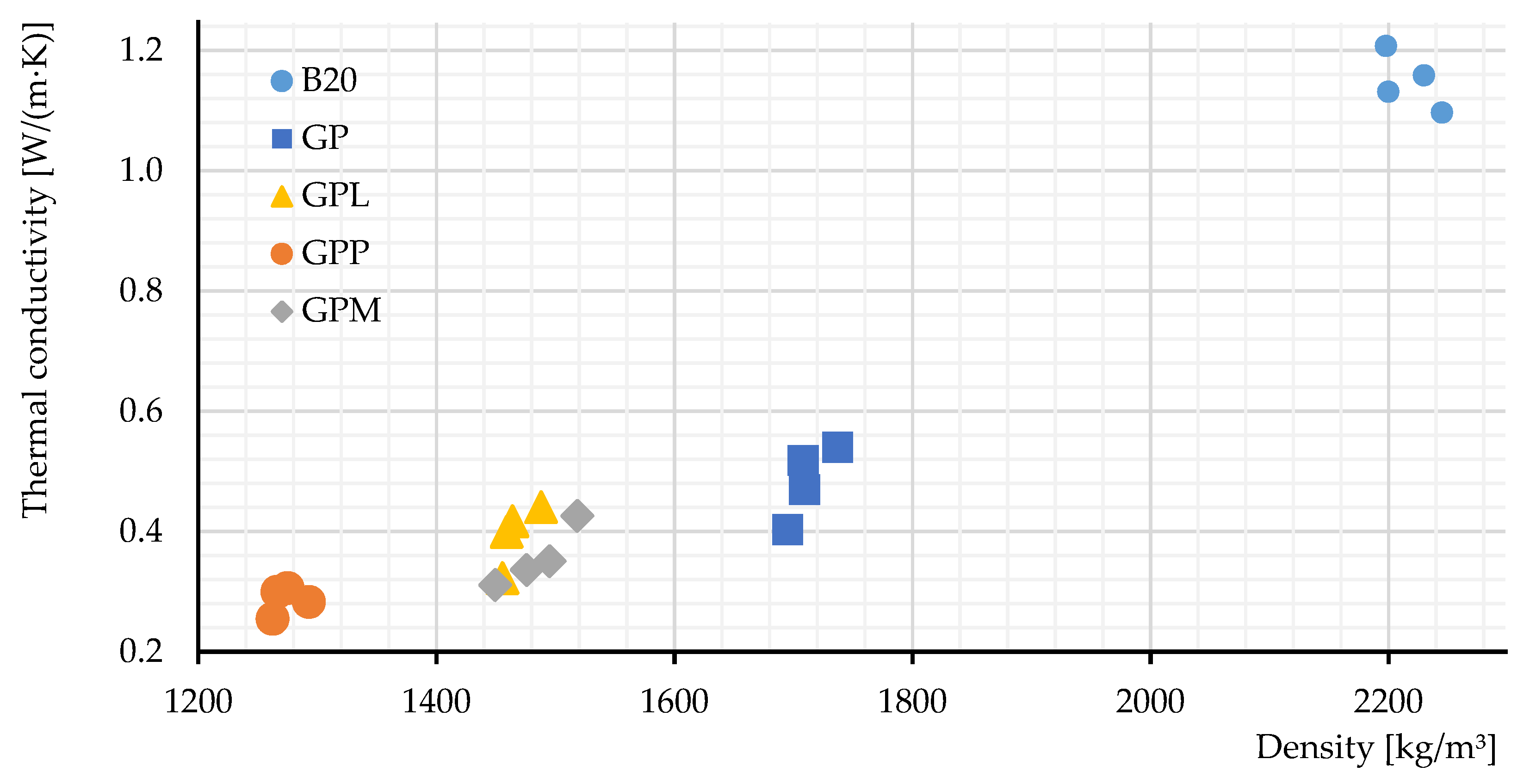

3.2. Thermal Conductivity and Density

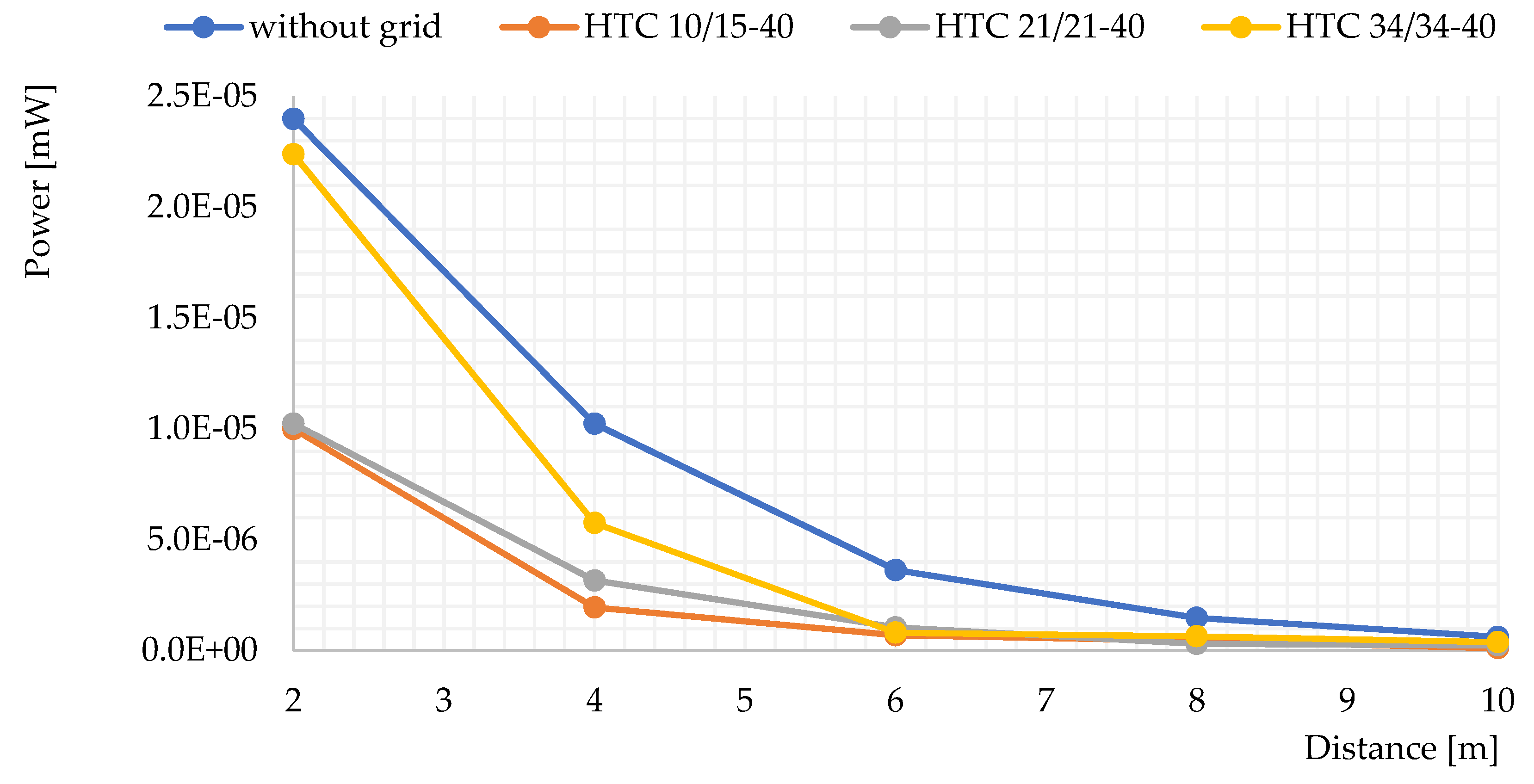

3.3. Electromagnetic Shielding Properties of Carbon Nets

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- McGrath, T.E.; Cox, S.; Soutsos, M.; Kong, D.; Mee, L.P.; Alengaram, J.U. Life cycle assessment of geopolymer concrete: A Malaysian context. IOP Conf. Ser. Mater. Sci. Eng. 2018, 431, 092001. [Google Scholar] [CrossRef] [Green Version]

- Korniejenko, K.; Łach, M. Geopolymers reinforced by short and long fibres—Innovative materials for additive manufacturing. Curr. Opin. Chem. Eng. 2020, 28, 167–172. [Google Scholar] [CrossRef]

- Thang, X.N.; Louda, P.; Kroisová, D. Thermophysical properties of woven fabrics reinforced geopolymer composites. World J. Eng. 2013, 10, 139–144. [Google Scholar] [CrossRef]

- Tran, D.H.; Kroisová, D.; Louda, P.; Bortnovsky, O.; Bezucha, P. Effect of curing temperature on flexural properties of silica-based geopolymer-carbon reinforced composite. Manuf. Eng. 2009, 37, 492–497. [Google Scholar]

- Blanco, I.; Poggetto, G.D.; Morrone, B.; Tranquillo, E.; Barrino, F.; Catauro, M. Fly Ash Filled Geopolymers: Preparation and Thermal Study. Macromol. Symp. 2020, 389, 1900052. [Google Scholar] [CrossRef]

- Levine, H.; Jørgensen, N.; Martino-Andrade, A.; Mendiola, J.; Weksler-Derri, D.; Mindlis, I.; Pinotti, R.; Swan, S.H. Temporal trends in sperm count: A systematic review and meta-regression analysis. Hum. Reprod. Update 2017, 23, 646–659. [Google Scholar] [CrossRef] [PubMed]

- Akdag, M.Z.; Dasdag, S.; Canturk, F.; Karabulut, D.; Caner, Y.; Adalier, N. Does prolonged radiofrequency radiation emitted from Wi-Fi devices induce DNA damage in various tissues of rats? J. Chem. Neuroanat. 2016, 75, 116–122. [Google Scholar] [CrossRef] [PubMed]

- Pall, M.L. Wi-Fi is an important threat to human health. Environ. Res. 2018, 164, 405–416. [Google Scholar] [CrossRef] [PubMed]

- Markovà, E.; Malmgren, L.O.G.; Belyaev, I.Y. Microwaves from Mobile Phones Inhibit 53BP1 Focus Formation in Human Stem Cells More Strongly Than in Differentiated Cells: Possible Mechanistic Link to Cancer Risk. Environ. Health Perspect. 2010, 118, 394–399. [Google Scholar] [CrossRef] [PubMed]

- Lewczuk, B.; Redlarski, G.; Zak, A.; Ziółkowska, N.; Przybylska-Gornowicz, B.; Krawczuk, M. Influence of Electric, Magnetic, and Electromagnetic Fields on the Circadian System: Current Stage of Knowledge. BioMed Res. Int. 2014, 2014, 169459. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fetahović, I.; Pejović, M.; Vujisić, M. Radiation Damage in Electronic Memory Devices. Int. J. Photoenergy 2013, 2013, 170269. [Google Scholar] [CrossRef]

- Tanaka, H. Information Leakage Via Electromagnetic Emanations and Evaluation of Tempest Countermeasures. In Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Berlin/Heidelberg, Germany, 2007; Volume 4812, pp. 167–179. [Google Scholar] [CrossRef]

- Russia Accused of Cyber-Attack on Chemical Weapons Watchdog | Russia | The Guardian. Available online: https://www.theguardian.com/world/2018/oct/04/netherlands-halted-russian-cyber-attack-on-chemical-weapons-body (accessed on 20 August 2021).

- Wanasinghe, D.; Aslani, F.; Ma, G. Electromagnetic shielding properties of carbon fibre reinforced cementitious composites. Constr. Build. Mater. 2020, 260, 120439. [Google Scholar] [CrossRef]

- BAUCIS LK: ČLUZ a.s. Available online: https://www.cluz.cz/en/baucis-lk (accessed on 8 September 2021).

- Panesar, D.K. Supplementary cementing materials. In Developments in the Formulation and Reinforcement of Concrete; Woodhead Publishing: Sawston, UK, 2019; pp. 55–85. [Google Scholar] [CrossRef]

- Luna-Galiano, Y.; Leiva, C.; Arenas, C.; Fernández, C.L. Fly ash based geopolymeric foams using silica fume as pore generation agent. Physical, mechanical and acoustic properties. J. Non-Cryst. Solids 2018, 500, 196–204. [Google Scholar] [CrossRef]

- Shahmansouri, A.A.; Yazdani, M.; Ghanbari, S.; Bengar, H.A.; Jafari, A.; Ghatte, H.F. Artificial neural network model to predict the compressive strength of eco-friendly geopolymer concrete incorporating silica fume and natural zeolite. J. Clean. Prod. 2020, 279, 123697. [Google Scholar] [CrossRef]

- Rill, E.; Lowry, D.R.; Kriven, W.M. Properties of basalt fiber reinforced geopolymer composites. Ceram. Eng. Sci. Proc. 2010, 31, 57–67. [Google Scholar] [CrossRef]

- Korniejenko, K.; Mucsi, G.; Halyag, N.P.; Szabó, R.; Mierzwiński, D.; Louda, P. Mechanical Properties of Basalt Fiber Reinforced Fly Ash-Based Geopolymer Composites. KnE Eng. Vol. 2020, 86–100. [Google Scholar] [CrossRef] [Green Version]

- ČSN EN 1015-11 (722400)—Zkušební Metody malt pro Zdivo-Část 11: Stanovení Pevnosti Zatvrdlých malt v tahu za ohybu a v tlaku-duben 2020—Technické normy—Ing. Jiří Hrazdil. Available online: https://shop.normy.biz/detail/509887 (accessed on 25 November 2021).

- 2,250lbf (10 kN) Instron 4202 Testing Machine Frank Bacon. Available online: https://frankbacon.com/product/2-250lbf-10kn-instron-4202-testing-machine/ (accessed on 22 November 2021).

- ČSN EN 1936 (721143). Available online: https://www.technicke-normy-csn.cz/csn-en-1936-721143-218488.html (accessed on 25 November 2021).

- Cao, V.D.; Pilehvar, S.; Salas-Bringas, C.; Szczotok, A.M.; Bui, T.Q.; Carmona, M.; Rodriguez, J.F.; Kjøniksen, A.-L. Thermal performance and numerical simulation of geopolymer concrete containing different types of thermoregulating materials for passive building applications. Energy Build. 2018, 173, 678–688. [Google Scholar] [CrossRef]

| BGF Sample | Binder | Silica Fume [%] | Basalt Fibers [%] | Fillers [Volume %] | Filler Types | |

|---|---|---|---|---|---|---|

| Metakaolin [%] | Alkaline Activator [%] | |||||

| GP | 100 | 90 | 10 | 1 | - | - |

| GPM | 30 | Microspheres | ||||

| GPL | 30 | Liapor | ||||

| GPP | 30 | Polystyrene | ||||

| Carbon Net Type | Crossways [mm] | Lengthways [mm] | Density [g/cm3] | Tensile Strength Lengthways [N/mm2] | Tensile Strength Crossways [N/mm2] |

|---|---|---|---|---|---|

| HTC 10/15–40 | 10 | 15 | 1.8 | 2551 | 2847 |

| HTC 21/21–40 | 21 | 21 | 1.8 | 2531 | 2841 |

| HTC 34/34–40 | 34 | 34 | 1.8 | 2544 | 2720 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, V.V.; Le, V.S.; Louda, P.; Szczypiński, M.M.; Ercoli, R.; Růžek, V.; Łoś, P.; Prałat, K.; Plaskota, P.; Pacyniak, T.; et al. Low-Density Geopolymer Composites for the Construction Industry. Polymers 2022, 14, 304. https://doi.org/10.3390/polym14020304

Nguyen VV, Le VS, Louda P, Szczypiński MM, Ercoli R, Růžek V, Łoś P, Prałat K, Plaskota P, Pacyniak T, et al. Low-Density Geopolymer Composites for the Construction Industry. Polymers. 2022; 14(2):304. https://doi.org/10.3390/polym14020304

Chicago/Turabian StyleNguyen, Van Vu, Van Su Le, Petr Louda, Michał Marek Szczypiński, Roberto Ercoli, Vojtěch Růžek, Piotr Łoś, Karol Prałat, Przemysław Plaskota, Tadeusz Pacyniak, and et al. 2022. "Low-Density Geopolymer Composites for the Construction Industry" Polymers 14, no. 2: 304. https://doi.org/10.3390/polym14020304