Effect of Cellulose Nanofibers’ Structure and Incorporation Route in Waterborne Polyurethane–Urea Based Nanocomposite Inks

Abstract

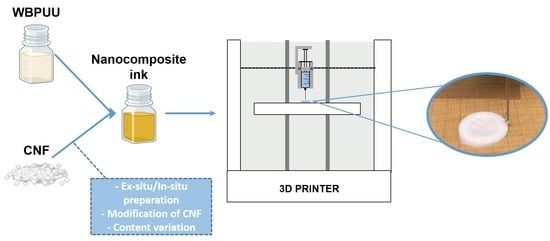

:1. Introduction

2. Materials and Methods

2.1. Synthesis Process and Obtaining of CNF

2.2. Ink Preparation

2.3. Three-Dimensional Printing

2.4. Characterization

Rheological Properties of the Prepared Inks

2.5. Characterization of 3D-Printed Composites

2.5.1. Scanning Electron Microscopy

2.5.2. Differential Scanning Calorimetry

2.5.3. Compression Tests

3. Results and Discussion

3.1. Rheological Characterization of the Inks

3.2. Characterization of the 3D-Printed Parts

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Camargo, J.C.; Machado, Á.R.; Almeida, E.C.; Silva, E.F.M.S. Mechanical properties of PLA-graphene filament for FDM 3D printing. Int. J. Adv. Manuf. Technol. 2019, 103, 2423–2443. [Google Scholar] [CrossRef]

- Lim, C.W.J.; Le, K.Q.; Lu, Q.; Wong, C.H. An overview of 3-D printing in manufacturing, aerospace, and automotive industries. IEEE Potentials 2016, 35, 18–22. [Google Scholar] [CrossRef]

- Al-Dulimi, Z.; Wallis, M.; Tan, D.K.; Maniruzzaman, M.; Nokhodchi, A. 3D printing technology as innovative solutions for biomedical applications. Drug Discov. Today 2020, 26, 360–383. [Google Scholar] [CrossRef]

- Perez-Valle, A.; Del Amo, C.; Andia, I. Overview of current advances in extrusion bioprinting for skin applications. Int. J. Mol. Sci. 2020, 21, 6679. [Google Scholar] [CrossRef]

- Murphy, S.V.; Atala, A. 3D bioprinting of tissues and organs. Nat. Biotechnol. 2014, 32, 773–785. [Google Scholar] [CrossRef] [PubMed]

- Vadillo, J.; Larraza, I.; Calvo-Correas, T.; Gabilondo, N.; Derail, C.; Eceiza, A. Design of a waterborne polyurethane–urea ink for direct ink writing 3D printing. Materials 2021, 14, 3287. [Google Scholar] [CrossRef]

- Calvo-Correas, T.; Martin, M.D.; Retegi, A.; Gabilondo, N.; Corcuera, M.A.; Eceiza, A. Synthesis and characterization of polyurethanes with high renewable carbon content and tailored properties. ACS Sustain. Chem. Eng. 2016, 4, 5684–5692. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Beg, M.D.H.; Ghazali, S.; Islam, M.R.; Jeyaratnam, N.; Yuvaraj, A.R. Polyurethane types, synthesis and applications—A review. RSC Adv. 2016, 6, 114453–114482. [Google Scholar] [CrossRef] [Green Version]

- Honarkar, H. Waterborne polyurethanes: A review. J. Dispers. Sci. Technol. 2018, 39, 507–516. [Google Scholar] [CrossRef]

- Przybytek, A.; Gubańska, I.; Kucińska-Lipka, J.; Janik, H. Polyurethanes as a potential medical-grade filament for use in fused deposition modeling 3D printers—A brief review. Fibres Text. East. Eur. 2018, 26, 120–125. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.P.; Bohn, A. Cellulose: Fascinating biopolymer and sustainable raw material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef] [PubMed]

- Tarabanko, N.; Baryshnikov, S.V.; Kazachenko, A.S.; Miroshnikova, A.V.; Skripnikov, A.M.; Lavrenov, A.V.; Taran, O.P.; Kuznetsov, B.N. Hydrothermal hydrolysis of microcrystalline cellulose from birch wood catalyzed by Al2O3-B2O3 mixed oxides. Wood Sci. Technol. 2022, 56, 437–457. [Google Scholar] [CrossRef]

- Das, T.K.; Remanan, S.; Ghosh, S.; Das, N.C. An environment friendly free-standing cellulose membrane derived for catalytic reduction of 4-nitrophenol: A sustainable approach. J. Environ. Chem. Eng. 2021, 9, 104596. [Google Scholar] [CrossRef]

- Randhawa, A.; Dutta, S.D.; Ganguly, K.; Patil, T.V.; Patel, D.K.; Lim, K.T. A review of properties of nanocellulose, its synthesis, and potential in biomedical applications. Appl. Sci. 2022, 12, 7090. [Google Scholar] [CrossRef]

- Wang, L.; Ando, M.; Kubota, M.; Ishihara, S.; Hikima, Y.; Ohshima, M.; Sekiguchi, T.; Sato, A.; Yano, H. Effects of hydrophobic-modified cellulose nanofibers (CNFs) on cell morphology and mechanical properties of high void fraction polypropylene nanocomposite foams. Compos. Part A Appl. Sci. Manuf. 2017, 98, 166–173. [Google Scholar] [CrossRef]

- Vadillo, J.; Larraza, I.; Calvo-Correas, T.; Gabilondo, N.; Derail, C.; Eceiza, A. Role of in situ added cellulose nanocrystals as rheological modulator of novel waterborne polyurethane urea for 3D-printing technology. Cellulose 2021, 28, 4729–4744. [Google Scholar] [CrossRef]

- Vadillo, J.; Larraza, I.; Calvo-correas, T.; Gabilondo, N. Bioactive inks suitable for 3D printing based on waterborne polyurethane urea, cellulose nanocrystals and Salvia extract. React. Funct. Polym. 2022, 175, 105286. [Google Scholar] [CrossRef]

- Markstedt, K.; Mantas, A.; Tournier, I.; Martínez Ávila, H.; Hägg, D.; Gatenholm, P. 3D bioprinting human chondrocytes with nanocellulose-alginate bioink for cartilage tissue engineering applications. Biomacromolecules 2015, 16, 1489–1496. [Google Scholar] [CrossRef]

- Olmos-Juste, R.; Guaresti, O.; Calvo-Correas, T.; Gabilondo, N.; Eceiza, A. Design of drug-loaded 3D printing biomaterial inks and tailor-made pharmaceutical forms for controlled release. Int. J. Pharm. 2021, 609, 121124. [Google Scholar] [CrossRef]

- Moon, R.J.; Schueneman, G.T.; Simonsen, J. Overview of cellulose nanomaterials, their capabilities and applications. JOM 2016, 68, 2383–2394. [Google Scholar] [CrossRef]

- Žepič, V.; Poljanšek, I.; Oven, P.; Čop, M. COST-FP1105: Properties of PLA films reinforced with unmodified and acetylated freeze dried nanofibrillated cellulose. Holzforschung 2016, 70, 1125–1134. [Google Scholar] [CrossRef]

- Larraza, I.; Vadillo, J.; Santamaria-Echart, A.; Tejado, A.; Azpeitia, M.; Vesga, E.; Orue, A.; Saralegi, A.; Arbelaiz, A.; Eceiza, A. The effect of the carboxylation degree on cellulose nanofibers and waterborne polyurethane/cellulose nanofiber nanocomposites properties. Polym. Degrad. Stab. 2020, 173, 109084. [Google Scholar] [CrossRef]

- Larraza, I.; Vadillo, J.; Calvo-Correas, T.; Tejado, A.; Olza, S.; Peña-Rodríguez, C.; Arbelaiz, A.; Eceiza, A. Cellulose and graphene based polyurethane nanocomposites for fdm 3d printing: Filament properties and printability. Polymers 2021, 13, 839. [Google Scholar] [CrossRef] [PubMed]

- Tejado, A.; Alam, M.N.; Antal, M.; Yang, H.; van de Ven, T.G.M. Energy requirements for the disintegration of cellulose fibers into cellulose nanofibers. Cellulose 2012, 19, 831–842. [Google Scholar] [CrossRef]

- Cyriac, F.; Lugt, P.M.; Bosman, R. On a new method to determine the yield stress in lubricating grease. Tribology Transactions 2015, 58, 1021–1030. [Google Scholar] [CrossRef] [Green Version]

- Calafel, I.; Aguirresarobe, R.H.; Peñas, M.I.; Santamaria, A.; Tierno, M.; Conde, J.I.; Pascual, B. Searching for rheological conditions for FFF 3D printing with PVC based flexible compounds. Materials 2020, 13, 178. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Liu, S.; Li, L. Rheological study on 3D printability of alginate hydrogel and effect of graphene oxide. Int. J. Bioprinting 2016, 2, 54–66. [Google Scholar] [CrossRef]

- Costakis, W.J.; Rueschhoff, L.M.; Diaz-Cano, A.I.; Youngblood, J.P.; Trice, R.W. Additive manufacturing of boron carbide via continuous filament direct ink writing of aqueous ceramic suspensions. J. Eur. Ceram. Soc. 2016, 36, 3249–3256. [Google Scholar] [CrossRef]

- Lewis, J.A.; Smay, J.E.; Stuecker, J.; Cesarano, J. Direct ink writing of three-dimensional ceramic structures. J. Am. Ceram. Soc. 2006, 89, 3599–3609. [Google Scholar] [CrossRef]

- Jiang, J.; Oguzlu, H.; Jiang, F. 3D printing of lightweight, super-strong yet flexible all-cellulose structure. Chem. Eng. J. 2021, 405, 126668. [Google Scholar] [CrossRef]

- Ma, T.; Lv, L.; Ouyang, C.; Hu, X.; Liao, X.; Song, Y.; Hu, X. Rheological behavior and particle alignment of cellulose nanocrystal and its composite hydrogels during 3D printing. Carbohydr. Polym. 2021, 253, 117217. [Google Scholar] [CrossRef] [PubMed]

- Hoeng, F.; Denneulin, A.; Bras, J. Use of nanocellulose in printed electronics: A review. Nanoscale 2016, 8, 13131–13154. [Google Scholar] [CrossRef] [PubMed]

- Rastin, H.; Ormsby, R.T.; Atkins, G.J.; Losic, D. 3D bioprinting of methylcellulose/gelatin-methacryloyl (MC/GelMA) bioink with high shape integrity. ACS Appl. Bio Mater. 2020, 3, 1815–1826. [Google Scholar] [CrossRef] [PubMed]

- Sahlin, K.; Forsgren, L.; Moberg, T.; Bernin, D.; Rigdahl, M.; Westman, G. Surface treatment of cellulose nanocrystals (CNC): Effects on dispersion rheology. Cellulose 2018, 25, 331–345. [Google Scholar] [CrossRef] [Green Version]

- Karppinen, A.; Vesterinen, A.H.; Saarinen, T.; Pietikäinen, P.; Seppälä, J. Effect of cationic polymethacrylates on the rheology and flocculation of microfibrillated cellulose. Cellulose 2011, 18, 1381–1390. [Google Scholar] [CrossRef] [Green Version]

- Pääkko, M.; Ankerfors, M.; Kosonen, H.; Nykänen, A.; Ahola, S.; Österberg, M.; Ruokolainen, J.; Laine, J.; Larsson, P.T.; Ikkala, O.; et al. Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 2007, 8, 1934–1941. [Google Scholar] [CrossRef]

- Moberg, T.; Sahlin, K.; Yao, K.; Geng, S.; Westman, G.; Zhou, Q.; Oksman, K.; Rigdahl, M. Rheological properties of nanocellulose suspensions: Effects of fibril/particle dimensions and surface characteristics. Cellulose 2017, 24, 2499–2510. [Google Scholar] [CrossRef]

- Kayra, N.; Aytekin, A.Ö. Synthesis of Cellulose-Based Hydrogels: Preparation, Formation, Mixture, and Modification. Cellulose-Based Superabsorbent Hydrogels. Polymers and Polymeric Composites: A Reference Series; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Chen, R.D.; Huang, C.F.; Hsu, S.H. Composites of waterborne polyurethane and cellulose nanofibers for 3D printing and bioapplications. Carbohydr. Polym. 2019, 212, 75–88. [Google Scholar] [CrossRef]

- Santamaria-Echart, A.; Ugarte, L.; Gonzalez, K.; Martin, L.; Irusta, L.; Gonzalez, A.; Corcuera, M.A.; Eceiza, A. The role of cellulose nanocrystals incorporation route in waterborne polyurethane for preparation of electrospun nanocomposites mats. Carbohydr. Polym. 2017, 166, 146–155. [Google Scholar] [CrossRef]

- Sonnenschein, M.F. Polyurethanes. Science, Technology, Markets, and Trends, 1st ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2015. [Google Scholar]

- Zhang, X.; Huo, W.; Liu, J.; Zhang, Y.; Zhang, S.; Yang, J. 3D printing boehmite gel foams into lightweight porous ceramics with hierarchical pore structure. J. Eur. Ceram. Soc. 2020, 40, 930–934. [Google Scholar] [CrossRef]

- Peak, C.W.; Stein, J.; Gold, K.A.; Gaharwar, A.K. Nanoengineered colloidal inks for 3D bioprinting. Langmuir 2018, 34, 917–925. [Google Scholar] [CrossRef]

- González, K.; Larraza, I.; Berra, G.; Eceiza, A.; Gabilondo, N. 3D printing of customized all-starch tablets with combined release kinetics. Int. J. Pharm. 2022, 622, 121872. [Google Scholar] [CrossRef] [PubMed]

- Olmos-Juste, R.; Alonso-Lerma, B.; Pérez-Jiménez, R.; Gabilondo, N.; Eceiza, A. 3D printed alginate-cellulose nanofibers based patches for local curcumin administration. Carbohydr. Polym. 2021, 264, 118026. [Google Scholar] [CrossRef] [PubMed]

- Dash, R.; Foston, M.; Ragauskas, A.J. Improving the mechanical and thermal properties of gelatin hydrogels cross-linked by cellulose nanowhiskers. Carbohydr. Polym. 2013, 91, 638–645. [Google Scholar] [CrossRef] [PubMed]

- Tarashi, S.; Nazockdast, H.; Sodeifian, G. Reinforcing effect of graphene oxide on mechanical properties, self-healing performance and recoverability of double network hydrogel based on κ-carrageenan and polyacrylamide. Polymer 2019, 183, 121837. [Google Scholar] [CrossRef]

- Siqueira, G.; Kokkinis, D.; Libanori, R.; Hausmann, M.K.; Gladman, A.S.; Neels, A.; Tingaut, P.; Zimmermann, T.; Lewis, J.A.; Studart, A.R. Cellulose nanocrystal inks for 3D printing of textured cellular architectures. Adv. Funct. Mater. 2017, 27, 1604619. [Google Scholar] [CrossRef]

- Lim, K.S.; Schon, B.S.; Mekhileri, N.V.; Brown, G.C.J.; Chia, C.M.; Prabakar, S.; Hooper, G.J.; Woodfield, T.B.F. New visible-light photoinitiating system for improved print fidelity in gelatin-based bioinks. ACS Biomater. Sci. Eng. 2016, 2, 1752–1762. [Google Scholar] [CrossRef]

- Baino, F.; Fiume, E. 3D printing of hierarchical scaffolds based on mesoporous bioactive glasses (MBGs)-fundamentals and applications. Materials 2020, 13, 1688. [Google Scholar] [CrossRef] [Green Version]

- Ashby, M.F. The properties of foams and lattices. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 364, 15–30. [Google Scholar] [CrossRef]

- Ribeiro Da Silva, V.; Mosiewicki, M.A.; Yoshida, M.I.; Coelho Da Silva, M.; Stefani, P.M.; Marcovich, N.E. Polyurethane foams based on modified tung oil and reinforced with rice husk ash I: Synthesis and physical chemical characterization. Polym. Test. 2013, 32, 438–445. [Google Scholar] [CrossRef]

| Sample | Preparation Method | Modification of CNF | Content of CNF (wt. %) | Content of PUU (wt. %) |

|---|---|---|---|---|

| 2CNF0EX | ex situ | Untreated | 2 | 33.9 |

| 3CNF0EX | ex situ | Untreated | 3 | 33.6 |

| 2CNF1EX | ex situ | Carboxylated | 2 | 33.9 |

| 3CNF1EX | ex situ | Carboxylated | 3 | 33.6 |

| 2CNFrIN | in situ | Unknown | 2 | 33.9 |

| 3CNFrIN | in situ | Unknown | 3 | 33.6 |

| 3CNF0IN | in situ | Untreated | 3 | 33.6 |

| 3CNF1IN | in situ | Carboxylated | 3 | 33.6 |

| Sample | η at 0.2 s−1 (Pa·s) | η at 100 s−1 (Pa·s) | n | ||

|---|---|---|---|---|---|

| WBPUU | 1.1 | 0.1 | 0.1 | 0.725 | |

| ex situ | 2CNF0EX | 217.9 | 18.5 | 1.5 | 0.198 |

| 3CNF0EX | 434.8 | 18.7 | 1.9 | 0.189 | |

| 2CNF1EX | 289.2 | 13.4 | 1.9 | 0.204 | |

| 3CNF1EX | 730.6 | 44.5 | 2.7 | 0.111 | |

| in situ | 2CNFrIN | 6.2 | 0.9 | 0.1 | 0.361 |

| 3CNFrIN | 222.9 | 9.2 | 1.0 | 0.184 | |

| 3CNF0IN | 256.0 | 14.0 | 2.0 | 0.254 | |

| 3CNF1IN | 348.2 | 19.9 | 2.3 | 0.204 |

| Sample | Yield Point (MPa) | Flow Point (MPa) | Structural Recovery (%) | |

|---|---|---|---|---|

| WBPUU | - | - | - | |

| ex situ | 2CNF0EX | 16.5 | 89.4 | 78 ± 4 |

| 3CNF0EX | 23.6 | 140.0 | 80 ± 9 | |

| 2CNF1EX | 15.3 | 59.2 | 75 ± 9 | |

| 3CNF1EX | 26.6 | 225.6 | 79 ± 3 | |

| in situ | 2CNFrIN | - | - | - |

| 3CNFrIN | 14.5 | 40.1 | 62 ± 2 | |

| 3CNF0IN | 14.7 | 61.6 | 67 ± 7 | |

| 3CNF1IN | 16.5 | 105.1 | 72 ± 9 |

| Sample | Tg (°C) | THS (°C) | ΔHHS (J·g−1) | |

|---|---|---|---|---|

| WBPUU | −49.1 | 74.7 | 9.0 | |

| ex situ | 3D-2CNF0EX | −49.7 | 78.0 | 12.4 |

| 3D-3CNF0EX | −49.0 | 82.0 | 15.5 | |

| 3D-2CNF1EX | −47.7 | 86.5 | 13.9 | |

| 3D-3CNF1EX | −48.3 | 81.9 | 16.0 | |

| in situ | 3D-3CNFrIN | −50.1 | 77.7 | 15.1 |

| 3D-3CNF0IN | −50.4 | 78.7 | 16.9 | |

| 3D-3CNF1IN | −48.4 | 78.0 | 17.6 |

| Sample | Density (g·cm−3) | Specific Young Modulus (MPa·cm3·g−1) | Stress at 60% Strain (MPa) | Densification Strain (MPa) | |

|---|---|---|---|---|---|

| ex situ | 3D-2CNF0EX | 0.36 ± 0.02 | 35.0 ± 6.0 | 2.8 ± 0.8 | 50.3 ± 0.3 |

| 3D-3CNF0EX | 0.36 ± 0.05 | 31.3 ± 3.1 | 2.1 ± 0.1 | 50.6 ± 0.5 | |

| 3D-2CNF1EX | 0.34± 0.03 | 39.1 ± 8.1 | 2.5 ± 0.3 | 51.1 ± 0.5 | |

| 3D-3CNF1EX | 0.35 ± 0.04 | 41.5 ± 4.0 | 2.5 ± 0.3 | 51.6 ± 0.6 | |

| in situ | 3D-3CNFrIN | 0.33 ± 0.02 | 42.5 ± 1.0 | 2.4 ± 0.3 | 51.3 ± 0.9 |

| 3D-3CNF0IN | 0.37 ± 0.02 | 56.8 ± 11.0 | 3.4 ±0.5 | 51.4 ±0.6 | |

| 3D-3CNF1IN | 0.35 ± 0.02 | 59.5 ± 14.9 | 3.3 ± 0.6 | 52.0 ± 1.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Larraza, I.; Vadillo, J.; Calvo-Correas, T.; Tejado, A.; Martin, L.; Arbelaiz, A.; Eceiza, A. Effect of Cellulose Nanofibers’ Structure and Incorporation Route in Waterborne Polyurethane–Urea Based Nanocomposite Inks. Polymers 2022, 14, 4516. https://doi.org/10.3390/polym14214516

Larraza I, Vadillo J, Calvo-Correas T, Tejado A, Martin L, Arbelaiz A, Eceiza A. Effect of Cellulose Nanofibers’ Structure and Incorporation Route in Waterborne Polyurethane–Urea Based Nanocomposite Inks. Polymers. 2022; 14(21):4516. https://doi.org/10.3390/polym14214516

Chicago/Turabian StyleLarraza, Izaskun, Julen Vadillo, Tamara Calvo-Correas, Alvaro Tejado, Loli Martin, Aitor Arbelaiz, and Arantxa Eceiza. 2022. "Effect of Cellulose Nanofibers’ Structure and Incorporation Route in Waterborne Polyurethane–Urea Based Nanocomposite Inks" Polymers 14, no. 21: 4516. https://doi.org/10.3390/polym14214516