Design and Analysis of CFRP Drilling by Electrical Discharge Machining

Abstract

:1. Introduction

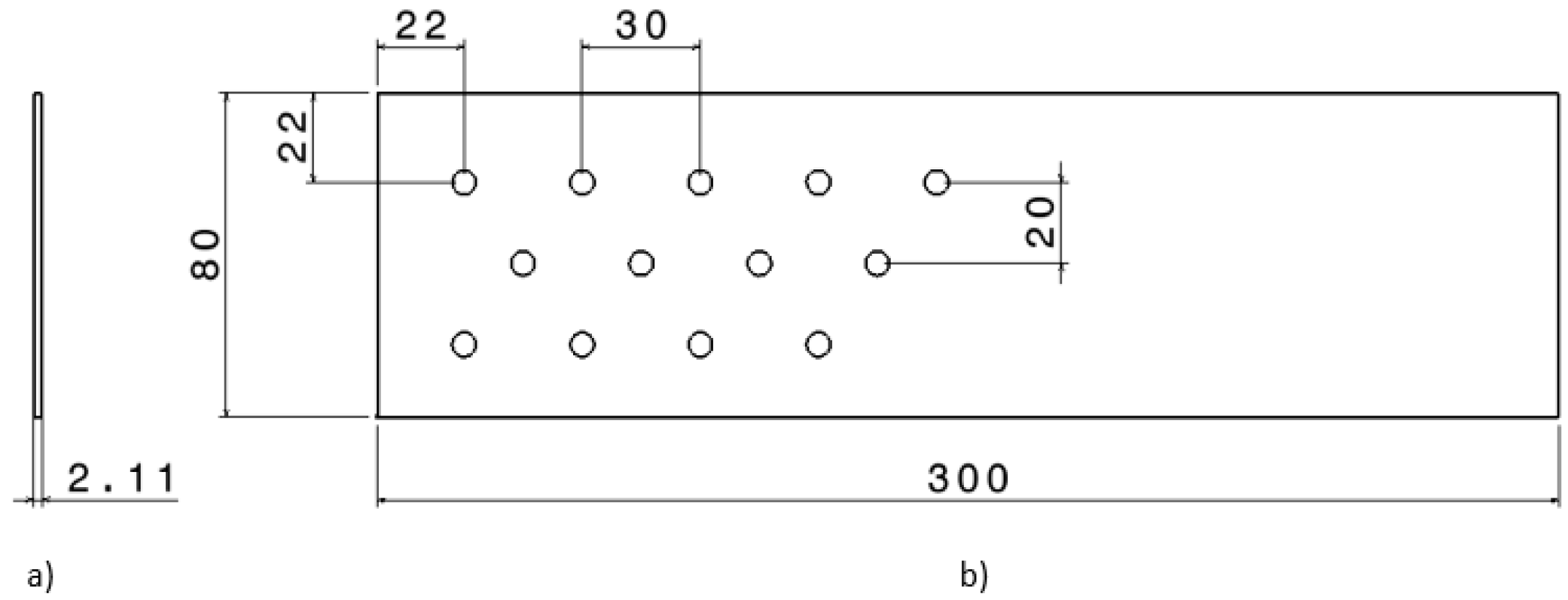

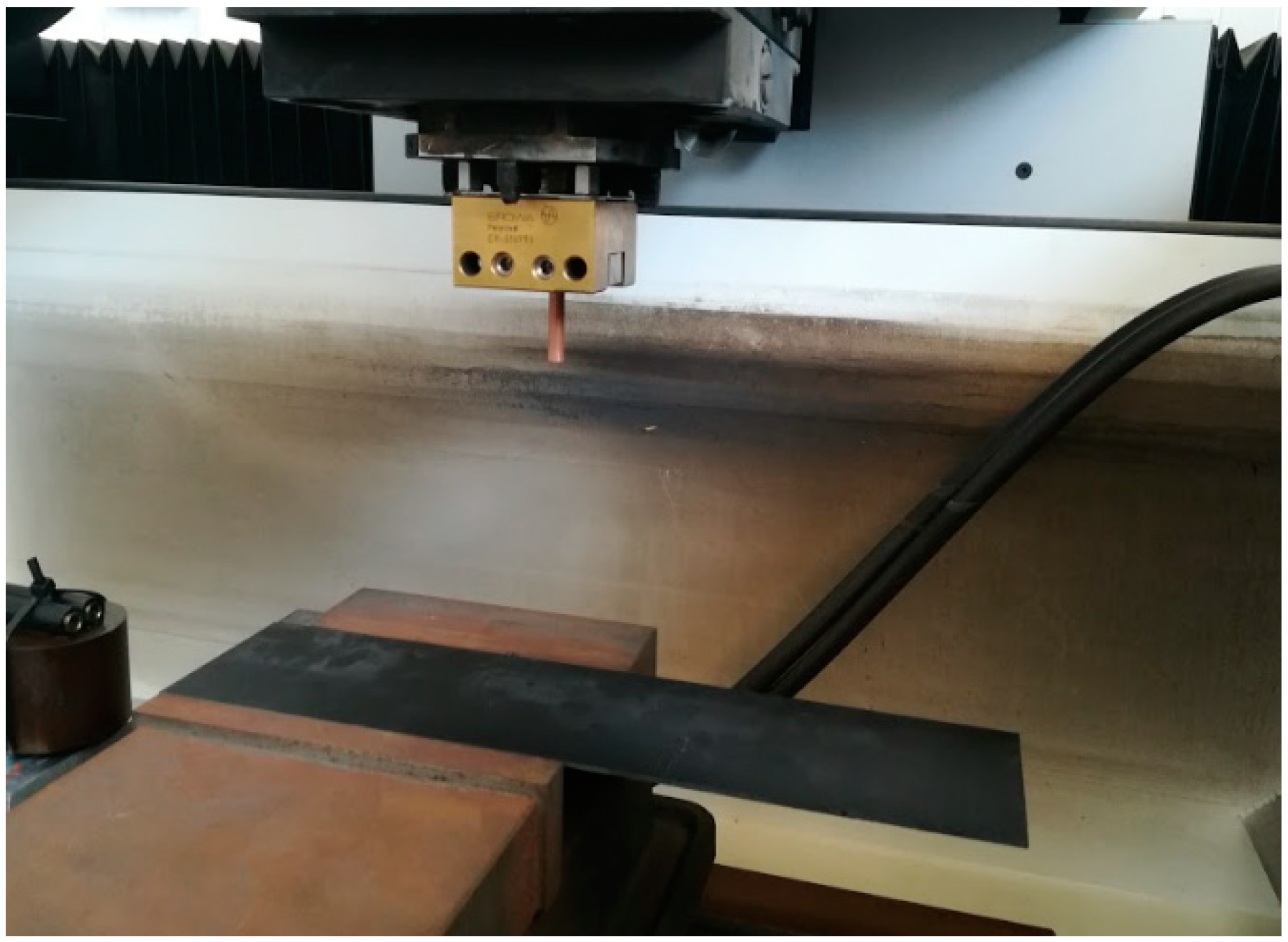

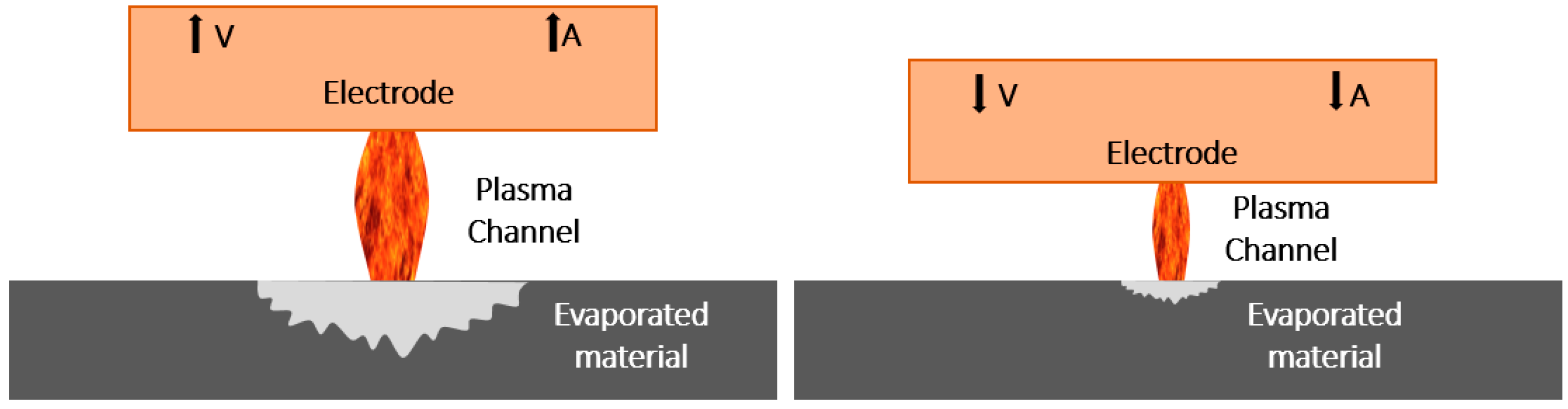

2. Materials and Methods

3. Results

3.1. Surface Quality

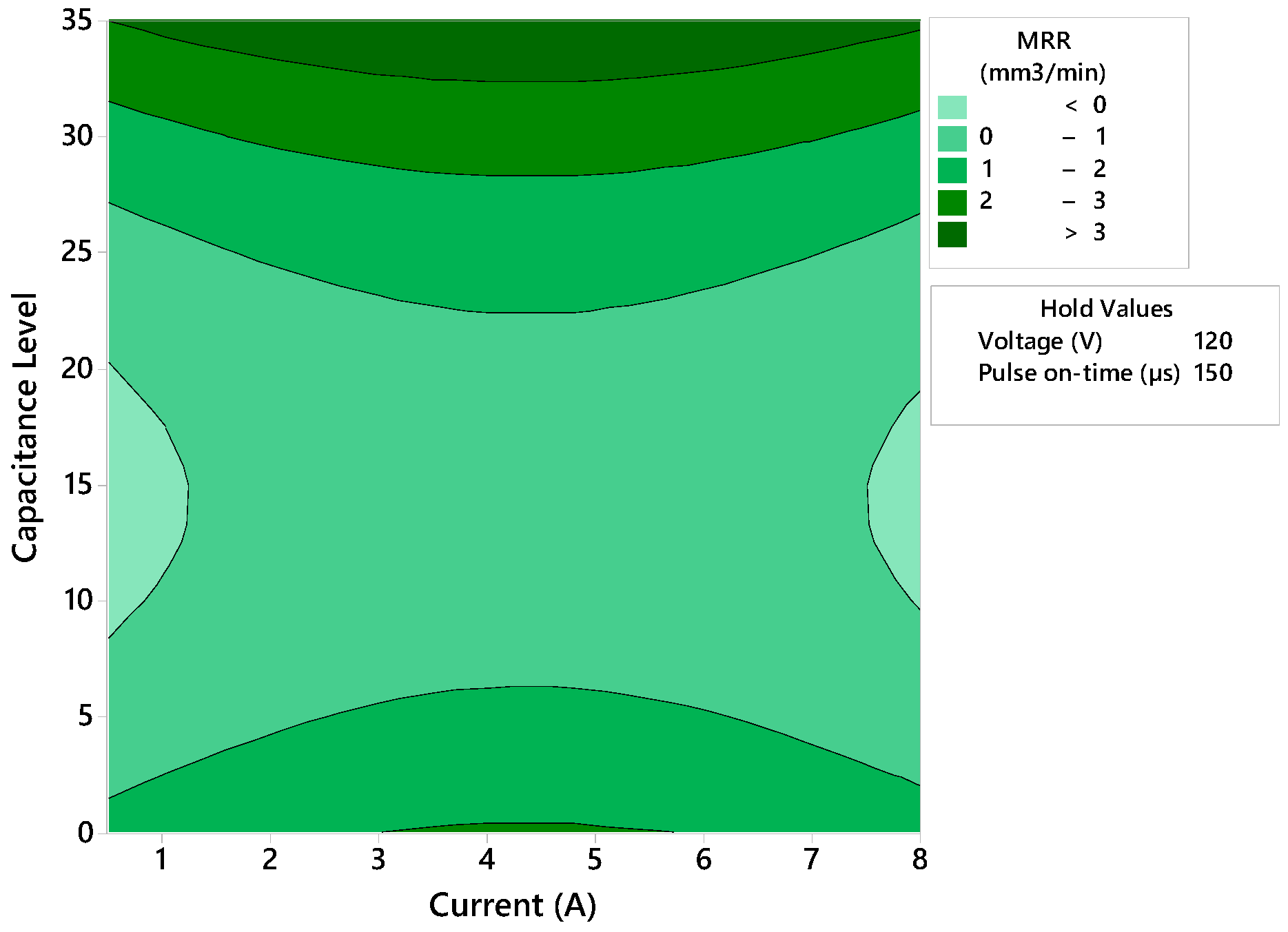

3.2. Material Remove Rate

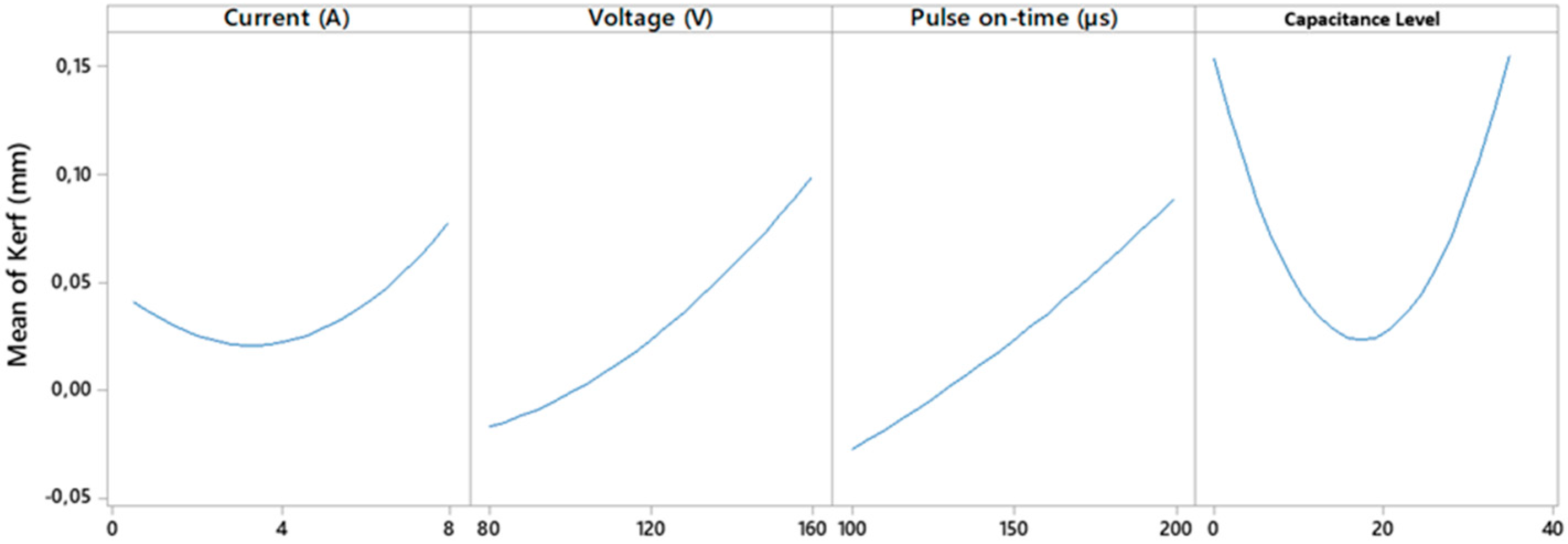

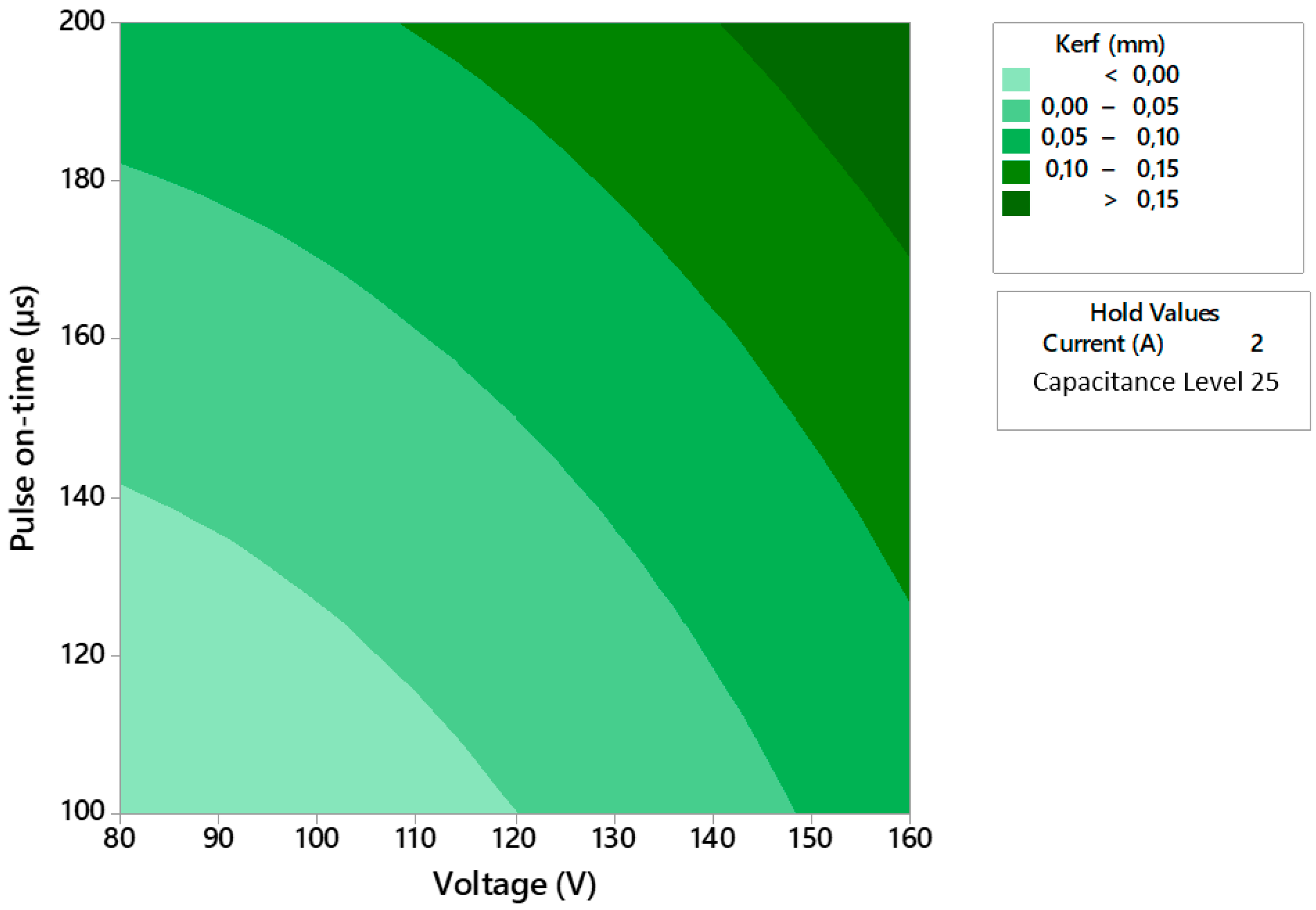

3.3. Kerf

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Hegde, S.; Satish Shenoy, B.; Chethan, K.N. Review on carbon fiber reinforced polymer (CFRP) and their mechanical performance. Mater. Today Proc. 2019, 19, 658–662. [Google Scholar] [CrossRef]

- Caggiano, A.; Napolitano, F.; Nele, L.; Teti, R. Study on thrust force and torque sensor signals in drilling of Al/CFRP stacks for aeronautical applications. Procedia CIRP 2019, 79, 337–342. [Google Scholar] [CrossRef]

- Seong Jang, T.; Soo Oh, D.; Kyu Kim, J.; In Kang, K.; Ho Cha, W.; Woo Rhee, S. Development of multi-functional composite structures with embedded electronics for space application. Acta Astronaut. 2011, 68, 240–252. [Google Scholar] [CrossRef]

- Forcellese, A.; Marconi, M.; Simoncini, M.; Vita, A. Life cycle impact assessment of different manufacturing technologies for automotive CFRP components. J. Clean. Prod. 2020, 271, 122677. [Google Scholar] [CrossRef]

- Merino-Pérez, J.L.; Royer, R.; Ayvar-Soberanis, S.; Merson, E.; Hodzic, A. On the temperatures developed in CFRP drilling using uncoated wc-co tools part I: Workpiece constituents, cutting speed and heat dissipation. Compos. Struct. 2015, 123, 161–168. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Lin, T.; Davim, J.P.; Chen, M.; El Mansori, M. Wear behavior of special tools in the drilling of CFRP composite laminates. Wear 2021, 476, 203738. [Google Scholar] [CrossRef]

- Ramirez, C.; Poulachon, G.; Rossi, F.; M’Saoubi, R. Tool wear monitoring and hole surface quality during CFRP drilling. Procedia CIRP 2014, 13, 163–168. [Google Scholar] [CrossRef] [Green Version]

- Samuel Raj, D.; Karunamoorthy, L. Performance of cryogenically treated WC drill using tool wear measurements on the cutting edge and hole surface topography when drilling CFRP. Int. J. Refract. Met. Hard Mater. 2019, 78, 32–44. [Google Scholar] [CrossRef]

- Fernandez-Vidal, S.; Fernandez-Vidal, S.; Batista, M.; Salguero, J. Tool Wear Mechanism in Cutting of Stack CFRP/UNS A97075. Materials 2018, 11, 1276. [Google Scholar] [CrossRef] [Green Version]

- Bañon, F.; Sambruno, A.; Fernandez-Vidal, S.; Fernandez-Vidal, S.R. One-shot drilling analysis of stack CFRP/UNS A92024 bonding by adhesive. Materials 2019, 12, 160. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Han, L.; Liu, H.; Li, K.; Ma, Y. Effect of cryogenic conditions on the drilling performance of carbon-carbon (c-c) composites. In Proceedings of the 12th International Manufacturing Science and Engineering Conference Collocated with the JSME/ASME 2017 6th International Conference on Materials and Processing, Los Angeles, CA, USA, 4–8 June 2017; pp. 1–6. [Google Scholar]

- Kang, S.-G.; Kim, M.-G.; Kim, C.-G. Evaluation of cryogenic performance of adhesives using composite–aluminum double-lap joints. Compos. Struct. 2007, 78, 440–446. [Google Scholar] [CrossRef]

- Shokrani, A.; Dhokia, V.; Muñoz-Escalona, P.; Newman, S.T. State-of-the-art cryogenic machining and processing. Int. J. Comput. Integr. Manuf. 2013, 26, 616–648. [Google Scholar] [CrossRef] [Green Version]

- Youssef, H.A.; El-Hofy, H.A.; Abdelaziz, A.M.; El-Hofy, M.H. Accuracy and surface quality of abrasive waterjet machined CFRP composites. J. Compos. Mater. 2020, 55, 1693–1703. [Google Scholar] [CrossRef]

- Bañon, F.; Sambruno, A.; Batista, M.; Simonet, B.; Salguero, J. Study of the surface quality of carbon fiber–reinforced thermoplastic matrix composite (CFRTP) machined by abrasive water jet (AWJM). Int. J. Adv. Manuf. Technol. 2020, 107, 3299–3313. [Google Scholar] [CrossRef]

- Niino, H.; Kawaguchi, Y.; Sato, T.; Narazaki, A.; Kurosaki, R.; Muramatsu, M.; Harada, Y.; Wakabayashi, K.; Nagashima, T.; Kase, Z.; et al. Laser cutting of carbon fiber reinforced plastics (CFRP) by fiber laser irradiation. In Proceedings of the 2013 Conference on Lasers and Electro-Optics/Pacific Rim, Kyoto, Japan, 30 June–4 July 2013. [Google Scholar]

- Siva Prasad, K.; Chaitanya, G. Optimization of process parameters on surface roughness during drilling of GFRP composites using taguchi technique. Mater. Today Proc. 2021, 39, 1553–1558. [Google Scholar] [CrossRef]

- Senthil Kannan, V.; Lenin, K.; Ellavarasan, M.; Gunaseelan, J. Investigation of parameters for machining microholes in AWJM process. Mater. Today Proc. 2020, 39, 428–433. [Google Scholar] [CrossRef]

- Mayuet Ares, P.F.; Girot Mata, F.; Batista Ponce, M.; Salguero Gómez, J. Defect Analysis and Detection of Cutting Regions in CFRP Machining Using AWJM. Materials 2019, 12, 4055. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Gan, G.; Zhang, Y.; Yang, X. Thermal damage of CFRP laminate in fiber laser cutting process and its impact on the mechanical behavior and strain distribution. Arch. Civ. Mech. Eng. 2019, 19, 1511–1522. [Google Scholar] [CrossRef]

- Muthuramalingam, T.; Mohan, B. A review on influence of electrical process parameters in EDM process. Arch. Civ. Mech. Eng. 2015, 15, 87–94. [Google Scholar] [CrossRef]

- Ho, K.H.; Newman, S.T. State of the art electrical discharge machining (EDM). Int. J. Mach. Tools Manuf. 2003, 43, 1287–1300. [Google Scholar] [CrossRef]

- Sapkal, S.U.; Jagtap, P.S. Optimization of Micro EDM Drilling Process Parameters for Titanium Alloy by Rotating Electrode. Procedia Manuf. 2018, 20, 119–126. [Google Scholar] [CrossRef]

- Risto, M.; Haas, R.; Munz, M. Optimization of the EDM Drilling Process to Increase the Productivity and Geometrical Accuracy. Procedia CIRP 2016, 42, 537–542. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, A.; Singh, I. Electric discharge drilling of micro holes in CFRP laminates. J. Mater. Process. Technol. 2018, 259, 150–158. [Google Scholar] [CrossRef]

- Kumaran, V.U.; Kliuev, M.; Billeter, R.; Wegener, K. Influence of Carbon based Fillers on EDM Machinability of CFRP. Procedia CIRP 2020, 95, 437–442. [Google Scholar] [CrossRef]

- Akematsu, Y.; Kageyama, K.; Murayama, H. Basic Characteristics of Electrical Discharge on CFRP by Using Thermal Camera. Procedia CIRP 2016, 42, 197–200. [Google Scholar] [CrossRef]

- Lodhi, B.K.; Verma, D.; Shukla, R. Optimization of Machining Parameters in EDM of CFRP Composite Using Taguchi Technique. Int. J. Mech. Eng. Technol. 2014, 5, 70–77. [Google Scholar]

- Dutta, H.; Debnath, K.; Sarma, D.K. Multi-objective optimization of hole dilation at inlet and outlet during machining of CFRP by μEDM using assisting-electrode and rotating tool. Int. J. Adv. Manuf. Technol. 2020, 110, 2305–2322. [Google Scholar] [CrossRef]

- Mazarbhuiya, R.M.; Dutta, H.; Debnath, K.; Rahang, M. Surface modification of CFRP composite using reverse-EDM method. Surf. Interfaces 2020, 18, 100457. [Google Scholar] [CrossRef]

- Sheikh-Ahmad, J.; Shinde, S.R. Machinability of Carbon/Epoxy Composites by Electrical Discharge Machining. Int. J. Mach. Mach. Mater. 2016, 18, 3–17. [Google Scholar]

- Yue, X.; Yang, X.; Tian, J.; He, Z.; Fan, Y. Thermal, mechanical and chemical material removal mechanism of carbon fiber reinforced polymers in electrical discharge machining. Int. J. Mach. Tools Manuf. 2018, 133, 4–17. [Google Scholar] [CrossRef]

- Kumar, R.; Agrawal, P.K.; Singh, I. Fabrication of micro holes in CFRP laminates using EDM. J. Manuf. Process. 2018, 31, 859–866. [Google Scholar] [CrossRef]

- Dutta, H.; Debnath, K.; Sarma, D.K. Improving the performance of μeD-milling using assisting electrode for fabricating micro-channels in CFRP composites. Mater. Today Proc. 2019, 28, 755–760. [Google Scholar] [CrossRef]

- Dewangan, S.; Deepak Kumar, S.; Kumar Jha, S.; Kumar Biswas, C. Optimization of Micro-EDM drilling parameters of Ti–6Al–4V alloy. Mater. Today Proc. 2020, 33, 5481–5485. [Google Scholar] [CrossRef]

- Guu, Y.H.; Hocheng, H.; Tai, N.H.; Liu, S.Y. Effect of electrical discharge machining on the characteristics of carbon fiber reinforced carbon composites. J. Mater. Sci. 2001, 36, 2037–2043. [Google Scholar] [CrossRef]

- Rao, P.S.; Ramji, K.; Satyanarayana, B. Experimental Investigation and Optimization of Wire EDM Parameters for Surface Roughness, MRR and White Layer in Machining of Aluminium Alloy. Procedia Mater. Sci. 2014, 5, 2197–2206. [Google Scholar] [CrossRef]

- Sheikh-Ahmad, J.Y. Hole Quality and Damage in Drilling Carbon/Epoxy Composites by Electrical Discharge Machining. Mater. Manuf. Process. 2016, 31, 941–950. [Google Scholar] [CrossRef]

- Abdallah, R.; Soo, S.L.; Hood, R. A feasibility study on wire electrical discharge machining of carbon fibre reinforced plastic composites. Procedia CIRP 2018, 77, 195–198. [Google Scholar] [CrossRef]

| Ref. | Voltage (V) | Amperage (A) | Pulse Time (µs) | Tool Speed (rpm) | Capacitance (µF) | Electrode |

|---|---|---|---|---|---|---|

| [28] | 50–70 | 2–6 | 70–90 | - | - | Cu |

| [29] | 100–190 | - | 10–40 | 200–500 | - | Cu |

| [30] | 45 | 2–8 | 600 | - | - | Cu, W |

| [25] | 80–120 | - | - | 1000–2000 | 33–1000 | W |

| [31] | 65 | 0.4–2 | 20–190 | - | - | Cu, C |

| [27] | 200–500 | - | - | - | 1–100 | Cu |

| [32] | 80–110 | 5–15 | 0.6–20 | - | Cu | |

| [33] | 80–100 | - | - | 1000–2000 | 0–100 | W |

| Properties | Copper | Epoxy Matrix Carbon Fibre | |

|---|---|---|---|

| Graphite | Epoxy | ||

| Density (g/cm3) | 8.9–8.94 | 1.63–1.67 | 1.11–1.40 |

| Electrical resistivity (μΩ × cm) | 1.4–5.01 | 158–501 | 1022 |

| Melting point (°C) | 982–1080 | 3.53 × 103–3.68 × 103 | 66.9–167 |

| Specific heat capacity (J/kg × °C) | 372–388 | 852–941 | 4.08 × 105–5.5 × 105 |

| Level | Current (A) | Voltage (V) | Impulse Time (μs) | Capacitance Level |

|---|---|---|---|---|

| 1 | 0.5 | 80 | 100 | 0 |

| 2 | 1 | 120 | 150 | 25 |

| 3 | 8 | 160 | 200 | 35 |

| Factor | Value |

|---|---|

| Pause time (μs) | 50 |

| Working time (s) | 0.75 |

| Reverse time (s) | 0.25 |

| Servo (V) | 45 |

| Electrode polarity | Positive |

| Security level | 3 |

| Criteria | Minimal wear |

| Trials | Current (A) | Voltage (V) | Impulse Time (μs) | Capacitance Level |

|---|---|---|---|---|

| 1 | 0.5 | 80 | 100 | 0 |

| 2 | 0.5 | 120 | 150 | 25 |

| 3 | 0.5 | 160 | 200 | 35 |

| 4 | 1 | 80 | 150 | 35 |

| 5 | 1 | 120 | 200 | 0 |

| 6 | 1 | 160 | 100 | 25 |

| 7 | 8 | 80 | 200 | 25 |

| 8 | 8 | 120 | 100 | 35 |

| 9 | 8 | 160 | 150 | 0 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 8 | 18.6421 | 2.33027 | 153.14 | 0 |

| Current (A) | 1 | 3.1955 | 3.19553 | 210 | 0 |

| Voltage (V) | 1 | 5.4271 | 5.42707 | 356.65 | 0 |

| Impulse time (µs) | 1 | 0.7927 | 0.79269 | 52.09 | 0.002 |

| Capacitance level | 1 | 1.1567 | 1.15669 | 76.01 | 0.001 |

| Error | 4 | 0.0609 | 0.01522 | ||

| Total | 12 | 18.703 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 8 | 11.1388 | 1.39235 | 35.02 | 0.002 |

| Current (A) | 1 | 2.0815 | 2.08149 | 52.36 | 0.002 |

| Voltage (V) | 1 | 0.085 | 0.08501 | 2.14 | 0.217 |

| Impulse time (µs) | 1 | 0.0013 | 0.00126 | 0.03 | 0.867 |

| Capacitance level | 1 | 1.9264 | 1.92643 | 48.46 | 0.002 |

| Error | 4 | 0.159 | 0.03975 | ||

| Total | 12 | 11.2978 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 8 | 21.3109 | 2.66386 | 6.3 | 0.047 |

| Current (A) | 1 | 0.0201 | 0.02012 | 0.05 | 0.838 |

| Voltage (V) | 1 | 0.0597 | 0.05967 | 0.14 | 0.726 |

| Impulse time (µs) | 1 | 0.0346 | 0.03458 | 0.08 | 0.789 |

| Capacitance level | 1 | 5.6093 | 5.60926 | 13.26 | 0.022 |

| Error | 4 | 1.6918 | 0.42296 | ||

| Total | 12 | 23.0027 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 8 | 0.108133 | 0.013517 | 14.87 | 0.010 |

| Current (A) | 1 | 0.002580 | 0.002580 | 2.84 | 0.167 |

| Voltage (V) | 1 | 0.022661 | 0.022661 | 24.94 | 0.008 |

| Impulse time (µs) | 1 | 0.025933 | 0.025933 | 28.54 | 0.006 |

| Capacitance level | 1 | 0.000005 | 0.000005 | 0.01 | 0.946 |

| Error | 4 | 0.003635 | 0.000909 | ||

| Total | 12 | 0.111769 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roldan-Jimenez, L.; Bañon, F.; Valerga, A.P.; Fernandez-Vidal, S.R. Design and Analysis of CFRP Drilling by Electrical Discharge Machining. Polymers 2022, 14, 1340. https://doi.org/10.3390/polym14071340

Roldan-Jimenez L, Bañon F, Valerga AP, Fernandez-Vidal SR. Design and Analysis of CFRP Drilling by Electrical Discharge Machining. Polymers. 2022; 14(7):1340. https://doi.org/10.3390/polym14071340

Chicago/Turabian StyleRoldan-Jimenez, Luis, Fermin Bañon, Ana P. Valerga, and Severo R. Fernandez-Vidal. 2022. "Design and Analysis of CFRP Drilling by Electrical Discharge Machining" Polymers 14, no. 7: 1340. https://doi.org/10.3390/polym14071340