Shear Strength Range of GF/Polyester Composites Controlled by Plasma Nanotechnology

Abstract

:1. Introduction

2. Materials and Methods

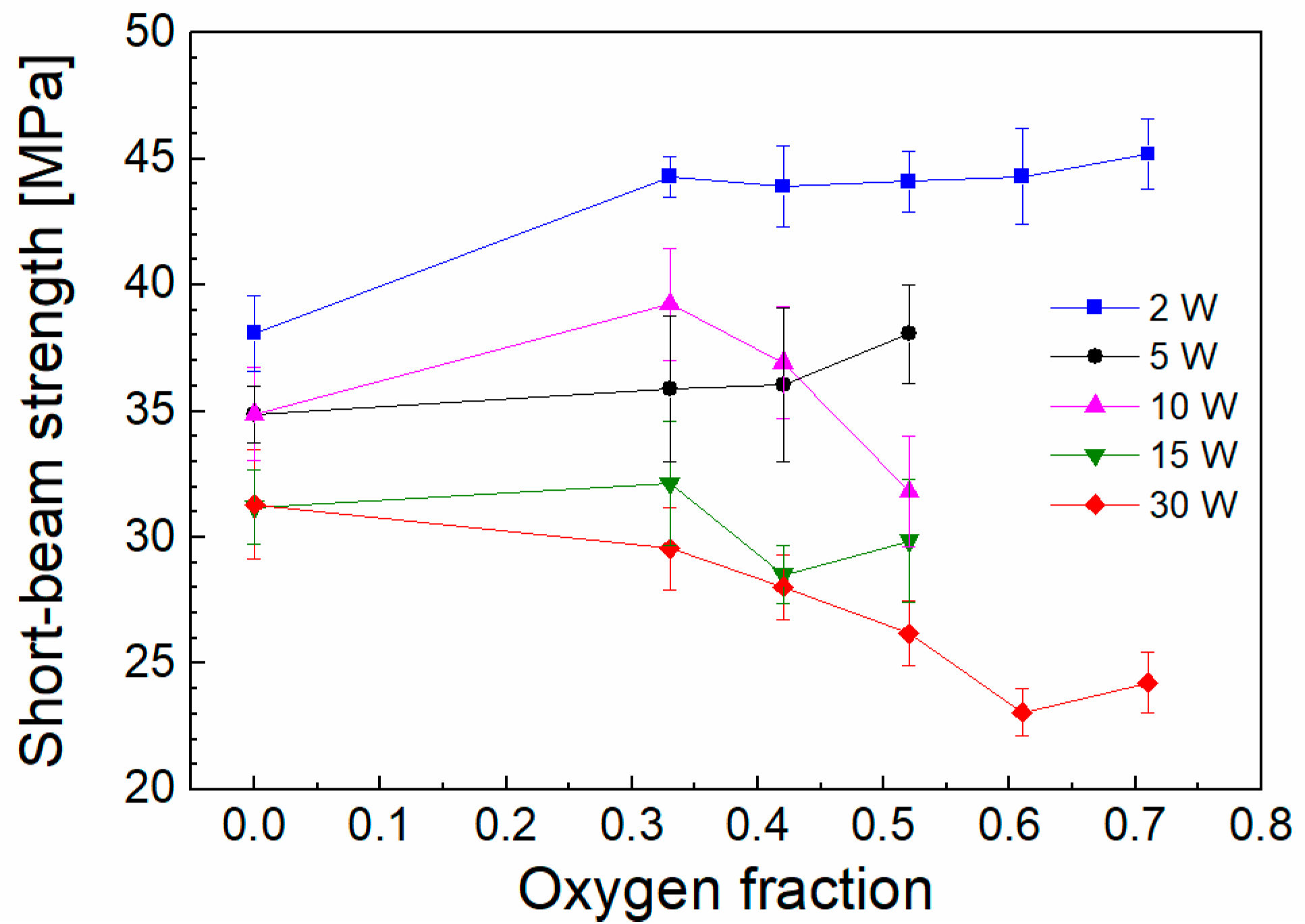

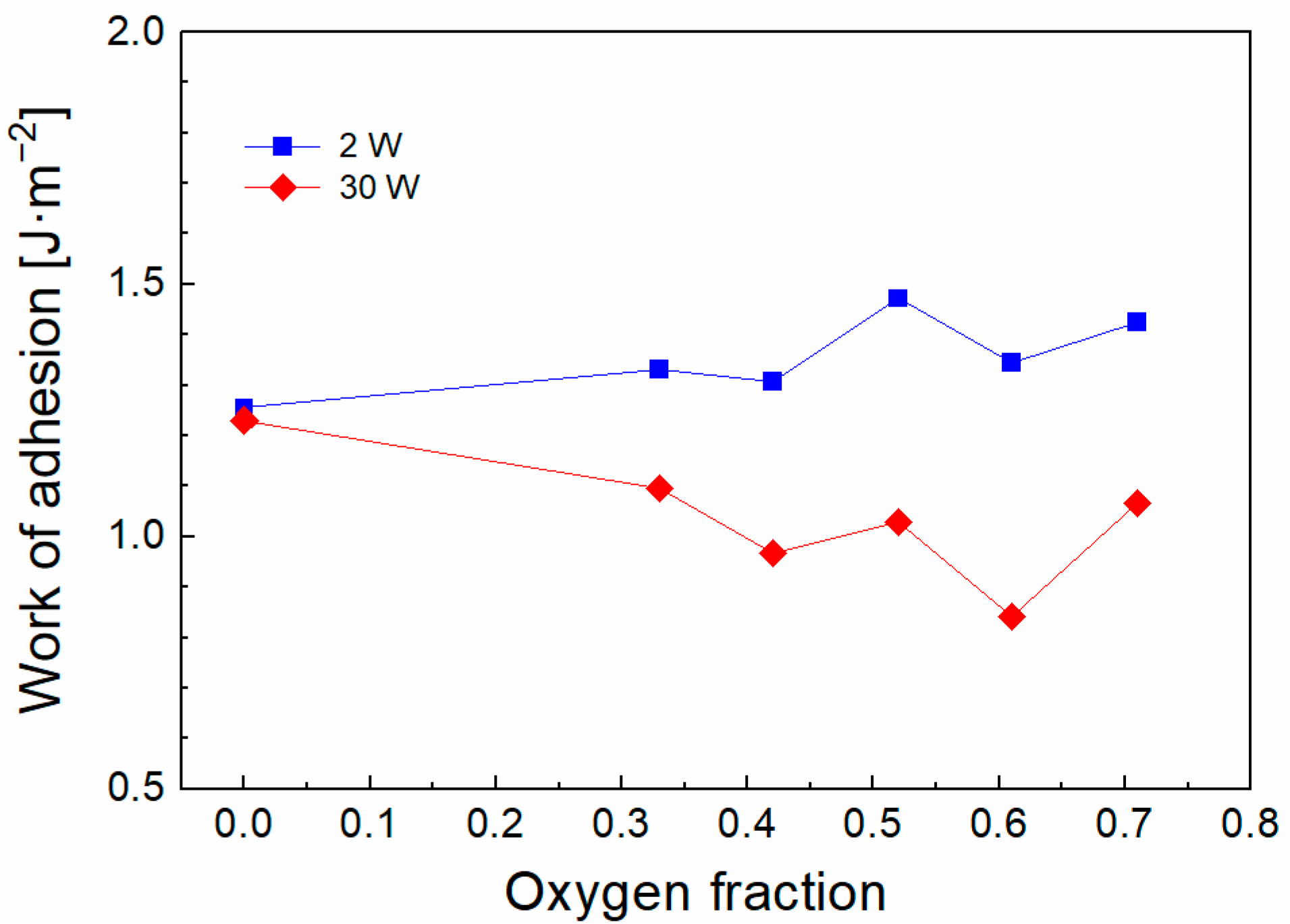

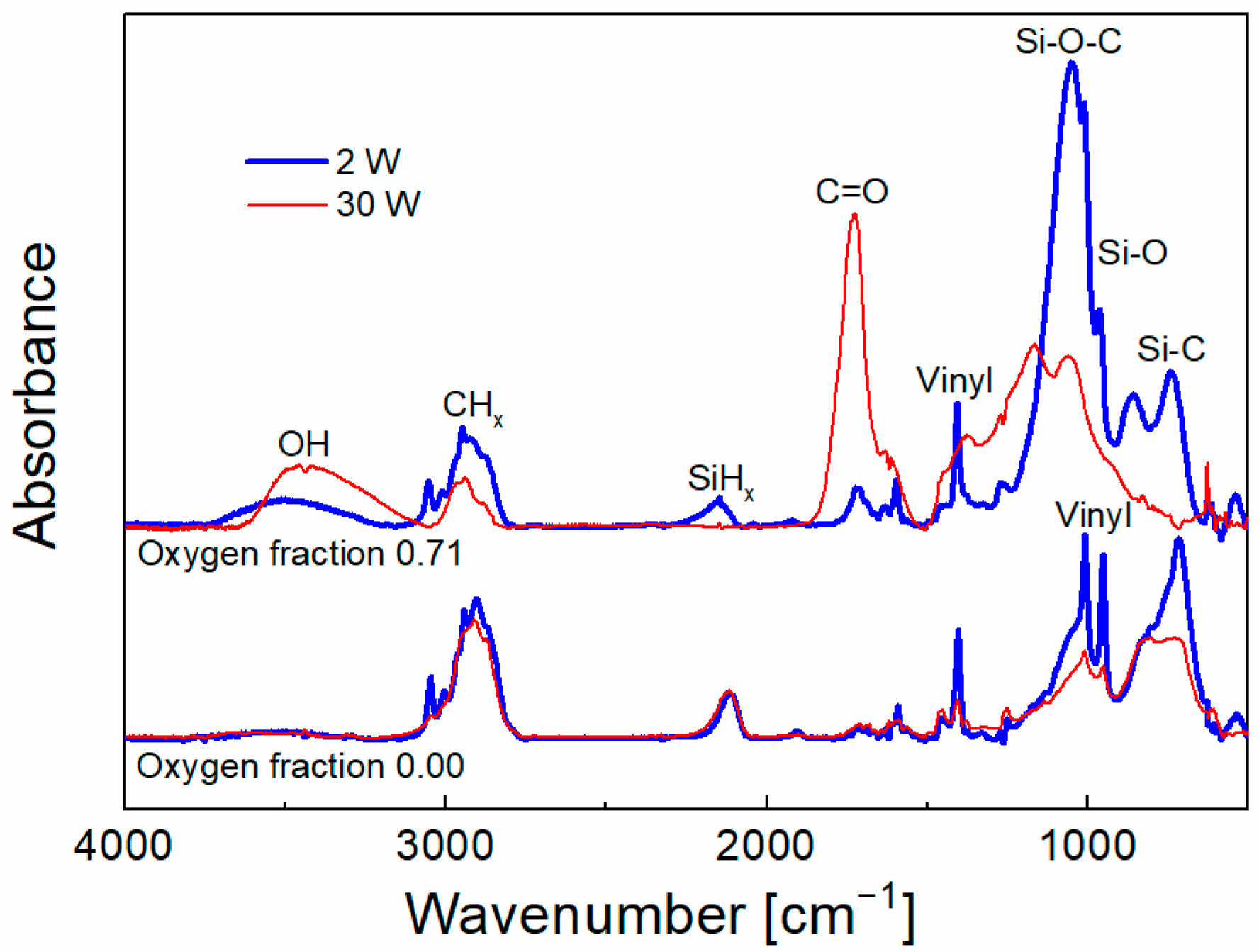

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fang, C.; Zhou, Y.; Jia, L.; Yan, R. Interfacial properties of multicomponent plasma-modified high-performance fiber-reinforced composites: A review. Polym. Compos. 2022, 43, 4866–4883. [Google Scholar] [CrossRef]

- Jurko, M.; Souckova, L.; Prokes, J.; Cech, V. The effect of glass fiber storage time on the mechanical response of polymer composite. Polymers 2022, 14, 4633. [Google Scholar] [CrossRef] [PubMed]

- Xian, G.; Guo, R.; Li, C.; Hong, B. Mechanical properties of carbon/glass fiber reinforced polymer plates with sandwich structure exposed to freezing-thawing environment: Effects of water immersion, bending loading and fiber hybrid mode. Mech. Adv. Mater. Struct. 2023, 30, 814–834. [Google Scholar] [CrossRef]

- Yang, X.; Chen, Y.; Zhang, C.; Duan, G.; Jiang, S. Electrospun carbon nanofibers and their reinforced composites: Preparation, modification, applications, and perspectives. Compos. Part B 2023, 249, 110386. [Google Scholar] [CrossRef]

- Karoly, Z.; Romanszki, L.; Weltz, G.; Mohai, M.; Moczo, J.; Klebert, S. Comparison of dielectric barrier discharge and radio-frequency plasma processing of carbon fibers. Express Polym. Lett. 2021, 15, 1004–1017. [Google Scholar] [CrossRef]

- Kantharaju, S.; Vinodhini, J.; Govindaraju, M.; Bhowmik, S. An investigation to enhance the mechanical property of high-performance thermoplastic composite through different plasma treatment. Polym. Compos. 2023, 44, 178–189. [Google Scholar] [CrossRef]

- Fang, C.Y.; Chen, Y.C.; Jia, L.X.; Yan, R.S. Cold nitrogen plasma treated glass fiber warp knitted structural composites: Mechanical properties and response surface analysis. J. Ind. Text. 2022, 52, 1–16. [Google Scholar] [CrossRef]

- Zhang, L.; Xia, Z.C.; He, Y.D.; Xin, C.L.; Yu, Y.; Ren, F.; Wang, R.X. Fiber reinforced polypropylene composites interfacial behavior improvement fabricated by cold plasma jet SiOx nanoparticles deposition. J. Compos Mater. 2023, 57, 1185–1198. [Google Scholar] [CrossRef]

- Xu, T.; Qi, Z.; Yin, Q.; Jiao, Y.; An, L.; Tan, Y. Effects of air plasma modification on aramid fiber surface and its composite interface and mechanical properties. Polymers 2022, 14, 4892. [Google Scholar] [CrossRef]

- Li, C.Y.; Song, J.J.; Xing, W.J.; Wang, L.X.; Cui, Y.Y.; Pei, X.Y. Mechanical properties of interlayer hybrid textile composite materials based on modified aramid and UHMWPE fabrics. Polym. Adv. Technol. 2023, 34, 205–216. [Google Scholar] [CrossRef]

- Mohammed, M.; Rasidi, M.S.M.; Mohammed, A.M.; Rahman, R.; Osman, A.F.; Adam, T.; Betar, B.O.; Dahham, O.S. Interfacial bonding mechanisms of natural fibre-matrix composites: An overview. BioResources 2022, 17, 7031–7090. [Google Scholar] [CrossRef]

- Gupta, U.S.; Tiwari, S. Mechanical and surface characterization of sisal fibers after cold glow discharge argon plasma treatment. Biomass Convers. Biorefinery 2022, 1–15. [Google Scholar] [CrossRef]

- Pillai, R.R.; Thomas, V. Plasma surface engineering of natural and sustainable polymeric derivatives and their potential applications. Polymers 2023, 15, 400. [Google Scholar] [CrossRef]

- Periasamy, K.; Kandare, E.; Das, R.; Darouie, M.; Khatibi, A.A. Interfacial engineering methods in thermoplastic composites: An overview. Polymers 2023, 15, 415. [Google Scholar] [CrossRef]

- Kosmachev, P.V.; Panin, S.V.; Panov, I.L.; Bochkareva, S.A. Surface Modification of carbon fibers by low-temperature plasma with runaway electrons for manufacturing PEEK-based laminates. Materials 2022, 15, 7625. [Google Scholar] [CrossRef]

- Cech, V.; Knob, A.; Hosein, H.A.; Babik, A.; Lepcio, P.; Ondreas, F.; Drzal, L.T. Enhanced interfacial adhesion of glass fibers by tetravinylsilane plasma modification. Compos. Part A 2014, 58, 84–89. [Google Scholar] [CrossRef]

- Cech, V.; Prikryl, R.; Balkova, R.; Grycova, A.; Vanek, J. Plasma surface treatment and modification of glass fibers. Compos. Part A 2002, 33, 1367–1372. [Google Scholar] [CrossRef]

- Wu, M.J.; Jia, L.X.; Lu, S.L.; Qin, Z.G.; Wei, S.N.; Yan, R.S. Interfacial performance of high-performance fiber-reinforced composites improved by cold plasma treatment: A review. Surf. Interfaces 2021, 24, 101077. [Google Scholar] [CrossRef]

- Zvonek, M.; Sirjovova, V.; Branecky, M.; Plichta, T.; Skacel, J.; Cech, V. Plasma nanocoatings developed to control the shear strength of polymer composites. Polymers 2019, 11, 1188. [Google Scholar] [CrossRef] [Green Version]

- Plichta, T.; Sirjovova, V.; Zvonek, M.; Kalinka, G.; Cech, V. The adhesion of plasma nanocoatings controls the shear properties of GF/polyester composite. Polymers 2021, 13, 593. [Google Scholar] [CrossRef]

- Cech, V.; Knob, A.; Lasota, T.; Lukes, J.; Drzal, L.T. Surface modification of glass fibers by oxidized plasma coatings to improve interfacial shear strength in GF/polyester composites. Polym. Compos. 2019, 40, E186–E193. [Google Scholar] [CrossRef]

- Cech, V.; Marek, A.; Knob, A.; Valter, J.; Branecky, M.; Plihal, P.; Vyskocil, J. Continuous surface modification of glass fibers in a roll-to-roll plasma-enhanced CVD reactor for glass fiber/polyester composites. Compos. Part A 2019, 121, 244–253. [Google Scholar] [CrossRef]

- Technical Data Sheet DISTITRON® 183 B1. Available online: https://www.polynt.com/wp-content/uploads/tds/DISTITRON_183_B1_EN.pdf (accessed on 1 August 2023).

- ASTM D2344; Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates. American Society for Testing and Materials: West Conshohocken, PA, USA, 2001.

- Cech, V.; Branecky, M. Synthesis of thin-film materials using nonthermal plasma at a higher degree of dissociation. Plasma. Process. Polym. 2023, 20, e2300019. [Google Scholar] [CrossRef]

- Ohring, M. Materials Science of Thin Films; Academic Press: San Diego, CA, USA, 2002; pp. 58–63. [Google Scholar]

- Mitchell, B.S. Materials Engineering and Science for Chemical and Materials Engineers; Wiley: Hoboken, NJ, USA, 2004; p. 851. [Google Scholar]

- Houdkova, J.; Branecky, M.; Plichta, T.; Jiricek, P.; Zemek, J.; Cech, V. Chemical depth profile of layered a-CSiO:H nanocomposites. Appl. Surf. Sci. 2018, 456, 941–950. [Google Scholar] [CrossRef]

- Prikryl, R.; Cech, V.; Kripal, L.; Vanek, J. Adhesion of pp-VTES films to glass substrates and their durability in aqueous environments. Int. J. Adhes. Adhes. 2005, 25, 121–125. [Google Scholar] [CrossRef]

- Palesch, E.; Knob, A.; Plichta, T.; Cech, V. Functional interlayers with controlled adhesion developed for polymer composites. Thin Solid Films 2018, 656, 37–43. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sirjovova, V.; Zvonek, M.; Jurko, M.; Cech, V. Shear Strength Range of GF/Polyester Composites Controlled by Plasma Nanotechnology. Polymers 2023, 15, 3331. https://doi.org/10.3390/polym15163331

Sirjovova V, Zvonek M, Jurko M, Cech V. Shear Strength Range of GF/Polyester Composites Controlled by Plasma Nanotechnology. Polymers. 2023; 15(16):3331. https://doi.org/10.3390/polym15163331

Chicago/Turabian StyleSirjovova, Veronika, Milan Zvonek, Michal Jurko, and Vladimir Cech. 2023. "Shear Strength Range of GF/Polyester Composites Controlled by Plasma Nanotechnology" Polymers 15, no. 16: 3331. https://doi.org/10.3390/polym15163331

APA StyleSirjovova, V., Zvonek, M., Jurko, M., & Cech, V. (2023). Shear Strength Range of GF/Polyester Composites Controlled by Plasma Nanotechnology. Polymers, 15(16), 3331. https://doi.org/10.3390/polym15163331