Mineralized Collagen/Polylactic Acid Composite Scaffolds for Load-Bearing Bone Regeneration in a Developmental Model

Abstract

:1. Introduction

2. Materials and Methods

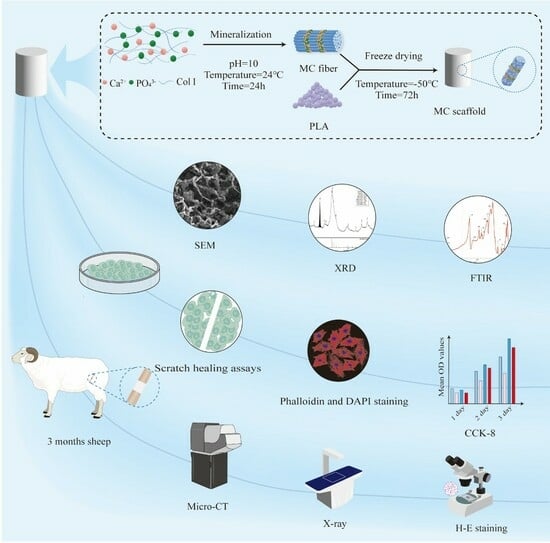

2.1. Fabrication of MC Power and the MC/PLA Composite Scaffold

2.2. Characterization of MC Power and Natural Bone

2.3. Cell Culture

2.4. Phalloidin and 4′,6-Diamidino-2-phenylindole Dye (DAPI) Staining

2.5. Cell Proliferation

2.6. Cell Migration

2.7. Characterization of the MC/PLA Scaffold

2.8. In Vivo Animal Experiments, the MC/PLA Scaffold

2.9. Statistical Analysis

3. Results and Discussion

3.1. Comparison of the Characteristics of MC and Natural Bone

3.2. Comparison of the Cell Compatibility of MC/PLA, HA/PLA, and MC Scaffolds

3.3. Characteristics and Mechanical Properties of the MC/PLA Scaffold

3.4. In Vivo Animal Experiments

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bondareva, J.V.; Dubinin, O.N.; Kuzminova, Y.O.; Shpichka, A.I.; Kosheleva, N.V.; Lychagin, A.V.; Shibalova, A.A.; Pozdnyakov, A.A.; Akhatov, I.S.; Timashev, P.S.; et al. Biodegradable iron-silicon implants produced by additive manufacturing. Biomed. Mater. 2022, 17, 035005. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Mir, S.M.; Aldulijan, I.; Mahajan, A.; Anwar, A.; Leon, C.H.; Terracciano, A.; Zhao, X.; Su, T.L.; Kalyon, D.M.; et al. Load-bearing biodegradable PCL-PGA-beta TCP scaffolds for bone tissue regeneration. J. Biomed Mater. Res. B Appl. Biomater. 2021, 109, 193–200. [Google Scholar] [CrossRef] [PubMed]

- Hersh, D.S.; Anderson, H.J.; Woodworth, G.F.; Martin, J.E.; Khan, Y.M. Bone Flap Resorption in Pediatric Patients Following Autologous Cranioplasty. Oper. Neurosurg. 2021, 20, 436–443. [Google Scholar] [CrossRef] [PubMed]

- Jain, S.; Wang, S.; Sandoval-Garcia, C.; Ibrahim, G.M.; Robinson, W.L.; Ragheb, J. Autologous Calvarial Bone Remodeling Technique for Small to Medium-Sized Cranial Defects in Young Children: The “Switch-Cranioplasty” Technique. Pediatr. Neurosurg. 2021, 56, 248–253. [Google Scholar] [CrossRef]

- Brugmans, M.M.; Soekhradj-Soechit, R.S.; van Geemen, D.; Cox, M.; Bouten, C.V.; Baaijens, F.P.; Driessen-Mol, A. Superior Tissue Evolution in Slow-Degrading Scaffolds for Valvular Tissue Engineering. Tissue Eng. Part A 2016, 22, 123–132. [Google Scholar] [CrossRef] [PubMed]

- Bhuiyan, D.B.; Middleton, J.C.; Tannenbaum, R.; Wick, T.M. Mechanical properties and osteogenic potential of hydroxyapatite-PLGA-collagen biomaterial for bone regeneration. J. Biomater. Sci. Polym. Ed. 2016, 27, 1139–1154. [Google Scholar] [CrossRef] [PubMed]

- Yavari, S.A.; van der Stok, J.; Chai, Y.C.; Wauthle, R.; Birgani, Z.T.; Habibovic, P.; Mulier, M.; Schrooten, J.; Weinans, H.; Zadpoor, A.A. Bone regeneration performance of surface-treated porous titanium. Biomaterials 2014, 35, 6172–6181. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Kong, J.; Qiu, Z.; Shang, T.; Chen, S.; Zhao, R.; Raucci, M.G.; Yang, X.; Wu, Z. Mineralized collagen-modified PMMA cement enhances bone integration and reduces fibrous encapsulation in the treatment of lumbar degenerative disc disease. Regen. Biomater. 2020, 7, 181–193. [Google Scholar] [CrossRef]

- Gomes, A.D.; de Oliveira, A.A.; Houmard, M.; Nunes, E.H. Gamma sterilization of collagen/hydroxyapatite composites: Validation and radiation effects. Appl Radiat Isot. 2021, 174, 109758. [Google Scholar] [CrossRef]

- Mazzoni, E.; D'Agostino, A.; Iaquinta, M.R.; Bononi, I.; Trevisiol, L.; Rotondo, J.C.; Patergnani, S.; Giorgi, C.; Gunson, M.J.; Arnett, G.W.; et al. Hydroxylapatite-collagen hybrid scaffold induces human adipose-derived mesenchymal stem cells to osteogenic differentiation in vitro and bone regrowth in patients. Stem Cells Transl. Med. 2020, 9, 377–388. [Google Scholar] [CrossRef]

- Dai, Y.; Xu, J.; Han, X.-H.; Cui, F.-Z.; Zhang, D.-S.; Huang, S.-Y. Clinical efficacy of mineralized collagen (MC) versus anorganic bovine bone (Bio-Oss) for immediate implant placement in esthetic area: A single-center retrospective study. BMC Oral Health 2021, 21, 390. [Google Scholar] [CrossRef] [PubMed]

- Gönder, N.; Demir, İ.H.; Öğümsöğütlü, E.; Kılınçoğlu, V. Collagen/Nano-hydroxyapatite Composite Scaffold Application with Exchange Reamed Nailing Accelerates Bone Union and Improves Quality of Life in Atrophic Femoral Shaft Nonunions: A Retrospective Comparative Study. Indian J. Orthop. 2021, 56, 412–420. [Google Scholar] [CrossRef] [PubMed]

- Ohba, S.; Shido, R.; Asahina, I. Application of hydroxyapatite/collagen composite material for maxillary sinus floor augmentation. J. Oral Sci. 2021, 63, 295–297. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Zhao, M.; Xu, F.; Yang, B.; Li, X.; Meng, X.; Teng, L.; Sun, F.; Li, Y. Synthesis and Biological Application of Polylactic Acid. Molecules 2020, 25, 5023. [Google Scholar] [CrossRef] [PubMed]

- Murariu, M.; Dubois, P. PLA composites: From production to properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef]

- Carvalho, J.R.G.; Conde, G.; Antonioli, M.L.; Santana, C.H.; Littiere, T.O.; Dias, P.P.; Chinelatto, M.A.; Canola, P.A.; Zara, F.J.; Ferraz, G.C. Long-Term Evaluation of Poly(lactic acid) (PLA) Implants in a Horse: An Experimental Pilot Study. Molecules 2021, 26, 7224. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Zuhri, M.Y.M.; Aisyah, H.A.; Asyraf, M.R.M.; Hassan, S.A.; Zainudin, E.S.; Sapuan, S.M.; Sharma, S.; Bangar, S.P.; Jumaidin, R.; et al. Natural Fiber-Reinforced Polylactic Acid, Polylactic Acid Blends and Their Composites for Advanced Applications. Polymers 2022, 14, 202. [Google Scholar] [CrossRef] [PubMed]

- Lett, J.A.; Sagadevan, S.; Léonard, E.; Fatimah, I.; Hossain, M.A.M.; Mohammad, F.; Al-Lohedan, H.A.; Paiman, S.; Alshahateet, S.F.; Razak, S.I.A.; et al. Bone tissue engineering potentials of 3D printed magnesium-hydroxyapatite in polylactic acid composite scaffolds. Artif. Organs 2021, 45, 1501–1512. [Google Scholar] [CrossRef]

- Joshi, D.S.; Singhvi, M.S.; Khire, J.M.; Gokhale, D.V. Strain improvement of Lactobacillus lactis for D-lactic acid production. Biotechnol. Lett. 2010, 32, 517–520. [Google Scholar] [CrossRef]

- Vasir, J.K.; Labhasetwar, V. Biodegradable nanoparticles for cytosolic delivery of therapeutics. Adv. Drug Deliv. Rev. 2007, 59, 718–728. [Google Scholar] [CrossRef]

- Chen, S.; Guo, R.; Liang, Q.; Xiao, X. Multifunctional modified polylactic acid nanofibrous scaffold incorporating sodium alginate microspheres decorated with strontium and black phosphorus for bone tissue engineering. J. Biomater. Sci. Polym. Ed. 2021, 32, 1598–1617. [Google Scholar] [CrossRef] [PubMed]

- Singhvi, M.S.; Zinjarde, S.S.; Gokhale, D.V. Polylactic acid: Synthesis and biomedical applications. J. Appl. Microbiol. 2019, 127, 1612–1626. [Google Scholar] [CrossRef]

- Mozdzen, L.C.; Rodgers, R.; Banks, J.M.; Bailey, R.C.; Harley, B.A. Increasing the strength and bioactivity of collagen scaffolds using customizable arrays of 3D-printed polymer fibers. Acta Biomater. 2016, 33, 25–33. [Google Scholar] [CrossRef] [PubMed]

- Ray, S.; Adelnia, H.; Ta, H.T. Collagen and the effect of poly-l-lactic acid based materials on its synthesis. Biomater. Sci. 2021, 9, 5714–5731. [Google Scholar] [CrossRef] [PubMed]

- Cui, M.; Liu, L.; Guo, N.; Su, R.; Ma, F. Preparation, cell compatibility and degradability of collagen-modified poly(lactic acid). Molecules 2015, 20, 595–607. [Google Scholar] [CrossRef]

- Liu, S.; Zheng, Y.; Liu, R.; Tian, C. Preparation and characterization of a novel polylactic acid/hydroxyapatite composite scaffold with biomimetic micro-nanofibrous porous structure. J. Mater. Sci. Mater. Med. 2020, 31, 74. [Google Scholar] [CrossRef] [PubMed]

- Marycz, K.; Smieszek, A.; Targonska, S.; Walsh, S.A.; Szustakiewicz, K.; Wiglusz, R.J. Three dimensional (3D) printed polylactic acid with nano-hydroxyapatite doped with europium(III) ions (nHAp/PLLA@Eu3+) composite for osteochondral defect regeneration and theranostics. Mater. Sci. Eng. C Mater. Biol. Appl. 2020, 110, 110634. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Liao, S.S.; Cui, F.Z. Hierarchical Self-Assembly of Nano-Fibrils in Mineralized Collagen. Chem. Mater. 2003, 15, 3221–3226. [Google Scholar] [CrossRef]

- Landis, W.J.; Song, M.J.; Leith, A.; McEwen, L.; McEwen, B.F. Mineral and organic matrix interaction in normally calcifying tendon visualized in three dimensions by high-voltage electron microscopic tomography and graphic image reconstruction. J. Struct. Biol. 1993, 110, 39–54. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, H.; Sun, X.-Y.; Xia, W.; Deng, C. In vitro and in vivo study on the osseointegration of magnesium and strontium ion with two different proportions of mineralized collagen and its mechanism. J. Biomater. Appl. 2021, 36, 528–540. [Google Scholar] [CrossRef]

- Kane, R.J.; Roeder, R.K. Effects of hydroxyapatite reinforcement on the architecture and mechanical properties of freeze-dried collagen scaffolds. J. Mech. Behav. Biomed. Mater. 2021, 7, 41–49. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.-C.; Hsu, P.-Y.; Tuan, W.-H.; Chen, C.-Y.; Wu, C.-J.; Lai, P.-L. Long-term in vitro degradation and in vivo evaluation of resorbable bioceramics. J. Mater. Sci. Mater. Med. 2021, 32, 13. [Google Scholar] [CrossRef] [PubMed]

- Xing, F.; Chi, Z.; Yang, R.; Xu, D.; Cui, J.; Huang, Y.; Zhou, C.; Liu, C. Chitin-hydroxyapatite-collagen composite scaffolds for bone regeneration. Int. J. Biol. Macromol. 2021, 184, 170–180. [Google Scholar] [CrossRef] [PubMed]

- Fu, X.; Liu, G.; Halim, A.; Ju, Y.; Luo, Q.; Song, G. Mesenchymal Stem Cell Migration and Tissue Repair. Cells 2019, 8, 784. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Hu, J.; Huang, Y.; Li, S.; Li, S.; Wang, M.; Xia, H.; Li-Ling, J.; Xie, H. Copper promotes the migration of bone marrow mesenchymal stem cells via Rnd3-dependent cytoskeleton remodeling. J. Cell. Physiol. 2020, 235, 221–231. [Google Scholar] [CrossRef] [PubMed]

- Dewey, M.J.; Johnson, E.M.; Weisgerber, D.W.; Wheeler, M.B.; Harley, B.A. Shape-fitting collagen-PLA composite promotes osteogenic differentiation of porcine adipose stem cells. J. Mech. Behav. Biomed. Mater. 2019, 95, 21–33. [Google Scholar] [CrossRef] [PubMed]

- Mehrabani, M.G.; Karimian, R.; Mehramouz, B.; Rahimi, M.; Kafil, H.S. Preparation of biocompatible and biodegradable silk fibroin/chitin/silver nanoparticles 3D scaffolds as a bandage for antimicrobial wound dressing. Int. J. Biol. Macromol. 2018, 114, 961–971. [Google Scholar] [CrossRef] [PubMed]

- Rüdrich, U.; Lasgorceix, M.; Champion, E.; Pascaud-Mathieu, P.; Damia, C.; Chartier, T.; Brie, J.; Magnaudeix, A. Pre-osteoblast cell colonization of porous silicon substituted hydroxyapatite bioceramics: Influence of microporosity and macropore design. Mater. Sci. Eng. C Mater. Biol. Appl. 2019, 97, 510–528. [Google Scholar] [CrossRef]

- Kretlow, J.D.; Mikos, A.G.; Kengla, C.; Renteria, E.; Wivell, C.; Atala, A.; Yoo, J.J.; Lee, S.J.; Shin, K.; Acri, T.; et al. Review: Mineralization of synthetic polymer scaffolds for bone tissue engineering. Tissue Eng. 2007, 13, 927–938. [Google Scholar] [CrossRef]

- Hutmacher, D.W.; Schantz, J.T.; Lam, C.X.F.; Tan, K.C.; Lim, T.C. State of the art and future directions of scaffold-based bone engineering from a biomaterials perspective. J. Tissue Eng. Regen. Med. 2007, 1, 45–260. [Google Scholar] [CrossRef]

- Tajbakhsh, S.; Hajiali, F. A comprehensive study on the fabrication and properties of biocomposites of poly(lactic acid)/ceramics for bone tissue engineering. Mater. Sci. Eng. C Mater. Biol. Appl. 2017, 70, 897–912. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, W.; Li, W.; Yao, M.; Wang, Y.; Zhang, W.; Li, C.; Wang, X.; Chen, W.; Lv, H. Mineralized Collagen/Polylactic Acid Composite Scaffolds for Load-Bearing Bone Regeneration in a Developmental Model. Polymers 2023, 15, 4194. https://doi.org/10.3390/polym15204194

Zhu W, Li W, Yao M, Wang Y, Zhang W, Li C, Wang X, Chen W, Lv H. Mineralized Collagen/Polylactic Acid Composite Scaffolds for Load-Bearing Bone Regeneration in a Developmental Model. Polymers. 2023; 15(20):4194. https://doi.org/10.3390/polym15204194

Chicago/Turabian StyleZhu, Wenbo, Wenjing Li, Mengxuan Yao, Yan Wang, Wei Zhang, Chao Li, Xiumei Wang, Wei Chen, and Hongzhi Lv. 2023. "Mineralized Collagen/Polylactic Acid Composite Scaffolds for Load-Bearing Bone Regeneration in a Developmental Model" Polymers 15, no. 20: 4194. https://doi.org/10.3390/polym15204194