Sustainable Composites: Analysis of Filler–Rubber Interaction in Natural Rubber–Styrene–Butadiene Rubber/Polyurethane Composites Using the Lorenz–Park Method and Scanning Electron Microscopy

Abstract

:1. Introduction

2. Experimental Process

2.1. Materials

2.2. Composite Preparation

2.3. Rheometric Properties

2.4. Density

2.5. Cross-Linking Density

2.6. Scanning Electron Microscopy (SEM)

2.7. Fourier Transform Infrared Spectroscopy in Attenuated Mode (FTIR-ATR)

2.8. Tensile Strength Test

2.9. Shore A Hardness Test

2.10. Abrasion Loss

2.11. Analysis of the Interactions between the Filler and the Polymer Matrix Using the Lorenz–Park Equation

3. Results and Discussion

3.1. Rheological Properties of Composites

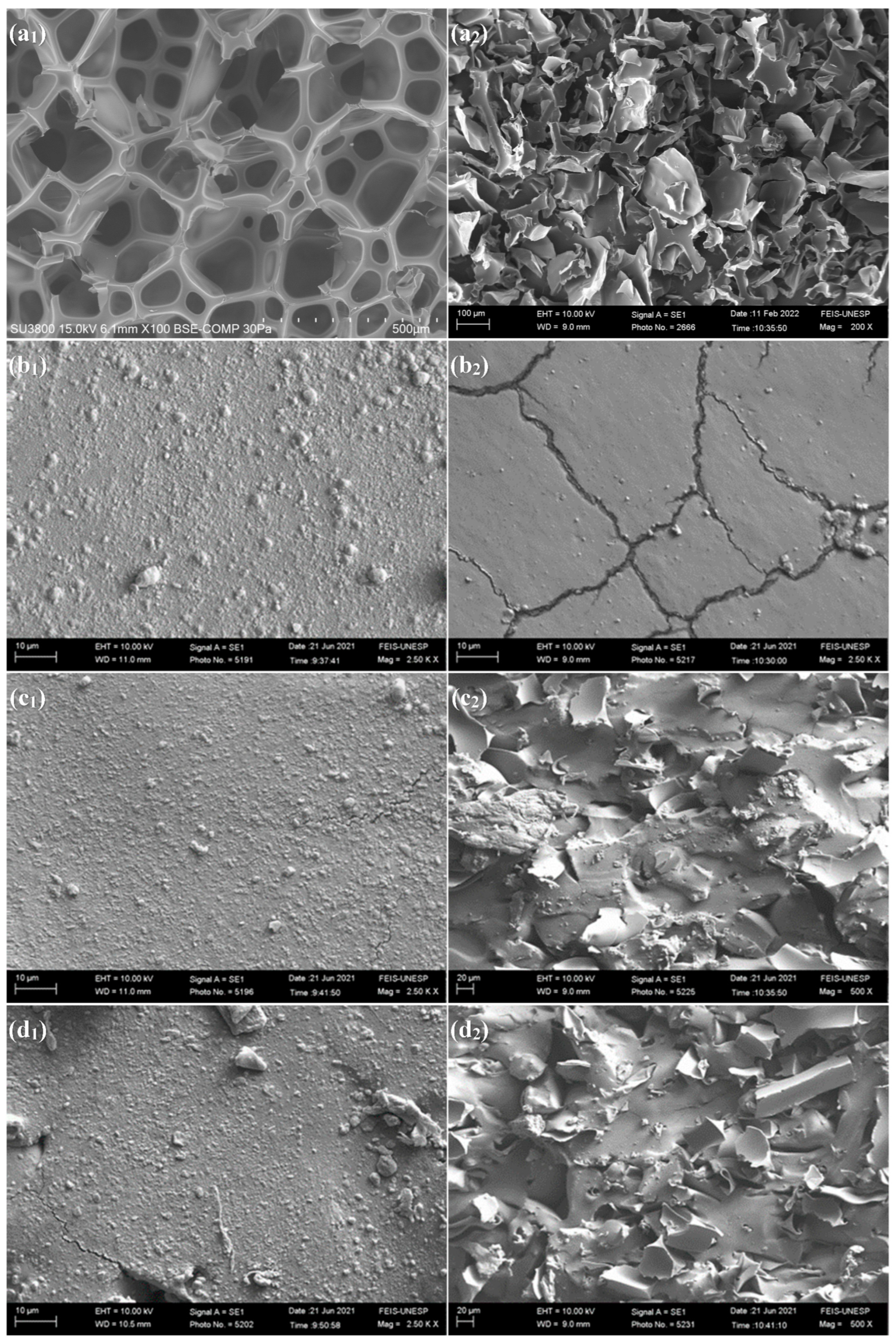

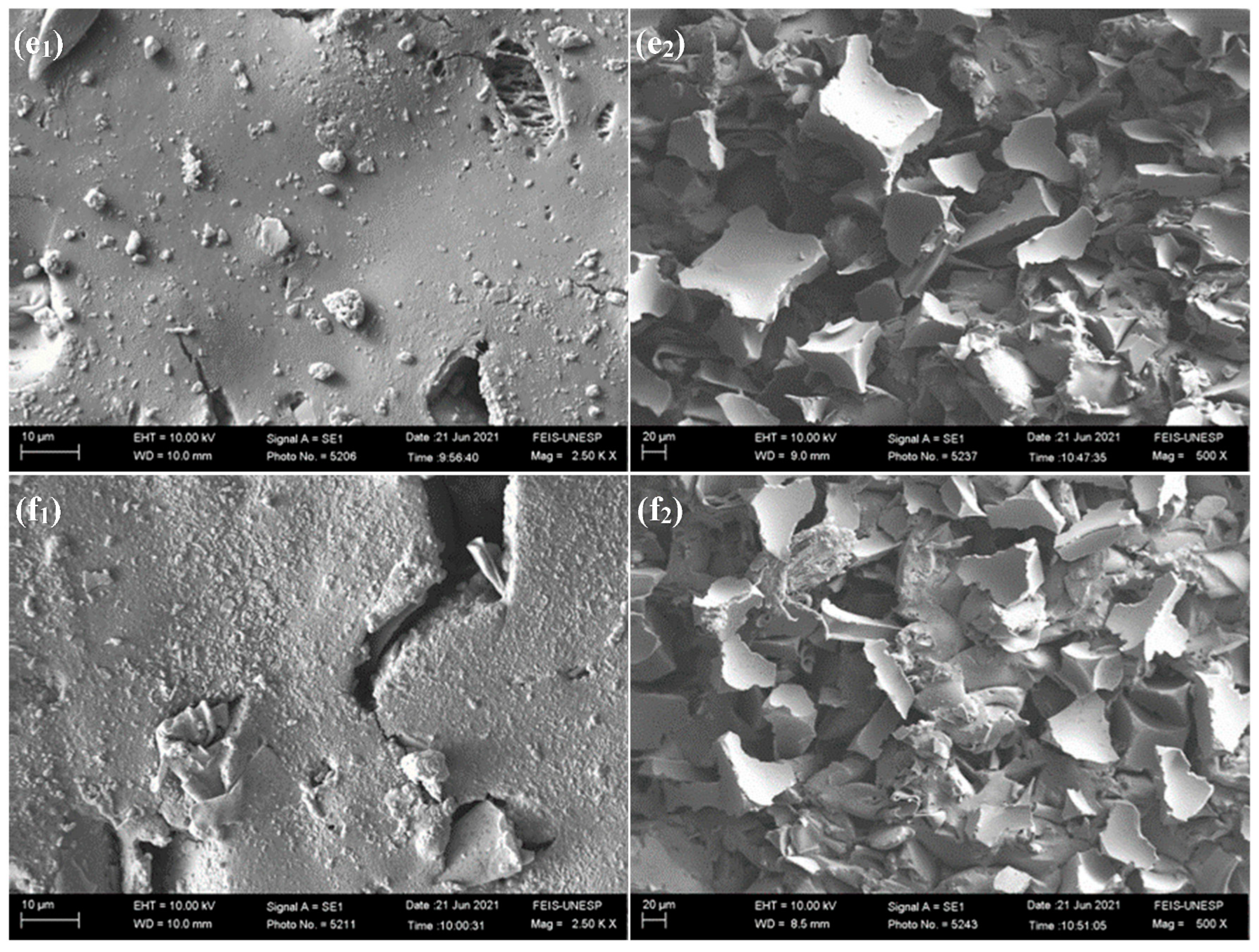

3.2. Scanning Electron Microscopy (SEM) Analysis

3.3. Density, Hardness (Shore A), Abrasion Loss

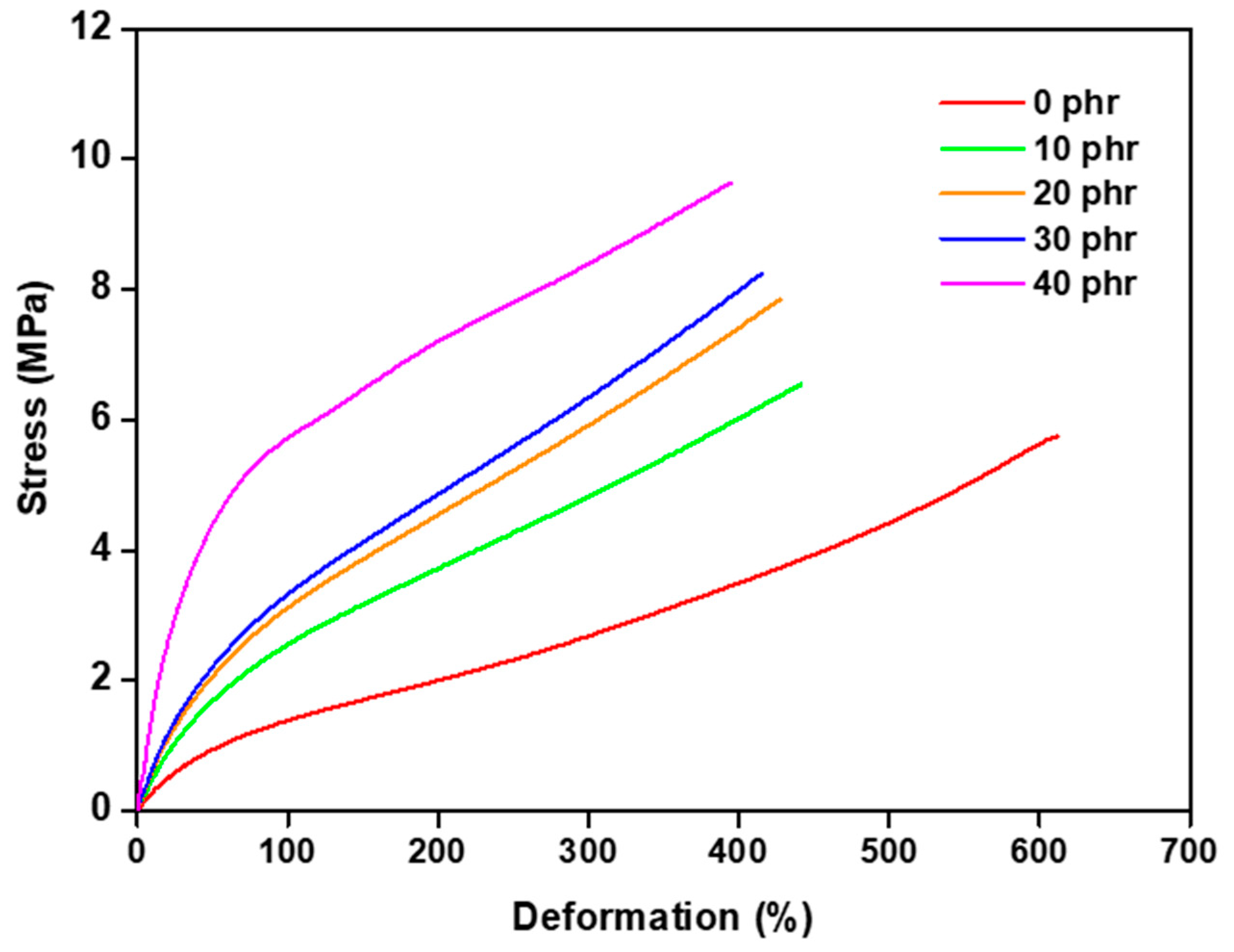

3.4. Tensile Strength Analysis

3.5. Analysis of Cross-Link Densities by the Organic Solvent Swelling Method—Flory–Rehner Method

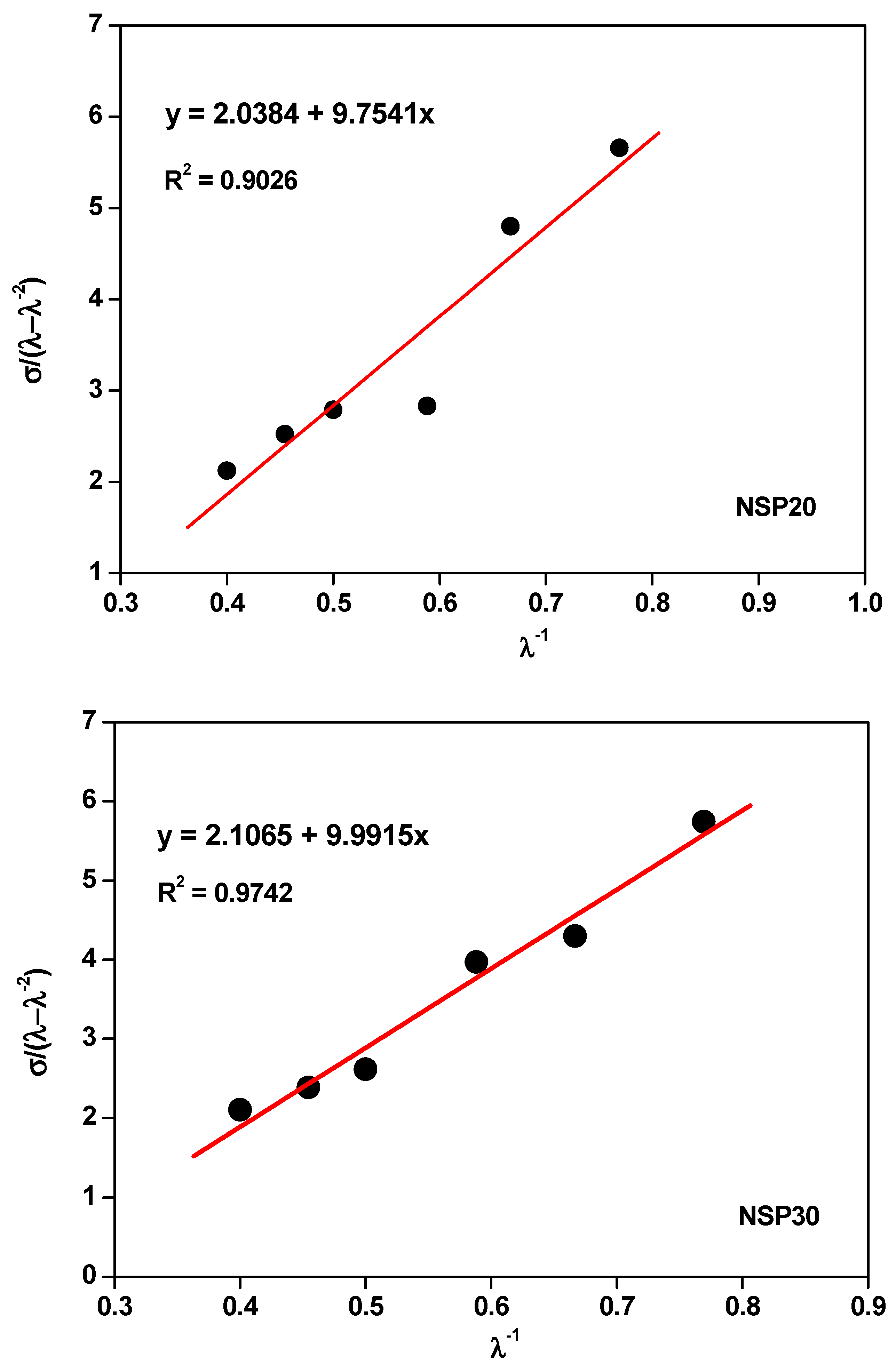

3.6. Analysis of Cross-Link Densities Using Tensile Strength Results—Mooney–Rivlin Method

3.7. Analysis of Interfacial Interaction Using the Lorenz–Park Methodology

3.8. Spectra Analysis in the Infrared with Fourier Transform in Attenuated Reflectance Mode

3.9. Application of Composite

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Khalid, M.Y.; Arif, Z.U.; Ahmed, W.; Arshad, H. Recent Trends in Recycling and Reusing Techniques of Different Plastic Polymers and Their Composite Materials. Sustain. Mater. Technol. 2022, 31, e00382. [Google Scholar] [CrossRef]

- Torres, G.B.; Hiranobe, C.T.; da Silva, E.A.; Cardim, G.P.; Cardim, H.P.; Cabrera, F.C.; Lozada, E.R.; Gutierrez-Aguilar, C.M.; Sánchez, J.C.; Carvalho, J.A.J.; et al. Eco-Friendly Natural Rubber–Jute Composites for the Footwear Industry. Polymers 2023, 15, 4183. [Google Scholar] [CrossRef]

- Predence Research Polyurethane Market Size, Trends, Share, Growth, Report 2032. Available online: https://www.precedenceresearch.com/polyurethane-market (accessed on 5 November 2023).

- Das, A.; Mahanwar, P. A brief discussion on advances in polyurethane applications. Adv. Ind. Eng. Polym. Res. 2020, 3, 93–101. [Google Scholar] [CrossRef]

- Kemona, A.; Piotrowska, M. Polyurethane Recycling and Disposal: Methods and Prospects. Polymers 2020, 12, 1752. [Google Scholar] [CrossRef]

- Llantoy, N.; Chàfer, M.; Cabeza, L.F. A Comparative Life Cycle Assessment (LCA) of Different Insulation Materials for Buildings in the Continental Mediterranean Climate. Energy Build 2020, 225, 110323. [Google Scholar] [CrossRef]

- Sułkowski, W.W.; Bartecka, G.; Sułkowska, A.; Maślanka, S.; Borek, J.; Moczyński, M. Thermogravimetric Analysis of Composites Obtained from Polyurethane and Rubber Waste. Mol. Cryst. Liq. Cryst. 2012, 556, 39–51. [Google Scholar] [CrossRef]

- Hu, S.; He, S.; Wang, Y.; Wu, Y.; Shou, T.; Yin, D.; Mu, G.; Zhao, X.; Gao, Y.; Liu, J.; et al. Self-Repairable, Recyclable and Heat-Resistant Polyurethane for High-Performance Automobile Tires. Nano Energy 2022, 95, 107012. [Google Scholar] [CrossRef]

- Gómez-Rojo, R.; Alameda, L.; Rodríguez, Á.; Calderón, V.; Gutiérrez-González, S. Characterization of Polyurethane Foam Waste for Reuse in Eco-Efficient Building Materials. Polymers 2019, 11, 359. [Google Scholar] [CrossRef] [PubMed]

- Cachaço, A.G.; Afonso, M.D.; Pinto, M.L. New applications for foam composites of polyurethane and recycled rubber. J. Appl. Polym. Sci. 2013, 129, 2873–2881. [Google Scholar] [CrossRef]

- Balan, A.K.; Mottakkunnu Parambil, S.; Vakyath, S.; Thulissery Velayudhan, J.; Naduparambath, S.; Etathil, P. Coconut shell powder reinforced thermoplastic polyurethane/natural rubber blend-composites: Effect of silane coupling agents on the mechanical and thermal properties of the composites. J. Mater. Sci. 2017, 52, 6712–6725. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhou, J.; Wu, D.; Zheng, J.; Zhang, L. Preparation and performance evaluation of rubber powder-polyurethane composite modified cold patch asphalt and cold patch asphalt mixture. Constr. Build. Mater. 2023, 369, 130473. [Google Scholar] [CrossRef]

- ASTM D3182-21a; Standard Practice for Rubber—Materials, Equipment, and Procedures for Mixing Standard Compounds and Preparing Standard Vulcanized Sheets. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2021.

- ASTM D2084-19a; Standard Test Method for Rubber Property-Vulcanization Using Oscillating Disk Cure Meter. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2019.

- ASTM D297-21; Standard Test Methods for Rubber Products-Chemical Analysis. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2021.

- Flory, P.J.; Rehner, J. Statistical Mechanics of Cross-Linked Polymer Networks, I. Rubberlike Elasticity. J. Chem. Phys. 1943, 11, 512–520. [Google Scholar] [CrossRef]

- Mooney, M. A Theory of Large Elastic Deformation. J. Appl. Phys. 1940, 11, 582–592. [Google Scholar] [CrossRef]

- Gruendken, M.; Koda, D.; Dryzek, J.; Blume, A. Low Molecular Weight ‘Liquid’ Polymer Extended Compounds, Impact on Free Volume and Crosslink Density Studied by Positron Lifetime Spectroscopy and Stress-Strain Analysis According to Mooney-Rivlin. Polym. Test. 2021, 100, 107239. [Google Scholar] [CrossRef]

- Sombatsompop, N. Practical Use of the Mooney-Rivlin Equation for Determination of Degree of Crosslinking of Swollen Nr Vulcanisates. ScienceAsia 1998, 24, 199–204. [Google Scholar] [CrossRef]

- ASTM D412-16; Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2021.

- ASTM D2240-15; Standard Test Method for Rubber Property—Durometer Hardness. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2021.

- ASTM D5963-22; Standard Test Method for Rubber Property—Abrasion Resistance (Rotary Drum Abrader). American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2022.

- Lorenz, O.; Parks, C.R. The Crosslinking Efficiency of Some Vulcanizing Agents in Natural Rubber. J. Polym. Sci. 1961, 50, 299–312. [Google Scholar] [CrossRef]

- Santos, R.J.; Hiranobe, C.T.; Dognani, G.; Silva, M.J.; Paim, L.L.; Cabrera, F.C.; Torres, G.B.; Job, A.E. Using the Lorenz–Park, Mooney–Rivlin, and Dynamic Mechanical Analysis Relationship on Natural Rubber/Leather Shavings Composites. J. Appl. Polym. Sci. 2022, 139, 51880. [Google Scholar] [CrossRef]

- Hiranobe, C.T.; Tolosa, G.R.; de Almeida Santos, G.T.; de Oliveira, J.P.J.; Budemberg, E.R.; da Silva, M.J.; Cabrera, F.C.; Job, A.E.; Paim, L.L.; Torres, G.B.; et al. Recycling Waste Polyurethane from the Refrigeration Industry as Filler in SBR/NR Composites for Industrial Applications. J. Appl. Polym. Sci. 2023, 140, e53709. [Google Scholar] [CrossRef]

- Nematollahi, M.; Jalali-Arani, A.; Modarress, H. High-performance Bio-based Poly(Lactic Acid)/Natural Rubber/Epoxidized Natural Rubber Blends: Effect of Epoxidized Natural Rubber on Microstructure, Toughness and Static and Dynamic Mechanical Properties. Polym. Int. 2019, 68, 439–446. [Google Scholar] [CrossRef]

- Chang, B.P.; Gupta, A.; Muthuraj, R.; Mekonnen, T.H. Bioresourced Fillers for Rubber Composite Sustainability: Current Development and Future Opportunities. Green Chem. 2021, 23, 5337–5378. [Google Scholar] [CrossRef]

- Nasruddin; Bondan, A.T. Natural Rubber Composites for Solid Tyre Used for Forklift Tensile Properties and Morphological Characteristics. J. Phys. Conf. Ser. 2019, 1282, 012061. [Google Scholar] [CrossRef]

- de Maria, V.P.K.; de Paiva, F.F.G.; Cabrera, F.C.; Hiranobe, C.T.; Ribeiro, G.D.; Paim, L.L.; Job, A.E.; dos Santos, R.J. Mechanical and Rheological Properties of Partial Replacement of Carbon Black by Treated Ultrafine Calcium Carbonate in Natural Rubber Compounds. Polym. Bull. 2022, 79, 7969–7987. [Google Scholar] [CrossRef]

- Anancharoenwong, E.; Chueangchayaphan, W.; Rakkapao, N.; Marthosa, S.; Chaisrikhwun, B. Thermo-Mechanical and Antimicrobial Properties of Natural Rubber-Based Polyurethane Nanocomposites for Biomedical Applications. Polym. Bull. 2021, 78, 833–848. [Google Scholar] [CrossRef]

- Abhisha, V.; Augustine, A.; Joseph, J.; Thomas, S.P.; Stephen, R. Effect of Halloysite Nanotubes and Organically Modified Bentonite Clay Hybrid Filler System on the Properties of Natural Rubber. J. Elastomers Plast. 2020, 52, 432–452. [Google Scholar] [CrossRef]

- Hayeemasae, N.; Ismail, H. Utilization of Tea Waste as an Alternative Filler for Natural Rubber. J. Teknol. 2020, 82, 4. [Google Scholar] [CrossRef]

- Nunes, A.T.; dos Santos, R.E.; Pereira, J.S.; Barbosa, R.; Ambrósio, J.D. Characterization of Waste Tire Rubber Devulcanized in Twin-Screw Extruder with Thermoplastics. Prog. Rubber Plast. Recycl. Technol. 2018, 34, 143–157. [Google Scholar] [CrossRef]

- Jana, G.K.; Das, C.K. Recycling Natural Rubber Vulcanizates through Mechanochemical Devulcanization. Macromol. Res. 2005, 13, 30–38. [Google Scholar] [CrossRef]

- Karekar, A.; Schicktanz, C.; Tariq, M.; Oßwald, K.; Reincke, K.; Cepus, V.; Langer, B.; Saalwächter, K. Effects of Artificial Weathering in NR/SBR Elastomer Blends. Polym. Degrad. Stab. 2023, 208, 110267. [Google Scholar] [CrossRef]

- El Mogy, S.A.; Lawandy, S.N. Enhancement of the Cure Behavior and Mechanical Properties of Nanoclay Reinforced NR/SBR Vulcanizates Based on Waste Tire Rubber. J. Thermoplast. Compos. Mater. 2023, 089270572311804. [Google Scholar] [CrossRef]

| Materials | Quantity of Components in phr | ||||

|---|---|---|---|---|---|

| NSP0 * | NSP10 * | NSP20 * | NSP30 * | NSP40 * | |

| NR | 50 | 50 | 50 | 50 | 50 |

| SBR 1502 | 50 | 50 | 50 | 50 | 50 |

| zinc oxide | 4 | 4 | 4 | 4 | 4 |

| Stearic Acid | 2 | 2 | 2 | 2 | 2 |

| Polyurethane residue | 0 | 10 | 20 | 30 | 40 |

| sulphur | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| MBTS accelerator | 1 | 1 | 1 | 1 | 1 |

| TMTD Accelerator | 1 | 1 | 1 | 1 | 1 |

| NSP Composites | ML (dNm) | MH (dNm) | ΔH = MH − ML (dNm) | tS1 (min) | t90 (min) |

|---|---|---|---|---|---|

| 0 phr | 0.44 ± 0.01 | 3.41 ± 0.32 | 2.97 ± 0.41 | 1.48 ± 0.21 | 3.25 ± 0.18 |

| 10 phr | 0.46 ± 0.01 | 4.17 ± 0.21 | 3.71 ± 0.24 | 1.63 ± 0.14 | 2.68 ± 0.15 |

| 20 phr | 0.61 ± 0.02 | 4.99 ± 0.3 | 4.38 ± 0.33 | 1.67 ± 0.11 | 2.77 ± 0.21 |

| 30 phr | 0.59 ± 0.01 | 5.73 ± 0.52 | 5.14 ± 0.51 | 1.78 ± 0.2 | 2.9 ± 0.17 |

| 40 phr | 0.63 ± 0.01 | 5.91 ± 0.43 | 5.28 ± 0.5 | 2.05 ± 0.31 | 3.42 ± 0.5 |

| NSP Composites | Density (g cm−3) | Hardness (Shore A) | Abrasion Loss (mm3/40 m) |

|---|---|---|---|

| 0 phr | 1.005 | 50 ± 3 | 282 ± 13 |

| 10 phr | 1.005 | 55 ± 2 | 295 ± 18 |

| 20 phr | 1.007 | 64 ± 3 | 307 ± 22 |

| 30 phr | 1.027 | 70 ± 2 | 400 ± 31 |

| 40 phr | 1.040 | 75 ± 4 | 431 ± 24 |

| NSP Composites | Stress (MPa) | Strain (%) |

|---|---|---|

| 0 phr | 5.81 ± 0.31 | 615 ± 21 |

| 10 phr | 6.54 ± 0.43 | 442 ± 18 |

| 20 phr | 7.92 ± 0.27 | 428 ± 31 |

| 30 phr | 8.23 ± 0.44 | 417 ± 19 |

| 40 phr | 9.66 ± 0.25 | 395 ± 25 |

| NSP Composites | Cross-Link Density 10−4 (mol cm−3) | Number of Cross-Links 1020 (cm3) |

|---|---|---|

| 0 phr | 1.90 | 1.1457 |

| 10 phr | 1.95 | 1.1458 |

| 20 phr | 2.04 | 1.2273 |

| 30 phr | 2.43 | 1.4606 |

| 40 phr | 2.65 | 1.6147 |

| NSP Composites | Cross-Link Density 10−4 (mol cm−3) | Number of Cross-Links 1020 (cm3) | C1 | C2 |

|---|---|---|---|---|

| 0 phr | 3.08 | 1.86 | 0.7044 | 3.9142 |

| 10 phr | 4.67 | 2.82 | 1.1567 | 6.9371 |

| 20 phr | 8.23 | 4.96 | 2.0384 | 9.7541 |

| 30 phr | 8.50 | 5.13 | 2.1065 | 9.9915 |

| 40 phr | 9.74 | 5.88 | 2.4141 | 13.7620 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Carvalho, A.P.; Dos Santos, H.F.; Ribeiro, G.D.; Hiranobe, C.T.; Goveia, D.; Gennaro, E.M.; Paim, L.L.; Dos Santos, R.J. Sustainable Composites: Analysis of Filler–Rubber Interaction in Natural Rubber–Styrene–Butadiene Rubber/Polyurethane Composites Using the Lorenz–Park Method and Scanning Electron Microscopy. Polymers 2024, 16, 471. https://doi.org/10.3390/polym16040471

De Carvalho AP, Dos Santos HF, Ribeiro GD, Hiranobe CT, Goveia D, Gennaro EM, Paim LL, Dos Santos RJ. Sustainable Composites: Analysis of Filler–Rubber Interaction in Natural Rubber–Styrene–Butadiene Rubber/Polyurethane Composites Using the Lorenz–Park Method and Scanning Electron Microscopy. Polymers. 2024; 16(4):471. https://doi.org/10.3390/polym16040471

Chicago/Turabian StyleDe Carvalho, Arthur Pimentel, Harison Franca Dos Santos, Gabriel Deltrejo Ribeiro, Carlos Toshiyuki Hiranobe, Danielle Goveia, Elmer Mateus Gennaro, Leonardo Lataro Paim, and Renivaldo José Dos Santos. 2024. "Sustainable Composites: Analysis of Filler–Rubber Interaction in Natural Rubber–Styrene–Butadiene Rubber/Polyurethane Composites Using the Lorenz–Park Method and Scanning Electron Microscopy" Polymers 16, no. 4: 471. https://doi.org/10.3390/polym16040471