Enhancing Thermal Conductivity in Polymer Composites through Molding-Assisted Orientation of Boron Nitride

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of Thermal Conductive PS/BN Composites

2.3. Characterization

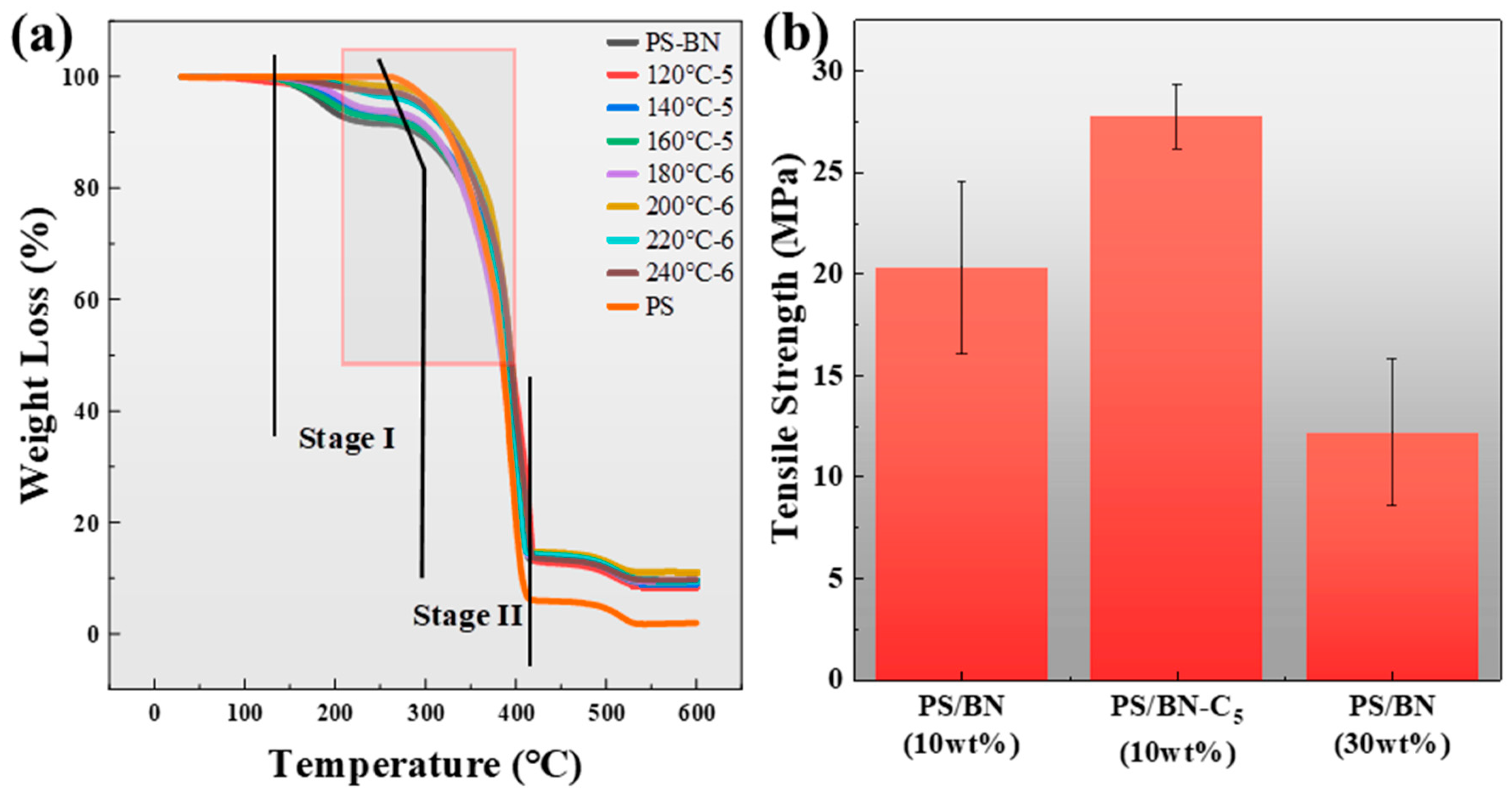

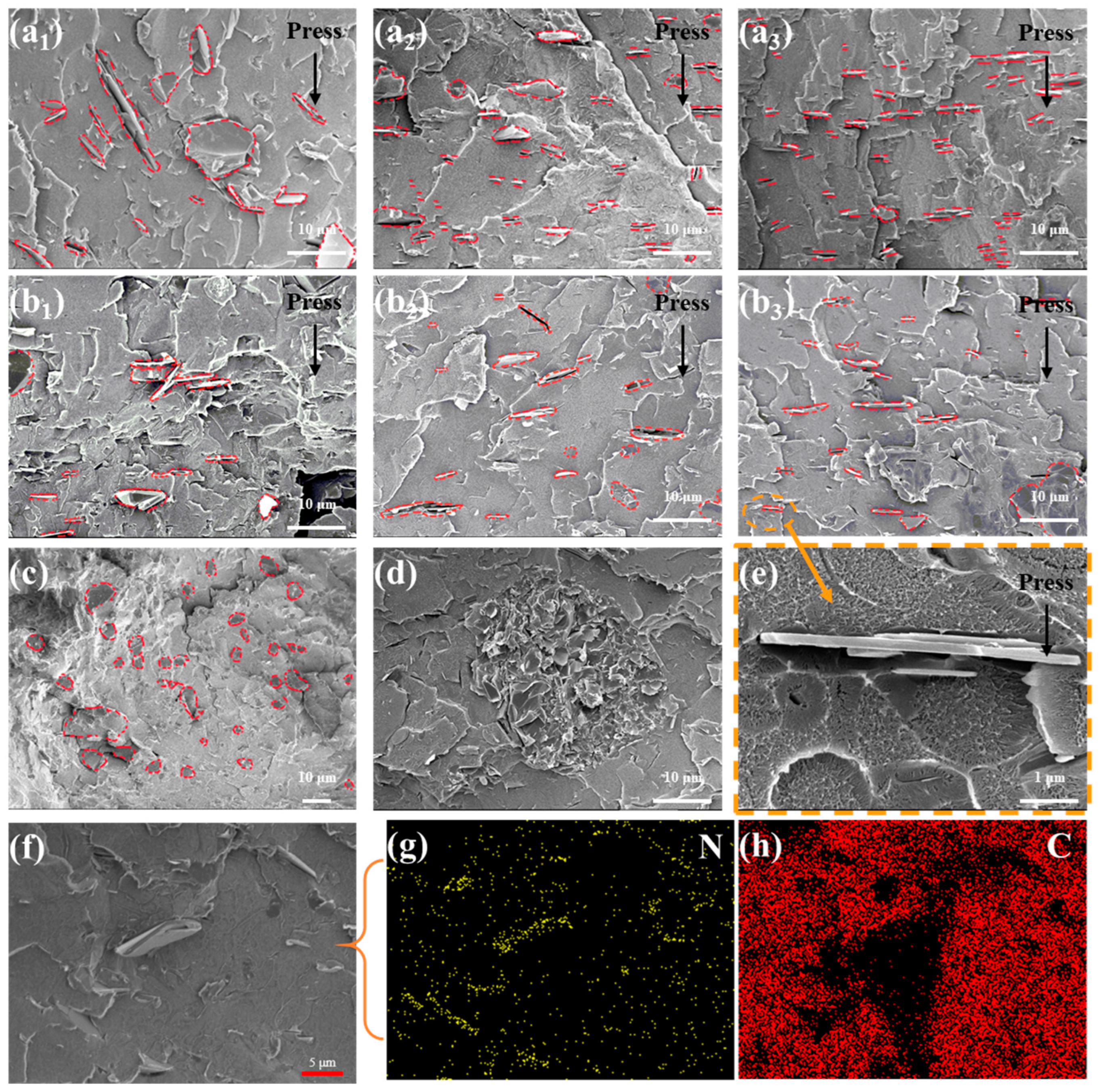

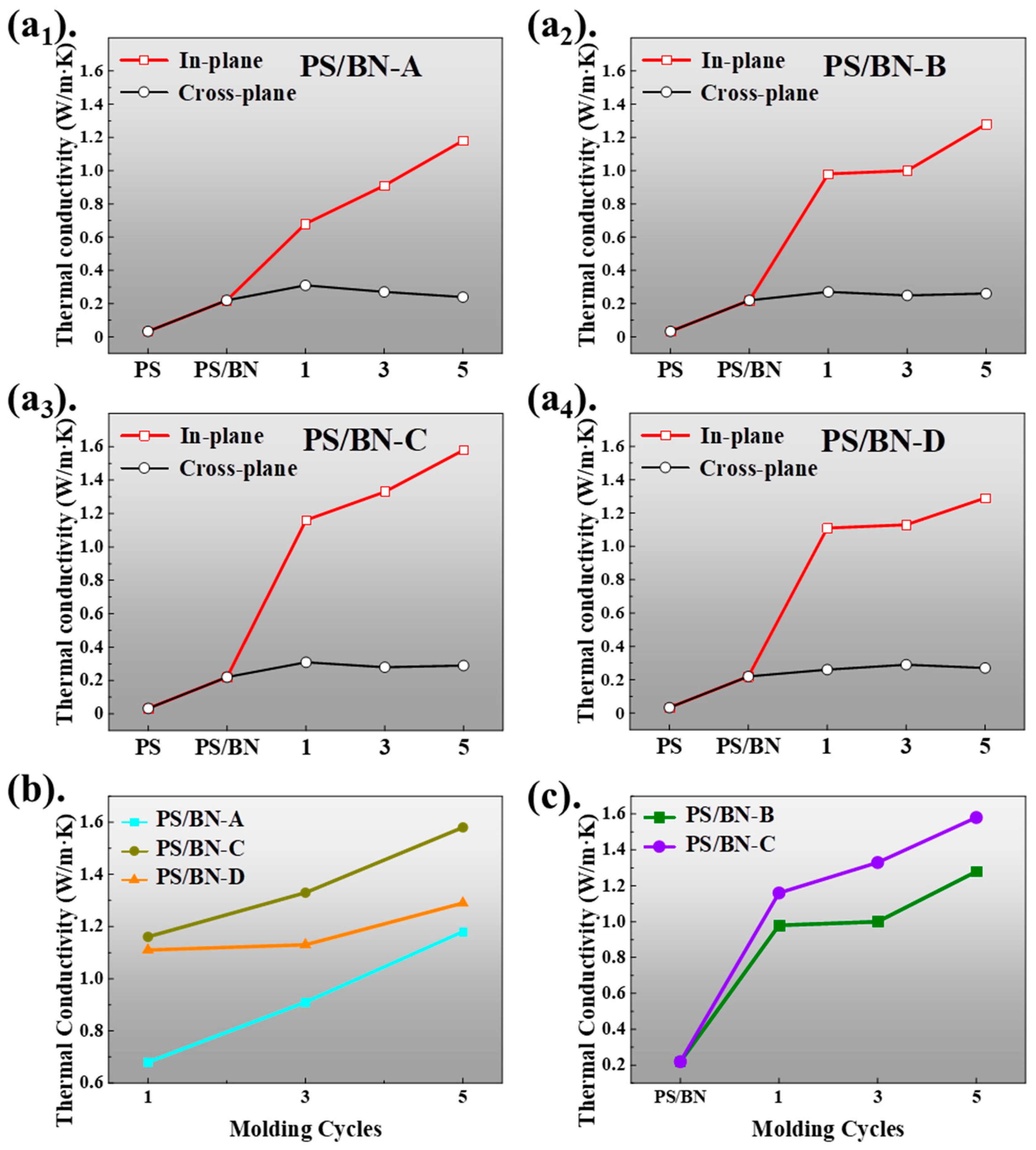

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.F.; Wu, Z.J.; Weng, L.; Ge, S.B.; Jiang, D.W.; Huang, M.A.; Mulvihill, D.M.; Chen, Q.G.; Guo, Z.H.; Jazzar, A.; et al. A Roadmap Review of Thermally Conductive Polymer Composites: Critical Factors, Progress, and Prospects. Adv. Funct. Mater. 2023, 33, 2301549. [Google Scholar] [CrossRef]

- Wang, Z.G.; Jin, Y.F.; Hong, R.; Du, J.G.; Dai, K.; Zhang, G.Q.; Gao, J.F.; Xu, L.; Xu, J.Z.; Li, Z.M. Dual-functional thermal management materials for highly thermal conduction and effectively heat generation. Compos. Part B-Eng. 2022, 242, 110084. [Google Scholar] [CrossRef]

- Yan, B.Y.; Zhang, Z.; Li, Y.; Cui, H.Z.; Zhang, C.; He, J.F. Research and Application Progress of Resin-Based Composite Materials in the Electrical Insulation Field. Materials 2023, 16, 6394. [Google Scholar] [CrossRef]

- Shi, Y.J.; Zhao, Y.S.; Hou, T.Q.; Liao, C.C.; Li, D.Y. Implementation of Epoxy Resin Composites Filled with Copper Nanowire-Modified Boron Nitride Nanosheets for Electronic Device Packaging. ACS Appl. Nano Mater. 2023, 6, 16768–16777. [Google Scholar] [CrossRef]

- Zhu, Y.; Che, Z.; Du, Y.P.; Hou, P.Y.; Zhang, L.J.; Wang, J.P.; Zhang, T.; Dai, Z.; Hong, Y.Q.; Han, W.J. A novel 3D woven carbon fiber composite with super interlayer performance hybridized by CNT tape and copper wire simultaneously. Sci. Eng. Compos. Mater. 2023, 30, 20220219. [Google Scholar] [CrossRef]

- Zhang, X.; Ye, Z.; Yang, X.; Fan, Y.; Hu, R.; Xie, B.; Luo, X. Quantitively evaluation of fillers’ alignment for targeted manufacturing of functional composite materials. Polym. Compos. 2023, 45, 653–667. [Google Scholar] [CrossRef]

- Tarhini, A.; Tehrani-Bagha, A.R. Advances in Preparation Methods and Conductivity Properties of Graphene-based Polymer Composites. Appl. Compos. Mater. 2023, 30, 1737–1762. [Google Scholar] [CrossRef]

- Tang, N.; Li, Q.L.; Song, S.Q.; An, X.Y.; Li, W.Z.; Jiang, Z.L.; Liu, Z.J.; Zhang, Y.; Zuo, Z.C. Spiderweb-inspired fabrication of 3D MXene hybrid filler with multilayer and multiscale features for multifunctional polydimethylsiloxane composites. Chem. Eng. J. 2023, 473, 145417. [Google Scholar] [CrossRef]

- Fu, X.; Lin, J.J.; Liang, Z.H.; Yao, R.H.; Wu, W.J.; Fang, Z.Q.; Zou, W.X.; Wu, Z.Y.; Ning, H.L.; Peng, J.B. Graphene oxide as a promising nanofiller for polymer composite. Surf. Interfaces 2023, 37, 102747. [Google Scholar] [CrossRef]

- Chen, H.; Chen, N.; Ma, Q.; He, Y. Experimental study on preparation and properties of carbon nanotubes-, graphene –natural rubber composites. J. Thermoplast. Compos. Mater. 2023, 08927057231211218. [Google Scholar] [CrossRef]

- Ghasemi, H.; Thoppey, N.; Huang, X.; Loomis, J.; Li, X.; Tong, J.; Wang, J.; Chen, G. High thermal conductivity ultra-high molecular weight polyethylene (UHMWPE) films. In Proceedings of the Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, Oriando, FL, USA, 27–30 June 2014; pp. 235–239. [Google Scholar]

- Wang, X.J.; Ho, V.; Segalman, R.A.; Cahill, D.G. Thermal Conductivity of High-Modulus Polymer Fibers. Macromolecules 2013, 46, 4937–4943. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, Q.; Mayo, A.; Ni, Z.H.; Yi, H.; Chen, Y.F.; Mu, R.; Bellan, L.M.; Li, D.Y. Thermal conductivity of electrospun polyethylene nanofibers. Nanoscale 2015, 7, 16899–16908. [Google Scholar] [CrossRef] [PubMed]

- Henry, A.; Chen, G. High Thermal Conductivity of Single Polyethylene Chains Using Molecular Dynamics Simulations. Phys. Rev. Lett. 2008, 101, 235502. [Google Scholar] [CrossRef]

- Shen, S.; Henry, A.; Tong, J.; Zheng, R.T.; Chen, G. Polyethylene nanofibres with very high thermal conductivities. Nat. Nanotechnol. 2010, 5, 251–255. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.-F.; Wang, Z.-G.; Yu, W.-C.; Ren, Y.; Lei, J.; Xu, J.-Z.; Li, Z.-M. Achieving high thermal conductivity and mechanical reinforcement in ultrahigh molecular weight polyethylene bulk material. Polymer 2019, 180, 121760. [Google Scholar] [CrossRef]

- Aized, T.; Khan, M.B.; Raza, H.; Ilyas, M. Production routes, electromechanical properties and potential application of layered nanomaterials and 2D nanopolymeric composites—A review. Int. J. Adv. Manuf. Technol. 2017, 93, 3449–3459. [Google Scholar] [CrossRef]

- Tian, R.; Jia, X.H.; Lan, M.; Yang, J.; Wang, S.Z.; Li, Y.; Shao, D.; Feng, L.; Song, H.J. Efficient exfoliation and functionalization of hexagonal boron nitride using recyclable ionic liquid crystal for thermal management applications. Chem. Eng. J. 2022, 446, 137255. [Google Scholar] [CrossRef]

- Han, G.J.; Cheng, H.L.; He, C.E.; Feng, Y.Z.; Liu, C.T. Silver nanoparticles bridging segregated hexagonal boron nitride networks for enhancing the thermal conductivity of polystyrene composites. Compos. Commun. 2022, 34, 101267. [Google Scholar] [CrossRef]

- Liu, S.; Wu, H.; Guo, S.Y.; Qiu, J.H. Ordered stacking of oriented BN in confined space to construct effective heat transfer pathways. Polymer 2021, 236, 124300. [Google Scholar] [CrossRef]

- Liang, Y.M.; Zhang, B.; Liu, Z.C.; Liu, W. Electroless deposition surface engineering of boron nitride sheets for enhanced thermal conductivity and decreased interfacial thermal resistance of epoxy composites. Int. J. Heat Mass Transf. 2021, 174, 121306. [Google Scholar] [CrossRef]

- Huang, X.W.; Wu, P.Y. A small amount of delaminated Ti2C3 flakes to greatly enhance the thermal conductivity of boron nitride papers by assembling a well-designed interface. Mater. Chem. Front. 2020, 4, 292–301. [Google Scholar] [CrossRef]

- Yuan, J.; Qian, X.T.; Meng, Z.C.; Yang, B.; Liu, Z.Q. Highly Thermally Conducting Polymer-Based Films with Magnetic Field-Assisted Vertically Aligned Hexagonal Boron Nitride for Flexible Electronic Encapsulation. ACS Appl. Mater. Interfaces 2019, 11, 17915–17924. [Google Scholar] [CrossRef] [PubMed]

- Yin, C.G.; Ma, Y.; Liu, Z.J.; Fan, J.C.; Shi, P.H.; Xu, Q.J.; Min, Y.L. Multifunctional boron nitride nanosheet/polymer composite nanofiber membranes. Polymer 2019, 162, 100–107. [Google Scholar] [CrossRef]

- Hu, J.T.; Huang, Y.; Zeng, X.L.; Li, Q.; Ren, L.L.; Sun, R.; Xu, J.B.; Wong, C.P. Polymer composite with enhanced thermal conductivity and mechanical strength through orientation manipulating of BN. Compos. Sci. Technol. 2018, 160, 127–137. [Google Scholar] [CrossRef]

- Kushwaha, A.D.; Patel, B.; Khan, I.A.; Agrawal, A. Fabrication and characterization of hexagonal boron nitride/polyester composites to study the effect of filler loading and surface modification for microelectronic applications. Polym. Compos. 2023, 44, 4579–4593. [Google Scholar] [CrossRef]

- Cheng, S.S.; Duan, X.Y.; Liu, X.Q.; Zhang, Z.Y.; An, D.; Zhao, G.Z.; Liu, Y.Q. Achieving significant thermal conductivity improvement constructing vertically arranged and covalently bonded silicon carbide nanowires/natural rubber composites. J. Mater. Chem. C 2021, 9, 7127–7141. [Google Scholar] [CrossRef]

- Song, N.; Hou, X.S.; Chen, L.; Cui, S.Q.; Shi, L.Y.; Ding, P. A Green Plastic Constructed from Cellulose and Functionalized Graphene with High Thermal Conductivity. ACS Appl. Mater. Interfaces 2017, 9, 17914–17922. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, Z.; Li, T.; Ma, P.M.; Zhang, X.H.; Xia, B.H.; Chen, M.Q.; Du, M.L.; Liu, T.X.; Dong, W.F. Artificial Nacre Epoxy Nanomaterials Based on Janus Graphene Oxide for Thermal Management Applications. ACS Appl. Mater. Interfaces 2020, 12, 44273–44280. [Google Scholar] [CrossRef] [PubMed]

- Park, W.; Hu, J.N.; Jauregui, L.A.; Ruan, X.L.; Chen, Y.P. Electrical and thermal conductivities of reduced graphene oxide/polystyrene composites. Appl. Phys. Lett. 2014, 104, 113101. [Google Scholar] [CrossRef]

- Chen, Y.; Hou, X.; Liao, M.; Dai, W.; Wang, Z.; Yan, C.; Li, H.; Lin, C.-T.; Jiang, N.; Yu, J. Constructing a “pea-pod-like” alumina-graphene binary architecture for enhancing thermal conductivity of epoxy composite. Chem. Eng. J. 2020, 381, 122690. [Google Scholar] [CrossRef]

- Li, J.C.; Zhao, X.Y.; Wu, W.J.; Ji, X.W.; Lu, Y.L.; Zhang, L.Q. Bubble-templated rGO-graphene nanoplatelet foams encapsulated in silicon rubber for electromagnetic interference shielding and high thermal conductivity. Chem. Eng. J. 2021, 415, 129054. [Google Scholar] [CrossRef]

- Jiang, F.; Cui, X.L.; Song, N.; Shi, L.Y.; Ding, P. Synergistic effect of functionalized graphene/boron nitride on the thermal conductivity of polystyrene composites. Compos. Commun. 2020, 20, 100350. [Google Scholar] [CrossRef]

- Yan, Z.; Nika, D.L.; Balandin, A.A. Thermal properties of graphene and few-layer graphene: Applications in electronics. IET Circuits Devices Syst. 2015, 9, 4–12. [Google Scholar] [CrossRef]

- Han, W.F.; Chen, M.Y.; Li, W.; Ge, C.H.; Zhang, R.; Zeng, H.R.; Zhang, X.D. Directly Grown Polystyrene Nanospheres on Graphene Oxide Enable Efficient Thermal Management. Ind. Eng. Chem. Res. 2021, 60, 7124–7131. [Google Scholar] [CrossRef]

- Wang, X.W.; Wu, P.Y. Fluorinated Carbon Nanotube/Nanofibrillated Cellulose Composite Film with Enhanced Toughness, Superior Thermal Conductivity, and Electrical Insulation. ACS Appl. Mater. Interfaces 2018, 10, 34311–34321. [Google Scholar] [CrossRef] [PubMed]

- Hu, M.; Cui, C.; Shi, C.; Wu, Z.-S.; Yang, J.; Cheng, R.; Guang, T.; Wang, H.; Lu, H.; Wang, X. High-Energy-Density Hydrogen-Ion-Rocking-Chair Hybrid Supercapacitors Based on Ti3C2Tx MXene and Carbon Nanotubes Mediated by Redox Active Molecule. ACS Nano 2019, 13, 6899–6905. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.G.; Yang, Y.L.; Zheng, Z.L.; Lan, R.T.; Dai, K.; Xu, L.; Huang, H.D.; Tang, J.H.; Xu, J.Z.; Li, Z.M. Achieving excellent thermally conductive and electromagnetic shielding performance by nondestructive functionalization and oriented arrangement of carbon nanotubes in composite films. Compos. Sci. Technol. 2020, 194, 108190. [Google Scholar] [CrossRef]

- Xiao, Y.J.; Wang, W.Y.; Lin, T.; Chen, X.J.; Zhang, Y.T.; Yang, J.H.; Wang, Y.; Zhou, Z.W. Largely Enhanced Thermal Conductivity and High Dielectric Constant of Poly(vinylidene fluoride)/Boron Nitride Composites Achieved by Adding a Few Carbon Nanotubes. J. Phys. Chem. C 2016, 120, 6344–6355. [Google Scholar] [CrossRef]

- Zheng, Z.H.; Li, W.C.; Liu, H.; Wang, X.D. Sustainable Interfacial Evaporation System Based on Hierarchical MXene/Polydopamine/Magnetic Phase-Change Microcapsule Composites for Solar-Driven Seawater Desalination. ACS Appl. Mater. Interfaces 2022, 14, 50966–50981. [Google Scholar] [CrossRef]

- Wu, Y.P.; Xue, Y.; Qin, S.; Liu, D.; Wang, X.B.; Hu, X.; Li, J.L.; Wang, X.G.; Bando, Y.; Golberg, D.; et al. BN Nanosheet/Polymer Films with Highly Anisotropic Thermal Conductivity for Thermal Management Applications. ACS Appl. Mater. Interfaces 2017, 9, 43163–43170. [Google Scholar] [CrossRef]

- Rahman, M.M.; Puthirath, A.B.; Adumbumkulath, A.; Tsafack, T.; Robatjazi, H.; Barnes, M.; Wang, Z.X.; Kommandur, S.; Susarla, S.; Sajadi, S.M.; et al. Fiber Reinforced Layered Dielectric Nanocomposite. Adv. Funct. Mater. 2019, 29, 1900056. [Google Scholar] [CrossRef]

- Wu, K.; Wang, J.M.; Liu, D.Y.; Lei, C.X.; Liu, D.; Lei, W.W.; Fu, Q. Highly Thermoconductive, Thermostable, and Super-Flexible Film by Engineering 1D Rigid Rod-Like Aramid Nanofiber/2D Boron Nitride Nanosheets. Adv. Mater. 2020, 32, e1906939. [Google Scholar] [CrossRef] [PubMed]

- Ding, D.L.; Shang, Z.H.; Zhang, X.; Lei, X.F.; Liu, Z.G.; Zhang, Q.Y.; Chen, Y.H. Greatly enhanced thermal conductivity of polyimide composites by polydopamine modification and the 2D-aligned structure. Ceram. Int. 2020, 46, 28363–28372. [Google Scholar] [CrossRef]

- Su, Z.; Wang, H.; Ye, X.Z.; Tian, K.H.; Huang, W.Q.; Xiao, C.; Tian, X.Y. Enhanced thermal conductivity of functionalized-graphene/boron nitride flexible laminated composite adhesive via a facile latex approach. Compos. Part A-Appl. Sci. Manuf. 2017, 99, 166–175. [Google Scholar] [CrossRef]

- Guerra, V.; Wan, C.Y.; McNally, T. Thermal conductivity of 2D nano-structured boron nitride (BN) and its composites with polymers. Prog. Mater. Sci. 2019, 100, 170–186. [Google Scholar] [CrossRef]

- Guo, F.M.; Shen, X.; Zhou, J.M.; Liu, D.; Zheng, Q.B.; Yang, J.L.; Jia, B.H.; Lau, A.K.T.; Kim, J.K. Highly Thermally Conductive Dielectric Nanocomposites with Synergistic Alignments of Graphene and Boron Nitride Nanosheets. Adv. Funct. Mater. 2020, 30, 1910826. [Google Scholar] [CrossRef]

- Wu, W.F.; Ren, T.L.; Liu, X.Q.; Davis, R.; Huai, K.; Cui, X.; Wei, H.X.; Hu, J.J.; Xia, Y.M.; Huang, S.H.; et al. Creating thermal conductive pathways in polymer matrix by directional assembly of synergistic fillers assisted by electric fields. Compos. Commun. 2022, 35, 101309. [Google Scholar] [CrossRef]

- Zhang, X.M.; Zhang, J.J.; Xia, L.C.; Li, C.H.; Wang, J.F.; Xu, F.; Zhang, X.L.; Wu, H.; Guo, S.Y. Simple and Consecutive Melt Extrusion Method to Fabricate Thermally Conductive Composites with Highly Oriented Boron Nitrides. ACS Appl. Mater. Interfaces 2017, 9, 22977–22984. [Google Scholar] [CrossRef]

- Yu, C.; Gong, W.; Tian, W.; Zhang, Q.; Xu, Y.; Lin, Z.; Hu, M.; Fan, X.; Yao, Y. Hot-pressing induced alignment of boron nitride in polyurethane for composite films with thermal conductivity over 50 Wm−1 K−1. Compos. Sci. Technol. 2018, 160, 199–207. [Google Scholar] [CrossRef]

| Sample | Molding Parameters |

|---|---|

| PS/BN-A1,3,5 | 120 °C/10 MPa |

| PS/BN-B1,3,5 | 140 °C/5 MPa |

| PS/BN-C1,3,5 | 140 °C/10 MPa |

| PS/BN-D1,3,5 | 160 °C/10 MPa |

| PS/BN | Solution casting |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Gong, W.; Liu, X.; Fan, Y.; He, A.; Nie, H. Enhancing Thermal Conductivity in Polymer Composites through Molding-Assisted Orientation of Boron Nitride. Polymers 2024, 16, 1169. https://doi.org/10.3390/polym16081169

Liu Y, Gong W, Liu X, Fan Y, He A, Nie H. Enhancing Thermal Conductivity in Polymer Composites through Molding-Assisted Orientation of Boron Nitride. Polymers. 2024; 16(8):1169. https://doi.org/10.3390/polym16081169

Chicago/Turabian StyleLiu, Yongjia, Weiheng Gong, Xingjian Liu, Yicheng Fan, Aihua He, and Huarong Nie. 2024. "Enhancing Thermal Conductivity in Polymer Composites through Molding-Assisted Orientation of Boron Nitride" Polymers 16, no. 8: 1169. https://doi.org/10.3390/polym16081169