3. Results and Discussion

The configuration of the industrial polyurethane foam plant line used for trials has imposed the limitation of having to include isocyanate in the formulation. This has led to the need of having to reformulate the tannin-furanic foams, to start a pure phenolic-type foam, into a hybrid system in which polymeric 4,4'-diphenylmethane diisocyanate had to be injected. This presented some challenges to adapt the formulation. In

Table 1, only the final series of formulations used are reported, from formulation R1, which was the one further analyzed for oligomeric structural elucidation to the R80 series of formulations that were characterized and used for the plant trial.

The formulations shown in

Table 1 led to simultaneous foaming of the tannin, furanic and polyurethane networks. Thus, all of the foams obtained presented a homogeneous aspect and were less friable than the simples tannin-furanic foams prepared in the past [

7,

8,

9,

11]. This effect is due to the appropriate balance between the different components of the resins and the selection of a suitable surfactant. The exotherm of foaming is lower when water is included in the resins, and consequently, the induction times are longer (Series 80 compositions). The resultant foams present less structural imperfections, mainly at higher room temperature (results not reported), because the expansion process occurs under more controlled conditions. The times presented in

Table 1, mainly the induction times, are indicative and can change depending on the length and type of mixing operation (stirring, injection), temperature,

etc. These times can be regulated for a given condition by proportionally changing the amount of catalyst and isocyanate. For instance, for 64.4 g of the R80B resin (

Table 1), when the temperature is around 28 °C, the catalyst and isocyanate amount must be fixed in 6.6 g and 22.6 g, respectively, in order to reach a controlled expansion of the foam.

As explained, the R80 series of resins are more stable than the R1 resin: this last formulation presents spontaneous polymerization and becomes a paste after a few hours, while for the R80 series resins (stored at room temperature), stability has been verified to be longer than five months. In particular, the viscosity of the resin used for the R80B foam containing the surfactant (Tegostab B8406) was 6000 Pa·s at 25 °C. After 24 h, the viscosity decreased to 5600 Pa·s at 25 °C. Such a decrease in viscosity during the first few hours is due to the completion of dissolving the tannin in the mixture. By 10 days after resin preparation, the viscosity has increased to 6600 Pa·s at 25 °C. The same resin, but without the surfactant, shows a viscosity at 25 °C of 5380 Pa·s, which decreases to 4900 Pa·s after 24 h and increases to 5020 Pa·s after 10 days of ageing.

The R80 series of formulations were used for industrial trials. The resin was prepared in the same way as that for the laboratory experiments, and after 72 h of continuous foaming, trials were carried out.

The analysis of the composition of the R80 series formulations (

Table 1) indicates that decreasing the relative proportion of glyoxal from R80B causes a decrease of the foam density (R80G). Thus, Basso

et al. [

11] have observed the same effect when formaldehyde is eliminated from purely tannin–furanic foam formulations. Increasing the relative proportion of surfactant extends reaction times and causes a decrease of the temperature during foaming [

14], giving more controlled, but slower foaming and rising foam density (R80S). Partially replacing water by ethylene glycol (R88) induced earlier foaming, because this solvent is less effective as a heat sink. The increase in foaming rate is lower than for R1, because for this last one, no water is included in the formulation, with just the water contained originally in the reagents (catalyst and glyoxal) being present.

The light grey foams so produced were tested, yielding a thermal conductivity from 0.036 to 0.046 W/mK for apparent densities in the 0.04–0.07 g/cm

3 range (

Table 1). Mechanical strength at 20% deformation for R80B samples is about 0.19 MPa with a Young’s modulus of 3.5 MPa. The mechanical characteristics of the R80B foam at 0.06 g/cm

3 are better than those of the pine tannin-furanic foams having the same density [

18]. They are comparable to those measured for quebracho tannin–furanic foams, presenting the same density, but also containing formaldehyde and a flammable solvent [

19], this latter needing special handling. Moreover, these latter foams, contrary to the R80B, do not satisfy the conditions needed for their manufacturing on an industrial line built for polyurethane foam manufacturing.

The outstanding fire retarding capability of foams based on tannin and furfuryl alcohol has already been demonstrated [

20] and is fully maintained in all of these new tannin–furanic–polyurethane foams. While the excellent fire resistance of the tannin–furanic–polyurethane foams represents a definite advantage over polyurethane foams, at equal density, the mechanical resistance of these latter is greater than that of these new materials. Thus, the improvement of the mechanical performance of the tannin–furanic–polyurethane foams remains a main objective for future research.

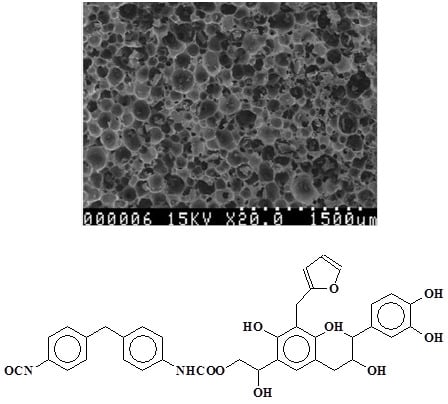

The cellular morphology of the P80 and R80B foams is shown in

Figure 1 and

Figure 2, respectively. The P80 foam shows broken and disordered cells, while for the new R80B foam, the cells are bigger, better preserved and evenly organized. This difference can be explained by considering that the exotherm of reaction is greater for the foams containing the isocyanate (>100 °C) [

13]. Thus, hardening is more favored for such foams, and thus, the structure resists the foam expansion better. Furthermore, the coexistence of the two networks, namely the phenolic-furanic one and the polyurethane one, leads to a stronger structure. For the R80 foam without isocyanate, the exotherm and foaming temperature are lower, and as a consequence, the hardening is great; this notwithstanding the application of external heat (35 °C) to facilitate it. Thus, for this foam, evaporation of the blowing agent (pentane) affects markedly its cellular structure.

Figure 1.

Scanning electron microscope (SEM) picture of P80 tannin–furanic foam.

Figure 1.

Scanning electron microscope (SEM) picture of P80 tannin–furanic foam.

Figure 2.

SEM picture of R80B tannin–furanic–polyurethane foam.

Figure 2.

SEM picture of R80B tannin–furanic–polyurethane foam.

Of greater interest was to determine if co-reaction occurred between the three main components of the formulation, namely flavonoid tannin, furfuryl alcohol and polymeric isocyanate. Thus, the resulting foam was analyzed by matrix-assisted laser desorption ionization time of flight (MALDI-TOF) mass spectrometry and by solid-state CP-MAS

13C NMR. Since its introduction by Karas and Hillenkamp [

17], MALDI-TOF has been used to good effect and has been shown to be a remarkably accurate analytical system to determine the oligomers’ distribution of polyflavonoid tannins [

21] and derived condensation products [

5,

8,

9]. The results of the MALDI-TOF analysis are shown in

Figure 3,

Figure 4,

Figure 5 and

Figure 6 and the interpretation in

Table 2.

In condensed tannins, generally the flavonoid units involved in the formation of the oligomers are of three types, respectively A (fisetinidin), B (robinetinidin and catechin) and C (gallocatechin) of respective masses of 274.3 Da, 290.3 Da and 306.3 Da. Two structures correspond to the mass of B, which both coexist (

Scheme 1).

Scheme 1.

Structure of the four basic flavonoids composing a condensed tannin.

Scheme 1.

Structure of the four basic flavonoids composing a condensed tannin.

The combinations of these masses (

A = 274,

B = 290,

C = 306) can be used to calculate the masses of the oligomer peaks in the spectra according to the expression M + Na

+ = 23.0 (Na) + 2.0 (end groups, 2X H) + 272.3A + 288.3B + 304.3C, when NaCl enhancer has been used [

21].

First of all, a few, but not many, unreacted flavonoid oligomers belonging to the tannin itself are noticed in

Table 2 and

Figure 3 and

Figure 4. These are the monomers at the peaks of 303 and 326 Da, and the pure flavonoid tetramers at 1225 and 1241 Da. These are few, the mix of oligomers formed rather being composed of a number of different co-reaction products.

Second, the oligomers resulting from the exothermic self-condensation of furfuryl alcohol from which the foaming of the tannin–furanic system is derived, and their subsequent reaction with the flavonoid aromatic nuclei are clearly present. Some of these have been observed before [

7,

8,

9]. These, where only tannin and furfuryl alcohol have reacted, are represented by the species peaks at 378, 393, 408, 472, 537, 552, 568 and 633 Da. However, at a higher molecular weight, when flavonoid and furfuryl alcohol are condensed together, they are also reacted with other reagents to yield more complex oligomers.

Table 2.

MALDI-ToF interpretation of species in the preparation of the co-reaction of tannin-polyurethane. Legend: Flavo, flavonoid, with unit molecular weight in parenthesis; Fur, furan cycle; I, isocyanate with unit molecular weight in parenthesis; U, urethane bridge; PhSulph, phenolsulfonic acid; Gly, glyoxal, –CH(OH)–CH(OH)–; ethylene glycol, –CH2CH2– and –CH2CH2–OH.

Table 2.

MALDI-ToF interpretation of species in the preparation of the co-reaction of tannin-polyurethane. Legend: Flavo, flavonoid, with unit molecular weight in parenthesis; Fur, furan cycle; I, isocyanate with unit molecular weight in parenthesis; U, urethane bridge; PhSulph, phenolsulfonic acid; Gly, glyoxal, –CH(OH)–CH(OH)–; ethylene glycol, –CH2CH2– and –CH2CH2–OH.

| Peak (Da) | Species |

|---|

| 303 | gallocatechin without Na+ |

| 326 | gallocatechin + Na+ |

| 334 | I(250)–U–CH2CH2–OH |

| 359/360 (big) | Flavo(274)–CH(OH)–C+H(OH) |

| 370 | I(250)–U–CH2–Fur |

| 374 | Flavo(274)–CH(OH)–CH(OH)–OH |

| 378(376) | Flavo(274)–CH2–Fur |

| 392–394 | Flavo(289)–CH2–Fur |

| 394 | HO–CH2CH2–U–I(250)–U–CH2CH2–OH |

| 405(404) | I(382) + 23 |

| 408(410) | Flavo(304)–CH2–Fur |

| 436(431 + protonation) | PhSulph–Gly–PhSulph (= PhSulph–CH(OH)–CH(OH)–PhSulph) |

| 440 | HO–CH2CH2–U–I(250)–[–U–CH2CH2–OH]2 |

| 465 | I(250)–(U–CH2–Fur)2 or Fur–CH2–U–I(250)–U–CH2–Fur |

| 466 | I(382)–U–CH2CH2–OH |

| 472 (small) | Flavo(289)–CH2–Fur–CH2–Fur |

| 480/482 | Flavo(289)–CH2–Fur–CH(OH)–CH(OH)–OH |

| 500/501 | I(382)–U–CH2–Fur |

| 507(510) | PhSulph–CH(OH)–CH(OH)–PhSulph–CH(OH)–CH–(OH)2 |

| 510 | +CH2CH2–U–I(382)–U–CH2CH2–OH |

| 525/526 | HO–CH2CH2–U–I(382)–U–CH2CH2–OH and/or Flavo(274)–[–CH2–Fur]2–CH2–Fur |

| 537 (big) | Flavo(289)–[–CH2–Fur]2–CH2–Fur |

| 552 | Flavo(304)–[–CH2–Fur]2–CH2–Fur |

| 568/570 | +CH2CH2–U–I(382)–[–U–CH2CH2–OH]2 |

| 586 | HO–CH2CH2–U–I(382)–[–U–CH2CH2–OH]2 |

| 622(621–622) | Flavo(274)–Gly–U–I(250) |

| 633 | Flavo(289)–[–CH2–Fur]3–CH2–Fur and +CH2CH2–U–I(382)–[–U–CH2CH2–OH]3 |

| 639(642) | Flavo(289)–Gly–U–I(250) |

| 656(655) | Flavo(304)–Gly–U–I(250) |

| 657(661) | Flavo(289)–Gly–Flavo(289) |

| 670 | PhSulph–CH(OH)–CH(OH)–PhSulph–CH(OH)–CH(OH)–PhSulph |

| 687 | HO–CH2CH2–U–I(250)–U–CH2CH2–U–I(250)–U–CH2CH2+ |

| 693/694 | I(382)–U–Flavo(274) |

| 702(701) (big) | Fur–CH2–Flavo(274)–Gly–U–I(250) |

| 708(705 protonated) | HO–CH2CH2–U–I(250)–U–CH2CH2–U–I(250)–U–CH2CH2–OH |

| 709 | I(382)–U–Flavo(289) |

| 712(714) | Flavo(274)–Gly–Flavo(274)–CH2–Fur |

| 716(720) | HO–CH2CH2–U–I(250)–U–CH(OH)CH(OH)–U–I(250)–U–CH2CH2+ |

| 718(718) | Fur–CH2–Flavo(289)–Gly–U–I(250) |

| 733 | HOCH2CH2–U–I(250)–U–CH(OH)CH(OH)–U–I(250)–U–CH2CH2OH |

| 734(732) | Fur–CH2–Flavo(304)–Gly–U–I(250) |

| 742(744) | Flavo(289)–Gly–Flavo(289)–CH2–Fur |

| 745 | PhSulph–Gly–PhSulph–Gly–PhSulph–CH(OH)–CH–(OH)2 |

| 754(756) | Flavo(274)–CH(OH)–CH(OH)–U–I(382) |

| 757(759/760) | Flavo(304)–Gly–Flavo(289)–CH2–Fur |

| 786(788) | Flavo(304)–CH(OH)–CH(OH)–U–I(382) |

| 834(833) | Fur–CH2–Flavo(274)–Gly–U–I(382) |

| 857 | (289)Flavo–U–I(250)–U–Flavo(289) |

| 868(872) | (289)Flavo–U–I(250)–U–Flavo(304) |

| 907(904) | PhSulph–Gly–PhSulph–Gly–PhSulph–Gly–PhSulph and I(382)–U–CH2–Fur–Gly–Fur–CH2–U–I(250) |

| 966(968) | Fur–CH2–Flavo(274)–Gly–U–I(382) |

| 976(978) | Fur–CH2–Flavo(274)–Flavo(274)–Gly–U–I(250) |

| 981(979) | (289)Flavo–U–I(382)–U–Flavo(289) and/or PhSulph–Gly–[–PhSulph–Gly–]3–CH(OH)–CH–(OH)2 |

| 995 (small) | (289)Flavo–U–I(382)–U–Flavo(304) |

| 1015 | HO–CH2CH2–U–I(250)–U–[–CH2CH2–U–I(250)–U–]2–CH2CH2–OH |

| 1024 | Fur–CH2–Flavo(289)–Flavo(304)–Gly–U–I(250) |

| 1056 | Fur–CH2–Flavo(274)–Flavo(274)–Gly–U–I(250)–U–CH2–Fur |

| 1129 | (304)Flavo–U-I(250)–U–Flavo(304)–U–I(250) |

| 1145 | PhSulph–Gly–[–PhSulph–Gly–]3–PhSulph |

| 1155 | Fur–CH2–Flavo(289)–Flavo(304)–Gly–U–I(382) |

| 1209(1207) | HO–CH2CH2–U–I(382)–U–[CH(OH)CH(OH)–U–I(250)–U]2–CH2CH2–OH |

| 1218(1214) | PhSulph–Gly–[–PhSulph–Gly–]4–PhSulph |

| 1225(1227) | Flavo(289)–Flavo(304)–Flavo(304)–Flavo(305) |

| 1241(1244) | Flavo(305)–Flavo(304)–Flavo(304)–Flavo(305) |

| 1360(1361) | (274)Flavo–U–I(250)–U–Flavo(274)–U–I(250)–U–Flavo(289) |

| 1361(1360) | HOCH2CH2UI(250)U[CH2CH2U–I(250)U]2–[CH(OH)CH(OH)–U–I(250)–U]CH2CH2+ |

| 1375(1373) | HOCH2CH2UI(250)U[CH2CH2U–I(250)U]2–[CH(OH)CH(OH)–U–I(250)–U]CH2CH2OH |

| 1376(1376) | (274)Flavo–U–I(250)–U–Flavo(289)–U–I(250)–U–Flavo(289) |

| 1403 | HO–CH2CH2–U–I(250)–U–[CH(OH)CH(OH)–U–I(250)–U]3–CH2CH2+ |

| 1405 | Flavo(274)–Gly–(274)Flavo–U–I(250)–U–Flavo(274)–U–I(250) and (304)Flavo–U–I(250)–U–Flavo(304)–U–I(250)–U–Flavo(274) and (289)Flavo–U–I(250)–U–Flavo(304)–U–I(250)–U–Flavo |

| 1417(1419) | HO–CH2CH2–U–I(250)–U–[CH(OH)CH(OH)–U–I(250)–U]3–CH2CH2–OH |

| 1465(1464) | (304)Flavo–U–I(250)–U–Flavo(304)–Gly–U–I(250)–U–Flavo(274) |

| 1420 | (274)Flavo–U–I(250)–U–Flavo(274)–Gly–U–I(250)–U–Flavo(289) |

| 1450 | (289)Flavo–U–I(250)–U–Flavo(289)–Gly–U–I(250)–U–Flavo(289) |

| 1466(1464/1466) | (289)Flavo–U–I(250)–U–Flavo(289)–U–I(250)–U–Flavo(289)–CH(OH)CH(OH)2 |

| 1537 | HO–CH2CH2–U–I(382)–U–[CH(OH)CH(OH)–U–I(250)–U]3–CH2CH2+ |

| 1551 | HO–CH2CH2–U–I(382)–U–[CH(OH)CH(OH)–U–I(250)–U]3–CH2CH2–OH |

| 1595(1597) | (274)Flavo–U–I(250)–U–Flavo(274)–U–I(250)–U–Flavo(274)–U–I(250) |

| 1597 | (274)Flavo–Gly–U–I(382)–U–Flavo(274)–U–I(250)–Gly–U–Flavo(274) and (274)Flavo–Gly–U–I(382)–U–Flavo(274)–U–I(250)U–CH2CH2–U–Flavo(274) |

| 1673 | HOCH2CH2U–I(382)U[CH(OH)CH(OH)UI(382)U]–[CH(OH)CH(OH)UI(250)U]2–CH2CH2+ |

| 1671(1674) | (289)Flavo–U–I(250)–U–Gly–Flavo(274)–U–I(250)–U–Flavo(274)–U–I(250) |

| 1670(1674) | (274)Flavo–U–I(382)–U–Flavo(274)–Gly–U–I(382)–U–Flavo(274) |

| 1685 | HOCH2CH2U–I(382)U[CH(OH)CH(OH)UI(382)U]–[CH(OH)CH(OH)UI(250)U]2–CH2CH2OH and (274)Flavo–U–I(382)–U–Flavo(274)–U–I(382)–U–Flavo(274)–CH(OH)CH(OH)2 |

| 1727 | (HOCH2CH2U)2–I(382)U[CH(OH)CH(OH)UI(382)U]–[CH(OH)CH(OH)UI(250)U]2–CH2CH2OH and (274)Flavo–U–I(382)–U–Flavo(274)–U–I(250)–U–Flavo(274)–U–I(250) |

| 1760 | HO–CH2CH2–U–I(250)–U–[CH(OH)CH(OH)-–U–I(250)–U]4–CH2CH2–OH |

| 1772 | (HOCH2CH2U)2–I(382)U[CH(OH)CH(OH)UI(382)U]–[CH(OH)CH(OH)UI(250)U]2–CH2CH2OH |

| 1816 | (304)Flavo–U–I(382)–U–Flavo(304)–U–I(250)–U–Flavo(304)–U–I(250) |

| 1847 | (274)Flavo–U–I(382)–U–Gly–Flavo(274)–U–I(250)–U–Gly–Flavo(274)–U–I(250) |

| 1862 | (274)Flavo–U–I(382)–U–Gly–Flavo(274)–U–I(250)–U–Flavo(274)–U–I(250)U–Gly–OH |

| 1893 | HO–CH2CH2–U–I(382)–U–[CH(OH)CH(OH)–U–I(250)–U]4–CH2CH2–OH |

| 1939 | (274)Flavo–U–I(250)–U–Flavo(274)–U–I(382)–U–Flavo(274)–U–I(382) |

| 1949 | (304)Flavo–U–I(382)–U–Flavo(304)–U–I(382)–U–Flavo(304)–U–I(250) |

| 1991(1993) | (274)Flavo–U–I(382)–U–Flavo(274)–U–I(382)–U–Flavo(274)–U–I(382) |

| 2025 | HO–CH2CH2UI(382)U–[CH(OH)CH(OH)U–I(382)–U]–[CH(OH)CH(OH)U–I(250)–U]3–CH2CH2–OH |

Figure 3.

The 300–500 Da range of the MALDI-TOF spectrum of tannin–furanic–polyisocyanate hardened foam.

Figure 3.

The 300–500 Da range of the MALDI-TOF spectrum of tannin–furanic–polyisocyanate hardened foam.

Figure 4.

The 500–700 Da range of the MALDI-TOF spectrum of tannin–furanic–polyisocyanate hardened foam.

Figure 4.

The 500–700 Da range of the MALDI-TOF spectrum of tannin–furanic–polyisocyanate hardened foam.

Figure 5.

The 700–1200 Da range of the MALDI-TOF spectrum of tannin–furanic–polyisocyanate hardened foam.

Figure 5.

The 700–1200 Da range of the MALDI-TOF spectrum of tannin–furanic–polyisocyanate hardened foam.

Figure 6.

The 1200–2000 Da of the range MALDI-TOF spectrum of tannin–furanic–polyisocyanate hardened foam.

Figure 6.

The 1200–2000 Da of the range MALDI-TOF spectrum of tannin–furanic–polyisocyanate hardened foam.

Several mixed copolymerization patterns can be noticed: flavonoids condensed through the reaction exclusively with the glyoxal, such as the peaks at 359–360 Da and at 374 Da. These materials participate then to the formation of urethanes by reaction with the isocyanate to form the peaks at 622, 639, 656, 754, 834, 966, 976, 1024, 1056 (with Fur (furan cycle), different origin perhaps), 1155, 1405 (possibly), 1420, 1450, 1465, 1597, 1670/1671 and 1685 Da (possibly). It must be pointed out that while in this series, flavonoid monomers and oligomers are reacted with glyoxal and with isocyanate, different cases appear to occur, such as (i) the isocyanate having formed the urethane with the glyoxal linked to the flavonoid, as well as (ii) the glyoxal having linked two flavonoid oligomers and the isocyanate having reacted with the flavonoid itself to form the urethane bridge or bridges. All that appears from this series is that oligomers obtained by co-reaction of flavonoids, glyoxal and isocyanate have been formed in considerable number and variety. Thus, for example, the oligomer at Peak 622 (

Table 2) has a structure as follows (

Scheme 2).

Scheme 2.

Urethane linkage between a glyoxalated flavonoid and a diisocyanate dimer.

Scheme 2.

Urethane linkage between a glyoxalated flavonoid and a diisocyanate dimer.

Present are also urethanes formed by the reaction of the isocyanate exclusively with glyoxal. This latter one gives rise to the series of peaks at 334, 394, 440, 466, 526, 570, 586, 633 (possibly), 687, 708, 716, 733, 1015, 1209, 1361, 1365, 1403, 1417, 1537, 1551, 1673, 1685, 1727, 1760, 1772, 1893 and 2025 Da. Given the relatively low proportion of glyoxal present, these peaks appear to be rather noticeable, possibly because other higher molecular weight species once reacted have a molecular weight too high for MALDI analysis.

The reaction products of furfuryl alcohol with isocyanate are represented by the peaks at 370, 465 and 500/501 Da. Mixed species in which glyoxal has formed a bridge between two furfuryl alcohol molecules, each of which has then reacted with isocyanate groups to form urethane bridges attached to the furan nuclei, are also present, such as the species at 904/907 Da. However, this is the only species of this type that appears to have been formed.

Thus, for example, the oligomer at 370–371 Da has a structure as follows (

Scheme 3).

Scheme 3.

Urethane linkage between diisocyanate dimer and furfuryl alcohol.

Scheme 3.

Urethane linkage between diisocyanate dimer and furfuryl alcohol.

Other peaks in which the furfuryl alcohol has reacted with a flavonoid oligomer, either pure or already reacted with glyoxal to a higher

MW, that has then reacted with the isocyanate are also present and are quite numerous. These, however, are not due to the direct reaction of furfuryl alcohol with the isocyanate. This appears to indicate that furfuryl alcohol favors more the formation of flavonoid-furan methylene (–CH

2–) bridges rather than reacting with isocyanate groups to form urethane bridges. Thus, for example, the structure of the oligomers corresponding to the 537 Da peaks in

Table 2 is shown in

Scheme 4.

Scheme 4.

Link between furfuryl alcohol oligomer and a flavonoid.

Scheme 4.

Link between furfuryl alcohol oligomer and a flavonoid.

Equally present are species in which the flavonoids of the tannin have reacted with the isocyanate to form one or several urethane bridges; among these are the species at 693/694, 708, 857, 868, 981, 995, 1129, 1360, 1376, 1405, 1595, 1727, 1816, 1939, 1949 and 1991 Da, Some are oligomers of flavonoids linked by urethane bridges to the skeleton of the isocyanate. To give an example, the species indicated in

Table 2 at 995 Da as (289)Flavo–U–I(382)–U–Flavo(304) can equally have the structure as shown in

Scheme 5,

Scheme 6,

Scheme 7 and

Scheme 8.

Scheme 5.

One of the possible structures of the diurethane between two flavonoid monomers and an isocyanate trimer.

Scheme 5.

One of the possible structures of the diurethane between two flavonoid monomers and an isocyanate trimer.

Scheme 6.

One of the possible structures of the urethane between a flavonoid dimer and an isocyanate trimer.

Scheme 6.

One of the possible structures of the urethane between a flavonoid dimer and an isocyanate trimer.

Scheme 7.

One of the possible structures of the urethane between a flavonoid dimer and an isocyanate trimer

Scheme 7.

One of the possible structures of the urethane between a flavonoid dimer and an isocyanate trimer

Structures of the same type as the one above, but where the flavonoid –OH in C3 is the one having reacted to form the urethane, are actually possible. An example is the following structure in

Scheme 8.

Scheme 8.

One of the possible structures of the diurethane between two flavonoid monomers and an isocyanate trimer.

Scheme 8.

One of the possible structures of the diurethane between two flavonoid monomers and an isocyanate trimer.

The CP-MAS 13C NMR examination discussed below indicated that C3-reacted structures of this last type predominate, but that also urethanes formed by the reaction of the isocyanate on phenolic hydroxyl groups were formed.

Given the relative abundance of the phenol sulfonic acid catalyst, there are also several oligomers formed by the reaction of its aromatic nuclei with glyoxal at 436, 507, 670, 745, 907, 981 (possibly), 1145 and 1218 Da. However, phenolsulfonic acid does not seem to have reacted with any other reagents other than glyoxal. What is interesting, however, is that it too has formed species of higher molecular weight, this eliminating the possibility of any acid residual mobility in, or leachability from, the foam structure.

Mixed flavonoid/glyoxal/furanic/isocyanate oligomers in which all of main components participate are also very present, such as the oligomer peaks at 702, 718, 742, 757, 834, 966, 976, 1024, 1056, 1155 and 1405 Da. An example is the structure of the simpler oligomer of this series at 702 Da (

Table 2,

Scheme 9).

Scheme 9.

Urethane linkage between a diisocyanate dimer and a gloxalated and furfurylated flavonois. Note the urethane linkage is with the glyoxal moiety.

Scheme 9.

Urethane linkage between a diisocyanate dimer and a gloxalated and furfurylated flavonois. Note the urethane linkage is with the glyoxal moiety.

One type of oligomer appears to be missing: formaldehyde formed by the splitting of FurCH2OCH2Fur species does not seem to have formed. The formation of FurCH2O CH2Fur species and their rearrangement to FurCH2Fur with splitting off of formaldehyde is known in fast reactions under acid setting conditions, but none is observed in this case.

CP-MAS

13C NMR gives also very useful information on the composition of the resulting foam [

22]. The spectrum of formulation 922 is shown in

Figure 7. The peak centered at 152.8 ppm shows three distinct peaks. Theoretically, a urethane bridge C=O with an aromatic ring should appear at 152 ppm; one with the –CH

2OH group of the furfuryl alcohol should appear at 155 ppm; and finally, one with the alcohol –OH group on the C3 of the heterocyclic ring of the flavonoid should appear at 153 ppm, the nearest to 152.8. Thus, the three peaks indicate the presence of urethanes having formed with all of these groups, in not dissimilar proportions. These peaks are superimposed on the C2 and C5 (

Scheme 10) of the unreacted flavonoid, hence the width of the complex f peaks centered at 152.8 ppm.

Scheme 10.

Numbering of flavonoid sites.

Scheme 10.

Numbering of flavonoid sites.

The 136.4-ppm peak is that of just aromatic carbons. At 129–130 ppm, there is the superposition of several signals explaining the intensity of this peak; thus, the signal of O(C=O)–NH– is superimposed on the 127 ppm of unreacted –N=C=O groups, and the 129.7 ppm signal of the (Ar)C in meta position to the –N=C=O group, while the 117 ppm one pertains to the (Ar)C in ortho position to the –N=C=O group.

Figure 7.

CP-MAS 13C NMR spectrum of tannin–furanic–polyisocyanate hardened foam.

Figure 7.

CP-MAS 13C NMR spectrum of tannin–furanic–polyisocyanate hardened foam.

The confirmation of the urethane bridges comes first from the huge peak at 70.3 ppm Effectively, the –CH2– is involved in the urethane bridge between the polymeric 4,4'-dimethyl methane diisocyanate (PMDI) and a –CH2OH group that could be either that of the furfuryl alcohol that should appear at 66.1 ppm or with the –CHOH of glyoxal, which is also likely. Effectively, a small peak at 66 ppm does appear, between two bigger peaks. The C2 next to the flavonoid heterocycle C3 involved in the urethane bridge should appear at 69.3 ppm. As the spectrum has a precision of ±1 ppm, this is the urethane most likely represented by the 70.3-ppm peak. This is supported by the clear and marked shoulder at 74.6 ppm, as the C3 of the flavonoid involved in a urethane bridge should occur at 75.1 ppm. These peaks confirm the presence of three types of urethane bridges.

The 63-ppm peak is that of the –CH2– of the CH2OH group of unreacted furfuryl alcohol. The 39.8-ppm one is the –CH2– inner bridge of the polymeric 4,4'-dimethyl methane diisocyanate (PMDI) superimposed on the unreacted C4 signal of the flavonoid. The shoulder at 27 ppm is the C site on the furan ring ortho to the–CH2– involved in the urethane bridge, and the 23-ppm one is the –CH2– linking two furan rings obtained by the polycondensation of two furfuryl alcohol molecules.

The conclusion that can be derived is that at least three types of urethane bridges occur. The most abundant is the one formed with the alcohol –OH on the C3 of the flavonoid heterocycle. The second is the one involving either the furfuryl alcohol alone or the glyoxal either alone or pre-linked to a flavonoid aromatic ring. Due to the low level of water present in the 922 formulation urethane linkages on the aromatic rings of the flavonoids, thus formed on the phenolic –OHs, also appear to occur, but the evidence for these is less circumstantial.