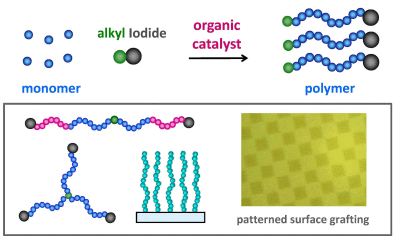

Macromolecular Architectures Designed by Living Radical Polymerization with Organic Catalysts

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. GPC Measurements

2.3. Preparation of Ethylene Glycol Bis(2-iodoisobutyrate) (EMA-II)

2.4. Preparation of Glycerol Tris(2-iodoisobutyrate) (EMA-III)

2.5. Preparation of 6-(2-iodo-2-isobutyloxy)Hexyltriethoxysilane (IHE)

2.6. Polymerization

2.7. Preparation of Poly(methyl methacrylate) Iodide (PMMA-I)

2.8. Preparation of Poly(butyl acrylate) Iodide (PBA-I)

2.9. Surface-Initiated Polymerization

3. Results and Discussion

3.1. Diblock Copolymers

| First block/second block | Entry | Polymerization | Monomer (equiv to [R-I]) | R-I | In a | Cat | [M]0/[R-I]0/[In]0/ [cat]0 b (mM) | T (°C) | t (h) | Conv. (%) | Mn c (Mn, theo) | PDI c | Ref. d |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MMA/GMA | 1 | 2nd block | GMA (200 eq) | PMMA-I e | – | BMPI | 8000/80/80 | 60 | 6 | 90 | 17,000 (17,000) | 1.23 | [27] |

| 2 | 1st block | MMA (100 eq) | CP-I | V65 | BMPI | 8000/80/15/80 f | 60 | 6 | 91 | 8300 (9100) | 1.13 | – | |

| 2nd block | GMA (100 eq) | – | – | – | +8000 | 60 | +6 | 200 | 17,000 (24,000) | 1.34 | – | ||

| 3 | 1st block | MMA (100 eq) | I2 | V70/V65 | BMPI | 8000/40/(60/15)/80 f | 60 | 6 | 89 | 8200 (8900) | 1.12 | – | |

| 2nd block | GMA (100 eq) | – | – | – | +8000 | 60 | +6 | 200 | 17,000 (24,000) | 1.39 | – | ||

| MMA/DMAEMA | 4 | 2nd block | DMAEMA (100 eq) | PMMA-I e | V70 | BMPI | 8000/80/10/10 | 50 | 2 | 95 | 18,000 (19,000) | 1.32 | – |

| 5 | 1st block | MMA (100 eq) | CP-I | V65 | BMPI | 8000/80/15/80 f | 60 | 6 | 91 | 8300 (9100) | 1.25 | – | |

| 2nd block | DMAEMA (100 eq) | – | V70 | – | +8000/15 | 50 | +4 | 178 | 21,000 (23,000) | 1.29 | – | ||

| 6 | 1st block | MMA (100 eq) | I2 | V70/V65 | BMPI | 8000/40/(60/15)/80 f | 60 | 6 | 89 | 8200 (8900) | 1.12 | – | |

| 2nd block | DMAEMA (100 eq) | – | V70 | – | +8000/15 | 50 | +4 | 172 | 21,000 (23,000) | 1.29 | – | ||

| MMA/(MMA/MAA) | 7 | 2nd block | MMA/MAA (24/16 eq) | PMMA-I e | V70 | CHD | 8000/160/80/5 | 40 | 2 | 80 | 6600 (5700) | 1.31 | [18] |

| MMA/BA | 8 | 2nd block | BA (100 eq) | PMMA–I e | – | BNI | 8000/80/320 | 110 | 24 | 65 | 15,000 (16,000) | 1.31 | [27] |

| 9 | 1st block | MMA (100 eq) | CP–I | – | BMPI | 8000/80/80 | 60 | 5 | 83 | 8400 (8300) | 1.10 | [27] | |

| 2nd block | BA (100 eq) | – | – | BNI | 8000/320 | 110 | 24 | 155 | 18,000 (18,000) | 1.32 | [27] | ||

| BA/MMA | 10 | 2nd block | MMA (100 eq) | PBA–I e | – | BNI | 8000/80/320 g | 110 | 5 | 86 | 16,000 (20,000) | 1.31 | [27] |

| 11 | 1st block | BA (100 eq) | CP–I | – | BNI | 8000/80/320 | 110 | 22 | 82 | 13,000 (11,000) | 1.28 | [27] | |

| 2nd block | MMA (100 eq) | – | – | – | +8000 f,g | 110 | 5 | 170 | 27,000 (21,000) | 1.39 | [27] |

3.2. Triblock Copolymers

| ABA block | Entry | Polymerization | Monomer (equiv to [R-I]) | R-I | In a | Cat | [M]0/[R-I]0/[In]0/ [cat]0b (mM) | T (°C) | t (h) | Conv. (%) | Mn c (Mn, theo) | PDI c |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BA/MMA/BA | 1 | 1st block | MMA (100 eq) | EMA-II | – | BMPI | 8000/80/80 d | 80 | 6 | 85 | 8800 (8500) | 1.32 |

| 2nd block | BA (100 eq) | – | – | BNI | +8000/320 | 110 | +24 | 154 | 17,000 (18,000) | 1.31 | ||

| MMA/BA/MMA | 2 | 1st block | BA (100 eq) | EMA-II | – | BNI | 8000/80/320 | 110 | 23 | 89 | 13,000 (11,000) | 1.21 |

| 2nd block | MMA (100 eq) | – | – | – | + 8000 d,e | 110 | +5 | 186 | 23,000 (21,000) | 1.33 | ||

| 3 | 1st block | BA (100 eq) | EMA-II | – | BNI/DABCO | 8000/80/(320/15) | 110 | 16 | 87 | 14,000 (11,000) | 1.37 | |

| 2nd block | MMA (100 eq) | – | – | – | +8000 d | 110 | +5 | 176 | 25,000 (20,000) | 1.39 | ||

| MMA/LMA/MMA | 4 | 1st block | LMA (100 eq) | EMA-II | V65 | BMPI | 8000/80/15/80 d | 60 | 6 | 84 | 17,000 (21,000) | 1.31 |

| 2nd block | MMA (100 eq) | – | V65 | 8000/10 | 60 | +6 | 162 | 24,000 (29,000) | 1.33 |

3.3. Three-Arm Star Polymer

3.4. Surface-Initiated Polymerization—Concentrated Polymer Brush

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Tsarevsky, N.V.; Sumerlin, B.S. Fundamentals of Controlled/Living Radical Polymerization; Royal Society of Chemistry: London, UK, 2013. [Google Scholar]

- Matyjaszewski, K.; Möller, M. Polymer Science: A Comprehensive Reference; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Moad, G.; Solomon, D.H. The Chemistry of Radical Polymerization; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Fukuda, T. Fundamental kinetic aspects of living radical polymerization and the use of gel permeation chromatography to shed light on them. J. Polym. Sci. Part A Polym. Chem. 2004, 42, 4743–4755. [Google Scholar] [CrossRef]

- Fischer, H. The persistent radical effect: A principle for selective radical reactions and living radical polymerizations. Chem. Rev. 2001, 101, 3581–3618. [Google Scholar] [CrossRef]

- Goto, A.; Fukuda, T. Kinetics of living radical polymerization. Prog. Polym. Sci. 2004, 29, 329–385. [Google Scholar] [CrossRef]

- Fukuda, T.; Goto, A. Controlled and Living Radical Polymerization—Principles and Fundamentals. In Polymer Science: A Comprehensive Reference; Matyjaszewski, K., Möller, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2012; pp. 120–157. [Google Scholar]

- Sciannamea, V.; Jérôme, R.; Detrembleur, C. In-situ nitroxide-mediated radical polymerization (NMP) processes: Their understanding and optimization. Chem. Rev. 2008, 108, 1104–1126. [Google Scholar] [CrossRef]

- Moad, G.; Rizzardo, E.; Thang, S.H. Living radical polymerization by the RAFT process—A second update. Aust. J. Chem. 2009, 62, 1402–1472. [Google Scholar] [CrossRef]

- Keddie, D.J.; Moad, G.; Rizzado, E.; Thang, S.H. RAFT agent design and synthesis. Macromolecules 2012, 45, 5321–5342. [Google Scholar] [CrossRef]

- David, G.; Boyer, C.; Tonnar, J.; Ameduri, B.; Lacroix-Desmazes, P.; Boutevin, B. Use of iodocompounds in radical polymerization. Chem. Rev. 2006, 106, 3936–3962. [Google Scholar] [CrossRef]

- Yamago, S. Precision polymer synthesis by degenerative transfer controlled/living radical polymerization using organotellurium, organostibine, and organobismuthine chain-transfer agents. Chem. Rev. 2009, 109, 5051–5068. [Google Scholar] [CrossRef]

- Ouchi, M.; Terashima, T.; Sawamoto, M. Transition metal-catalyzed living radical polymerization: Toward perfection in catalysis and precision polymer synthesis. Chem. Rev. 2009, 109, 4963–5050. [Google Scholar] [CrossRef]

- Lena, F.; Matyjaszewski, K. Transition metal catalysts for controlled radical polymerization. Prog. Polym. Sci. 2010, 35, 959–1021. [Google Scholar] [CrossRef]

- Matyjaszewski, K. Atom transfer radical polymerization (ATRP): Current status and future perspectives. Macromolecules 2012, 45, 4015–4039. [Google Scholar] [CrossRef]

- Goto, A.; Zushi, H.; Hirai, N.; Wakada, T.; Tsujii, Y.; Fukuda, T. Living radical polymerizations with germanium, tin, and phosphorus catalysts—Reversible chain transfer catalyzed polymerizations (RTCPs). J. Am. Chem. Soc. 2007, 129, 13347–13354. [Google Scholar] [CrossRef]

- Goto, A.; Hirai, N.; Wakada, T.; Nagasawa, K.; Tsujii, Y.; Fukuda, T. Living radical polymerization with nitrogen Catalyst: Reversible chain transfer catalyzed polymerization with N-iodosuccinimide. Macromolecules 2008, 41, 6261–6264. [Google Scholar] [CrossRef]

- Goto, A.; Hirai, N.; Nagasawa, K.; Tsujii, Y.; Fukuda, T.; Kaji, H. Phenols and carbon compounds as efficient organic catalysts for reversible chain transfer catalyzed living radical polymerization (RTCP). Macromolecules 2010, 43, 7971–7978. [Google Scholar] [CrossRef]

- Vana, P.; Goto, A. Kinetic simulations of reversible chain transfer catalyzed polymerization (RTCP): Guidelines to optimum molecular weight control. Macromol. Theory Simul. 2010, 19, 24–35. [Google Scholar]

- Yorizane, M.; Nagasuga, T.; Kitayama, Y.; Tanaka, A.; Minami, H.; Goto, A.; Fukuda, T.; Okubo, M. Reversible chain transfer catalyzed polymerization (RTCP) of methyl methacrylate with nitrogen catalyst in an aqueous microsuspension system. Macromolecules 2010, 43, 8703–8705. [Google Scholar] [CrossRef]

- Kuroda, T.; Tanaka, A.; Taniyama, T.; Minami, H.; Goto, A.; Fukuda, T.; Okubo, M. Iodine transfer dispersion polymerization (dispersion ITP) with CHI3 and reversible chain transfer catalyzed dispersion polymerization (dispersion RTCP) with GeI4 of styrene in supercritical carbon dioxide. Polymer 2012, 53, 1212–1218. [Google Scholar] [CrossRef]

- Goto, A.; Tsujii, Y.; Fukuda, T. Reversible chain transfer catalyzed polymerization (RTCP): A new class of living radical polymerization. Polymer 2008, 49, 5177–5185. [Google Scholar] [CrossRef]

- Goto, A.; Tsujii, Y.; Kaji, H. Living Radical Polymerizations with Organic Catalysts. In Fundamentals of Controlled/Living Radical Polymerization; Tsarevsky, N.V., Sumerlin, B.S., Eds.; Royal Society of Chemistry: London, UK, 2013; pp. 250–286. [Google Scholar]

- Goto, A.; Suzuki, T.; Ohfuji, H.; Tanishima, M.; Fukuda, T.; Tsujii, Y.; Kaji, H. Reversible complexation mediated living radical polymerization (RCMP) using organic catalysts. Macromolecules 2011, 44, 8709–8715. [Google Scholar] [CrossRef]

- Goto, A.; Tsujii, Y.; Kaji, H. Reversible complexation mediated polymerization (RCMP) of methyl methacrylate. ACS Symp. Ser. 1100, 305–315. [Google Scholar]

- Ohtsuki, A.; Goto, A.; Kaji, H. Visible-Light-Induced reversible complexation mediated living radical polymerization of methacrylates with organic catalysts. Macromolecules 2013, 46, 96–102. [Google Scholar] [CrossRef]

- Goto, A.; Ohtsuki, A.; Ohfuji, H.; Tanishima, M.; Kaji, H. Reversible generation of a carbon-centered radical from alkyl iodide using organic salts and their application as organic catalysts in living radical polymerization. J. Am. Chem. Soc. 2013, 135, 11131–11139. [Google Scholar]

- Ohno, K.; Morinaga, T.; Koh, K.; Tsujii, Y.; Fukuda, T. Synthesis of monodisperse silica particles coated with well-defined, high-density polymer brushes by surface-initiated atom transfer radical polymerization. Macromolecules 2005, 38, 2137–2142. [Google Scholar] [CrossRef]

- Lacroix-Desmazes, P.; Severac, R.; Boutevin, B. Reverse iodine transfer polymerization of methyl acrylate and n-butyl acrylate. Macromolecules 2005, 38, 6299–6309. [Google Scholar] [CrossRef]

- Tonnar, P.; Lacroix-Desmazes, P. Use of sodium iodide as the precursor to the control agent in ab initio emulsion polymerization. Angew. Chem. Int. Ed. 2008, 47, 1294–1297. [Google Scholar] [CrossRef]

- Tsujii, Y.; Ohno, K.; Yamamoto, S.; Goto, A.; Fukuda, T. Structure and properties of high-density polymer brushes prepared by surface-initiated living radical polymerization. Adv. Polym. Sci. 2006, 197, 1–45. [Google Scholar] [CrossRef]

- Edmondson, S.; Osborne, V.L.; Huck, W.T.S. Polymer brushes via surface-initiated polymerizations. Chem. Soc. Rev. 2004, 33, 14–22. [Google Scholar] [CrossRef]

- Barbey, R.; Lavanant, L.; Paripovic, D.; Schuwer, N. Sugnaux, C.; Tugulu, S.; Klok, H. Polymer brushes via surface-initiated controlled radical polymerization: Synthesis, characterization, properties, and applications. Chem. Rev. 2009, 109, 5437–5527. [Google Scholar] [CrossRef]

- Ejaz, M.; Yamamoto, S.; Ohno, K.; Tsujii, Y.; Fukuda, T. Controlled graft polymerization of methyl methacrylate on silicon substrate by the combined use of the langmuir-blodgett and atom transfer radical polymerization techniques. Macromolecules 1998, 31, 5934–5936. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Tanishima, M.; Goto, A.; Lei, L.; Ohtsuki, A.; Kaji, H.; Nomura, A.; Tsujii, Y.; Yamaguchi, Y.; Komatsu, H.; Miyamoto, M. Macromolecular Architectures Designed by Living Radical Polymerization with Organic Catalysts. Polymers 2014, 6, 311-326. https://doi.org/10.3390/polym6020311

Tanishima M, Goto A, Lei L, Ohtsuki A, Kaji H, Nomura A, Tsujii Y, Yamaguchi Y, Komatsu H, Miyamoto M. Macromolecular Architectures Designed by Living Radical Polymerization with Organic Catalysts. Polymers. 2014; 6(2):311-326. https://doi.org/10.3390/polym6020311

Chicago/Turabian StyleTanishima, Miho, Atsushi Goto, Lin Lei, Akimichi Ohtsuki, Hironori Kaji, Akihiro Nomura, Yoshinobu Tsujii, Yu Yamaguchi, Hiroto Komatsu, and Michihiko Miyamoto. 2014. "Macromolecular Architectures Designed by Living Radical Polymerization with Organic Catalysts" Polymers 6, no. 2: 311-326. https://doi.org/10.3390/polym6020311

APA StyleTanishima, M., Goto, A., Lei, L., Ohtsuki, A., Kaji, H., Nomura, A., Tsujii, Y., Yamaguchi, Y., Komatsu, H., & Miyamoto, M. (2014). Macromolecular Architectures Designed by Living Radical Polymerization with Organic Catalysts. Polymers, 6(2), 311-326. https://doi.org/10.3390/polym6020311