Effects of Graphene Nanoplatelets and Reduced Graphene Oxide on Poly(lactic acid) and Plasticized Poly(lactic acid): A Comparative Study

Abstract

:1. Introduction

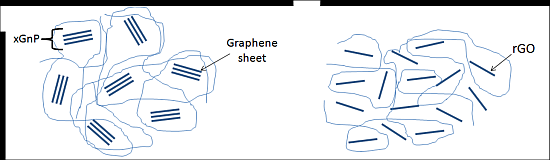

2. Experimental Section

2.1. Materials

2.2. Preparation of Plasticized PLA/xGnP and Plasticized PLA/rGO Nanocomposites

2.3. Characterizations

2.3.1. X-ray Diffraction (XRD)

2.3.2. Fourier Transform Infrared (FTIR)

2.3.3. Tensile Properties Measurement

2.3.4. Thermal Properties

2.3.5. Morphology

3. Results and Discussion

3.1. Fourier Transform Infrared (FTIR)

3.2. X-ray Diffraction (XRD)

3.3. Tensile Properties

3.4. Thermogravimetric Analysis (TGA)

| Samples | Tonset | T50 | Tmax |

|---|---|---|---|

| PLA | 274.3 | 339.2 | 345.1 |

| PLA/rGO | 304.9 | 349.7 | 353.7 |

| PLA/EPO/rGO | 341.3 | 384.7 | 388.3 |

| PLA/PEG/rGO | 217.3 | 311.0 | 321.1 |

| PLA/xGnP | 297.3 | 339.7 | 347.9 |

| PLA/EPO/xGnP | 337.5 | 381.7 | 386.6 |

| PLA/PEG/xGnP | 201.1 | 296.6 | 307.5 |

3.5. Scanning Electron Microscopy (SEM)

3.6. Transmission Electron Microscopy (TEM)

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Geim, A.K. Graphene: Status and prospects. Science 2009, 324, 1530–1534. [Google Scholar] [CrossRef]

- Kalaitzidou, K.; Fukushima, H.; Drzal, L.T. Mechanical properties and morphological characterization of exfoliated graphite-polypropylene nanocomposites. Compos. A Appl. Sci. Manuf. 2007, 38, 1675–1682. [Google Scholar] [CrossRef]

- Dreyer, D.R.; Jarvis, K.A.; Ferreira, P.J.; Bielawski, C.W. Graphite oxide as a carbocatalyst for the preparation of fullerene-reinforced polyester and polyamide nanocomposites. Polym. Chem. 2012, 3, 757–766. [Google Scholar] [CrossRef]

- Dreyer, D.R.; Jarvis, K.A.; Ferreira, P.J.; Bielawski, C.W. Graphite oxide as a dehydrative polymerization catalyst: A one-step synthesis of carbon-reinforced poly(phenylene methylene) composites. Macromolecules 2011, 44, 7659–7667. [Google Scholar] [CrossRef]

- Raquez, J.-M.; Habibi, Y.; Murariu, M.; Dubois, P. Polylactide (PLA)-based nanocomposites. Prog. Polym. Sci. 2013, 38, 1504–1542. [Google Scholar] [CrossRef]

- Notta-Cuvier, D.; Odent, J.; Delille, R.; Murariu, M.; Lauro, F.; Raquez, J.M.; Bennani, B.; Dubois, P. Tailoring polylactide (PLA) properties for automotive applications: Effect of addition of designed additives on main mechanical properties. Polym. Test. 2014, 36, 1–9. [Google Scholar] [CrossRef]

- Chieng, B.W.; Ibrahim, N.A.; Yunus, W.M.Z.W.; Hussein, M.Z. Poly(lactic acid)/Poly(ethylene glycol) polymer nanocomposites: Effects of graphene nanoplatelets. Polymers 2014, 6, 93–104. [Google Scholar]

- Silverajah, V.S.G.; Ibrahim, N.A.; Yunus, W.M.Z.W.; Hassan, H.A.; Chieng, B.W. A comparative study on the mechanical, thermal and morphological characterization of poly(lactic acid)/epoxidized palm oil blend. Int. J. Mol. Sci. 2012, 13, 5878–5898. [Google Scholar] [CrossRef]

- Chieng, B.W.; Ibrahim, N.A.; Yunus, W.M.Z.W.; Hussein, M.Z. Plasticized poly(lactic acid) with low molecular weight poly(ethylene glycol): Mechanical, thermal, and morphology properties. J. Appl. Polym. Sci. 2013, 130, 4576–4580. [Google Scholar]

- Chieng, B.W.; Ibrahim, N.A.; Yunus, W.M.Z.W.; Hussein, M.Z.; Silverajah, V.S.G. Graphene nanoplatelets as novel reinforcement filler in poly(lactic acid)/epoxidized palm oil green nanocomposites: Mechanical properties. Int. J. Mol. Sci. 2012, 13, 10920–10934. [Google Scholar] [CrossRef]

- Chieng, B.W.; Ibrahim, N.A.; Yunus, W.M.Z.W. Optimization of tensile strength of poly(lactic acid)/graphene nanocomposites using response surface methodology. Polym. Plast. Technol. Eng. 2012, 51, 791–799. [Google Scholar] [CrossRef]

- Gumus, S.; Ozkoc, G.; Aytac, A. Plasticized and unplasticized PLA/organoclay nanocomposites: Short- and long-term thermal properties, morphology, and nonisothermal crystallization behavior. J. Appl. Polym. Sci. 2011, 123, 2837–2848. [Google Scholar] [CrossRef]

- Wu, C.-S.; Liao, H.-T. Study on the preparation and characterization of biodegradable polylactide/multi-walled carbon nanotubes nanocomposites. Polymer 2007, 48, 4449–4458. [Google Scholar] [CrossRef]

- Chiang, M.-F.; Wu, T.-M. Synthesis and characterization of biodegradable poly(l-lactide)/layered double hydroxide nanocomposites. Compos. Sci. Technol. 2010, 70, 110–115. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Gu, Y.T. Mechanical properties of graphene: Effects of layer number, temperature and isotope. Comput. Mater. Sci. 2013, 71, 197–200. [Google Scholar] [CrossRef] [Green Version]

- Via, M.D.; King, J.A.; Keith, J.M.; Miskioglu, I.; Cieslinski, M.J.; Anderson, J.J.; Bogucki, G.R. Tensile modulus modeling of carbon black/polycarbonate, carbon nanotube/polycarbonate, and exfoliated graphite nanoplatelet/polycarbonate composites. J. Appl. Polym. Sci. 2012, 124, 2269–2277. [Google Scholar] [CrossRef]

- Xu, Z.; Gao, C. In situ polymerization approach to graphene-reinforced nylon-6 composites. Macromolecules 2010, 43, 6716–6723. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, X.; Jin, X.; Wang, T. Study on the PMMA/GO nanocomposites with good thermal stability prepared by in situ Pickering emulsion polymerization. J. Therm. Anal. Calorim. 2014, 117, 755–763. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Seidel, C.; Schulte, K. Preparation and characterization of graphite nano-platelet (GNP)/epoxy nano-composite: Mechanical, electrical and thermal properties. Eur. Polym. J. 2013, 49, 3878–3888. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X.; Xu, C.; Zhang, M.; Shang, X. Preparation of graphene/poly(vinyl alcohol) nanocomposites with enhanced mechanical properties and water resistance. Polym. Int. 2011, 60, 816–822. [Google Scholar] [CrossRef]

- Oxfall, H.; Rondin, J.; Bouquey, M.; Muller, R.; Rigdahl, M.; Rychwalski, R.W. Elongational flow mixing for manufacturing of graphite nanoplatelet/polystyrene composites. J. Appl. Polym. Sci. 2013, 128, 2679–2686. [Google Scholar] [CrossRef]

- Haghighi, A.; Sheydaei, M.; Allahbakhsh, A.; Ghatarband, M.; Hosseini, F. Thermal performance of poly(ethylene disulfide)/expanded graphite nanocomposites. J. Therm. Anal. Calorim. 2014, 117, 525–535. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, M.; Ning, X.; Chen, X.; Sun, Z.; Ma, Y.; Yu, J.; Zhang, Z.; Bo, X.; Yang, L.; et al. Influences of coupling agent on thermal properties, flammability and mechanical properties of polypropylene/thermoplastic polyurethanes composites filled with expanded graphite. J. Therm. Anal. Calorim. 2014, 115, 689–695. [Google Scholar] [CrossRef]

- Cao, Y.; Feng, J.; Wu, P. Preparation of organically dispersible graphene nanosheet powders through a lyophilization method and their poly(lactic acid) composites. Carbon 2010, 48, 3834–3839. [Google Scholar] [CrossRef]

- Pinto, A.M.; Cabral, J.; Tanaka, D.A.P.; Mendes, A.M.; Magalhães, F.D. Effect of incorporation of graphene oxide and graphene nanoplatelets on mechanical and gas permeability properties of poly(lactic acid) films. Polym. Int. 2013, 62, 33–40. [Google Scholar] [CrossRef]

- Rafiee, M.A.; Rafiee, J.; Wang, Z.; Song, H.; Yu, Z.-Z.; Koratkar, N. Enhanced mechanical properties of nanocomposites at low graphene content. ACS Nano 2009, 3, 3884–3890. [Google Scholar] [CrossRef]

- Inuwa, I.M.; Hassan, A.; Samsudin, S.A.; Mohamad Kassim, M.H.; Jawaid, M. Mechanical and thermal properties of exfoliated graphite nanoplatelets reinforced polyethylene terephthalate/polypropylene composites. Polym. Compos. 2014, 2014. [Google Scholar] [CrossRef]

- Standard Test Method for Tensile Properties of Plastics; ASTM D638-10; ASTM (American Society for Testing and Materials) International: West Conshohocken, PA, USA, 2010.

- Li, W.; Xu, Z.; Chen, L.; Shan, M.; Tian, X.; Yang, C.; Lv, H.; Qian, X. A facile method to produce graphene oxide-g-poly(l-lactic acid) as an promising reinforcement for PLLA nanocomposites. Chem. Eng. J. 2014, 237, 291–299. [Google Scholar] [CrossRef]

- Daniels, P.H. A brief overview of theories of PVC plasticization and methods used to evaluate PVC-plasticizer interaction. J. Vinyl Addit. Technol. 2009, 15, 219–223. [Google Scholar] [CrossRef]

- Kuila, T.; Bose, S.; Mishra, A.K.; Khanra, P.; Kim, N.H.; Lee, J.H. Effect of functionalized graphene on the physical properties of linear low density polyethylene nanocomposites. Polym. Test. 2012, 31, 31–38. [Google Scholar] [CrossRef]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Chieng, B.W.; Ibrahim, N.A.; Yunus, W.M.Z.W.; Hussein, M.Z.; Then, Y.Y.; Loo, Y.Y. Effects of Graphene Nanoplatelets and Reduced Graphene Oxide on Poly(lactic acid) and Plasticized Poly(lactic acid): A Comparative Study. Polymers 2014, 6, 2232-2246. https://doi.org/10.3390/polym6082232

Chieng BW, Ibrahim NA, Yunus WMZW, Hussein MZ, Then YY, Loo YY. Effects of Graphene Nanoplatelets and Reduced Graphene Oxide on Poly(lactic acid) and Plasticized Poly(lactic acid): A Comparative Study. Polymers. 2014; 6(8):2232-2246. https://doi.org/10.3390/polym6082232

Chicago/Turabian StyleChieng, Buong Woei, Nor Azowa Ibrahim, Wan Md Zin Wan Yunus, Mohd Zobir Hussein, Yoon Yee Then, and Yuet Ying Loo. 2014. "Effects of Graphene Nanoplatelets and Reduced Graphene Oxide on Poly(lactic acid) and Plasticized Poly(lactic acid): A Comparative Study" Polymers 6, no. 8: 2232-2246. https://doi.org/10.3390/polym6082232