Near Surface Mounted Composites for Flexural Strengthening of Reinforced Concrete Beams

Abstract

:1. Introduction

2. Experimental Program

2.1. Test Matrix

2.2. Specimen Configuration

2.3. Material Properties

2.4. Strengthening Procedure

2.5. Test Setup

3. Results and Discussion

3.1. Load-Deflection Behavior

3.2. Characteristics of Crack

3.3. Modes of Failure

3.4. Concrete Compressive Strain in the Beam Surface

3.5. Tensile Strain in Main Reinforcement

3.6. Sectional Strain Profile

4. Parametric Study

4.1. The Effect of NSM Reinforcement Amount on Strengthening

4.2. The Effect of Type of NSM Reinforcement on Strengthening

4.3. The Effect of Number of NSM Groove

5. Analytical Study

5.1. Concrete Cover Separation Model

5.2. Deflection Prediction Model

5.3. Crack Spacing Prediction Model

5.4. Crack Width Prediction Model

6. Verification of Experimental Results

6.1. Validation of Ultimate Loading

6.2. Validation of Ultimate Deflection

6.3. Validation of Maximum Crack Spacing

6.4. Validation of Maximum Crack Width

7. Conclusions

- The NSM strengthening technique with steel bars is a very cost effective method to improve the flexural strength of RC beams.

- The strengthened beam specimens expressed a bi-linear response to loading, characterized by cracking and ultimate stages. The cracking stage of the strengthened beams followed a linear elastic shape identical to the control beam.

- The NSM steel or CFRP bar technique increased the first crack load. Strengthened beams exhibited smaller crack spacing than the control beam. Thus, beams strengthened with NSM bars develop more and finer cracks with closer spacing than unstrengthened beams.

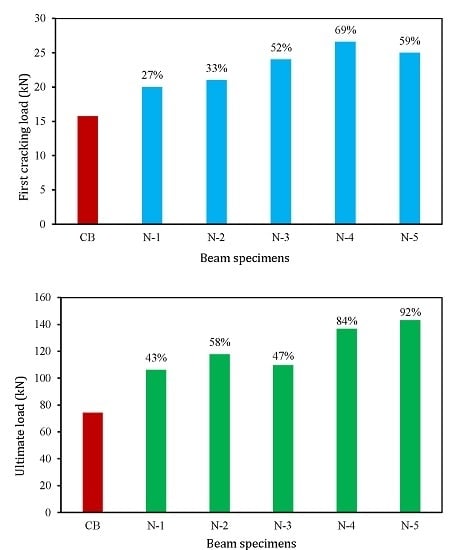

- Increasing the amount of NSM steel reinforcement from 100 to 226 mm2 improves the first crack load from 27% to 69% and the ultimate load capacity from 43% to 84%, respectively. NSM-CFRP increases the first cracking and ultimate load of 59% and 92%, respectively. After the yielding of internal reinforcement, NSM reinforcement controls crack widths until failure of the beam.

- The strengthened beams failed in premature debonding. The ultimate load was reached in the instant of debonding and directly afterwards, after which imposed loading decreased rapidly. The predicted results from the analytical models complied very well with the experimental results.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bakis, C.; Bank, L.C.; Brown, V.; Cosenza, E.; Davalos, J.F.; Lesko, J.J.; Machida, A.; Rizkalla, S.H.; Triantafillou, T.C. Fiber-reinforced polymer composites for construction-state-of-the-art review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef]

- Sharif, A.; Al-Sulaimani, G.J.; Basunbul, I.A.; Baluch, M.H.; Ghaleb, B.N. Strengthening of initially loaded reinforced concrete beams using FRP plates. ACI Struct. J. 1994, 91, 160–168. [Google Scholar]

- Hosen, M.A.; Jumaat, M.Z.; Islam, A.S. Side Near Surface Mounted (SNSM) technique for flexural enhancement of RC beams. Mater. Des. 2015, 83, 587–597. [Google Scholar] [CrossRef]

- Almassri, B.; Mahmoud, F.A.; Francois, R. Behaviour of corroded Reinforced Concrete beams repaired with NSM CFRP rods, experimental and finite element study. Compos. B Eng. 2015. [Google Scholar] [CrossRef]

- Bilotta, A.; Ceroni, F.; Nigro, E.; Pecce, M. Efficiency of CFRP NSM strips and EBR plates for flexural strengthening of RC beams and loading pattern influence. Compos. Struct. 2015, 124, 163–175. [Google Scholar] [CrossRef]

- Martinelli, E.; Napoli, A.; Nunziata, B.; Realfonzo, R. RC beams strengthened with mechanically fastened composites: Experimental results and numerical modeling. Polymers 2014, 6, 613–633. [Google Scholar] [CrossRef]

- Bossio, A.; Fabbrocino, F.; Lignola, G.P.; Prota, A.; Manfredi, G. Simplified model for strengthening design of beam-column internal joints in reinforced concrete frames. Polymers 2015, 7, 1732–1754. [Google Scholar] [CrossRef]

- Yang, D.S.; Park, S.K.; Neale, K.W. Flexural behaviour of reinforced concrete beams strengthened with prestressed carbon composites. Compos. Struct. 2009, 88, 497–508. [Google Scholar] [CrossRef]

- Zhou, Y.; Gou, M.; Zhang, F.; Zhang, S.; Wang, D. Reinforced concrete beams strengthened with carbon fiber reinforced polymer by friction hybrid bond technique: Experimental investigation. Mater. Des. 2013, 50, 130–139. [Google Scholar] [CrossRef]

- Hawileh, R.A.; Rasheed, H.A.; Abdalla, J.A.; Al-Tamimi, A.K. Behavior of reinforced concrete beams strengthened with externally bonded hybrid fiber reinforced polymer systems. Mater. Des. 2014, 53, 972–982. [Google Scholar] [CrossRef]

- Hawileh, R.A.; El-Maaddawy, T.A.; Naser, M.Z. Nonlinear finite element modeling of concrete deep beams with openings strengthened with externally-bonded composites. Mater. Des. 2012, 42, 378–387. [Google Scholar] [CrossRef]

- Ritchie, P.A.; Thomas, D.A.; Lu, L.W.; Conelly, G.M. External reinforcement of concrete beams using fiber reinforced plastics. ACI Struct. J. 1991, 88, 490–500. [Google Scholar]

- Rahimi, H.; Hutchinson, A. Concrete beams strengthened with externally bonded FRP plates. J. Compos. Constr. 2001, 5, 44–56. [Google Scholar] [CrossRef]

- Akbarzadeh, H.; Maghsoudi, A.A. Experimental and analytical investigation of reinforced high strength concrete continuous beams strengthened with fiber reinforced polymer. Mater. Des. 2010, 31, 1130–1147. [Google Scholar] [CrossRef]

- Arduini, M.; di Tommaso, A.; Nanni, A. Brittle failure in FRP plate and sheet bonded beams. ACI Struct. J. 1997, 94, 363–370. [Google Scholar]

- Jumaat, M.Z.; Alam, M.A. Behaviour of U and L shaped end anchored steel plate strengthened reinforced concrete beams. Eur. J. Sci. Res. 2008, 22, 184–196. [Google Scholar]

- Shukri, A.A.; Jumaat, M.Z. The tension-stiffening contribution of NSM CFRP to the behavior of strengthened RC beams. Materials 2015, 8, 4131–4146. [Google Scholar] [CrossRef]

- Rosenboom, O.; Rizkalla, S. Behavior of prestressed concrete strengthened with various CFRP systems subjected to fatigue loading. J. Compos. Constr. 2006, 10, 492–502. [Google Scholar] [CrossRef]

- Soliman, S.M.; El-Salakawy, E.; Benmokrane, B. Flexural behaviour of concrete beams strengthened with near surface mounted fibre reinforced polymer bars. Can. J. Civ. Eng. 2010, 37, 1371–1382. [Google Scholar] [CrossRef]

- El-Hacha, R.; Rizkalla, S.H. Near-surface-mounted fiber-reinforced polymer reinforcements for flexural strengthening of concrete structures. ACI Struct. J. 2004, 101, 717–726. [Google Scholar]

- El-Hacha, R.; Gaafar, M. Flexural strengthening of reinforced concrete beams using prestressed, near-surface-mounted CFRP bars. PCI J. 2011, 56, 134–151. [Google Scholar] [CrossRef]

- Badawi, M.; Soudki, K. Flexural strengthening of RC beams with prestressed NSM CFRP rods–experimental and analytical investigation. Constr. Build. Mater. 2009, 23, 3292–3300. [Google Scholar] [CrossRef]

- Al-Mahmoud, F.; Castel, A.; François, R.; Tourneur, C. Strengthening of RC members with near-surface mounted CFRP rods. Compos. Struct. 2009, 91, 138–147. [Google Scholar] [CrossRef]

- Rahal, K.N.; Rumaih, H.A. Tests on reinforced concrete beams strengthened in shear using near surface mounted CFRP and steel bars. Eng. Struct. 2011, 33, 53–62. [Google Scholar] [CrossRef]

- Garrity, S. Strengthening of masonry arch bridges with near-surface reinforcement: A case study. Int. J. Eng. Tech. 2013, 5, 370–373. [Google Scholar] [CrossRef]

- Almusallam, T.H.; Elsanadedy, H.M.; Al-Salloum, Y.A.; Alsayed, S.H. Experimental and numerical investigation for the flexural strengthening of RC beams using near-surface mounted steel or GFRP bars. Constr. Build. Mater. 2013, 40, 145–161. [Google Scholar] [CrossRef]

- Construction Reinforcing Steel Bar. Product Data Sheet. Available online: http://www.alibaba.com/product-detail/Construction-Reinforcing-Steel-Bar-Price_60372899188.html?spm=a2700.7724857.29.30.lMPCt2&s=p (accessed on 20 December 2015).

- Carbon Fiber Bars. Product Catalog. Available online: http://www.hccomposite.com/en/catalog/38/225.html (accessed on 20 December 2015).

- ACI 318 Committee. Building Code Requirements for Structural Concrete (318-11) and Commentary-(318R-11), 1st ed.; American Concrete Institute: Detroit, MI, USA; Washington, DC, USA, 2011; p. 503. [Google Scholar]

- Teychenné, D.C.; Franklin, R.E.; Erntroy, H.C.; Nicholls, J.C.; Hobbs, D.W.; Marsh, D. Design of Normal Concrete Mixes; Building Research Establishment Ltd.: Garston, UK, 1997. [Google Scholar]

- Publication, B.S. Testing Hardened Concrete. Making and Curing Specimens for Strength Tests; BS-EN-12390-2:2009; British Standards Institute: London, UK, 2009; p. 12. [Google Scholar]

- Sikadur®-30. Product Data Sheet-Adhesive for Bonding Reinforcement. Available online: http://mys.sika.com/en/solutions_products/02/02a013/02a013sa06/02a013sa06100/02a013sa06105.html (accessed on 20 December 2015).

- Zhang, D.; Ueda, T.; Furuuchi, H. Concrete cover separation failure of overlay-strengthened reinforced concrete beams. Constr. Build. Mater. 2012, 26, 735–745. [Google Scholar] [CrossRef]

- Al-Mahmoud, F.; Castel, A.; François, R.; Tourneur, C. RC beams strengthened with NSM CFRP rods and modeling of peeling-off failure. Compos. Struct. 2010, 92, 1920–1930. [Google Scholar] [CrossRef]

- Bischoff, P.H. Reevaluation of deflection prediction for concrete beams reinforced with steel and fiber reinforced polymer bars. J. Struct. Eng. 2005, 131, 752–767. [Google Scholar] [CrossRef]

- Said, H. Deflection prediction for FRP-strengthened concrete beams. J. Compos. Constr. 2009, 14, 244–248. [Google Scholar] [CrossRef]

- Eurocode 2. Design of Concrete Structures—Part 1.1: General Rules and Rules for Buildings. Available online: https://law.resource.org/pub/eu/eurocode/en.1992.1.2.2004.pdf (accessed on 20 December 2015).

| Beam ID | Strengthening bars | NSM strengthening materials | |

|---|---|---|---|

| Number | Diameter (mm) | ||

| CB | Control beam (Unstrengthened) | ||

| N-1 | 2 | 8 | Steel bars |

| N-2 | 2 | 10 | |

| N-3 | 1 | 16 | |

| N-4 | 2 | 12 | |

| N-5 | 2 | 12 | CFRP bars |

| Slump (mm) | W/C Ratio | Quantity (kg/m3) | |||

|---|---|---|---|---|---|

| Cement | Coarse aggregate | Fine aggregate | Water | ||

| 45 | 0.50 | 420 | 892 | 888 | 224 |

| Properties | Strength (MPa) |

|---|---|

| Compressive strength | 95 |

| Tensile strength | 31 |

| Shear strength | 19 |

| Modulus of elasticity | 11,200 |

| Specimens | First cracking load (kN) | Increase in first cracking load (%) | Ultimate load (kN) | Increase in ultimate load (%) |

|---|---|---|---|---|

| CB | 15.75 | – | 74.37 | – |

| N1 | 20.00 | 26.98 | 106.24 | 42.85 |

| N2 | 21.00 | 33.33 | 117.75 | 58.33 |

| N3 | 24.00 | 52.38 | 109.56 | 47.32 |

| N4 | 26.60 | 68.89 | 136.75 | 83.88 |

| N5 | 25.00 | 58.73 | 143.03 | 92.32 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hosen, M.A.; Jumaat, M.Z.; Alengaram, U.J.; Islam, A.B.M.S.; Bin Hashim, H. Near Surface Mounted Composites for Flexural Strengthening of Reinforced Concrete Beams. Polymers 2016, 8, 67. https://doi.org/10.3390/polym8030067

Hosen MA, Jumaat MZ, Alengaram UJ, Islam ABMS, Bin Hashim H. Near Surface Mounted Composites for Flexural Strengthening of Reinforced Concrete Beams. Polymers. 2016; 8(3):67. https://doi.org/10.3390/polym8030067

Chicago/Turabian StyleHosen, Md. Akter, Mohd Zamin Jumaat, Ubagaram Johnson Alengaram, A. B. M. Saiful Islam, and Huzaifa Bin Hashim. 2016. "Near Surface Mounted Composites for Flexural Strengthening of Reinforced Concrete Beams" Polymers 8, no. 3: 67. https://doi.org/10.3390/polym8030067

APA StyleHosen, M. A., Jumaat, M. Z., Alengaram, U. J., Islam, A. B. M. S., & Bin Hashim, H. (2016). Near Surface Mounted Composites for Flexural Strengthening of Reinforced Concrete Beams. Polymers, 8(3), 67. https://doi.org/10.3390/polym8030067