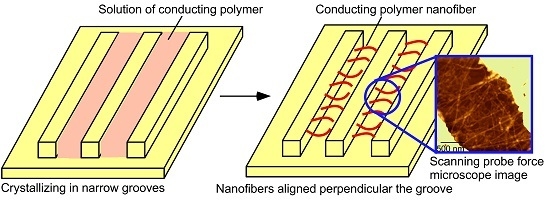

Crystallization of Poly(3-hexylthiophene) Nanofiber in a Narrow Groove

Abstract

:1. Introduction

2. Experimental Section

2.1. Nanofiber Formation

2.2. Preparation of Nanogrooves

2.3. Characterization of Nanofiber Orientation

3. Results and Discussion

3.1. Nanofiber Growth in Grooves

3.1.1. CYTOPTM Grooves

3.1.2. PMMA Grooves

3.2. Morphology of Nanofibers on a CYTOP™ Surface

3.3. Mechanism of Nanofiber Orientation in the CYTOPTM Groove

3.4. Conductivity of Nanofibers Oriented in the Groove

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Heath, J.R. Analytical chemistry in molecular electronics. Annu. Rev. Mater. Res. 2009, 39, 1–23. [Google Scholar] [CrossRef]

- Xiang, D.; Wang, X.; Jia, C.; Lee, T.; Guo, X. Molecular-scale electronics: From concept to function. Chem. Rev. 2016, 116, 4318–4440. [Google Scholar] [CrossRef] [PubMed]

- McCulloch, I.; Heeney, M.; Chabinyc, M.L.; DeLongchamp, D.; Kline, R.J.; Cölle, M.; Duffy, W.; Fischer, D.; Gundlach, D.; Hamadani, B.; et al. Semiconducting thienothiophene copolymers: Design, synthesis, morphology, and performance in thin-film organic transistors. Adv. Mater. 2009, 21, 1091–1109. [Google Scholar] [CrossRef]

- Ihn, K.J.; Moulton, J.; Smith, P. Whiskers of poly(3-alkylthiophene)s. J. Polym. Sci. B Polym. Phys. 1993, 31, 735–742. [Google Scholar] [CrossRef]

- Merlo, J.A.; Frisbie, C.D. Field effect conductance of conducting polymer nanofibers. J. Polym. Sci. B Polym. Phys. 2003, 41, 2674–2680. [Google Scholar] [CrossRef]

- Kiriy, N.; Jahne, E.; Adler, H.J.; Schneider, M.; Kiriy, A.; Gorodyska, G.; Minko, S.; Jehnichen, D.; Simon, P.; Fokin, A.A.; et al. One-dimensional aggregation of regioregular polyalkylthiophenes. Nano Lett. 2003, 3, 707–712. [Google Scholar] [CrossRef]

- Kline, R.J.; McGehee, M.D.; Kadnikova, E.N.; Liu, J.; Fréchet, J.M.J. Controlling the field-effect mobility of regioregular polythiophene by changing the molecular weight. Adv. Mater. 2003, 18, 1519–1522. [Google Scholar] [CrossRef]

- Mas-Torrent, M.; den Boer, D.; Durkut, M.; Hadley, P.; Schenning, A.P.H.J. Field effect transistors based on poly(3-hexylthiophene) at different length scales. Nanotechnology 2004, 15, S265–S269. [Google Scholar] [CrossRef]

- Zen, A.; Pflaum, J.; Hirschmann, S.; Zhuang, W.; Jaiser, F.; Asawapirom, U.; Rabe, J.P.; Scherf, U.; Neher, D. Effect of molecular weight and annealing of poly(3-hexylthiophene)s on the performance of organic field-effect transistors. Adv. Funct. Mater. 2004, 14, 757–764. [Google Scholar] [CrossRef]

- Kim, D.H.; Han, J.T.; Park, Y.D.; Jang, Y.; Cho, J.H.; Hwang, M.; Cho, K. Single-crystal polythiophene microwires grown by self-assembly. Adv. Mater. 2006, 18, 719–723. [Google Scholar] [CrossRef]

- Samitsu, S.; Shimomura, T.; Heike, S.; Hashizume, T.; Ito, K. Effective production of poly(3-alkylthiophene) nanofibers by means of whisker method using anisole solvent: Structural, optical, and electrical properties. Macromolecules 2008, 41, 8000–8010. [Google Scholar] [CrossRef]

- Oosterbaan, W.D.; Vrindts, V.; Berson, S.; Guillerez, S.; Douhéret, O.; Ruttens, B.; D’Haen, J.; Adriaensens, P.; Manca, J.; Lutsen, L.; et al. Efficient formation, isolation and characterization of poly(3-alkylthiophene) nanofibres: probing order as a function of side-chain length. J. Mater. Chem. 2009, 19, 5424–5435. [Google Scholar] [CrossRef]

- Arif, M.; Liu, J.; Zhai, L.; Khondaker, S.I. Poly(3-hexylthiophene) crystalline nanoribbon network for organic field effect transistors. Appl. Phys. Lett. 2010, 96. [Google Scholar] [CrossRef]

- Shimomura, T.; Takahashi, T.; Ichimura, Y.; Nakagawa, S.; Noguchi, K.; Heike, S.; Hashizume, T. Relationship between structural coherence and intrinsic carrier transport in an isolated poly(3-hexylthiophene) nanofiber. Phys. Rev. B 2011, 83. [Google Scholar] [CrossRef]

- Chen, J.-Y.; Kuo, C.-C.; Lai, C.-S.; Chen, W.-C.; Chen, H.-L. Manipulation on the morphology and electrical properties of aligned electrospun nanofibers of poly(3-hexylthiophene) for field-effect transistor applications. Macromolecules 2011, 44, 2883–2892. [Google Scholar] [CrossRef]

- Yin, K.; Zhang, L.; Lai, C.; Zhong, L.; Smith, S.; Fong, H.; Zhu, Z.J. Photoluminescence anisotropy of uni-axially aligned electrospun conjugated polymer nanofibers of MEH-PPV and P3HT. J. Matter. Chem. 2011, 21, 444–448. [Google Scholar] [CrossRef]

- Chou, C.C.; Wu, H.-C.; Lin, C.-J.; Ghelichkhani, H.; Chen, W.-C. Morphology and field-effect transistor characteristics of electrospun nanofibers prepared from crystalline poly(3-hexylthiophene) and polyacrylate blends. Macromol. Chem. Phys. 2013, 214, 751–760. [Google Scholar] [CrossRef]

- Gao, Q.; Meguro, H.; Okamoto, S.; Kimura, M. Flexible tactile sensor using the reversible deformation of poly(3-hexylthiophene) nanofiber assemblies. Langmuir 2012, 28, 17593–17596. [Google Scholar] [CrossRef] [PubMed]

- Yonemura, H.; Yuno, K.; Yamada, S. Orientation of nanowires consisting of poly(3-butylthiophene) using strong magnetic field. Jpn. J. Appl. Phys. 2010, 49. [Google Scholar] [CrossRef]

- Samitsu, S.; Takanishi, Y.; Yamamoto, J. Self-assembly and one-dimensional alignment of a conducting polymer nanofiber in a nematic liquid crystal. Macromolecules 2009, 42, 4366–4368. [Google Scholar] [CrossRef]

- Kim, N.K.; Jang, S.Y.; Pace, G.; Caironi, M.; Park, W.T.; Khim, D.; Kim, J.; Kim, D.Y.; Noh, Y.Y. High-performance organic field-effect transistors with directionally aligned conjugated polymer film deposited from pre-aggregated solution. Chem. Mater. 2015, 27, 8345–8353. [Google Scholar] [CrossRef]

- Wu, H.; Wang, W.; Huang, Y.; Su, Z. Orientation of syndiotactic polystyrene crystallized in cylindrical nanopores. Macromol. Rapid Commun. 2009, 30, 194–198. [Google Scholar] [CrossRef] [PubMed]

- Guan, Y.; Liu, G.; Gao, P.; Li, L.; Ding, G.; Wang, D. Manipulating crystal orientation of poly(ethylene oxide) by nanopores. ACS Macro Lett. 2013, 2, 181–184. [Google Scholar] [CrossRef]

- Maiz, J.; Martin, J.; Mijangos, C. Confinement effects on the crystallization of poly(ethylene oxide) nanotubes. Langmuir 2012, 28, 12296–12303. [Google Scholar] [CrossRef] [PubMed]

- Nojima, S.; Ohguma, Y.; Kadena, K.-I.; Ishizone, T.; Iwasaki, Y.; Yamaguchi, K. Crystal orientation of poly(ε-caprolactone) homopolymers confined in cylindrical nanodomains. Macromolecules 2010, 43, 3916–3923. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Imprint of sub-25 nm vias and trenches in polymers. Appl. Phys. Lett. 1995, 67, 3114–3116. [Google Scholar] [CrossRef]

| Sample | 2θ100/deg. | d100/Å | 2θ020/deg. | d020/Å |

|---|---|---|---|---|

| Nanofiber on CYTOP™ | 5.41 | 16.3 | 23.09 | 3.85 |

| Casted Nanofiber | 5.23 | 16.9 | 23.47 | 3.79 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kushi, S.; Tsukada, R.; Noguchi, K.; Shimomura, T. Crystallization of Poly(3-hexylthiophene) Nanofiber in a Narrow Groove. Polymers 2016, 8, 231. https://doi.org/10.3390/polym8060231

Kushi S, Tsukada R, Noguchi K, Shimomura T. Crystallization of Poly(3-hexylthiophene) Nanofiber in a Narrow Groove. Polymers. 2016; 8(6):231. https://doi.org/10.3390/polym8060231

Chicago/Turabian StyleKushi, Satoshi, Ryota Tsukada, Keiichi Noguchi, and Takeshi Shimomura. 2016. "Crystallization of Poly(3-hexylthiophene) Nanofiber in a Narrow Groove" Polymers 8, no. 6: 231. https://doi.org/10.3390/polym8060231

APA StyleKushi, S., Tsukada, R., Noguchi, K., & Shimomura, T. (2016). Crystallization of Poly(3-hexylthiophene) Nanofiber in a Narrow Groove. Polymers, 8(6), 231. https://doi.org/10.3390/polym8060231