Evaluation of Low Pressure Fogging System for Improving Crop Yield of Tomato (Lycopersicon esculentum Mill.): Grown under Heat Stress Conditions

Abstract

:1. Introduction

2. Results and Discussion

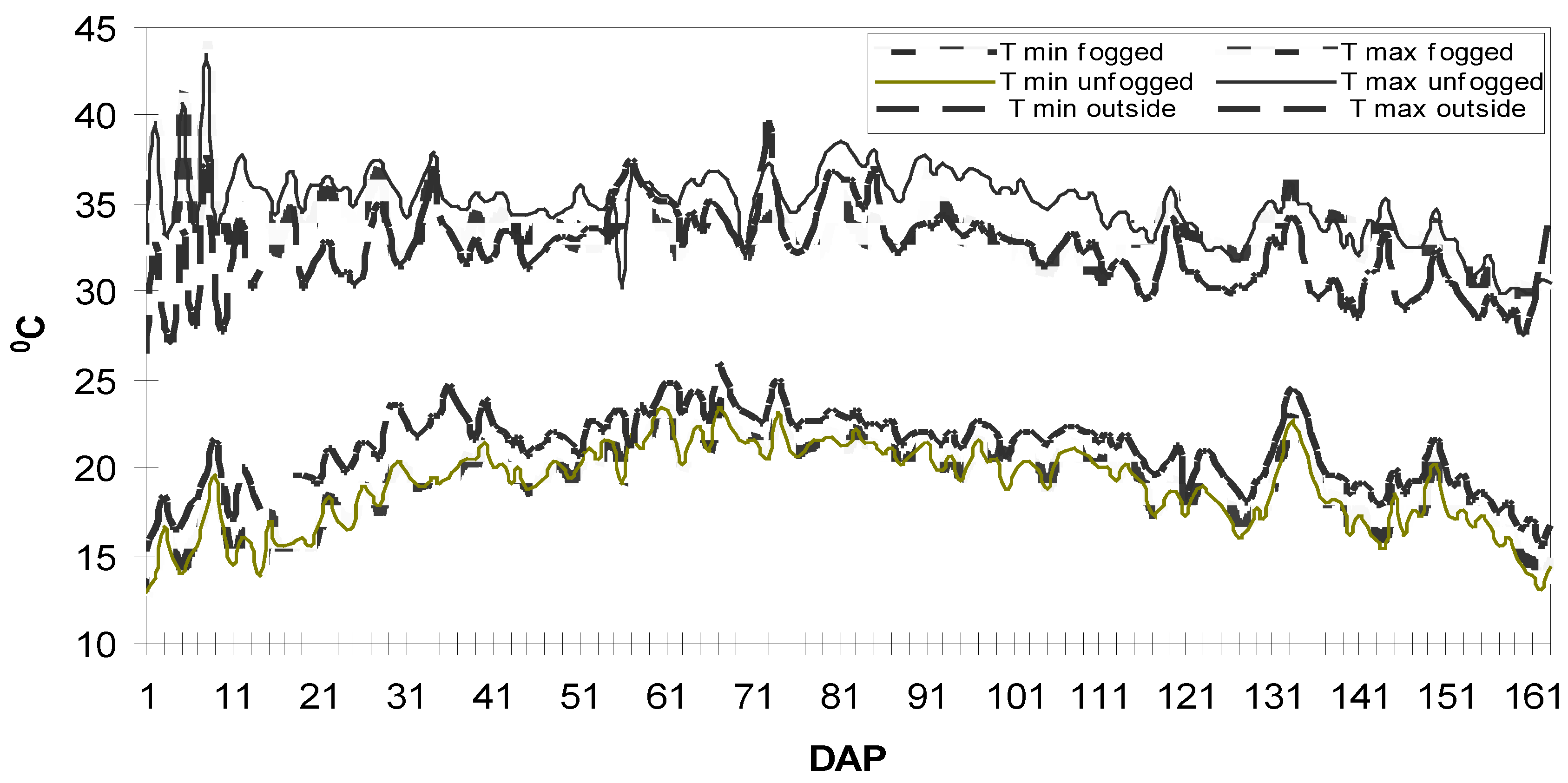

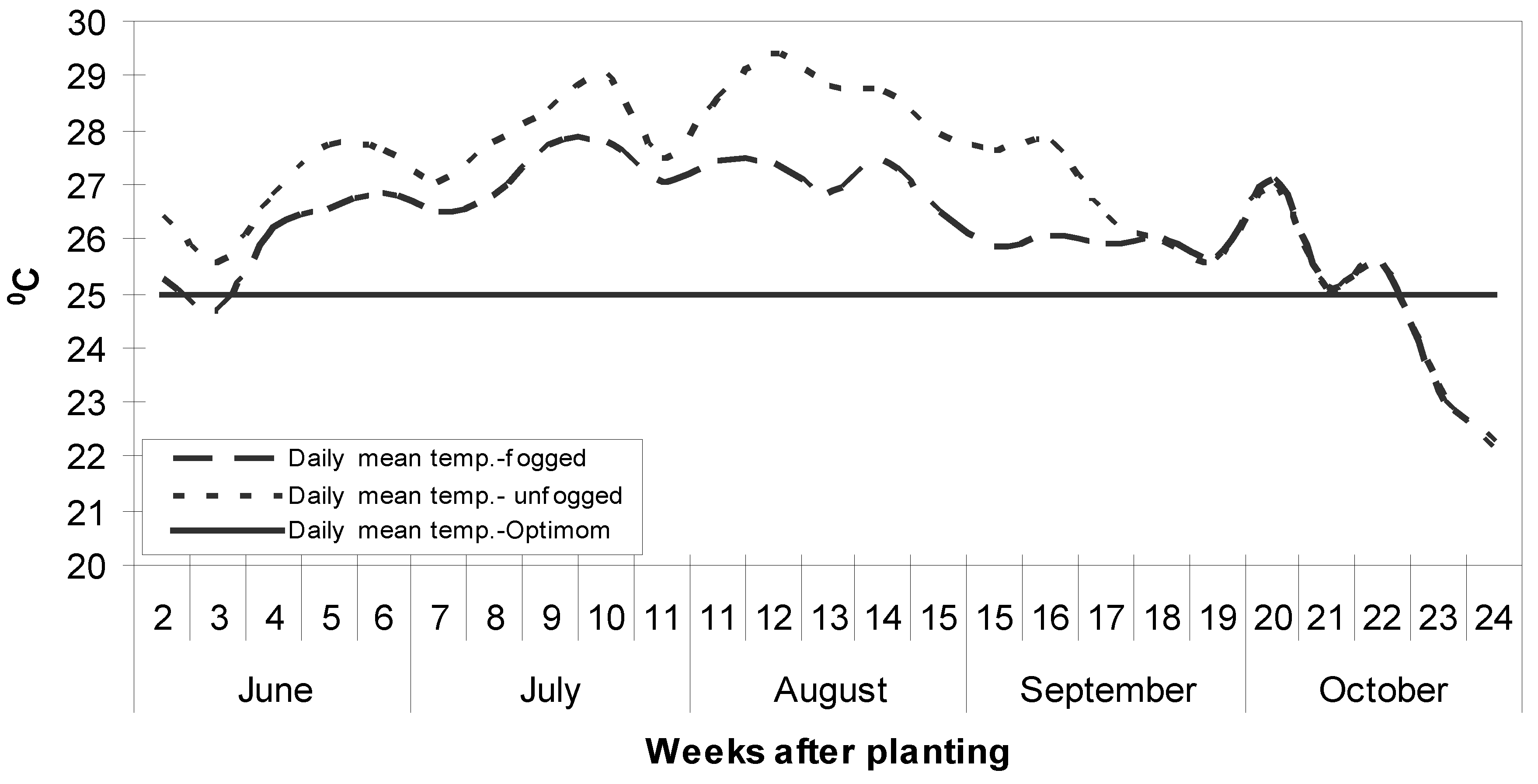

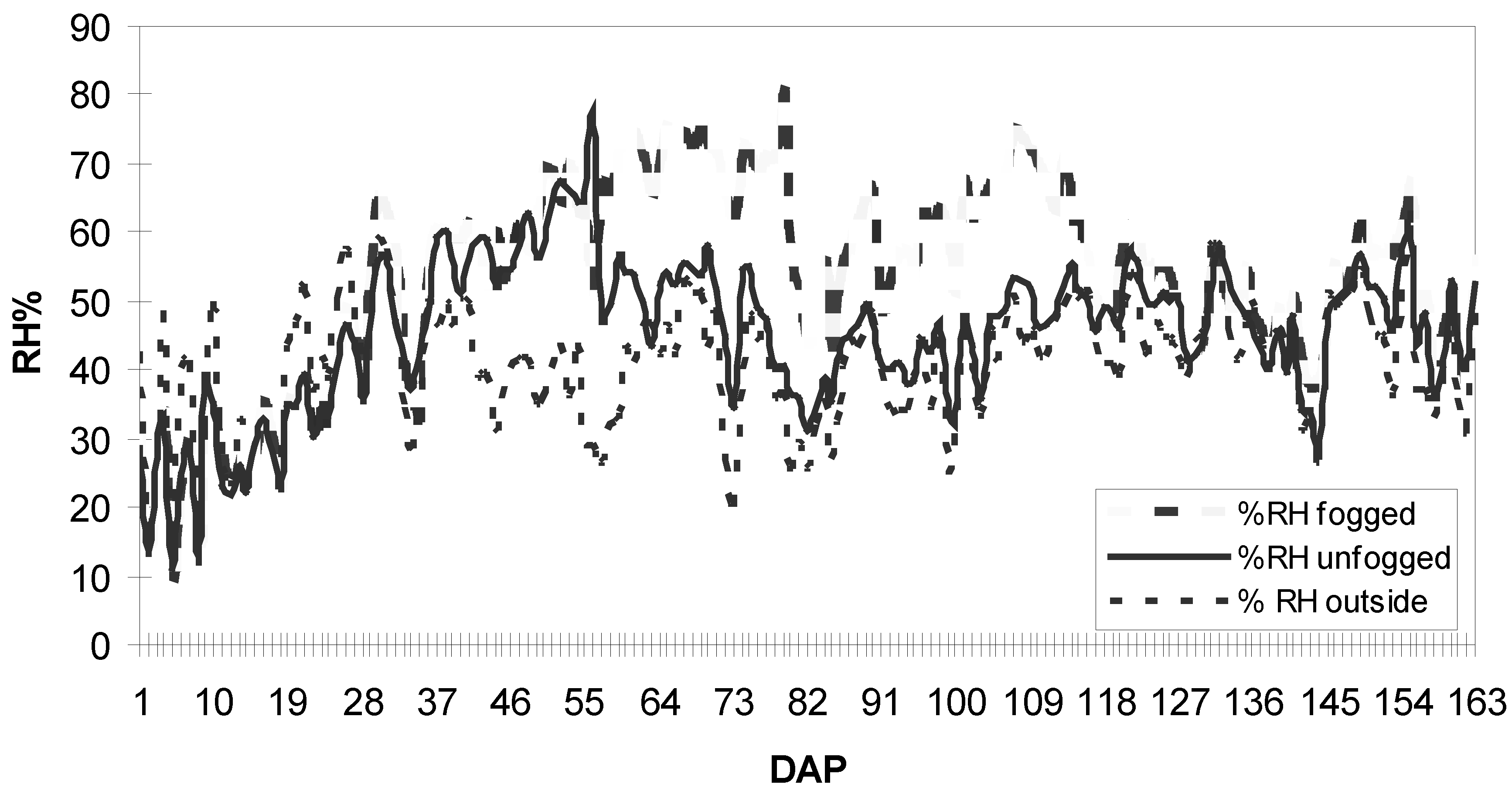

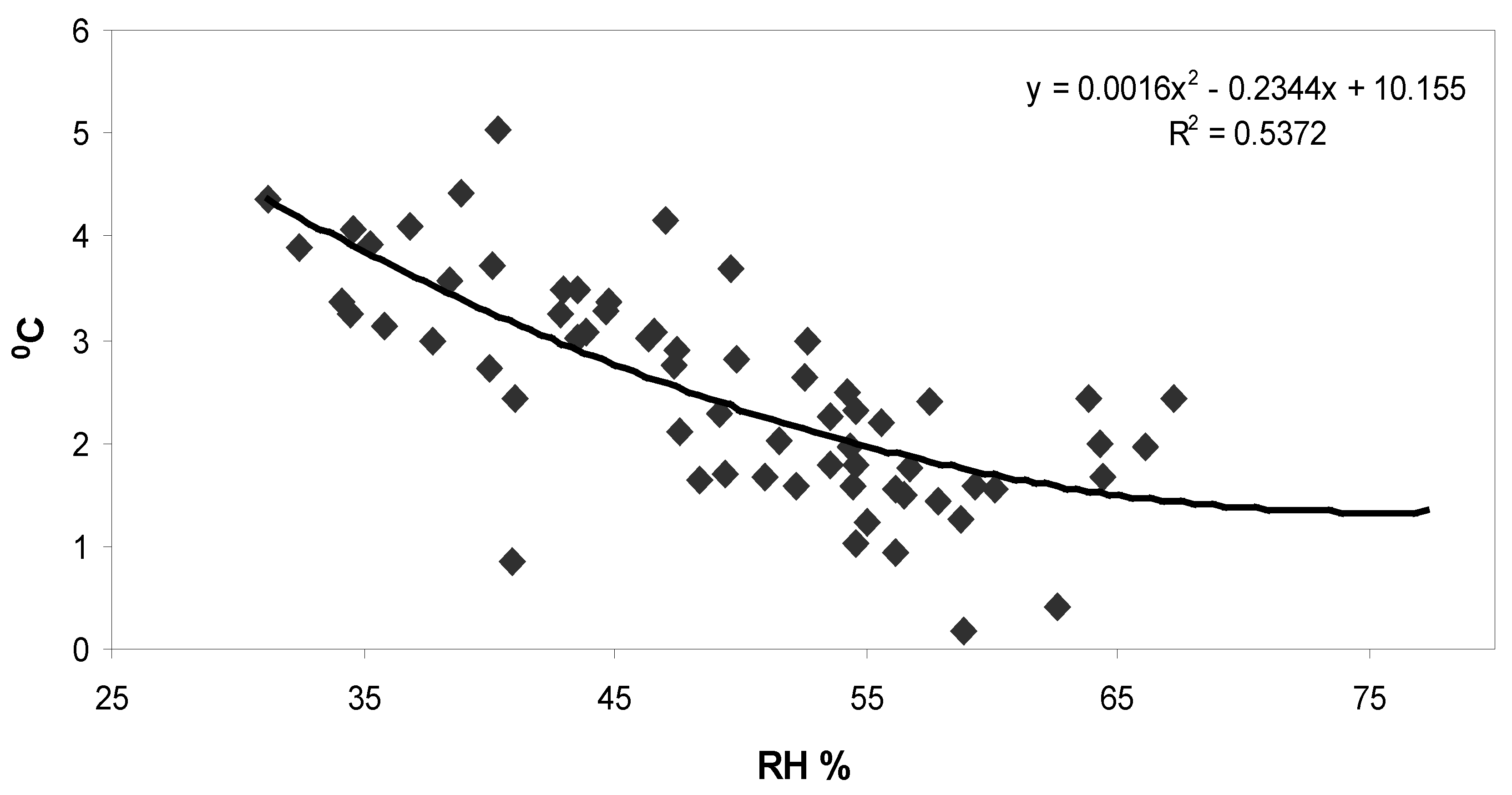

2.1. Fogging and Its Influence on Air Temperature and Relative Humidity

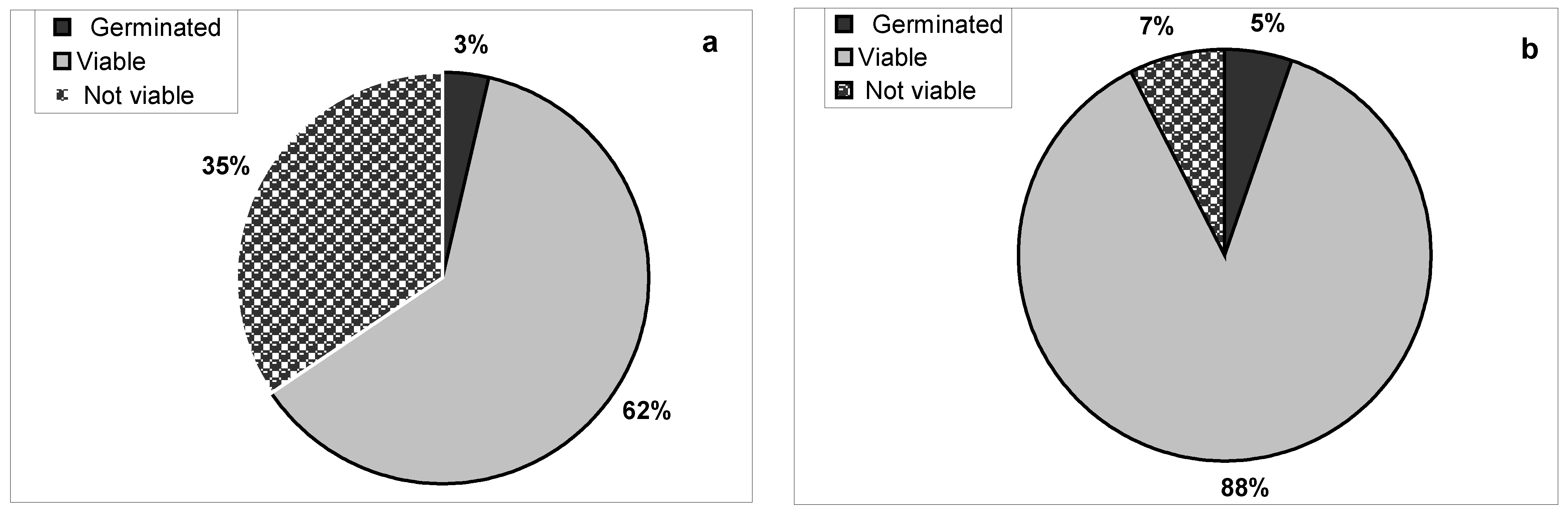

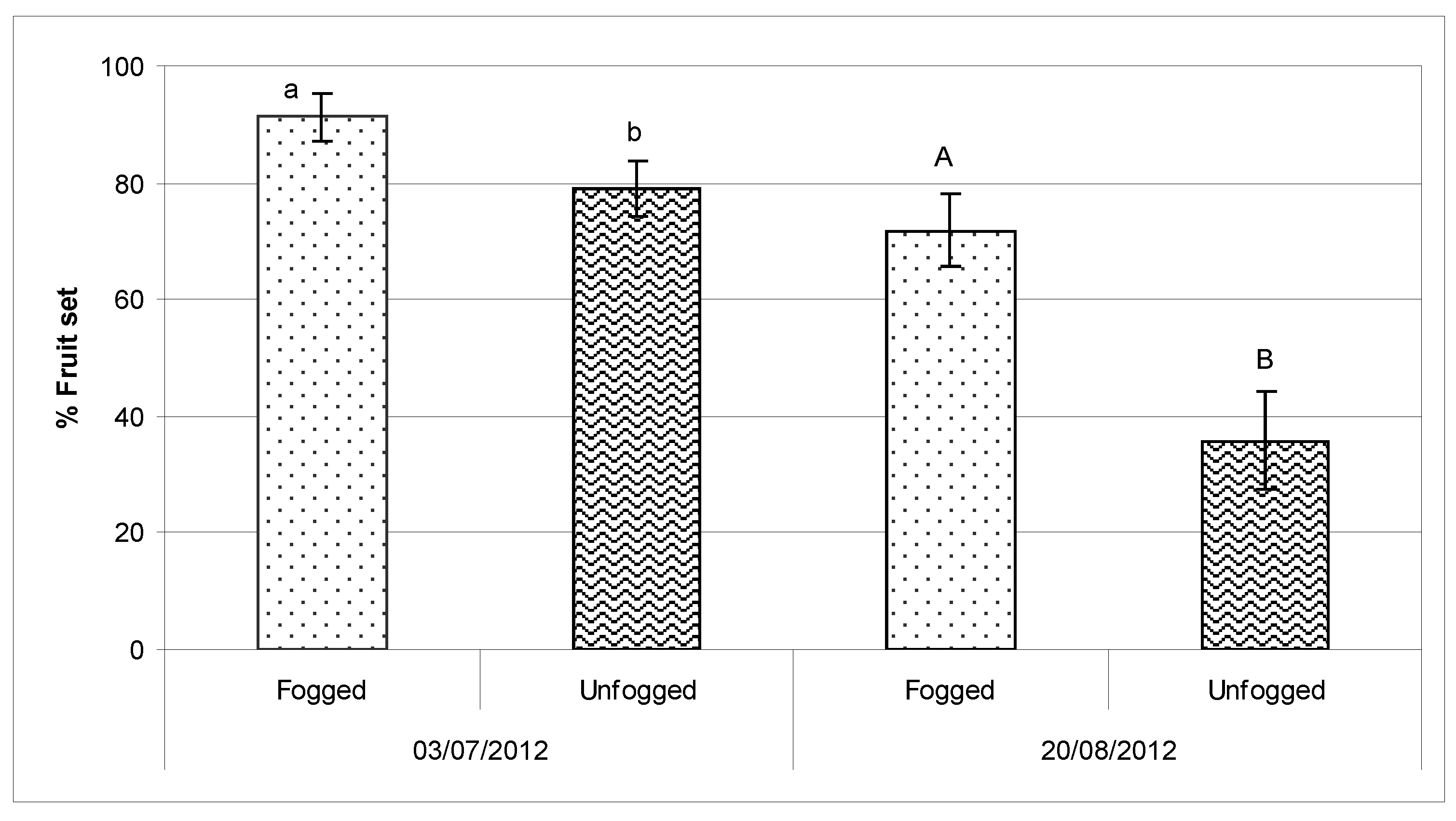

2.2. Pollen Quality and Fruit Set Rates

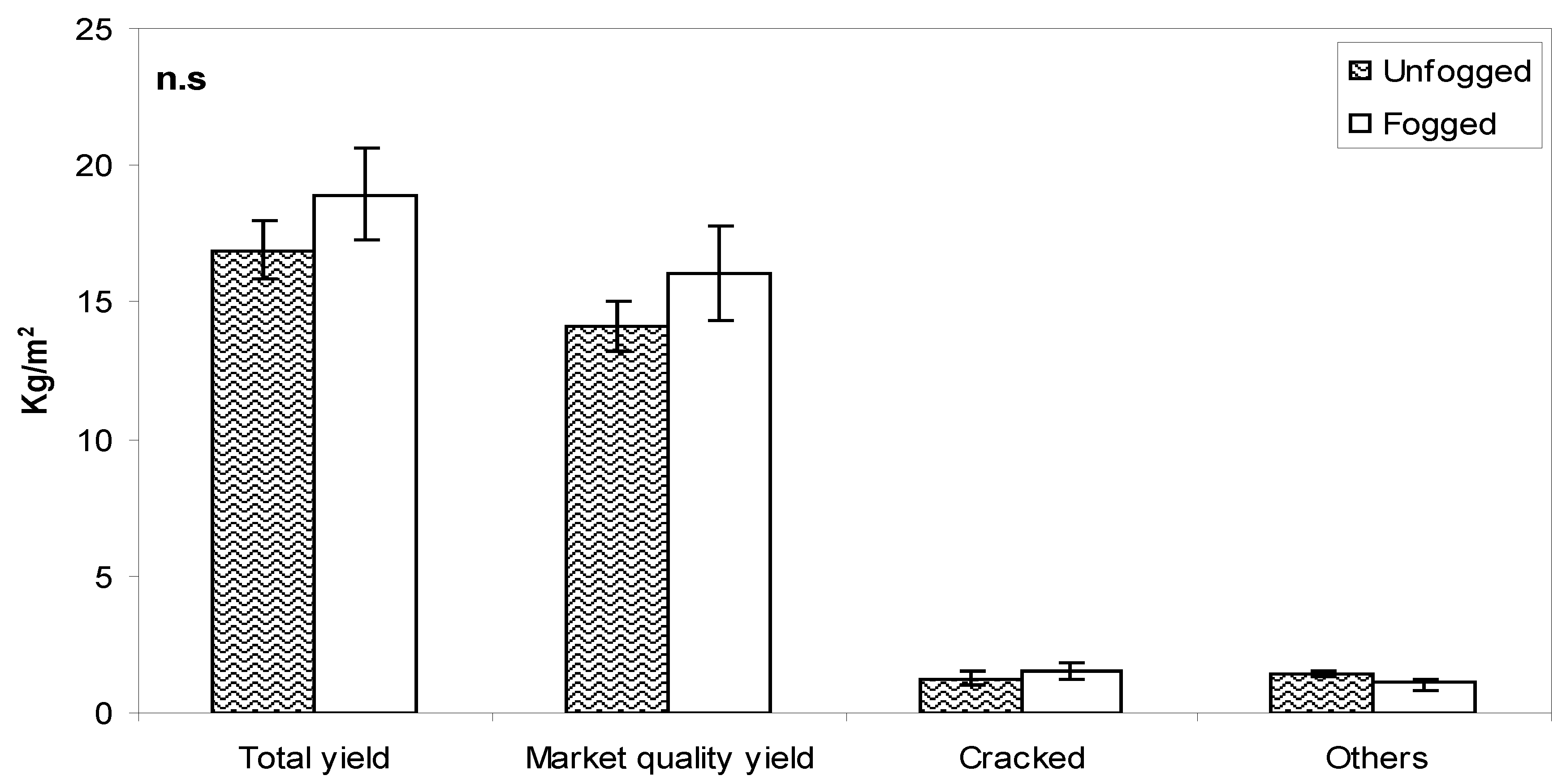

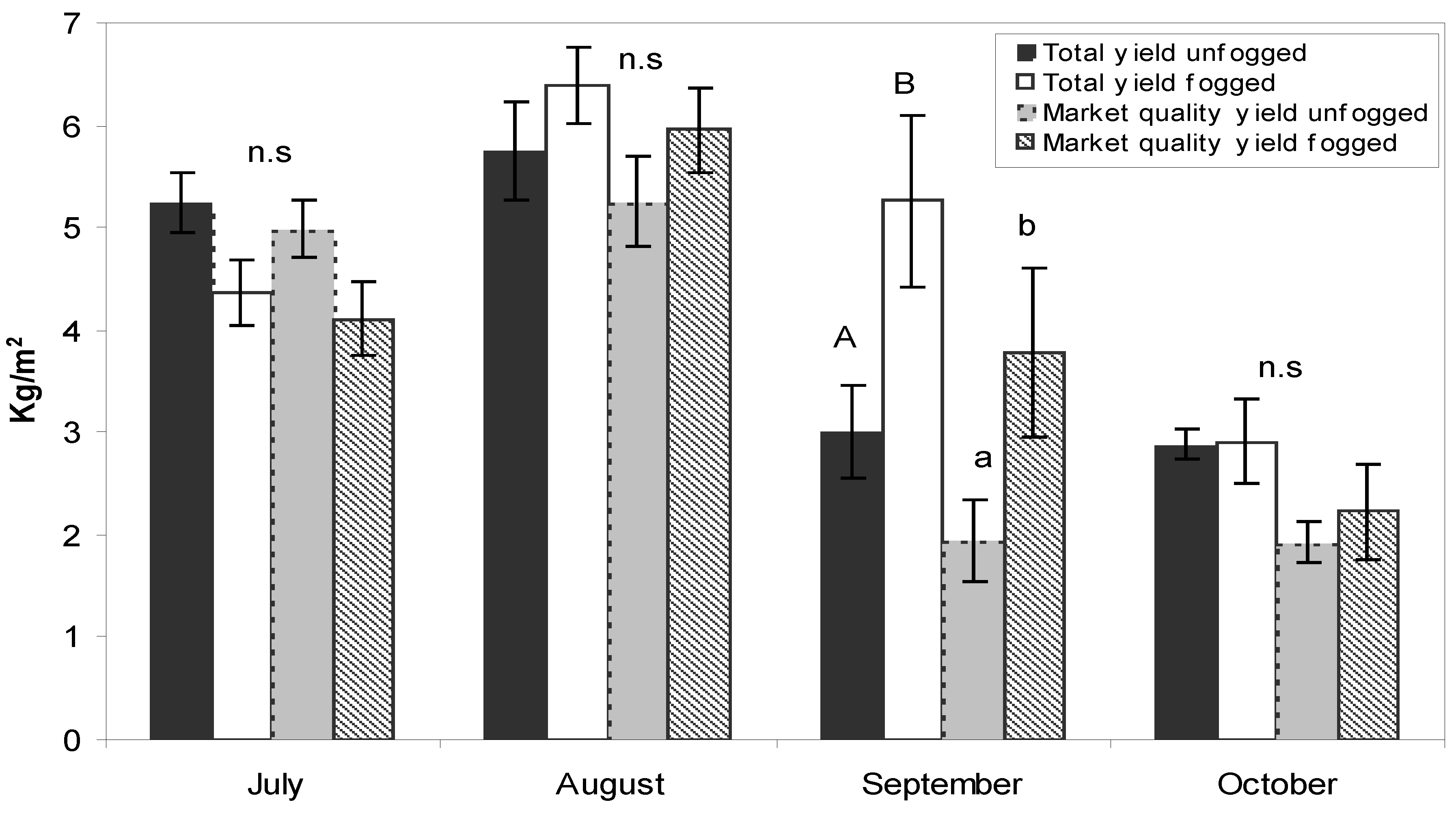

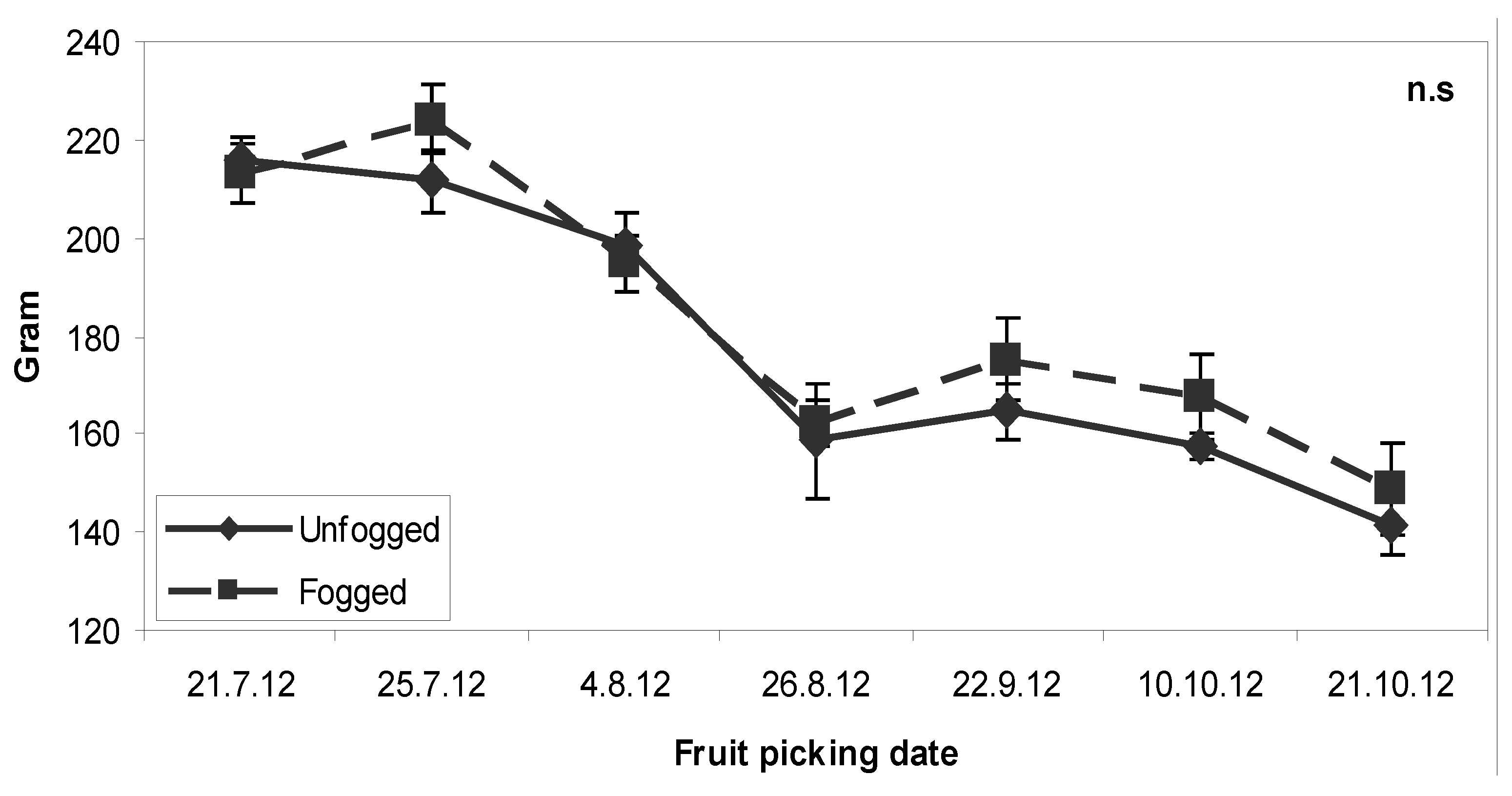

2.3. Fruit Yield, Fruit Weight and Post Harvest Fruit Quality

| Treatment | Cracked | Firm | Flexible | Soft | Rotten | Irregular color | Fruit quality score |

|---|---|---|---|---|---|---|---|

| % | % | % | % | % | % | (1–10) | |

| Unfogged | 6.11 | 32 | 40 | 27 | 19 | 30 | 1.2 |

| Fogged | 10.6 | 27 | 38 | 35 | 27 | 36 | −0.8 |

2.4. Discussion

3. Experimental Section

3.1. Plant Cultivation

3.2. Net House, Fogging System and Climate Data Collection

| EC | PH | Cl | Ca | CaCO3 | Mg |

|---|---|---|---|---|---|

| (ds/m) | (mg/L) | (mg/L) | (mg/L) | (mg/L) | |

| 0.5 | 7.2 | 68 | 32 | 110 | 7.31 |

3.3. Mature Pollen Quality

3.4. Fruit Quality and Post Harvest Tests

3.5. Data Analysis

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Pressman, E.; Peet, M.M.; Pharr, D.M. The effect of heat stress on tomato pollen characteristics is associated with changes in carbohydrate concentration in the developing anthers. Ann. Bot. 2002, 90, 631–636. [Google Scholar] [CrossRef]

- Peet, M.M.; Willits, D.H.; Gardner, R. Response of development and post-pollen production processes in sterile tomatoes to chronic sub-acute high temperature stress. J. Ex. Bot. 1997, 48, 101–111. [Google Scholar] [CrossRef]

- Sato, S.; Peet, M.M.; Thomas, J.F. Determining critical pre-and post-anthesis periods and physiological processes in Lycopersicon esculentum Mill. exposed to moderately elevated temperatures. J. Ex. Bot. 2002, 53, 1187–1195. [Google Scholar] [CrossRef]

- Sato, S.; Kamiyama, M.; Iwata, T.; Makita, N.; Furukawa, H.; Ikeda, H. Moderate increase of mean daily temperature adversely affects fruit set of Lycopersicon esculentum by disrupting specific physiological processes in male reproductive development. Ann. Bot. 2006, 97, 731–738. [Google Scholar] [CrossRef]

- Baille, A. Overview of greenhouse climate control in the Mediterranean regions. Cahiers Op. Available online: http://om.ciheam.org/om/pdf/c31/CI020831.pdf (accessed on 16 June 2013).

- Meca, D.; López, J.C.; Gázquez, J.C.; Baeza, E.; Pérez Parra, J.; Zaragoza, G. Comparison of three different cooling systems in parral type greenhouses in Almería. Span. J. Agric. Res. 2007, 5, 285–292. [Google Scholar]

- Li, S.; Willits, D.H. Comparing low-pressure and high-pressure fogging systems in naturally ventilated greenhouses. Bios. Eng. 2008, 101, 69–77. [Google Scholar] [CrossRef]

- Li, S.; Willits, D.H.; Yunker, C.A. Experimental Study of Low Pressure Fogging System in Naturally Ventilated Greenhouses. American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2005. [Google Scholar]

- Öztürk, H.H. Evaporative cooling efficiency of a fogging system for greenhouses. Turk. J. Agric. For. 2003, 27, 49–57. [Google Scholar]

- Vara-Prasad, P.V.; Craufurd, P.Q.; Summerfield, R.J. Fruit number in relation to pollen production and viability in groundnut exposed to short episodes of heat stress. Ann. Bot. 1999, 84, 381–386. [Google Scholar] [CrossRef]

- Sato, S.; Peet, M.M.; Thomas, J.F. Physiological factors limit fruit set of tomato (Lycopersicon esculentum Mill.) under chronic, mild heat stress. Plant Cell Environ. 2000, 23, 719–726. [Google Scholar] [CrossRef]

- Pressman, E.; Moshkovitch, H.; Rosenfeld, K.; Shaked, R.; Gamliel, B.; Aloni, B. Influence of low night temperatures on sweet pepper flower quality and the effect of repeated pollinations, with viable pollen, on fruit setting. J. Hortic. Sci. Bio. 1998, 73, 131–136. [Google Scholar]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Harel, D.; Fadida, H.; Gantz, S.; Shilo, K.; Yasuor, H. Evaluation of Low Pressure Fogging System for Improving Crop Yield of Tomato (Lycopersicon esculentum Mill.): Grown under Heat Stress Conditions. Agronomy 2013, 3, 497-507. https://doi.org/10.3390/agronomy3020497

Harel D, Fadida H, Gantz S, Shilo K, Yasuor H. Evaluation of Low Pressure Fogging System for Improving Crop Yield of Tomato (Lycopersicon esculentum Mill.): Grown under Heat Stress Conditions. Agronomy. 2013; 3(2):497-507. https://doi.org/10.3390/agronomy3020497

Chicago/Turabian StyleHarel, Danny, Hadar Fadida, Shelly Gantz, Kobi Shilo, and Hagai Yasuor. 2013. "Evaluation of Low Pressure Fogging System for Improving Crop Yield of Tomato (Lycopersicon esculentum Mill.): Grown under Heat Stress Conditions" Agronomy 3, no. 2: 497-507. https://doi.org/10.3390/agronomy3020497