Performance Analysis for the Anaerobic Membrane Bioreactor Combined with the Forward Osmosis Membrane Bioreactor: Process Conditions Optimization, Wastewater Treatment and Sludge Characteristics

Abstract

:1. Introduction

2. Materials and Methods

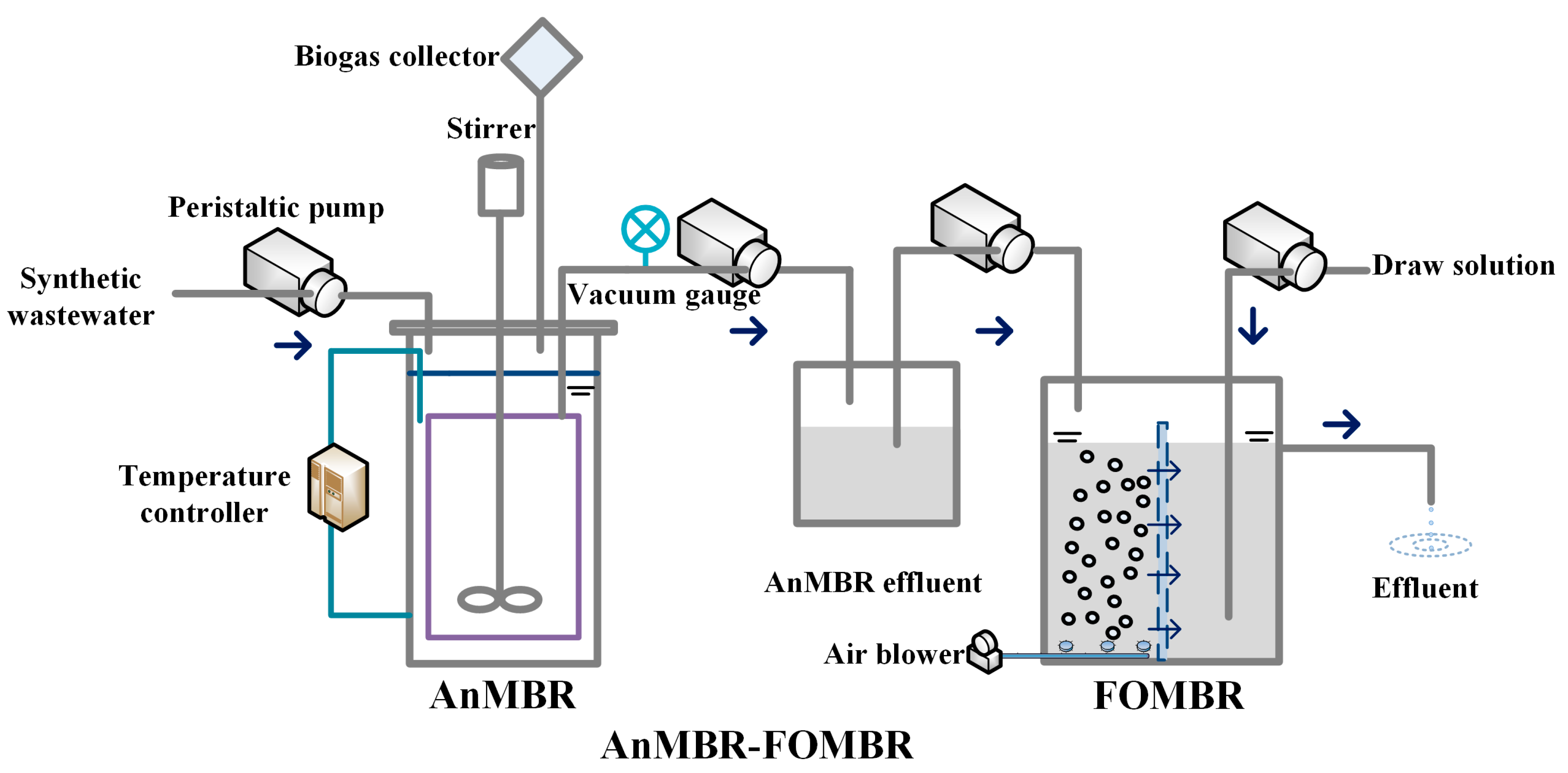

2.1. Experimental Set-Up of AnMBR-FOMBR

2.2. Feed and Operating Conditions

2.3. Analytical Methods

3. Results and Discussion

3.1. Optimization of Process Conditions for the AnMBR and the FOMBR

3.1.1. Optimization of the AnMBR’s Operational Conditions

3.1.2. Optimization of the FOMBR’s Operational Conditions

3.2. Biogas Production and VFA Generation

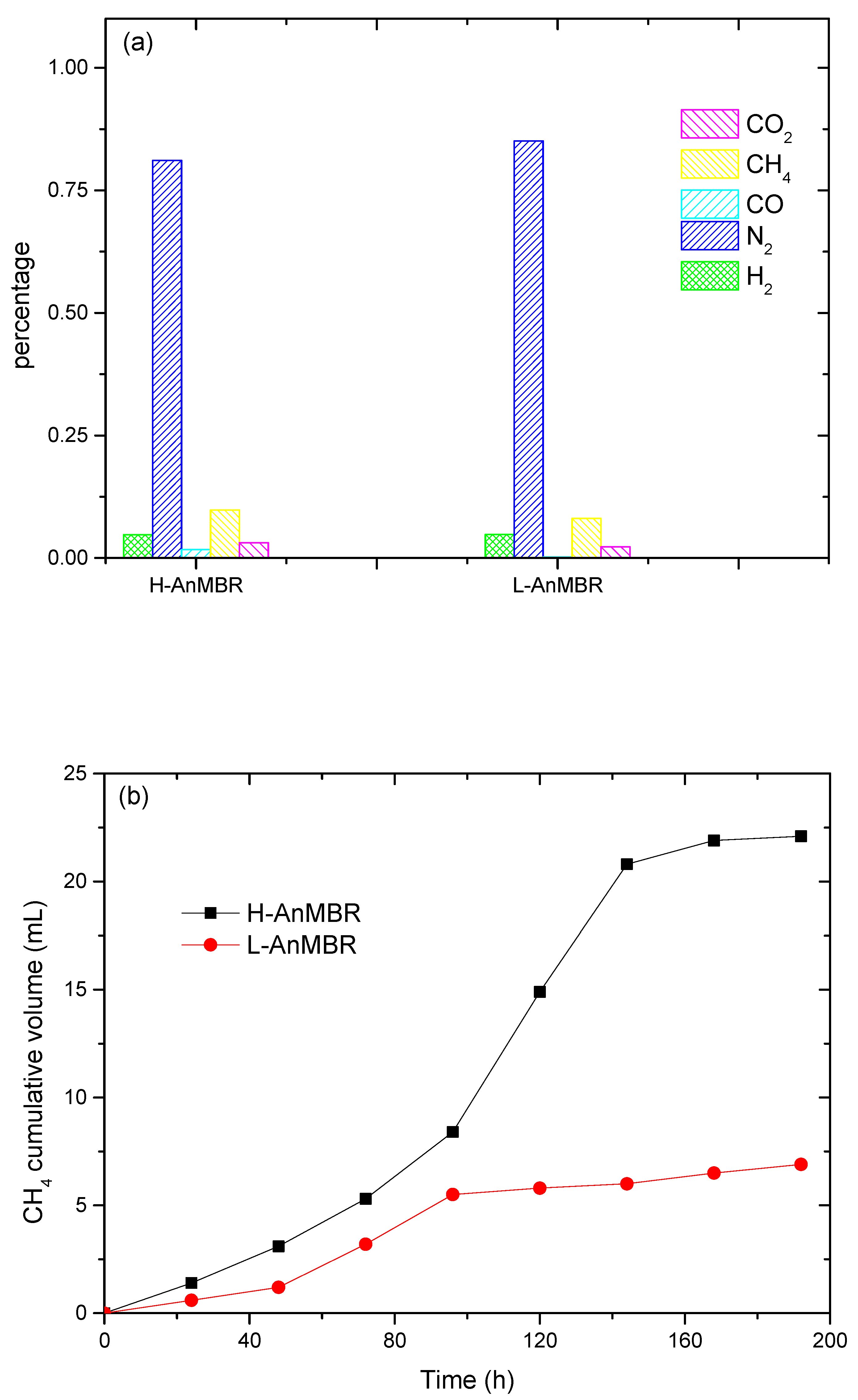

3.2.1. Gas Production of the AnMBR for Long-Term Wastewater Treatment

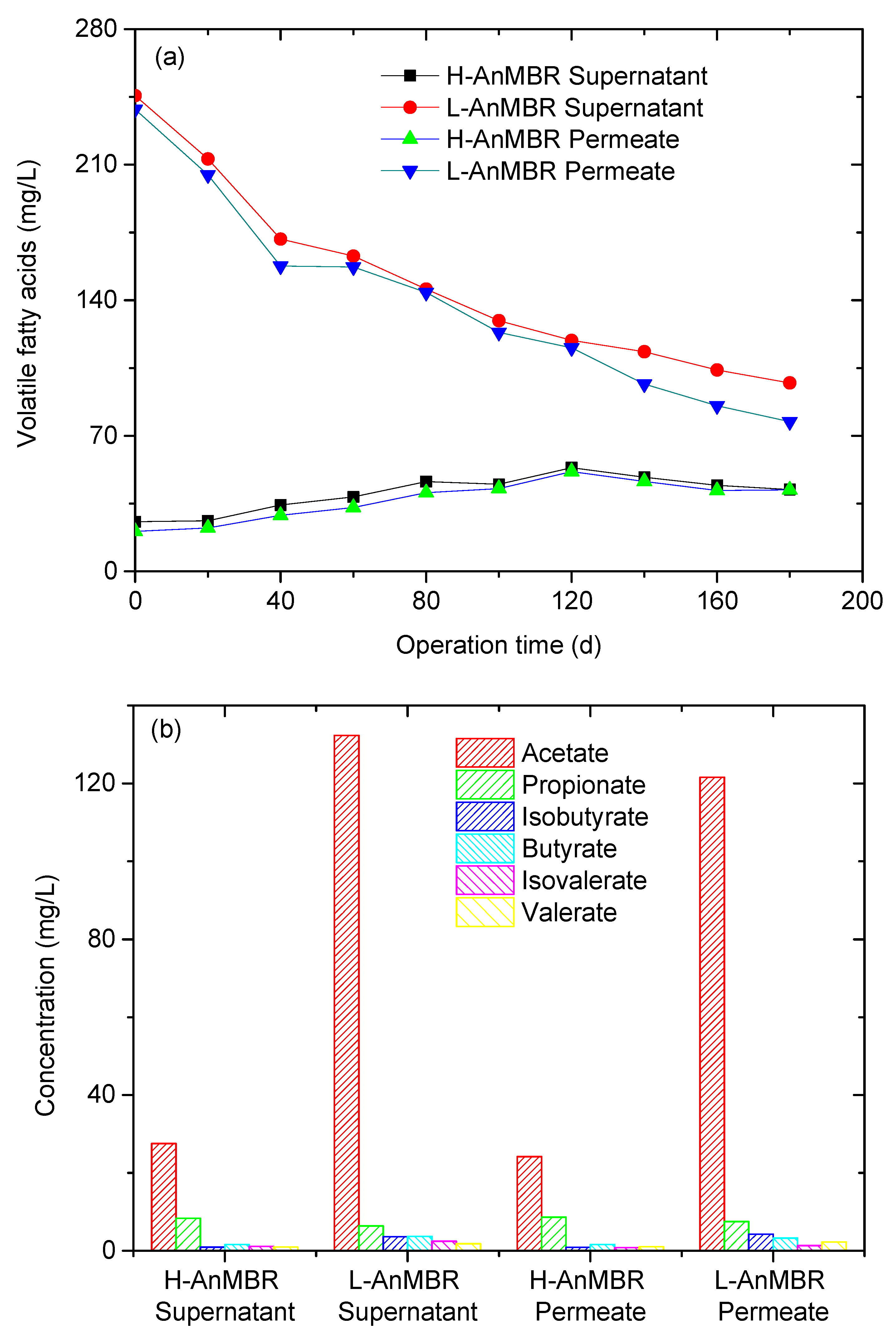

3.2.2. VFA Production of the AnMBR for Long-Term Wastewater Treatment

3.3. Wastewater Treatment Performance of the AnMBR and FOMBR

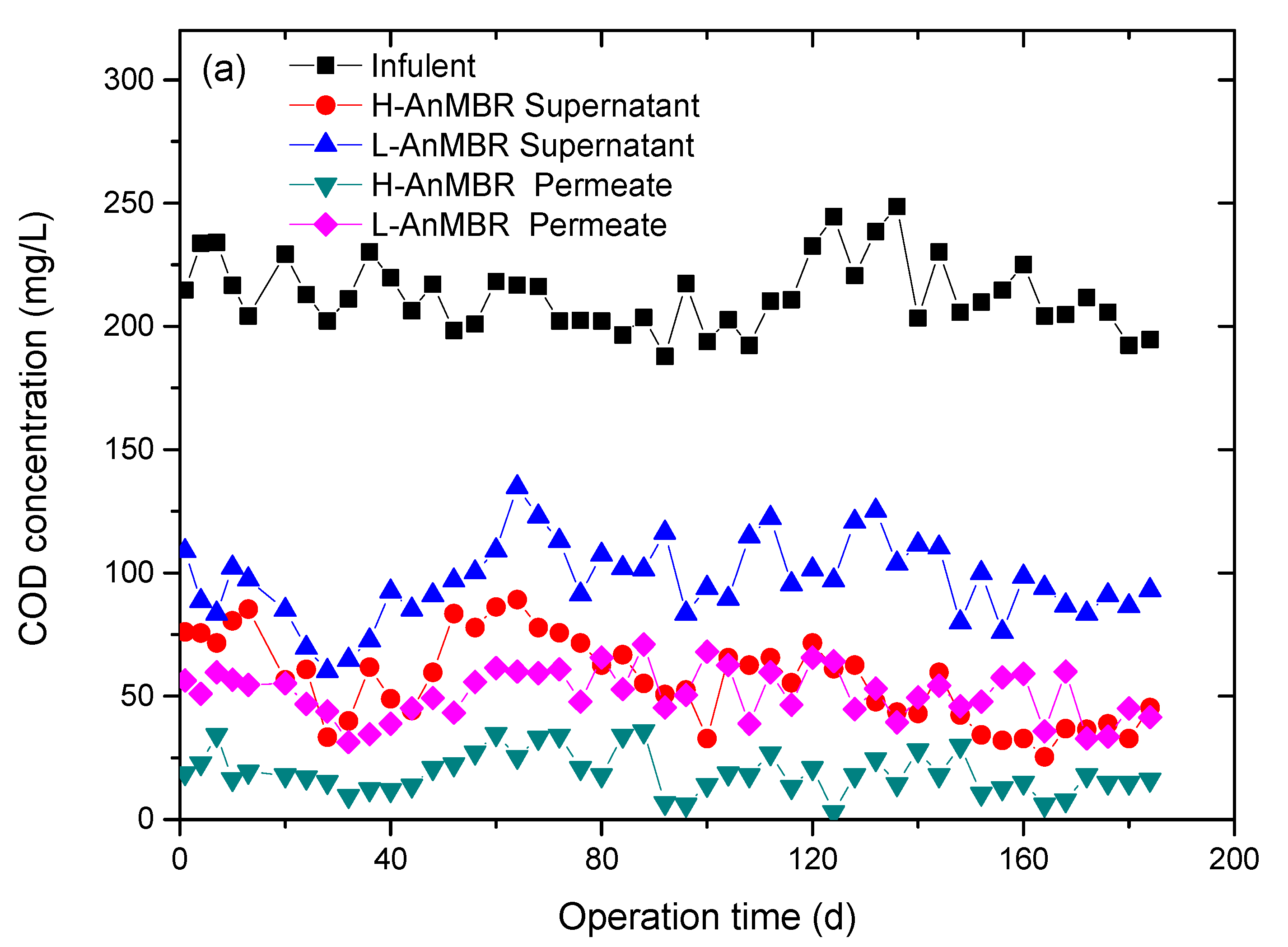

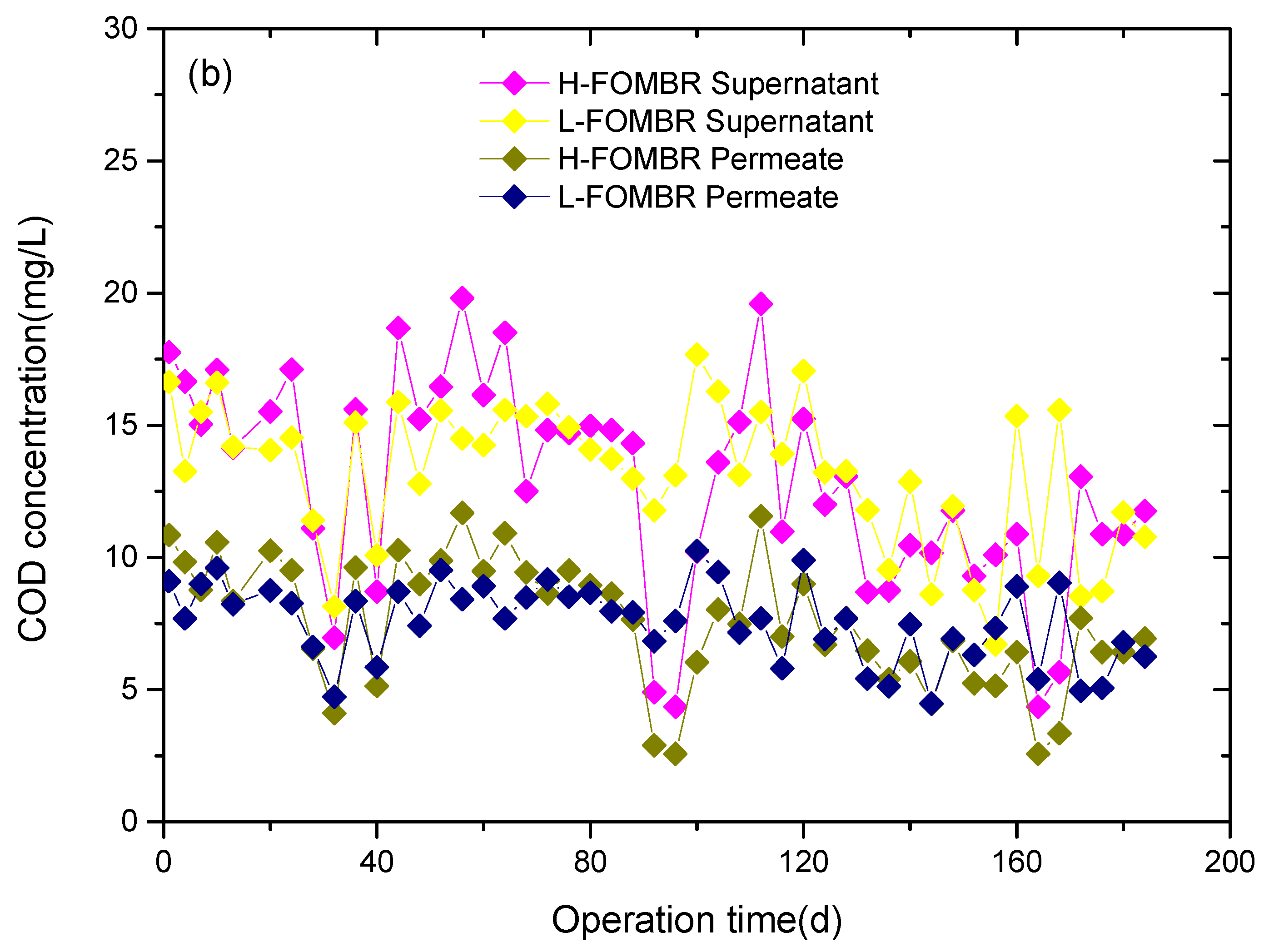

3.3.1. COD Removal of the AnMBR+FOMBR

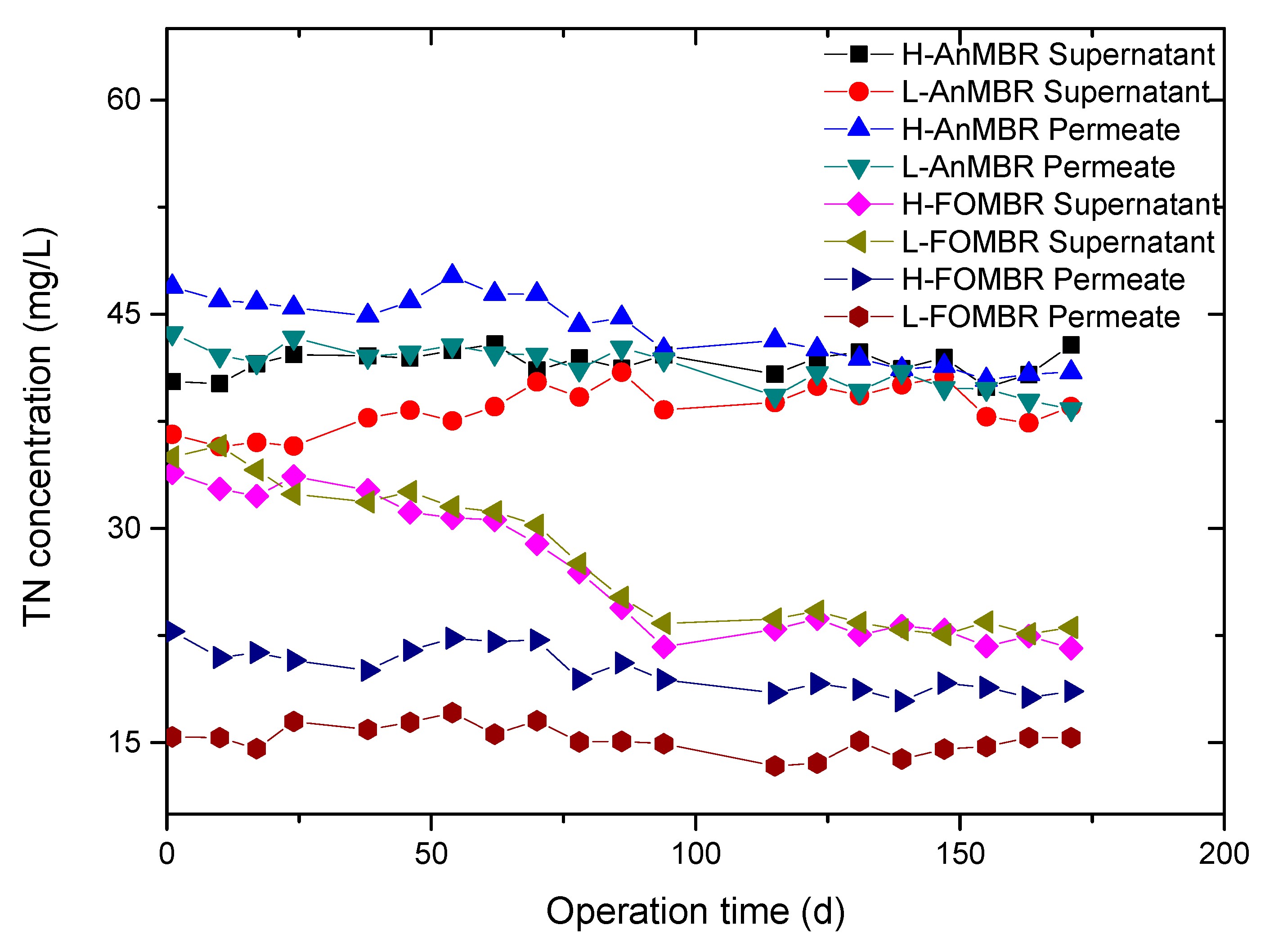

3.3.2. The Total Nitrogen Concentration Changes in the AnMBR

3.4. Sludge Characteristics of the AnMBR and FOMBR

3.4.1. Basic Physical Properties of Sludge

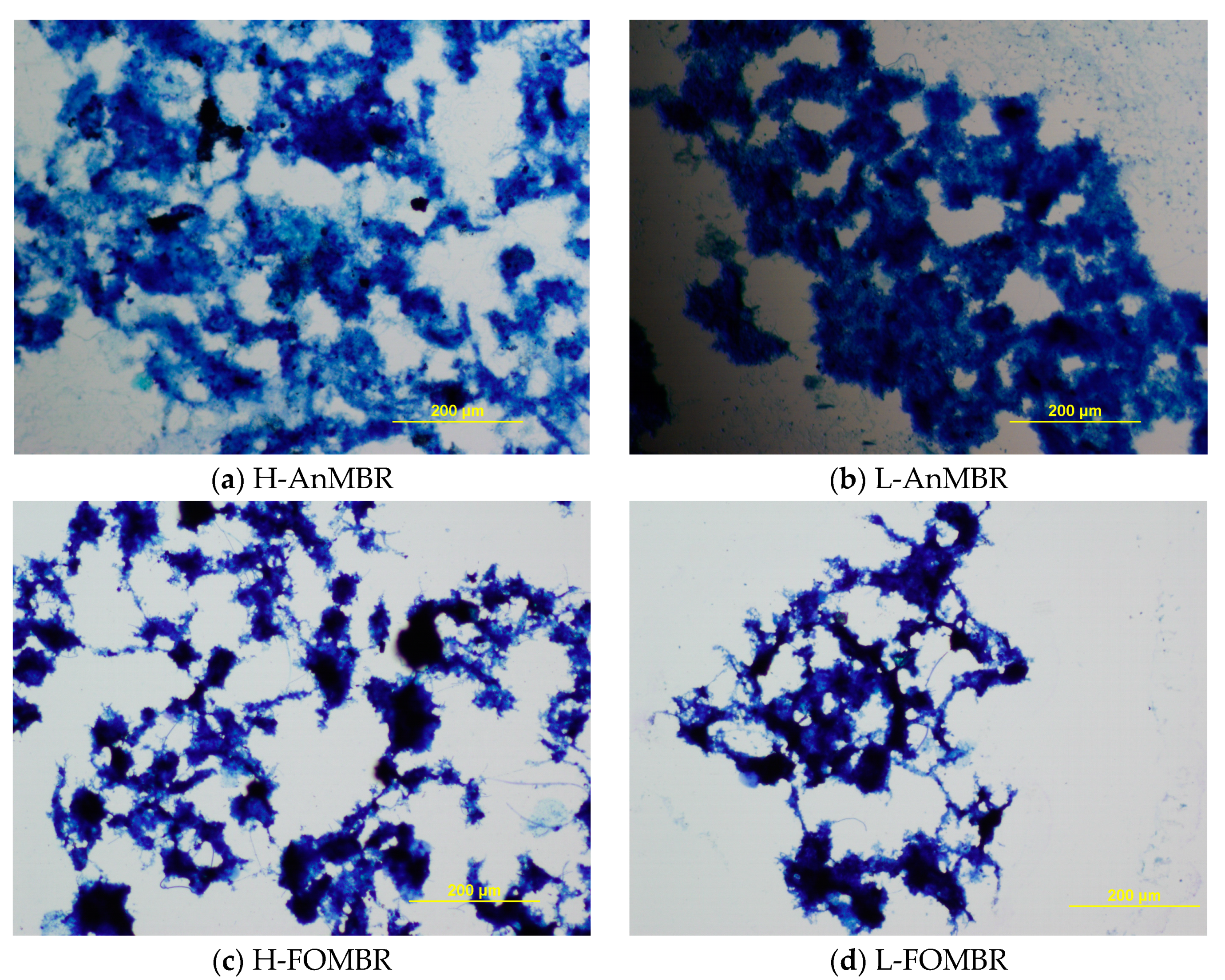

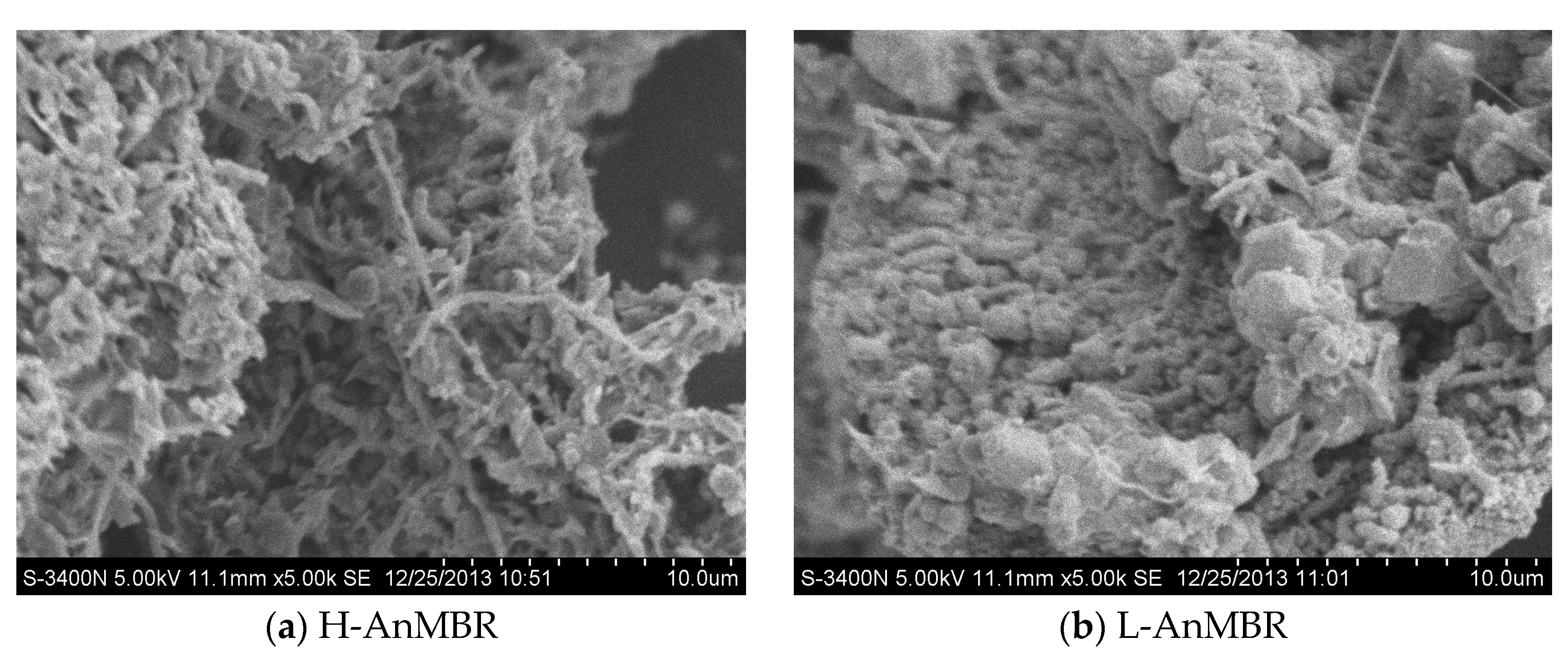

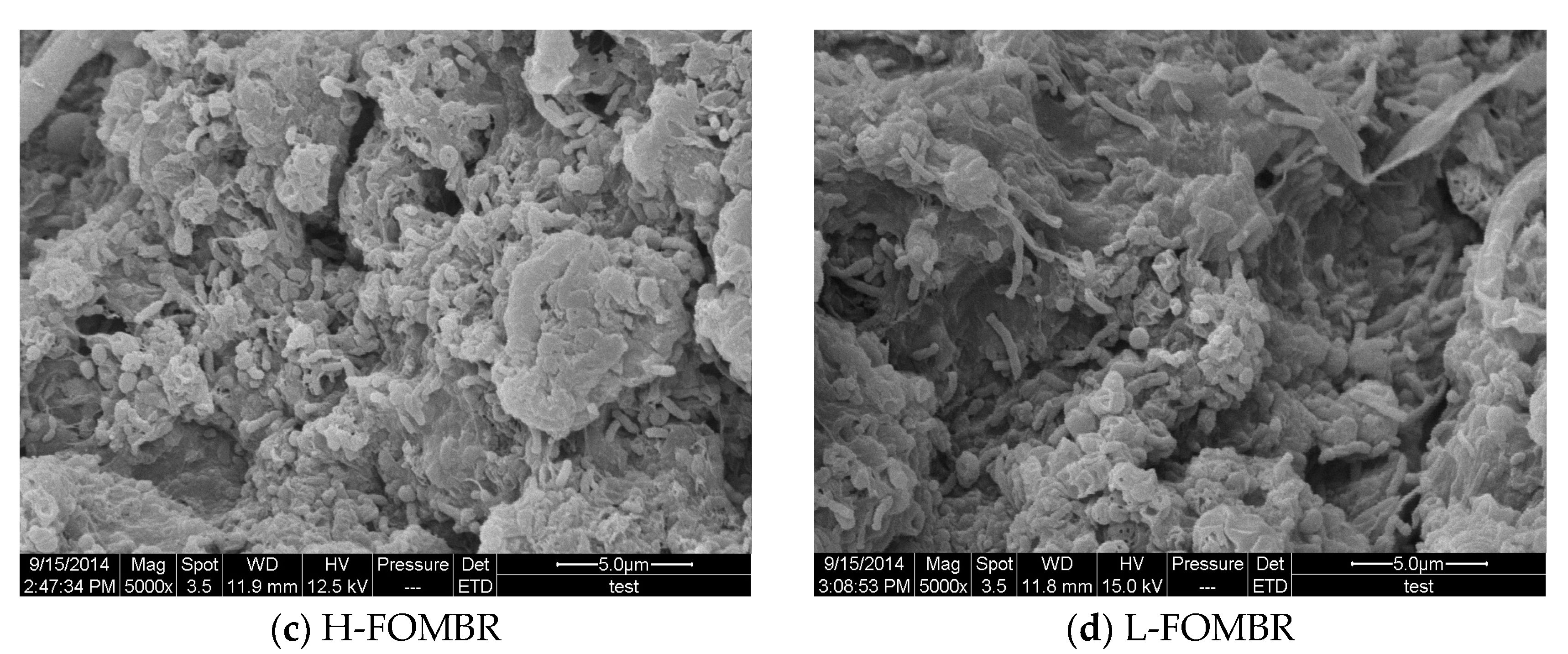

3.4.2. Morphologies of Activated Sludge Flocs

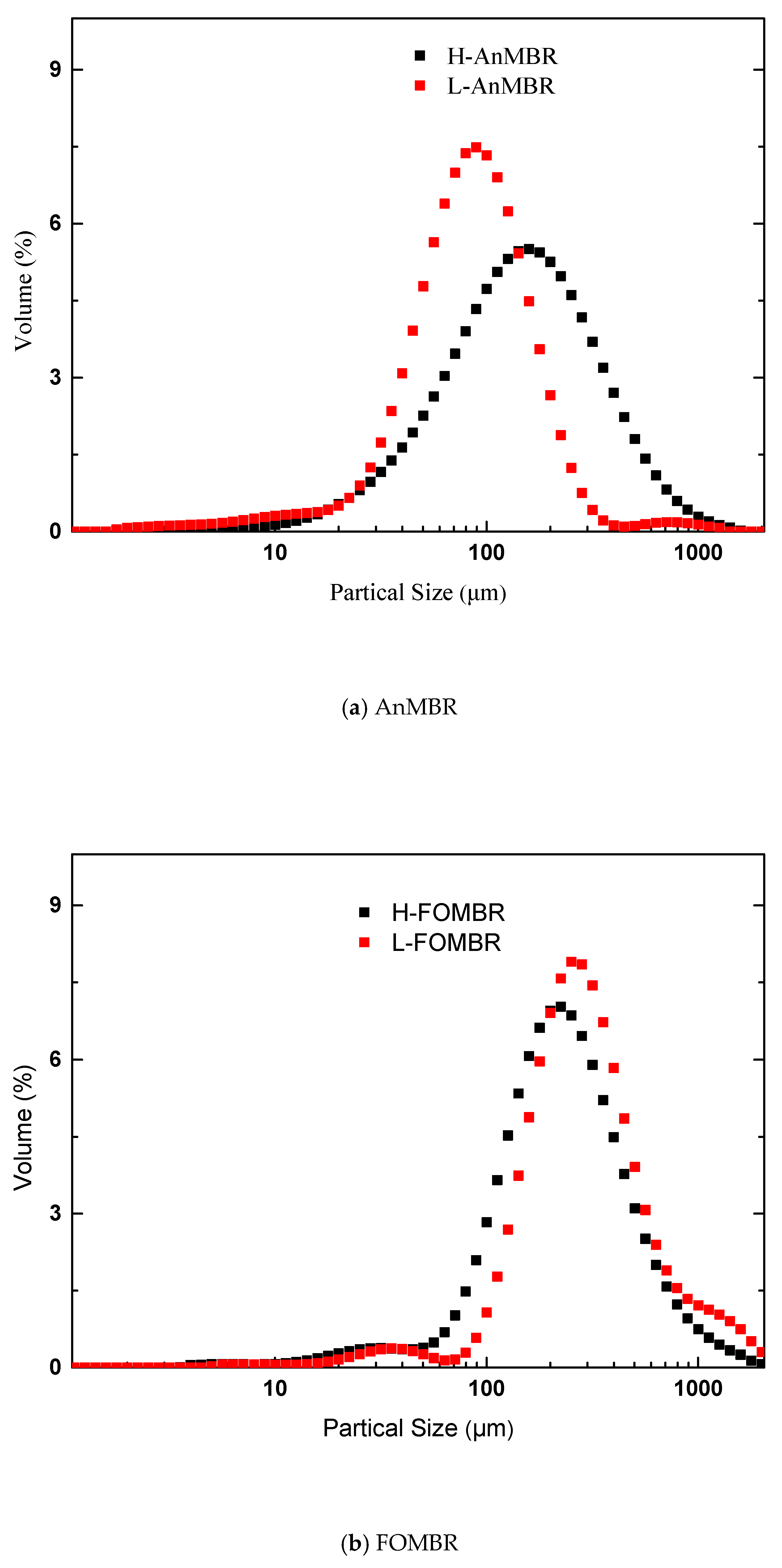

3.4.3. Particle Size Distribution of Sludge Flocs

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Vinardell, S.; Astals, S.; Peces, M.; Cardete, M.A.; Fernández, I.; Mata-Alvarez, J.; Dosta, J. Advances in anaerobic membrane bioreactor technology for municipal wastewater treatment: A 2020 updated review. Renew. Sustain. Energy Rev. 2020, 130, 109936. [Google Scholar] [CrossRef]

- Lim, M.; Patureau, D.; Heran, M.; Lesage, G.; Kim, J. Removal of organic micropollutants in anaerobic membrane bioreactors in wastewater treatment: Critical review. Environ. Sci. Water Res. Technol. 2020, 6, 1230–1243. [Google Scholar] [CrossRef]

- Zhen, L.; Shuming, Y.; Yuyou, L.; Wen, W.; Wang, X.C.; Rong, C. Application of anaerobic membrane bioreactors to municipal wastewater treatment at ambient temperature: A review of achievements, challenges, and perspectives. Bioresour. Technol. 2018, 267, 756–768. [Google Scholar]

- Ozgun, H.; Dereli, R.K.; Ersahin, M.E.; Kinaci, C.; Spanjers, H.; van Lier, J.B. A review of anaerobic membrane bioreactors for municipal wastewater treatment: Integration options, limitations and expectations. Sep. Purif. Technol. 2013, 118, 89–104. [Google Scholar] [CrossRef]

- Martinez-Sosa, D.; Helmreich, B.; Netter, T.; Paris, S.; Bischof, F.; Horn, H. Anaerobic submerged membrane bioreactor (AnSMBR) for municipal wastewater treatment under mesophilic and psychrophilic temperature conditions. Bioresour. Technol. 2011, 102, 10377–10385. [Google Scholar] [CrossRef]

- Foglia, A.; Akyol, Ç.; Frison, N.; Katsou, E.; Eusebi, A.L.; Fatone, F. Long-term operation of a pilot-scale anaerobic membrane bioreactor (AnMBR) treating high salinity low loaded municipal wastewater in real environment. Sep. Purif. Technol. 2020, 236, 116279. [Google Scholar] [CrossRef]

- Zhen, G.; Pan, Y.; Lu, X.; Li, Y.-Y.; Zhang, Z.; Niu, C.; Kumar, G.; Kobayashi, T.; Zhao, Y.; Xu, K. Anaerobic membrane bioreactor towards biowaste biorefinery and chemical energy harvest: Recent progress, membrane fouling and future perspectives. Renew. Sustain. Energy Rev. 2019, 115, 109392. [Google Scholar] [CrossRef]

- Lin, H.J.; Peng, W.; Zhang, M.J.; Chen, J.R.; Hong, H.C.; Zhang, Y. A review on anaerobic membrane bioreactors: Applications, membrane fouling and future perspectives. Desalination 2013, 314, 169–188. [Google Scholar] [CrossRef]

- Smith, A.L.; Stadler, L.B.; Love, N.G.; Skerlos, S.J.; Raskin, L. Perspectives on anaerobic membrane bioreactor treatment of domestic wastewater: A critical review. Bioresour. Technol. 2012, 122, 149–159. [Google Scholar] [CrossRef]

- Wang, X.; Wang, C.; Tang, C.Y.; Hu, T.; Li, X.; Ren, Y. Development of a novel anaerobic membrane bioreactor simultaneously integrating microfiltration and forward osmosis membranes for low-strength wastewater treatment. J. Membr. Sci. 2017, 527, 1–7. [Google Scholar] [CrossRef]

- Cornelissen, E.R.; Harmsen, D.; de Korte, K.F.; Ruiken, C.J.; Qin, J.J.; Oo, H.; Wessels, L.P. Membrane fouling and process performance of forward osmosis membranes on activated sludge. J. Membr. Sci. 2008, 319, 158–168. [Google Scholar] [CrossRef]

- Achilli, A.; Cath, T.Y.; Marchand, E.A.; Childress, A.E. The forward osmosis membrane bioreactor: A low fouling alternative to MBR processes. Desalination 2009, 239, 10–21. [Google Scholar] [CrossRef]

- Yap, W.J.; Zhang, J.S.; Lay, W.C.L.; Cao, B.; Fane, A.G.; Liu, Y. State of the art of osmotic membrane bioreactors for water reclamation. Bioresour. Technol. 2012, 122, 217–222. [Google Scholar] [CrossRef] [PubMed]

- Cornelissen, E.R.; Harmsen, D.; Beerendonk, E.F.; Qin, J.J.; Oo, H.; de Korte, K.F.; Kappelhof, J.W.M.N. The innovative Osmotic Membrane Bioreactor (OMBR) for reuse of wastewater. Water Sci. Technol. 2011, 63, 1557–1565. [Google Scholar] [CrossRef] [PubMed]

- Qin, J.J.; Kekre, K.A.; Oo, M.H.; Tao, G.H.; Lay, C.L.; Lew, C.H.; Cornelissen, E.R.; Ruiken, C.J. Preliminary study of osmotic membrane bioreactor: Effects of draw solution on water flux and air scouring on fouling. Water Sci. Technol. 2010, 62, 1353–1360. [Google Scholar] [CrossRef]

- Lay, W.C.L.; Zhang, Q.Y.; Zhang, J.S.; McDougald, D.; Tang, C.Y.; Wang, R.; Liu, Y.; Fane, A.G. Study of integration of forward osmosis and biological process: Membrane performance under elevated salt environment. Desalination 2011, 283, 123–130. [Google Scholar] [CrossRef]

- Zhang, J.S.; Loong, W.L.C.; Chou, S.R.; Tang, C.Y.; Wang, R.; Fane, A.G. Membrane biofouling and scaling in forward osmosis membrane bioreactor. J. Membr. Sci. 2012, 403, 8–14. [Google Scholar] [CrossRef]

- Ding, Y.; Liang, Z.L.; Guo, Z.S.; Li, Z.P.; Hou, X.G.; Jin, C. The Performance and Microbial Community Identification in Mesophilic and Atmospheric Anaerobic Membrane Bioreactor for Municipal Wastewater Treatment Associated with Different Hydraulic Retention Times. Water 2019, 11, 160. [Google Scholar] [CrossRef] [Green Version]

- Chinese Environmental Science Press. Standard Methods for Examination of Water and Wastewater, 4th ed.; Chinese Environmental Science Press: Beijing, China, 2002. [Google Scholar]

- Baek, S.H.; Pagilla, K.R.; Kim, H.-J. Lab-scale study of an anaerobic membrane bioreactor (AnMBR) for dilute municipal wastewater treatment. Biotechnol. Bioproc. E 2010, 15, 704–708. [Google Scholar] [CrossRef]

- Dvořák, L.; Gómez, M.; Dolina, J.; Černín, A. Anaerobic membrane bioreactors—A mini review with emphasis on industrial wastewater treatment: Applications, limitations and perspectives. Desalin. Water Treat. 2015, 57, 19062–19076. [Google Scholar] [CrossRef] [Green Version]

- Nemestóthy, N.; Bakonyi, P.; Szentgyrgyi, E.; Kumar, G.; Nguyen, D.D.; Chang, S.W.; Kim, S.H.; Bélafi-Bakó, K. Evaluation of a membrane permeation system for biogas upgrading using model and real gaseous mixtures: The effect of operating conditions on separation behaviour, methane recovery and process stability. J. Clean. Prod. 2018, 185, 44–51. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, W.; Sethupathi, S.; Kanadasan, G.; Lau, L.C.; Kanthasamy, R. A review on the removal of hydrogen sulfide from biogas by adsorption using sorbents derived from waste. Rev. Chem. Eng. 2019. [Google Scholar] [CrossRef]

- Agustini, C.; da Costa, M.; Gutterres, M. Biogas production from tannery solid wastes–Scale-up and cost saving analysis. J. Clean. Prod. 2018, 187, 158–164. [Google Scholar] [CrossRef]

- Abad, V.; Avila, R.; Vicent, T.; Font, X. Promoting circular economy in the surroundings of an organic fraction of municipal solid waste anaerobic digestion treatment plant: Biogas production impact and economic factors. Bioresour. Technol. 2019, 283, 10–17. [Google Scholar] [CrossRef] [PubMed]

- Trzcinski, A.P.; Stuckey, D.C. Treatment of municipal solid waste leachate using a submerged anaerobic membrane bioreactor at mesophilic and psychrophilic temperatures: Analysis of recalcitrants in the permeate using GC-MS. Water Res. 2010, 44, 671–680. [Google Scholar] [CrossRef] [Green Version]

- Dhaked, R.K.; Singh, P.; Singh, L. Biomethanation under psychrophilic conditions. Waste Manag. 2010, 30, 2490–2496. [Google Scholar] [CrossRef]

- Christensen, M.L.; Niessen, W.; Sørensen, N.B.; Hansen, S.H.; Jørgensen, M.K.; Nielsen, P.H. Sludge fractionation as a method to study and predict fouling in MBR systems. Sep. Purif. Technol. 2018, 194, 329–337. [Google Scholar] [CrossRef]

- Dong, Q.; Parker, W.; Dagnew, M. Impact of FeCl3 dosing on AnMBR treatment of municipal wastewater. Water Res. 2015, 80, 281–293. [Google Scholar] [CrossRef]

- Ozgun, H.; Tao, Y.; Ersahin, M.E.; Zhou, Z.; Gimenez, J.B.; Spanjers, H.; van Lier, J.B. Impact of temperature on feed-flow characteristics and filtration performance of an upflow anaerobic sludge blanket coupled ultrafiltration membrane treating municipal wastewater. Water Res. 2015, 83, 71–83. [Google Scholar] [CrossRef]

- Zhou, Z.; Tao, Y.; Zhang, S.; Xiao, Y.; Meng, F.; Stuckey, D.C. Size-dependent microbial diversity of sub-visible particles in a submerged anaerobic membrane bioreactor (SAnMBR): Implications for membrane fouling. Water Res. 2019, 159, 20–29. [Google Scholar] [CrossRef]

| Membrane Module Configuration | Mixing Speed (rpm) | Suction and Pause Time (min/min) | SRT (d) | COD Removal Efficiency (%) |

|---|---|---|---|---|

| Ring Type | 150 | 4/1 | 300 | 89.1 |

| Flat-Sheet | 150 | 4/1 | 300 | 87.5 |

| Curtain Type | 150 | 4/1 | 300 | 88.7 |

| Ring Type | 250 | 4/1 | 300 | 70.9 |

| Ring Type | 50 | 4/1 | 300 | 86.3 |

| Ring Type | 150 | 8/2 | 300 | 84.4 |

| Ring Type | 150 | 7/3 | 300 | 84.9 |

| Ring Type | 150 | 4/1 | 150 | 80.4 |

| Ring Type | 150 | 4/1 | 450 | 82.9 |

| The Species of Draw Solution | The Orientation of the Active Layer | The Concentration of Dissolved Oxygen (mg/L) | SRT (d) | The Concentration of Draw Solution (mol/L) | The Membrane Fouling Cycle (d) |

|---|---|---|---|---|---|

| NaCl | the reaction pool | 2.5 | 80 | 1 | 30 |

| MgCl2 | the reaction pool | 2.5 | 80 | 1 | 18 |

| NaCl | the driving pool | 2.5 | 80 | 1 | 25 |

| NaCl | the reaction pool | 4.0 | 80 | 1 | 23 |

| NaCl | the reaction pool | 2.5 | 40 | 1 | 20 |

| NaCl | the reaction pool | 2.5 | 80 | 2 | 28 |

| MLSS (mg/L) | MLVSS (mg/L) | SVI (mL/g) | Viscosity (Pa·s) | CST (s) | |

|---|---|---|---|---|---|

| H-AnMBR | 5861 | 5211 | 118.58 | 1.31 | 49.5 |

| L-AnMBR | 6024 | 5098 | 151.89 | 2.09 | 69.6 |

| H-FOMBR | 2500 | 1212 | 134.00 | 1.48 | 15.6 |

| L-FOMBR | 3200 | 2210 | 92.19 | 1.44 | 14.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, Y.; Guo, Z.; Hou, X.; Mei, J.; Liang, Z.; Li, Z.; Zhang, C.; Jin, C. Performance Analysis for the Anaerobic Membrane Bioreactor Combined with the Forward Osmosis Membrane Bioreactor: Process Conditions Optimization, Wastewater Treatment and Sludge Characteristics. Water 2020, 12, 2958. https://doi.org/10.3390/w12112958

Ding Y, Guo Z, Hou X, Mei J, Liang Z, Li Z, Zhang C, Jin C. Performance Analysis for the Anaerobic Membrane Bioreactor Combined with the Forward Osmosis Membrane Bioreactor: Process Conditions Optimization, Wastewater Treatment and Sludge Characteristics. Water. 2020; 12(11):2958. https://doi.org/10.3390/w12112958

Chicago/Turabian StyleDing, Yi, Zhansheng Guo, Xuguang Hou, Junxue Mei, Zhenlin Liang, Zhipeng Li, Chunpeng Zhang, and Chao Jin. 2020. "Performance Analysis for the Anaerobic Membrane Bioreactor Combined with the Forward Osmosis Membrane Bioreactor: Process Conditions Optimization, Wastewater Treatment and Sludge Characteristics" Water 12, no. 11: 2958. https://doi.org/10.3390/w12112958