Optimization Research on the Space-V-Type Biomimetic Surface Grooves of a Marine Centrifugal Pump

Abstract

:1. Introduction

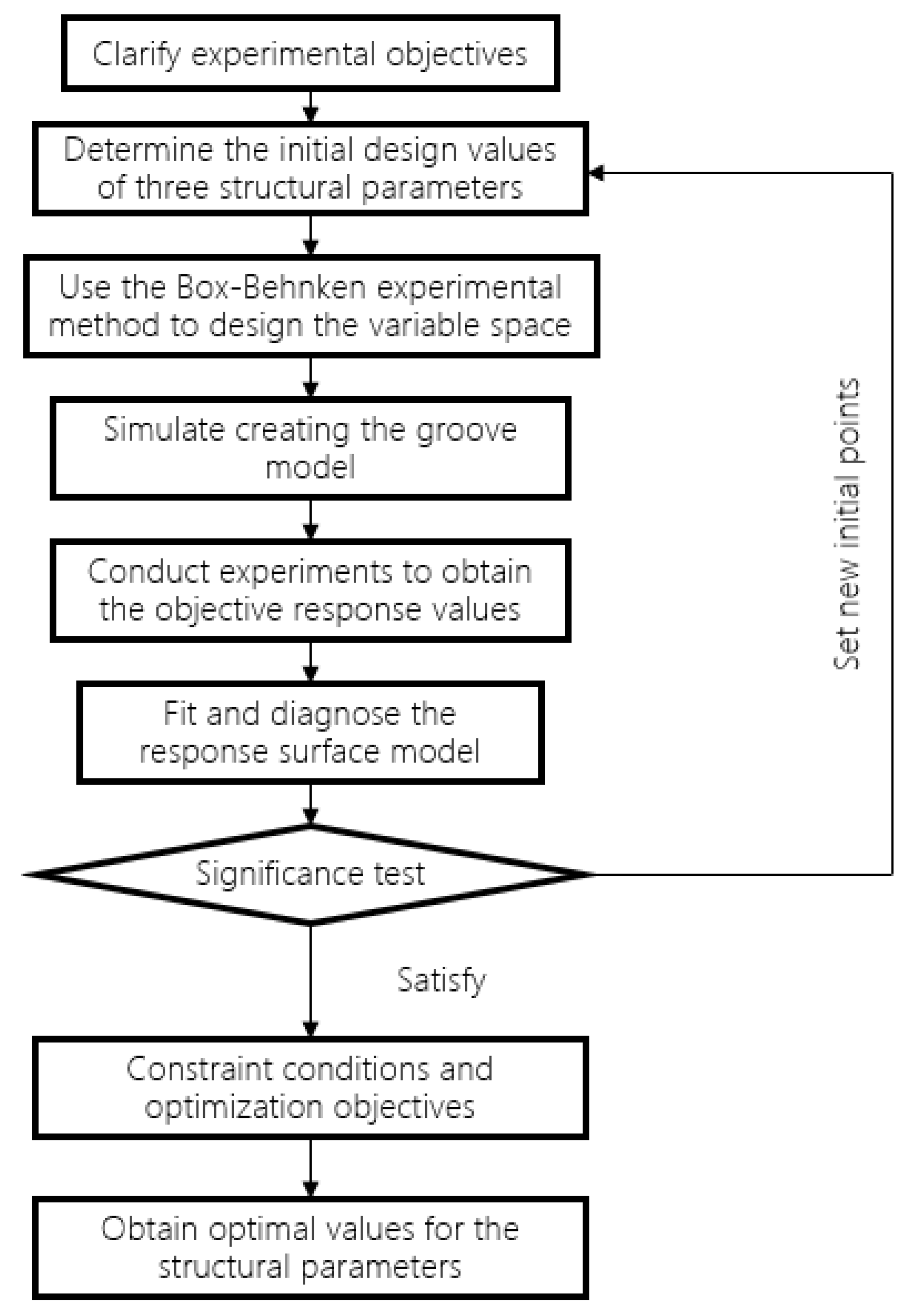

2. Response Surface Experimental Design

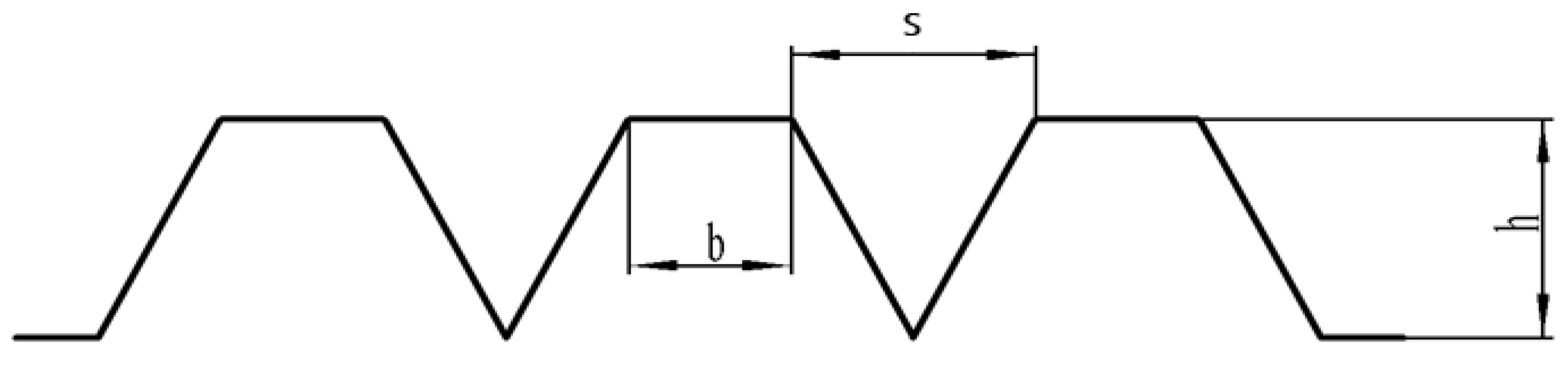

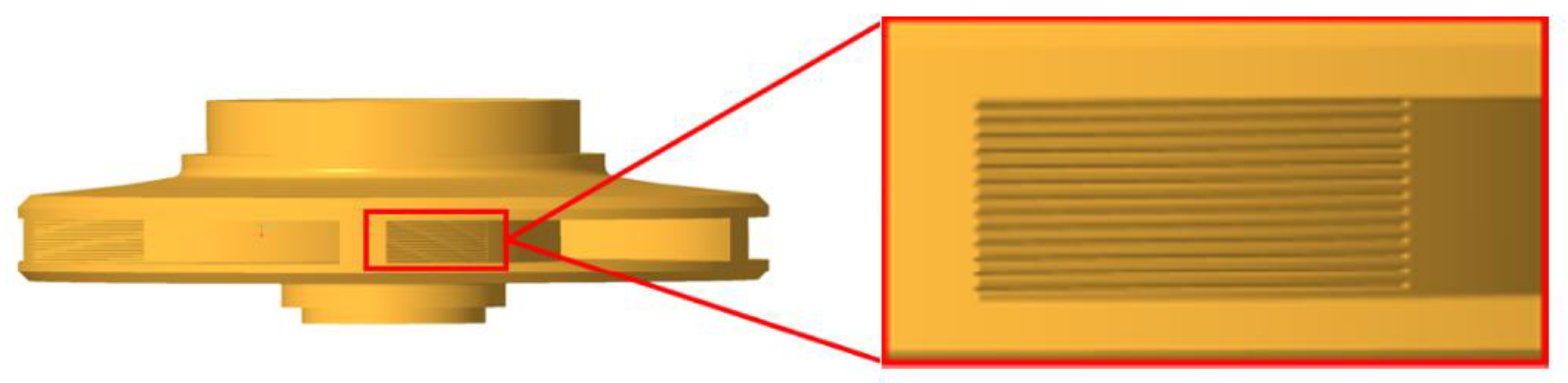

2.1. Space-V Groove Layout

2.2. Selection of Experimental Factors and Changes in Coding Levels

2.3. Experimental Design

3. Response Surface Optimization Results Analysis

3.1. Analysis of Parameter Significance

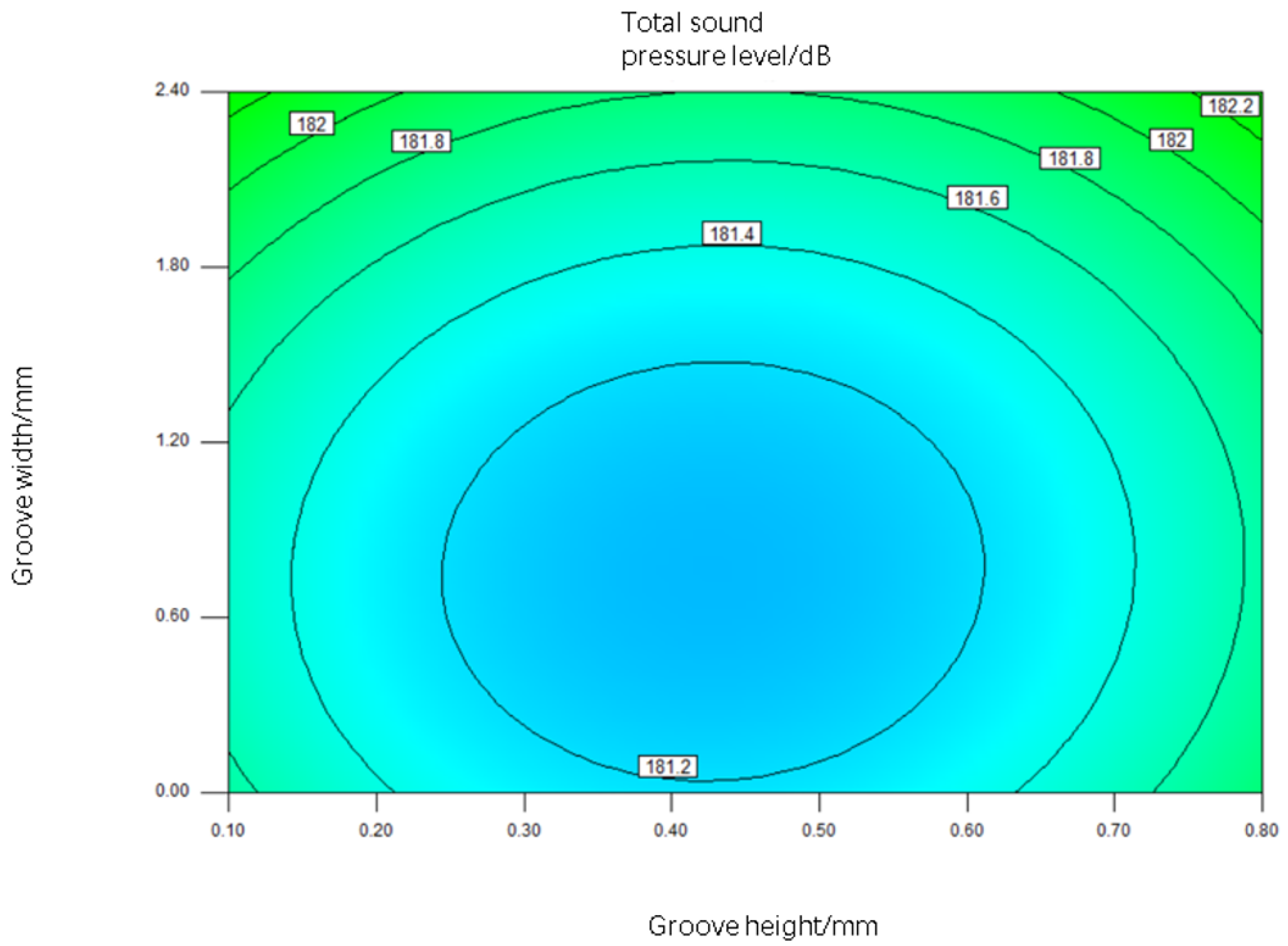

3.2. Interaction Effects of Parameters on Total Sound Pressure Level

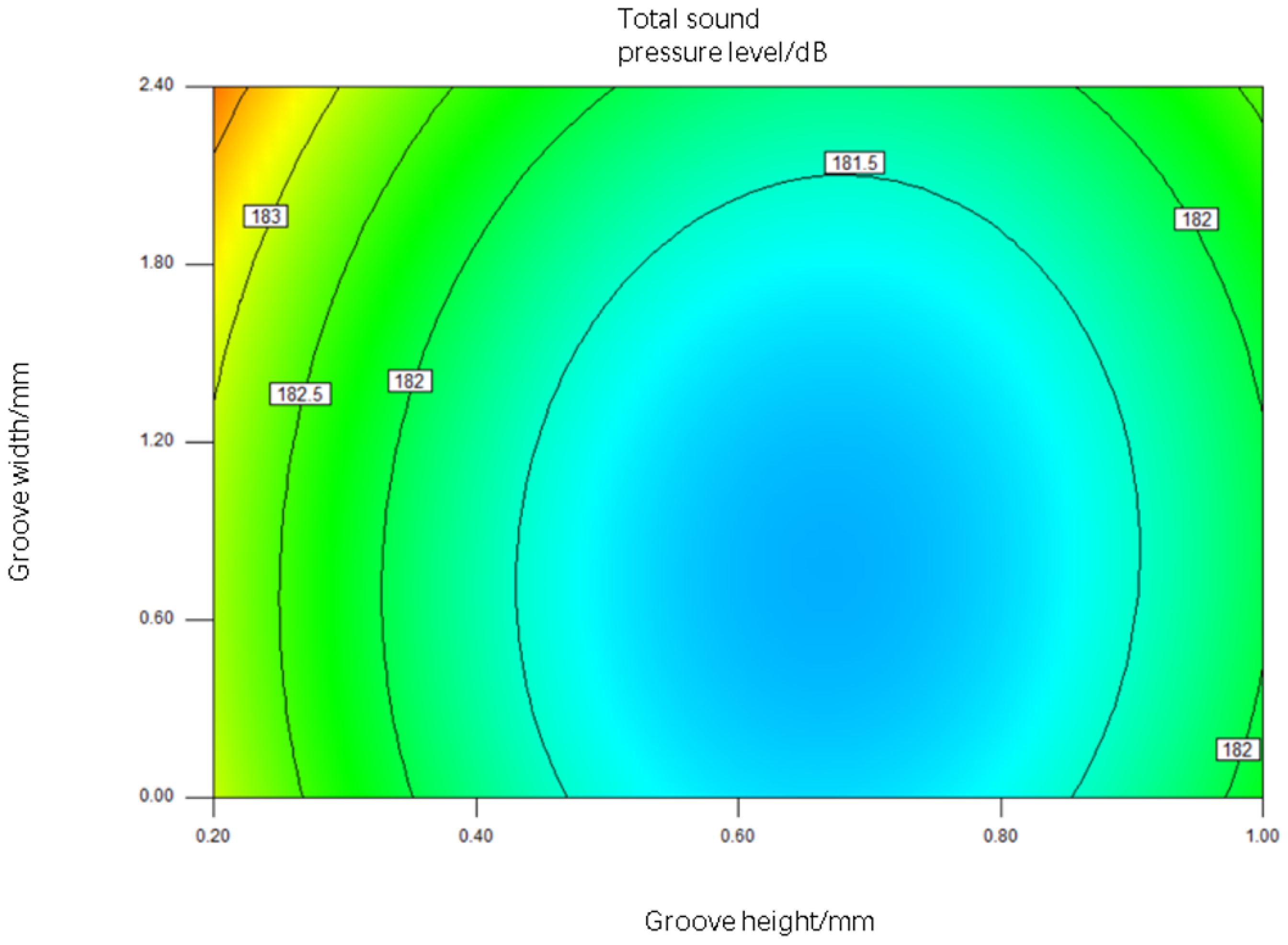

4. Comparison of Performance of Biomimetic Marine Centrifugal Pump before and after Optimization

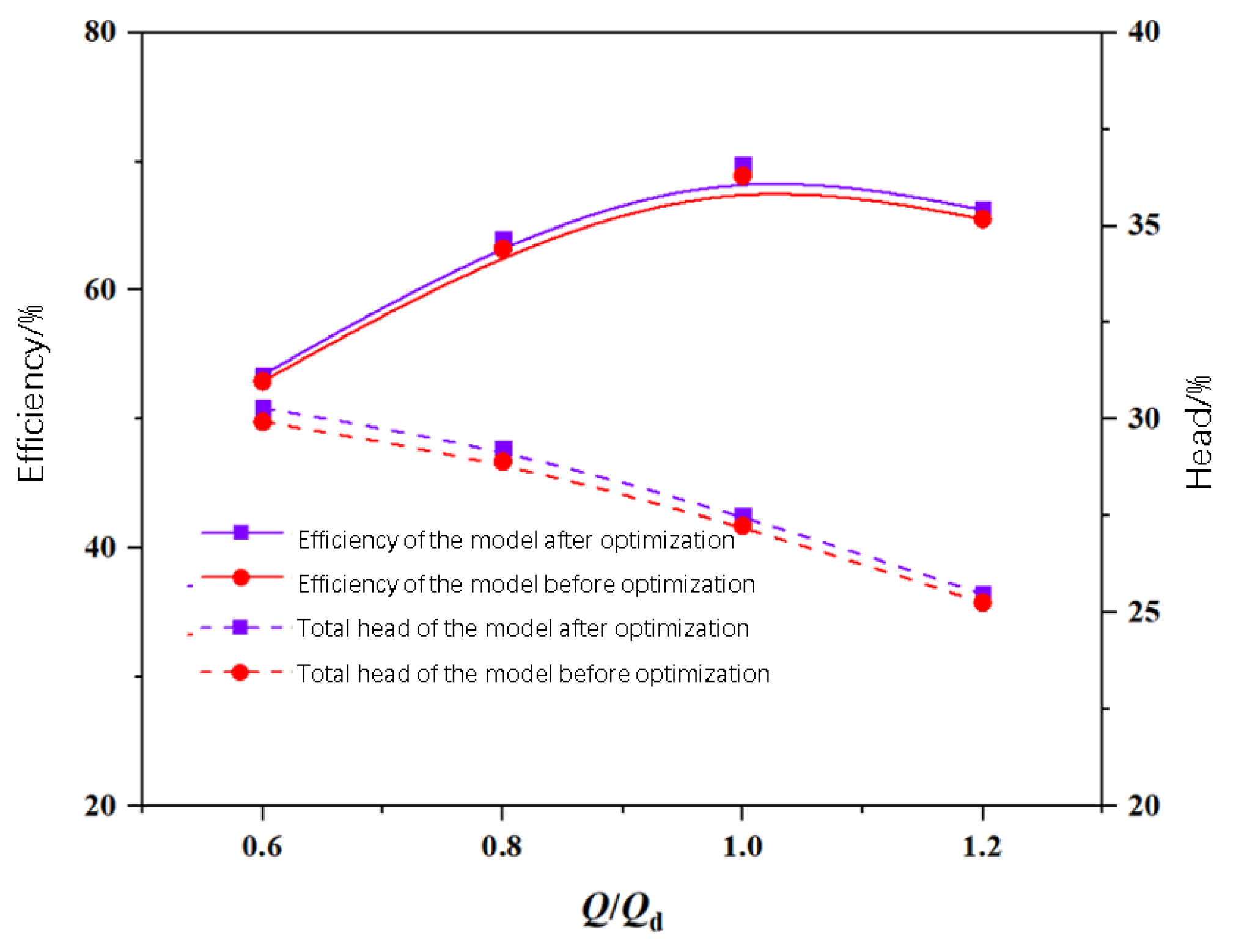

4.1. Hydraulic Performance Comparison Analysis

4.2. Analysis of In-Field Noise Comparison

5. Conclusions

- (1)

- The BBD method was used to experimentally design the height, width, and spacing of the biomimetic grooved structure, and a multivariate regression equation was established between the total sound pressure level of the marine centrifugal pump and the three geometric parameters of the grooves. The significance of the model was verified through a variance analysis.

- (2)

- With the increase in groove height, the total sound pressure level first decreases and then increases; with the increase in groove width, the total sound pressure level first decreases and then increases; and with the increase in groove spacing, the total sound pressure level increases.

- (3)

- The optimization scheme for the groove parameters was determined to be height: h = 0.65 mm, width: s = 0.6 mm, spacing: b = 0.8 mm.

- (4)

- The comparative analysis conducted on the Space-V groove model before and after optimization revealed notable improvements in the head and efficiency under various operating conditions. Additionally, the optimized model effectively reduced broadband noise and discrete noise at various characteristic frequencies. Specifically, the optimized Space-V groove model exhibited an increased head of 0.27 m, an increased efficiency of 1.21%, and a drag reduction rate higher than the unoptimized model by 0.87% under the rated condition. Furthermore, in comparison to the smooth model at the rated condition, the optimized Space-V groove model displayed an efficiency improvement of 4.51%, a resistance reduction of 3.73%, and a decrease in the overall sound pressure level by 1.81%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mou, J.G.; Dai, D.S.; Gu, Y.Q.; Liu, H.; Chen, J.; Li, Y.; Yan, J. Influence of biomimetic snail shell structure on the pulsation characteristics in the baffle region of a centrifugal pump. J. Shanghai Jiaotong Univ. 2016, 50, 1493–1499. [Google Scholar]

- Mou, J.G.; Liu, J.; Gu, Y.Q.; Wei, J.; Yuchan, W.; Diyi, C. Analysis of unsteady flow characteristics inside a biomimetic snail shell centrifugal pump. J. Zhejiang Univ. 2016, 50, 927–933. [Google Scholar]

- Zhang, X.P. Experimental Study on Drag Reduction and Noise Reduction of Flexible Biomimetic Surface of Cooling Fans for Electronic Devices; Jilin University: Changchun, China, 2012. [Google Scholar]

- Dai, C.; Ge, Z.P.; Dong, L.; Guo, C.; Liu, H. Study on drag reduction and noise reduction characteristics of biomimetic surface of centrifugal pump. J. Huazhong Univ. Sci. Technol. 2020, 48, 113–118. [Google Scholar]

- Dai, C.; Guo, C.; Ge, Z.P.; Liu, H.; Dong, L. Study on drag and noise reduction of bionic blade of centrifugal pump and mechanism. J. Bionic Eng. 2021, 18, 428–440. [Google Scholar] [CrossRef]

- Tian, L.; Jin, E.; Li, Z.; Mei, J.; Wang, Y.; Shang, Y. The fluid control mechanism of bionic structural heterogeneous composite materials and its potential application in enhancing pump efficiency. Adv. Mech. Eng. 2015, 7, 1393–1396. [Google Scholar] [CrossRef]

- Konovalov, S.F.; Lashkov, Y.A.; Mikhailov, V.V. Effect of longitudinal riblets on the aerodynamic characteristics of a straight wing. Fluid Dyn. 1995, 30, 183–187. [Google Scholar] [CrossRef]

- Lee, S.J.; Jang, Y.G. Control of flow around a NACA 0012 airfoil with a micro-riblet film. J. Fluids Struct. 2005, 20, 659–672. [Google Scholar] [CrossRef]

- Chamoro, L.P.; Arndt, E.A.; Sotiropoulos, F. Drag reduction of large wind turbine blades through riblets: Evaluation of riblet geometry and application strategies. Renew. Energy 2013, 50, 1095–1105. [Google Scholar] [CrossRef]

- Walsh, M.J. Riblets as a viscous drag reduction technique. AIAA J. 1983, 21, 485–486. [Google Scholar] [CrossRef]

- Park, S.R.; Wallace, J.M. Flow alteration and drag reduction by riblets in a turbulent boundary layer. AIAA J. 1994, 32, 31–38. [Google Scholar] [CrossRef]

- Dai, C.; Chao, G.; Chen, Y.; Dong, L.; Liu, H. Analysis of the Influence of Different Bionic Structures on the Noise Reduction Performance of the Centrifugal Pump. Sensors 2021, 21, 886. [Google Scholar] [CrossRef] [PubMed]

- Dai, C.; Chen, Y.; Dong, L.; Mou, J.; Wu, D.; Yan, M. Placement of bionic non-smooth Structure of centrifugal pump blade. J. Drain. Irrig. Mach. Eng. 2020, 38, 241–247. [Google Scholar]

- Li, T.; Zhu, H.; Kong, N. Optimal design of load bearing beam for loading safety valve based on Response Surface Method. Manuf. Autom. 2022, 44, 73–76. [Google Scholar]

- Liu, D.; Dai, Y.; Shan, C.; Li, D.; Tang, C. Optimization of resonant element structure of oscillation balance based on response surface Method. J. Heilongjiang Univ. Sci. Technol. 2022, 32, 111–116. [Google Scholar]

- Qiang, D.; Li, H.; You, F.; You, F.; Li, J.; Hao, W. Optimization of feeding robot screw shaft structure based on Response surface method. Mach. Manuf. 2022, 60, 21–25. [Google Scholar]

- Zhang, D.S.; Mei, J.; Zhao, R.J.; Liu, H.; Xie, L. Optimization design of fluoroplastic two-phase flow pump based on response surface methodology. J. Drain. Irrig. Mach. Eng. 2020, 38, 898–903. [Google Scholar]

- Aelaei, M.; Karimian, S.; Ommi, F. Sensitivity analysis and optimization of delta wing design parameters using cfd–based response surface method. J. Appl. Fluid Mech. 2019, 12, 1885–1903. [Google Scholar] [CrossRef]

- Thakkar, S.; Vala, H.; Patel, V.K.; Patel, R. Performance improvement of the sanitary centrifugal pump through an integrated approach based on response surface methodology multi-objective optimization and CFD. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 24. [Google Scholar] [CrossRef]

- Liu, H.L.; Cheng, Z.M.; Ge, Z.P.; Dong, L.; Dai, C. Collaborative improvement of efficiency and noise of bionic vane centrifugal pump based on multi-objective optimization. Adv. Mech. Eng. 2021, 13, 1687814021994976. [Google Scholar] [CrossRef]

- Zhang, C. Drag Reduction Research on Biomimetic Non-smooth Surface Flow Field Control of Turbomachinery; Jilin University: Changchun, China, 2007. [Google Scholar]

- Chen, Y. Noise Reduction Research of Centrifugal Pumps Based on Biomimetic Structures; Jiangsu University: Zhenjiang, China, 2020. [Google Scholar]

- Mao, S.; Wang, J.; Pu, X. Advanced Mathematical Statistics; Higher Education Press: Beijing, China, 2006. [Google Scholar]

| Coding | Experimental Factor | Coding Level | ||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| A | Groove height/mm | 0.2 | 0.6 | 1.0 |

| B | Groove width/mm | 0.1 | 0.45 | 0.8 |

| C | Groove spacing/mm | 0 | 1.2 | 2.4 |

| Number | A | B | C | Total Sound Pressure Level (dB) |

|---|---|---|---|---|

| 1 | 0.2 | 0.1 | 1.2 | 184.13 |

| 2 | 1 | 0.1 | 1.2 | 182.11 |

| 3 | 0.2 | 0.8 | 1.2 | 183.12 |

| 4 | 1 | 0.8 | 1.2 | 182.56 |

| 5 | 0.2 | 0.45 | 0 | 182.73 |

| 6 | 1 | 0.45 | 0 | 182.21 |

| 7 | 0.2 | 0.45 | 2.4 | 183.65 |

| 8 | 1 | 0.45 | 2.4 | 182.86 |

| 9 | 0.6 | 0.1 | 0 | 181.56 |

| 10 | 0.6 | 0.8 | 0 | 182.11 |

| 11 | 0.6 | 0.1 | 2.4 | 181.98 |

| 12 | 0.6 | 0.8 | 2.4 | 182.43 |

| 13 | 0.6 | 0.45 | 1.2 | 181.76 |

| 14 | 0.6 | 0.45 | 1.2 | 181.70 |

| 15 | 0.6 | 0.45 | 1.2 | 181.21 |

| 16 | 0.6 | 0.45 | 1.2 | 180.53 |

| 17 | 0.6 | 0.45 | 1.2 | 180.37 |

| Factor | Sum of Squares | Degrees of Freedom | Mean Square | F-Value | Prob (P) > F | Significance |

|---|---|---|---|---|---|---|

| Model | 13.34 | 9 | 1.48 | 4.60 | 0.0283 | Significant |

| A | 1.89 | 1 | 1.89 | 5.87 | 0.0459 | Significant |

| B | 0.024 | 1 | 0.024 | 0.075 | 0.7920 | Not significant |

| C | 0.67 | 1 | 0.67 | 2.07 | 0.1935 | Not significant |

| AB | 0.53 | 1 | 0.53 | 1.65 | 0.2394 | Not significant |

| AC | 0.018 | 1 | 0.018 | 0.057 | 0.8189 | Not significant |

| BC | 0.0025 | 1 | 0.0025 | 0.007756 | 0.9323 | Not significant |

| A2 | 7.72 | 1 | 7.72 | 23.96 | 0.0018 | Significant |

| B2 | 1.10 | 1 | 1.10 | 3.42 | 0.1068 | Not significant |

| C2 | 0.65 | 1 | 0.65 | 2.03 | 0.1972 | Not significant |

| Q/Qd | Torque/N∙m | Drag Reduction Rate/% | |||

|---|---|---|---|---|---|

| Smooth Model | Unoptimized Space-V Groove Model | Optimized Space-V Groove Model | Unoptimized Drag Reduction Rate | Optimized Drag Reduction Rate | |

| 0.6 | 3.19 | 3.24 | 3.20 | −1.56 | −0.31 |

| 0.8 | 3.45 | 3.41 | 3.38 | 1.16 | 2.03 |

| 1.0 | 3.85 | 3.74 | 3.71 | 2.86 | 3.73 |

| 1.2 | 4.31 | 4.27 | 4.23 | 0.93 | 1.86 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Yu, Z.; Hua, R.; Li, C.; Guo, C.; Liu, H.; Dong, L. Optimization Research on the Space-V-Type Biomimetic Surface Grooves of a Marine Centrifugal Pump. Water 2023, 15, 4031. https://doi.org/10.3390/w15224031

Li H, Yu Z, Hua R, Li C, Guo C, Liu H, Dong L. Optimization Research on the Space-V-Type Biomimetic Surface Grooves of a Marine Centrifugal Pump. Water. 2023; 15(22):4031. https://doi.org/10.3390/w15224031

Chicago/Turabian StyleLi, Hua, Zifeng Yu, Runan Hua, Chenqi Li, Chao Guo, Houlin Liu, and Liang Dong. 2023. "Optimization Research on the Space-V-Type Biomimetic Surface Grooves of a Marine Centrifugal Pump" Water 15, no. 22: 4031. https://doi.org/10.3390/w15224031

APA StyleLi, H., Yu, Z., Hua, R., Li, C., Guo, C., Liu, H., & Dong, L. (2023). Optimization Research on the Space-V-Type Biomimetic Surface Grooves of a Marine Centrifugal Pump. Water, 15(22), 4031. https://doi.org/10.3390/w15224031