Research Advancements in Swine Wastewater Treatment and Resource-Based Safe Utilization Management Technology Model Construction

Abstract

:1. Introduction

2. Methods

3. Pollution Characteristics of Swine Wastewater and Its Impact on the Environment

3.1. Pollution Characteristics of Swine Wastewater

| Type of Wastewater | pH | Concentration of Pollutants (mg/L) | Reference | |||

|---|---|---|---|---|---|---|

| TN | Ammonia Nitrogen | TP | COD | |||

| Pig | 6.77–8.90 | 210–2100 | 110–1650 | 100–620 | 3000–30,000 | [13,21] |

| Cattle | 6.00–8.50 | 100–830 | 50–300 | 9–280 | 3000–10,500 | [11,17] |

| Poultry | 7.1–7.3 | 56.5–70.7 | — | 0.2–0.6 | 480–850 | [11] |

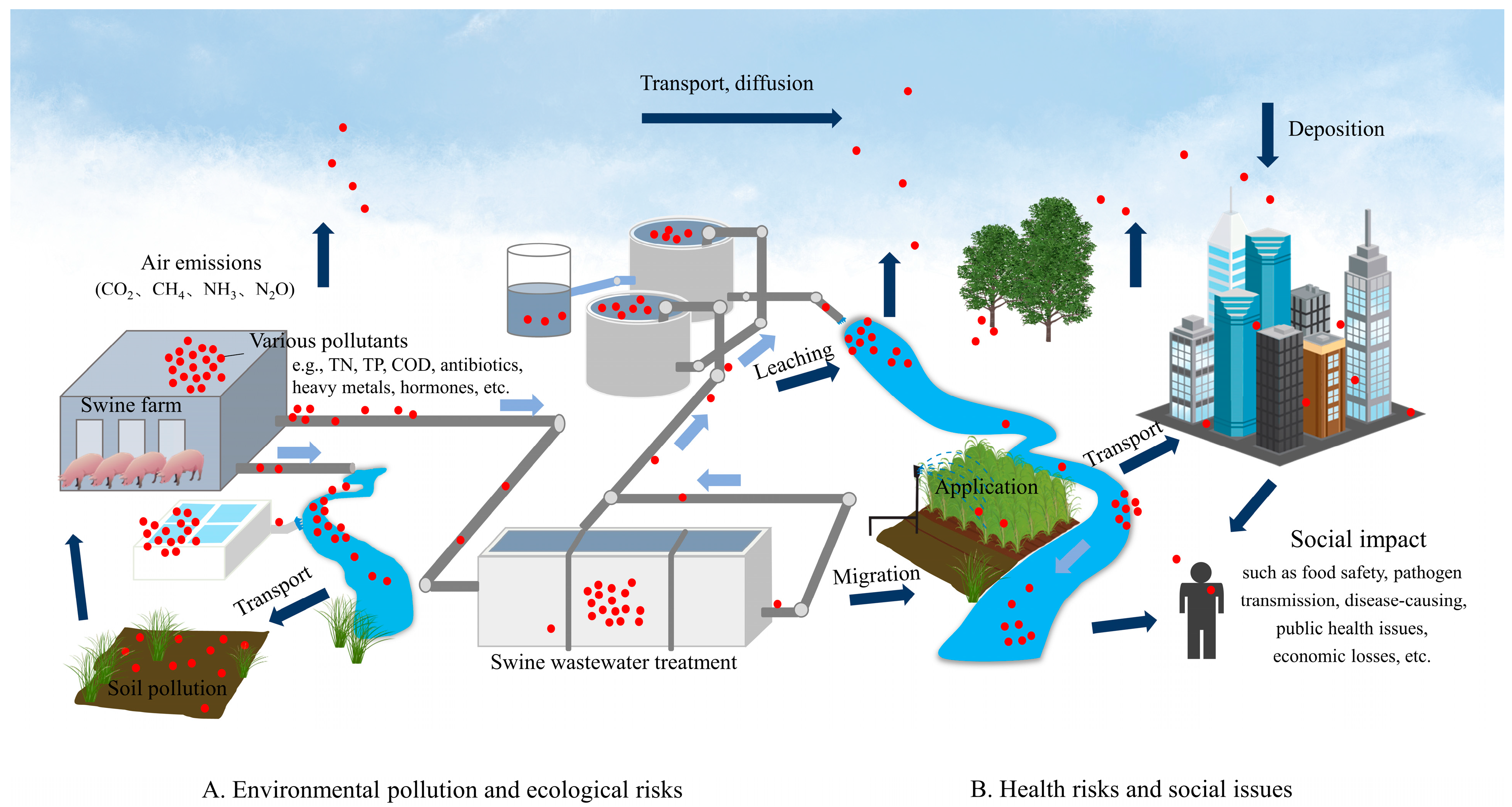

3.2. Effects of Swine Wastewater on the Environment, Society, and Economy

3.2.1. Impact of Swine Wastewater on the Environment

- Harm to the water environment

- Harm to the soil environment

- Harm to the atmospheric environment [13]

- Harm to the ecosystem

3.2.2. Effects of Swine Wastewater on Society

3.2.3. Effect of Swine Wastewater on the Economy

4. Research Progress on Swine Wastewater Treatment Methods

4.1. Physicochemical Treatment Technology

4.1.1. Membrane Processing

4.1.2. Adsorption

4.1.3. AOP

4.2. Biological Method

4.2.1. Aerobic Treatment

4.2.2. AD

4.2.3. Anaerobic Ammonia Oxidation Treatment

4.2.4. Constructed Wetlands

4.2.5. Microalgae Cultivation

| Treatment Technology | Advantages | Disadvantages | Future Development Direction | |

| Physical chemical method | Membrane treatment [29] | Simple operation, small footprint, efficient interception and removal of most pollutants, and resource recovery | The membrane is easily blocked and lost, thus requiring regular replacement and high costs | (1) Research and development of new membrane materials; (2) improving the efficiency and stability of membrane treatment; (3) cost reduction |

| Adsorption [57] | The process is simple; the operation is flexible; and the maintenance is convenient, economical, and efficient | The adsorption efficiency is affected by the type of adsorbent and the characteristics of the adsorbate, and most of the adsorbents have poor regeneration | Low-cost, high-adsorption capacity, and good regeneration of new adsorption materials, such as modified carbon nanotubes, graphene-based materials, and functional covalent organic framework materials | |

| Advanced oxidation [1] | Fast reaction speed and good treatment effect | The operation cost is high, and it may produce a large number of harmful intermediate products | (1) Improve the choice of oxidant; (2) improve the processing efficiency; and (3) reduce operating costs | |

| Aerobic treatment [4] | Good stability, mature research | Long hydraulic retention time, large area, narrow scope of application | (1) Combine with other processes; (2) design new reactors | |

| Anaerobic digestion [4] | Convert pollutants into biogas and organic fertilizer to achieve resource utilization; the operating cost is relatively low | Regular maintenance, high maintenance costs | New attempts to combine bioaugmentation, molecular biology, nanomaterials, artificial intelligence, and other new technologies | |

| Anaerobic ammonia oxidation [4] | High-efficiency denitrification, low cost, and broad prospects for engineering applications | The growth rate of anaerobic ammonia-oxidizing bacteria is slow, the culture time is long, and the reaction conditions are harsh | (1) Combination with anaerobic digestion and physical and chemical methods; (2) in the case of high ammonia nitrogen, efficient treatment of pollutants and resource recovery are achieved | |

| Constructed wetlands [13] | No secondary pollution, low treatment and maintenance costs, and high efficiency | The treatment efficiency is greatly affected by climatic conditions, and the stability and treatment effect must be improved | (1) Improve the design and operation mode of constructed wetlands to improve their treatment efficiency and stability; (2) combine with other wastewater treatment technologies, such as biofilm reactors and microalgae cultures, to form a combined process; (3) use the Internet of Things, big data, artificial intelligence, and other means to achieve remote monitoring and intelligent operation | |

| Microalgae cultivation [55,58] | Various pollutants can be removed simultaneously; low cost, high efficiency, environmental friendliness, and energy | The growth rate of microalgae is slow and has certain requirements for environmental conditions (to a certain extent, it is inhibited by antibiotics, toxic metal elements, and other pollutants in aquaculture wastewater) | (1) Microalgae and other microbial symbiosis cultivation; (2) biomass biofuels | |

5. Discussion and Outlook

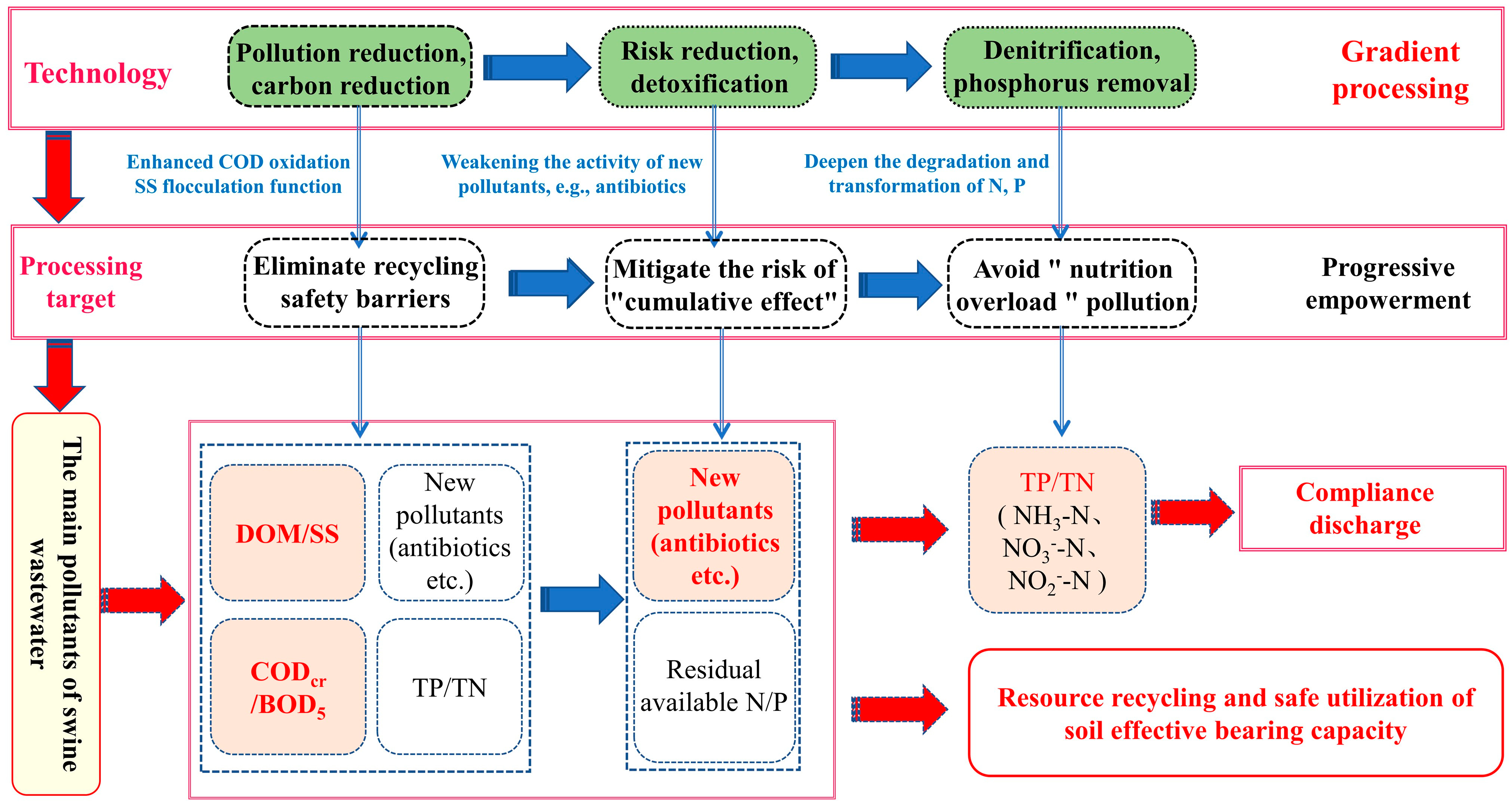

5.1. Gradient Progressive Treatment and Safe Utilization Management Mode of Swine Wastewater

5.2. Future Research Perspectives

- (1)

- Prevention and control of emerging pollutants (e.g., disinfection by-products, antibiotics, and ARGs), based on which the development of multifunctional and high-performance biological methods (e.g., microalgae, artificial wetlands, and microbial fuel cells) will further expand the scope and scale of engineering applications.

- (2)

- Using electronic information, big data, artificial intelligence, and other means to identify various pollutants (especially emergency pollutants); optimize the construction of treatment systems (based on accurate energy flow calculation, economic analysis, and carbon balance analysis); and establish automatic control systems, which is the future development trend.

- (3)

- Promoting the construction of a convenient gradient and progressive technology for wastewater treatment; enhancing the resource performance of treatment; strengthening the integration of pollution control, resource reuse, and animal husbandry; achieving the overall goal of discharge standard compliance for wastewater and effective utilization by planting industries; and improving the circular economy system.

- (4)

- With the continuous promotion of the “CO2 emission peak and carbon neutrality” goal, the pollutant control–animal husbandry cycle model of green, low carbon, and sustainable development is the mainstream of future development, especially the combination of automated swine wastewater treatment and smart agriculture.

6. Conclusions

- (1)

- In terms of source control and reduction, it is necessary to reasonably arrange breeding farms and strictly control the production process; develop environmentally friendly feed (improved feed) and control the addition of veterinary drugs to reduce the entry of pollutants such as toxic metal elements, antibiotics, and ARGs from the source; and improve the breeding method, promote clean production, and reduce the discharge of wastewater to reduce the subsequent treatment difficulty and cost at the source.

- (2)

- In terms of end-of-pipe pollution treatment, although physical and chemical methods can remove most organic and inorganic pollutants, they cannot effectively degrade antibiotics in swine wastewater, and the cost is high; meanwhile, biological treatment methods remain a cost-effective and promising wastewater treatment technology, but its resource utilization must be optimized. Its improvement methods include coupling multiple processes, operating serial reactors, and so on.

- (3)

- It is particularly important to establish a convenient treatment and safe utilization management model for swine wastewater based on the construction of a gradient and progressive treatment system. By integrating individual treatment units into a unified system, large-scale intensive breeding can be organically combined with crop cultivation, achieving a balance between breeding and cultivation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Domingues, E.; Fernandes, E.; Gomes, J.; Martins, R.C. Advanced Oxidation Processes Perspective Regarding Swine Wastewater Treatment. Sci. Total Environ. 2021, 776, 145958. [Google Scholar] [CrossRef]

- Hu, Y.; Cheng, H.; Tao, S. Environmental and Human Health Challenges of Industrial Livestock and Poultry Farming in China and their Mitigation. Environ. Int. 2017, 107, 111–130. [Google Scholar] [CrossRef]

- Duan, N.; Khoshnevisan, B.; Lin, C.; Liu, Z.; Liu, H. Life Cycle Assessment of Anaerobic Digestion of Pig Manure Coupled with Different Digestate Treatment Technologies. Environ. Int. 2020, 137, 105522. [Google Scholar] [CrossRef] [PubMed]

- Chen, N.; Zhang, X.; Du, Q.; Huo, J.; Wang, H.; Wang, Z.; Guo, W.; Ngo, H.H. Advancements in Swine Wastewater Treatment: Removal Mechanisms, Influential Factors, and Optimization Strategies. J. Water Process. Eng. 2023, 54, 103986. [Google Scholar] [CrossRef]

- Deng, L.; Zheng, D.; Zhang, J.; Yang, H.; Wang, L.; Wang, W.; He, T.; Zhang, Y. Treatment and Utilization of Swine Wastewater—A Review On Technologies in Full-Scale Application. Sci. Total Environ. 2023, 880, 163223. [Google Scholar] [CrossRef] [PubMed]

- García, D.; Posadas, E.; Grajeda, C.; Blanco, S.; Martínez-Páramo, S.; Acién, G.; García-Encina, P.; Bolado, S.; Muñoz, R. Comparative Evaluation of Swine Wastewater Treatment in Algal-Bacterial Photobioreactors Under Indoor and Outdoor Conditions. Bioresour. Technol. 2017, 245, 483–490. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Zhao, H.; Liu, J.; Li, B.; Chang, Y.; Yao, D. A New Green Model for the Bioremediation and Resource Utilization of Livestock Wastewater. Int. J. Environ. 2021, 18, 8634. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Fan, Z.Z.; Yang, X.P. Removal of Characteristic Pollutants in Livestock Wastewater by Horizontal Subsurface Flow Constructed Wetlands. Environ. Sci. 2021, 42, 5865–5875. [Google Scholar]

- Danner, M.; Robertson, A.; Behrends, V.; Reiss, J. Antibiotic Pollution in Surface Fresh Waters: Occurrence and Effects. Sci. Total Environ. 2019, 664, 793–804. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Yang, W.; Liu, L.; Liu, X.; Qiu, F.; Ma, X. Development and Environmental Impacts of China’s Livestock and Poultry Breeding. J. Clean. Prod. 2022, 371, 133586. [Google Scholar] [CrossRef]

- Vaishnav, S.; Saini, T.; Chauhan, A.; Gaur, G.K.; Tiwari, R.; Dutt, T.; Tarafdar, A. Livestock and Poultry Farm Wastewater Treatment and its Valorization for Generating Value-Added Products: Recent Updates and Way Forward. Bioresour. Technol. 2023, 382, 129170. [Google Scholar] [CrossRef]

- Zhang, J.; Han, Z.; Zheng, D.; Wang, W.; Deng, L. Technical Status and Trends in Animal Wastewater Treatment. J. Agro-Environ. Sci. 2021, 40, 2320–2329. [Google Scholar]

- Hu, H.; Li, X.; Wu, S.; Yang, C. Sustainable Livestock Wastewater Treatment Via Phytoremediation: Current Status and Future Perspectives. Bioresour. Technol. 2020, 315, 123809. [Google Scholar] [CrossRef]

- Wang, Y.; Han, M.; Jia, T.; Hu, X.; Zhu, H.; Tong, Z.; Lin, Y.; Wang, C.; Liu, D.; Peng, Y.; et al. Emissions, Measurement, and Control of Odor in Livestock Farms: A Review. Sci. Total Environ. 2021, 776, 145735. [Google Scholar] [CrossRef]

- López-Sánchez, A.; Silva-Gálvez, A.L.; Aguilar-Juárez, Ó.; Senés-Guerrero, C.; Orozco-Nunnelly, D.A.; Carrillo-Nieves, D.; Gradilla-Hernández, M.S. Microalgae-Based Livestock Wastewater Treatment (Mbwt) as a Circular Bioeconomy Approach: Enhancement of Biomass Productivity, Pollutant Removal and High-Value Compound Production. J. Environ. Manag. 2022, 308, 114612. [Google Scholar] [CrossRef] [PubMed]

- Lourinho, G.; Rodrigues, L.F.T.G.; Brito, P.S.D. Recent Advances on Anaerobic Digestion of Swine Wastewater. Int. J. Environ. Sci. Technol. 2020, 17, 4917–4938. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, W.; Peng, Y.; Song, X. Anaerobic Membrane Bioreactors for Livestock Wastewater Treatment and Resource Recovery: Opportunities and Challenges. Curr. Pollut. Rep. 2021, 7, 277–285. [Google Scholar] [CrossRef]

- Ibekwe, A.M.; Bhattacharjee, A.S.; Phan, D.; Ashworth, D.; Schmidt, M.P.; Murinda, S.E.; Obayiuwana, A.; Murry, M.A.; Schwartz, G.; Lundquist, T.; et al. Potential Reservoirs of Antimicrobial Resistance in Livestock Waste and Treated Wastewater that Can be Disseminated to Agricultural Land. Sci. Total Environ. 2023, 872, 162194. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Feng, C.; Duan, Y.; Wang, P.; Peng, C.; Li, Z.; Yu, L.; Liu, M.; Wang, F. Ecological Risk Under the Dual Threat of Heavy Metals and Antibiotic Resistant Escherichia Coli in Swine-Farming Wastewater in Shandong Province, China. Environ. Pollut. 2023, 319, 120998. [Google Scholar] [CrossRef]

- Wu, D.; Sui, Q.; Mei, X.; Yu, X.; Gu, Y.; Zhao, W. Non-Antibiotics Matter: Evidence from a One-Year Investigation of Livestock Wastewater from Six Farms in East China. Sci. Total Environ. 2022, 846, 157418. [Google Scholar] [CrossRef]

- Cheng, D.L.; Ngo, H.H.; Guo, W.S.; Chang, S.W.; Nguyen, D.D.; Kumar, S.M. Microalgae Biomass from Swine Wastewater and its Conversion to Bioenergy. Bioresour. Technol. 2019, 275, 109–122. [Google Scholar] [CrossRef] [PubMed]

- Pan, Z.; Dai, R.; Liao, J.; Lin, J.; Hong, Y.; Ling, J.; Xu, Y.; Li, Y.; Peng, J. Spontaneous Formation and Mechanism of Anaerobic Ammonium Oxidation (Anammox) Bacteria in Swine Wastewater Treatment System. Int. Biodeterior. Biodegrad. 2020, 154, 105058. [Google Scholar] [CrossRef]

- Sun, H.; Wu, S.; Feng, S.; Jiang, C.; Wang, R.; Xu, S.; Cui, L.; Zhuang, X. Impact of Influent Strengths on Nitrous Oxide Emission and its Molecular Mechanism in Constructed Wetlands Treating Swine Wastewater. Environ. Res. 2022, 210, 112957. [Google Scholar] [CrossRef]

- Zalewska, M.; Błażejewska, A.; Czapko, A.; Popowska, M. Antibiotics and Antibiotic Resistance Genes in Animal Manure—Consequences of its Application in Agriculture. Front. Microbiol. 2021, 12, 610656. [Google Scholar] [CrossRef]

- Ramírez-Islas, M.E.; Güereca, L.P.; Sosa-Rodriguez, F.S.; Cobos-Peralta, M.A. Environmental Assessment of Energy Production from Anaerobic Digestion of Pig Manure at Medium-Scale Using Life Cycle Assessment. Waste Manag. 2020, 102, 85–96. [Google Scholar] [CrossRef]

- He, L.; He, L.; Liu, Y.; Zhang, M.; Zhao, J.; Zhang, Q.; Ying, G. Microbial Diversity and Antibiotic Resistome in Swine Farm Environments. Sci. Total Environ. 2019, 685, 197–207. [Google Scholar] [CrossRef]

- Semedo, M.; Song, B. Sediment Metagenomics Reveals the Impacts of Poultry Industry Wastewater on Antibiotic Resistance and Nitrogen Cycling Genes in Tidal Creek Ecosystems. Sci. Total Environ. 2023, 857, 159496. [Google Scholar] [CrossRef] [PubMed]

- Fan, D.; Mao, Y.; Xu, L.; Wang, W. Effects of Livestock and Poultry Breeding Pollution on Health Risks: Evidence from a Hog Breeding Case in Rural China. Chin. J. Popul. Resour. Environ. 2020, 18, 342–349. [Google Scholar] [CrossRef]

- Phoon, B.L.; Ong, C.C.; Mohamed Saheed, M.S.; Show, P.; Chang, J.; Ling, T.C.; Lam, S.S.; Juan, J.C. Conventional and Emerging Technologies for Removal of Antibiotics from Wastewater. J. Hazard. Mater. 2020, 400, 122961. [Google Scholar] [CrossRef]

- Rizzioli, F.; Bertasini, D.; Bolzonella, D.; Frison, N.; Battista, F. A Critical Review on the Techno-Economic Feasibility of Nutrients Recovery from Anaerobic Digestate in the Agricultural Sector. Sep. Purif. Technol. 2023, 306, 122690. [Google Scholar] [CrossRef]

- Song, Y.; Wang, G.; Li, R.; Chen, G. Research Progress of Biogas Slurry Treatment and Resource Utilization. Trans. Chin. Soc. Agric. Eng. 2021, 37, 237–250. [Google Scholar]

- González-García, I.; Riaño, B.; Cuéllar-Franca, R.M.; Molinuevo-Salces, B.; García-González, M.C. Environmental Sustainability Performance of a Membrane-Based Technology for Livestock Wastewater Treatment with Nutrient Recovery. J. Environ. 2022, 10, 107246. [Google Scholar] [CrossRef]

- He, Y.; Ifthikar, J.; Yang, L.; Chen, Z. Simultaneous Elimination of Vanadium(V) and Sulfamethoxazole from Livestock Wastewater with Nitrogen-Impregnated Biochar. J. Environ. 2023, 11, 111105. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, Z.; Liang, Y.; Wu, T.; Chen, Y.; Yan, J.; Zhu, Y.; Ding, D. Adsorptive Decontamination of Antibiotics from Livestock Wastewater by Using Alkaline-Modified Biochar. Environ. Res. 2023, 226, 115676. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, T.; Meng, X.; Ma, X.; Zhang, S.; Jin, M.; Li, C. Research on Resource Utilization and Energy Utilization of Livestock and Poultry Wastewater-Taking Swine Wastewater as an Example. J. Northeast Agric. Univ. 2023, 54, 88–96. [Google Scholar]

- Wu, H.; Vaneeckhaute, C. Nutrient Recovery from Wastewater: A Review on the Integrated Physicochemical Technologies of Ammonia Stripping, Adsorption and Struvite Precipitation. Chem. Eng. J. 2022, 433, 133664. [Google Scholar] [CrossRef]

- Reza, A.; Chen, L. Electrochemical Treatment of Livestock Waste Streams. A Review. Environ. Chem. Lett. 2022, 20, 1863–1895. [Google Scholar] [CrossRef]

- Yang, H.; Zheng, X. Application and Research Progress of Advanced Oxidation Process for Degradation of Organic Pollutants. Technol. Water Treat. 2021, 47, 13–18. [Google Scholar]

- Qian, M.; Yang, L.; Chen, X.; Li, K.; Xue, W.; Li, Y.; Zhao, H.; Cao, G.; Guan, X.; Shen, G. The Treatment of Veterinary Antibiotics in Swine Wastewater by Biodegradation and Fenton-Like Oxidation. Sci. Total Environ. 2020, 710, 136299. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhang, J.; Yuan, X.; Jiang, L.; Xia, Q.; Chen, H. Photocatalytic Removal of Antibiotics from Natural Water Matrices and Swine Wastewater Via Cu(I) Coordinately Polymeric Carbon Nitride Framework. Chem. Eng. J. 2020, 392, 123638. [Google Scholar] [CrossRef]

- Garcia, B.B.; Lourinho, G.; Romano, P.; Brito, P.S.D. Photocatalytic Degradation of Swine Wastewater on Aqueous TiO2 Suspensions: Optimization and Modeling Via Box-Behnken Design. Heliyon 2020, 6, e03293. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Li, H.; Li, X.; He, H.; Yang, C. Performances and Mechanisms of Efficient Degradation of Atrazine Using Peroxymonosulfate and Ferrate as Oxidants. Chem. Eng. J. 2018, 353, 533–541. [Google Scholar] [CrossRef]

- Zheng, T.; Li, P.; Ma, X.; Sun, X.; Wu, C.; Wang, Q.; Gao, M. Pilot-Scale Multi-Level Biological Contact Oxidation System On the Treatment of High Concentration Poultry Manure Wastewater. Process Saf. Environ. Prot. 2018, 120, 187–194. [Google Scholar] [CrossRef]

- Chen, X.C.; Chen, B.; Xiao, L.; Fukushi, K.; Zhang, J.; Niu, J.; Xu, K. Optimisation of an Original CO2-Enhanced Natural Treatment System for Reclaiming and Reusing Anaerobically Digested Strong Wastewater from Animal Breeding Industry. J. Clean. Prod. 2021, 291, 125946. [Google Scholar] [CrossRef]

- Khalil, M.; Berawi, M.A.; Heryanto, R.; Rizalie, A. Waste to Energy Technology: The Potential of Sustainable Biogas Production from Animal Waste in Indonesia. Renew. Sustain. Energ. Rev. 2019, 105, 323–331. [Google Scholar] [CrossRef]

- Thao, N.T.P.; Nga, N.T.T.; Kim, H.T.T.; Kien, T.T.; Hieu, T.T.; Thang, N.V.; Tri, N.L.M.; Le, T.H. Combination of Biochar Filtration and Ozonation Processes in Livestock Wastewater Treatment and Application for Soil Cultivation. Case Stud. Chem. Environ. Eng. 2023, 7, 100286. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Y.; Zhao, J.; Liu, W.; Chen, J.; Zhang, Q.; He, L.; Ying, G. Variations of Antibiotic Resistome in Swine Wastewater during Full-Scale Anaerobic Digestion Treatment. Environ. Int. 2021, 155, 106694. [Google Scholar] [CrossRef]

- Chen, H.; Yuan, J.; Xu, Q.; Yang, E.; Yang, T.; Shi, L.; Liu, Z.; Yu, H.; Cao, J.; Zhou, Q.; et al. Swine Wastewater Treatment Using Combined Up-Flow Anaerobic Sludge Blanket and Anaerobic Membrane Bioreactor: Performance and Microbial Community Diversity. Bioresour. Technol. 2023, 373, 128606. [Google Scholar] [CrossRef]

- Zhou, Q.; Li, X.; Wu, S.; Zhong, Y.; Yang, C. Enhanced Strategies for Antibiotic Removal from Swine Wastewater in Anaerobic Digestion. Trends Biotechnol. 2021, 39, 8–11. [Google Scholar] [CrossRef]

- Li, Y.; Pan, Z.; Liao, J.; Dai, R.; Lin, J.; Ling, J.; Xu, Y. Micro-Aeration and Low Influent C/N are Key Environmental Factors for Achieving Anammox in Livestock Farming Wastewater Treatment Plants. Water Res. 2023, 253, 120141. [Google Scholar] [CrossRef] [PubMed]

- Nagarajan, D.; Kusmayadi, A.; Yen, H.; Dong, C.; Lee, D.; Chang, J. Current Advances in Biological Swine Wastewater Treatment Using Microalgae-Based Processes. Bioresour. Technol. 2019, 289, 121718. [Google Scholar] [CrossRef] [PubMed]

- Brienza, C.; Donoso, N.; Luo, H.; Vingerhoets, R.; de Wilde, D.; van Oirschot, D.; Sigurnjak, I.; Biswas, J.K.; Michels, E.; Meers, E. Evaluation of a New Approach for Swine Wastewater Valorisation and Treatment: A Combined System of Ammonium Recovery and Aerated Constructed Wetland. Ecol. Eng. 2023, 189, 106919. [Google Scholar] [CrossRef]

- Bôto, M.L.; Dias, S.M.; Crespo, R.D.; Mucha, A.P.; Almeida, C.M.R. Removing Chemical and Biological Pollutants from Swine Wastewater through Constructed Wetlands Aiming Reclaimed Water Reuse. J. Environ. Manag. 2023, 326, 116642. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Qu, W.; Chang, H.; Li, J.; Ho, S. Microalgae-Driven Swine Wastewater Biotreatment: Nutrient Recovery, Key Microbial Community and Current Challenges. J. Hazard. Mater. 2022, 440, 129785. [Google Scholar] [CrossRef]

- Chen, B.; Zhu, Y.; Wang, K.; Xiao, Y.; Huang, J.; Zhang, J.; Zhang, X.; Chen, X. Research Progress on the Mechanisms and Influencing Factors for the Microalgae-Bacteria Symbiosis System for Treating Biogas Slurry from Livestock and Poultry Industry. Trans. Chin. Soc. Agric. Eng. 2023, 39, 14–24. [Google Scholar]

- Chen, C.; Kuo, E.; Nagarajan, D.; Ho, S.; Dong, C.; Lee, D.; Chang, J. Cultivating Chlorella Sorokiniana Ak-1 with Swine Wastewater for Simultaneous Wastewater Treatment and Algal Biomass Production. Bioresour. Technol. 2020, 302, 122814. [Google Scholar] [CrossRef]

- Yu, F.; Li, Y.; Han, S.; Ma, J. Adsorptive Removal of Antibiotics from Aqueous Solution Using Carbon Materials. Chemosphere 2016, 153, 365–385. [Google Scholar] [CrossRef]

- Dai, C.; Wang, F. Potential Applications of Microalgae–Bacteria Consortia in Wastewater Treatment and Biorefinery. Bioresour. Technol. 2024, 393, 130019. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, B.; Zhu, Y.; Wu, M.; Xiao, Y.; Huang, J.; Lin, C.; Weng, B. Research Advancements in Swine Wastewater Treatment and Resource-Based Safe Utilization Management Technology Model Construction. Water 2024, 16, 661. https://doi.org/10.3390/w16050661

Chen B, Zhu Y, Wu M, Xiao Y, Huang J, Lin C, Weng B. Research Advancements in Swine Wastewater Treatment and Resource-Based Safe Utilization Management Technology Model Construction. Water. 2024; 16(5):661. https://doi.org/10.3390/w16050661

Chicago/Turabian StyleChen, Biao, Yong Zhu, Meijin Wu, Yanchun Xiao, Jing Huang, Chengfei Lin, and Boqi Weng. 2024. "Research Advancements in Swine Wastewater Treatment and Resource-Based Safe Utilization Management Technology Model Construction" Water 16, no. 5: 661. https://doi.org/10.3390/w16050661