The Prediction Methods for Potential Suspended Solids Clogging Types during Managed Aquifer Recharge

Abstract

:1. Introduction

2. Materials and Methods

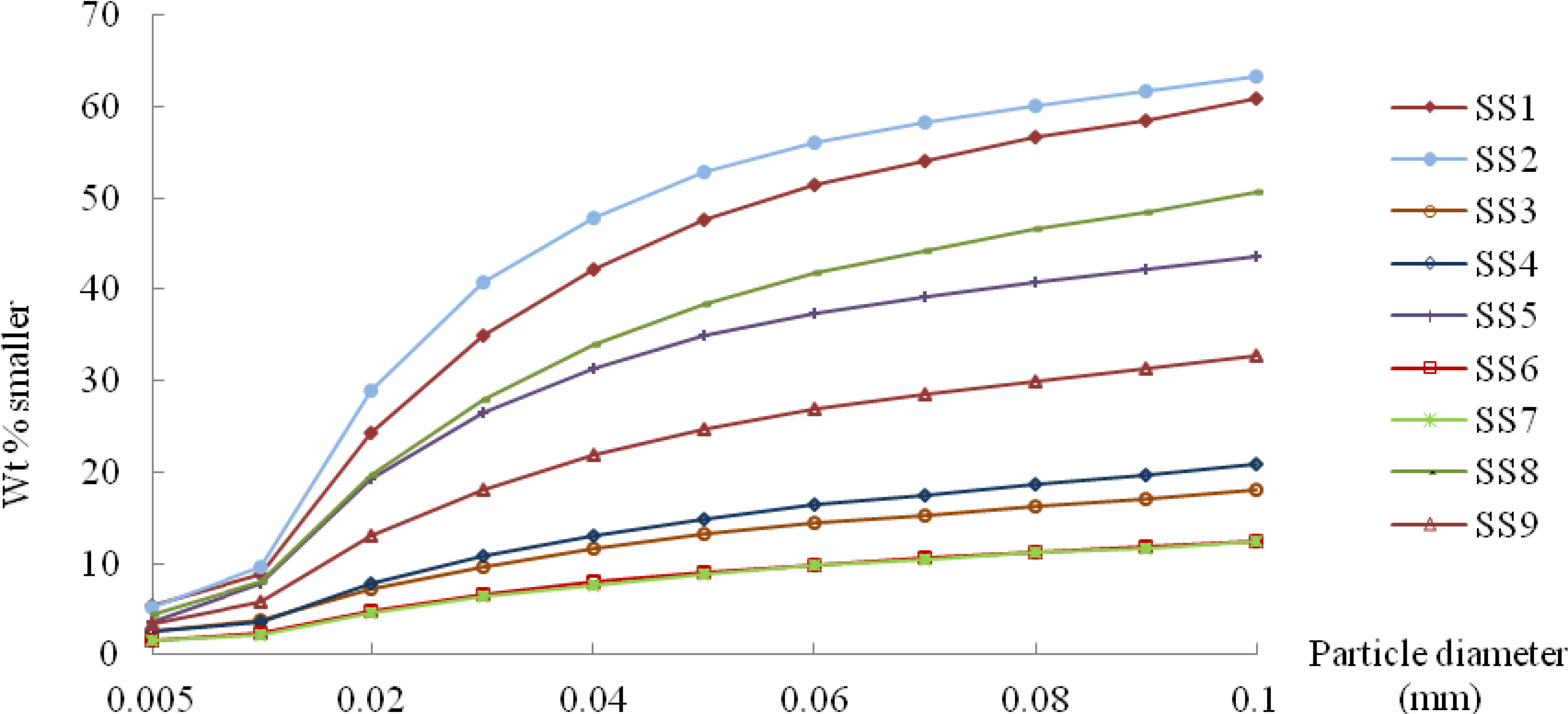

2.1. Lab-Based Approach

| Sample No. | SS1 | SS2 | SS3 | SS4 | SS5 | SS6 | SS7 | SS8 | SS9 |

|---|---|---|---|---|---|---|---|---|---|

| Quartz | 37 | 42 | 46 | 47 | 38 | 43 | 56 | 47 | 49 |

| Alkali feldspar | 11 | 16 | 17 | 22 | 11 | 14 | 10 | 14 | 15 |

| Plagioclase | 20 | 23 | 21 | 22 | 18 | 30 | 21 | 22 | 21 |

| Calcite | 8 | 3 | 4 | 4 | 4 | 2 | 4 | 8 | 6 |

| Illite-smectite mixed-layer | 6 | 2 | 2 | 0 | 4 | 3 | 3 | 4 | 0 |

| Illite | 12 | 8 | 6 | 0 | 15 | 5 | 2 | 0 | 6 |

| Kaolinite | 5 | 5 | 3 | 4 | 9 | 3 | 4 | 4 | 3 |

| Amphibole | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 |

| Experiment No. | Medium and Dp (mm) | di (mm) | Dp/d10 | Dp/d20 | Dp/d30 | Dp/d40 | Dp/d50 | Dp/d60 | Dp/d70 | Dp/d80 | Dp/d90 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| E2 | Coarse sand (I), 0.453 | <0.013 | 453.0 | 348.5 | 266.5 | 215.7 | 181.2 | 151.0 | 129.5 | 105.4 | 80.89 |

| E4 | Coarse sand (II), 0.108 | 0.075–0.05 | 2.08 | 2.00 | 1.93 | 1.86 | 1.77 | 1.71 | 1.64 | 1.59 | 1.52 |

| E5 | 0.05–0.0385 | 2.77 | 2.70 | 2.63 | 2.57 | 2.51 | 2.45 | 2.35 | 2.30 | 2.25 | |

| E6 | <0.0385 | 13.50 | 12.00 | 10.80 | 9.82 | 8.31 | 7.20 | 6.35 | 5.40 | 4.15 | |

| E7 | <0.013 | 108.0 | 83.08 | 63.53 | 51.43 | 43.20 | 36.00 | 30.86 | 25.12 | 19.29 | |

| E9 | Medium sand, 0.066 | 0.075–0.05 | 1.27 | 1.22 | 1.18 | 1.14 | 1.08 | 1.05 | 1.00 | 0.97 | 0.93 |

| E10 | 0.05–0.0385 | 1.69 | 1.65 | 1.61 | 1.57 | 1.53 | 1.50 | 1.43 | 1.40 | 1.38 | |

| E11 | <0.0385 | 8.25 | 7.33 | 6.60 | 6.00 | 5.08 | 4.40 | 3.88 | 3.30 | 2.54 | |

| E12 | <0.013 | 66.00 | 50.77 | 38.82 | 31.43 | 26.40 | 22.00 | 18.86 | 15.35 | 11.79 | |

| E14 | Fine sand, 0.046 | 0.075–0.05 | 0.88 | 0.85 | 0.82 | 0.79 | 0.75 | 0.73 | 0.70 | 0.68 | 0.65 |

| E15 | 0.05–0.0385 | 1.18 | 1.15 | 1.12 | 1.10 | 1.07 | 1.05 | 1.00 | 0.98 | 0.96 | |

| E16 | <0.0385 | 5.75 | 5.11 | 4.60 | 4.18 | 3.54 | 3.07 | 2.71 | 2.30 | 1.77 | |

| E17 | <0.013 | 46.00 | 35.38 | 27.06 | 21.90 | 18.40 | 15.33 | 13.14 | 10.70 | 8.21 | |

| E19 | Mixed sand (I), 0.078 | 0.075–0.05 | 1.50 | 1.44 | 1.39 | 1.34 | 1.28 | 1.24 | 1.18 | 1.15 | 1.10 |

| E20 | 0.05–0.0385 | 2.00 | 1.95 | 1.90 | 1.86 | 1.81 | 1.77 | 1.70 | 1.66 | 1.63 | |

| E21 | <0.0385 | 9.75 | 8.67 | 7.80 | 7.09 | 6.00 | 5.20 | 4.59 | 3.90 | 3.00 | |

| E22 | <0.013 | 78.00 | 60.00 | 45.88 | 37.14 | 31.20 | 26.00 | 22.29 | 18.14 | 13.93 |

2.2. Prediction Methods of Suspended Solids Clogging Types

2.2.1. Ratio of Pore Diameter (Dp) and Grain Diameter (d)

2.2.2. Bayesian Discrimination Method

and sample dispersion matrix St/n of the training samples can be used.

and sample dispersion matrix St/n of the training samples can be used.

is the estimate of the kth population average μk;

is the estimate of the kth population average μk;  is the estimate of the population covariance matrix Σ; and Sk is the intragroup covariance matrix of number k population.

is the estimate of the population covariance matrix Σ; and Sk is the intragroup covariance matrix of number k population.

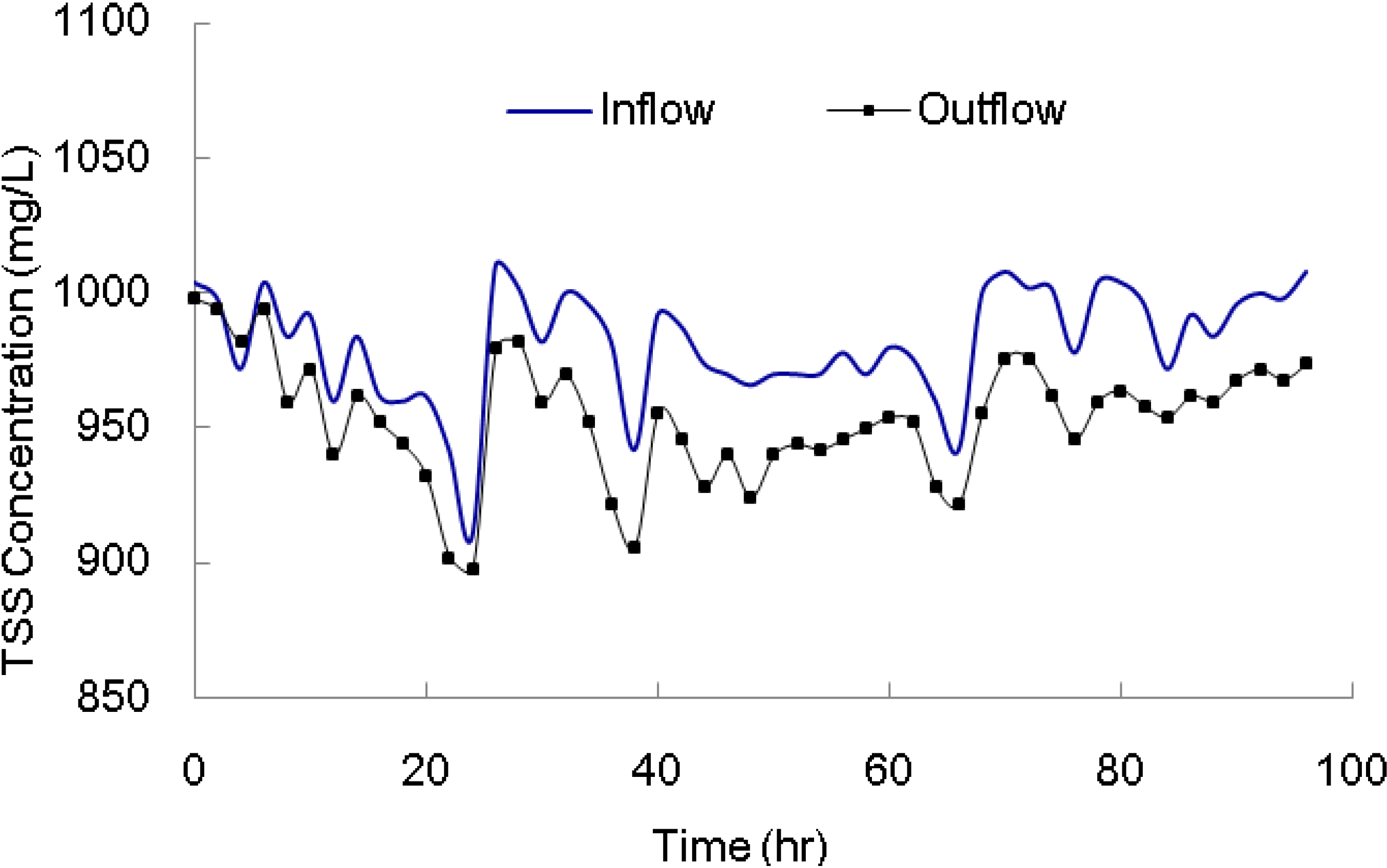

2.3. Case Verification

3. Results and Discussion

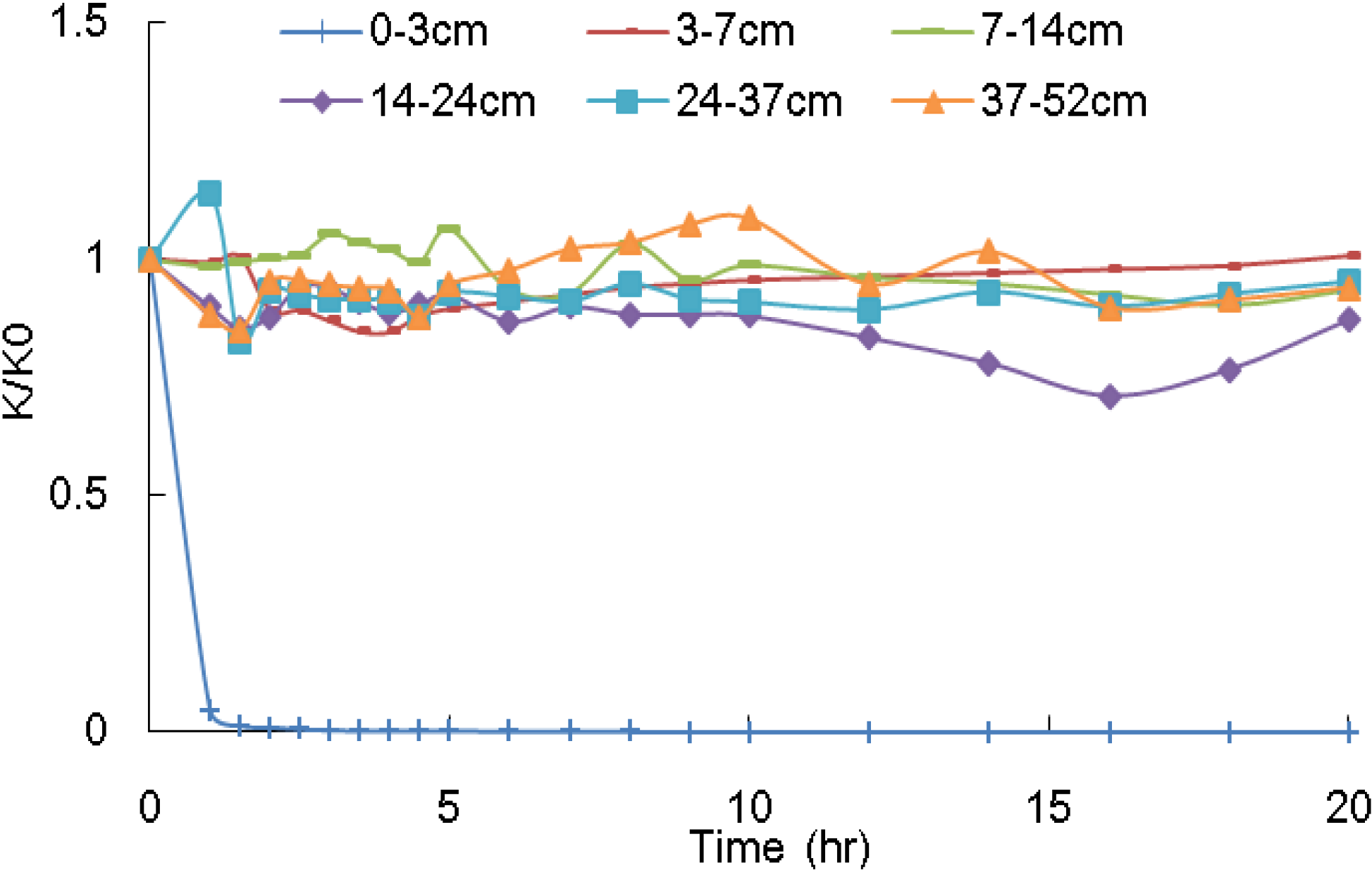

3.1. Suspended Solids Clogging Types

3.1.1. Surface Clogging (S)

3.1.2. Inner Clogging (I)

3.1.3. Mixed Clogging (M)

3.2. Judgment Criteria of Suspended Solids Clogging Types

| Experiment No. | Clogging type | Experiment No. | Clogging type | Experiment No. | Clogging type |

|---|---|---|---|---|---|

| E2 | I | E10 | S | E17 | M |

| E4 | M | E11 | S | E19 | S |

| E5 | M | E12 | M | E20 | S |

| E6 | M | E14 | S | E21 | M |

| E7 | M | E15 | S | E22 | M |

| E9 | S | E16 | S | ||

3.2.1. Ratio of Pore Diameter and Grain Diameter

3.2.2. Bayesian Discrimination Method

3.3. Case Verification Results

| Test No. | Experimental observations | Dp/d50 | Bayesian method predict result | |||

|---|---|---|---|---|---|---|

| Dp (mm) | d50 (mm) | Dp/d50 | Predict result | |||

| T1 | S | 0.078 | 0.023 | 3.41 | S | S |

| T2 | S | 0.074 | 0.023 | 3.23 | S | S |

| T3 | S | 0.807 | 0.023 | 35.24 | M | S |

4. Conclusions

Acknowledgments

Authors Contributions

Conflicts of Interest

References

- Dillon, P.; Pavelic, P.; Toze, S.; Rinck-Pfeiffer, S.; Martin, R.; Knapton, A.; Pidsley, D. Role of aquifer storage in water reuse. Desalination 2006, 188, 123–134. [Google Scholar] [CrossRef]

- Bouwer, H. Artificial recharge of groundwater: Hydrogeology and Engineering. Hydrogeol. J. 2008, 10, 121–142. [Google Scholar] [CrossRef]

- Du, X.; Ye, X.; Lu, Y.; Chi, B.; Birk, S.; Yang, Y. Research progress of artificial recharge clogging problem. Adv. Earth Sci. 2009, 24, 973–980. [Google Scholar]

- Bekele, E.; Toze, S.; Patterson, B.; Higginson, S. Managed aquifer recharge of treated wastewater: Water quality changes resulting from infiltration through the vadose zone. Water Res. 2011, 45, 5764–5772. [Google Scholar] [CrossRef]

- Quanrud, D.; Hafer, J.; Karpiscak, M.; Zhang, H.; Lansey, K.; Arnold, R. Fate of organics during soil-aquifer treatment: Sustainability of removals in the field. Water Res. 2003, 37, 3401–3411. [Google Scholar] [CrossRef]

- Vanderzalm, J.; Page, D.; Barry, K.; Dillon, P. A comparison of the geochemical response to different managed aquifer recharge operations for injection of urban stormwater in a carbonate aquifer. Appl. Geochem. 2010, 25, 1350–1360. [Google Scholar] [CrossRef]

- Montgomery-Brown, J.; Drewes, J.; Fox, P.; Reinhard, M. Behavior of alkylphenol polyethoxylate metabolites during soil aquifer treatment. Water Res. 2003, 37, 3672–3681. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, X.; Liu, C.; Shi, H.; Hu, H. Nitrogen removal enhanced by intermittent operation in a subsurface wastewater infiltration system. Ecol. Eng. 2005, 25, 419–428. [Google Scholar] [CrossRef]

- Schafer, A.; Ustohal, P.; Harms, H.; Stauffer, F.; Dracos, T.; Zehnder, A. Transport of bacteria in unsaturated porous media. J. Contam. Hydrol. 1998, 33, 149–169. [Google Scholar] [CrossRef]

- Toze, S.; Bekele, E.; Page, D.; Sidhu, J.; Shackleton, M. Use of static Quantitative Microbial Risk Assessment to determine pathogen risks in an unconfined carbonate aquifer used for Managed Aquifer Recharge. Water Res. 2010, 44, 1038–1049. [Google Scholar] [CrossRef]

- Anders, R.; Chrysikopoulos, C.V. Virus fate and transport during artificial recharge with recycled water. Water Resour. Res. 2005, 41. [Google Scholar] [CrossRef]

- Lindsey, G.; Roberts, L.; Page, W. Inspection and maintenance of infiltration Facilities. Soil Water Conserv. 1992, 47, 481–486. [Google Scholar]

- Frycklund, C. Artificial Recharge of Groundwater for Public Water Supply. Potential and Limitations in Boreal Conditions. Ph.D. Thesis, Department of Civil Engineering, Royal Institute of Technology (KTH), Stockholm, Sweden, 1998. [Google Scholar]

- Chrysikopoulos, C.V.; Masciopinto, C.; La Mantia, R.; Manariotis, I.D. Removal of biocolloids suspended in reclaimed wastewater by injection in a fractured aquifer model. Environ. Sci. Technol. 2010, 44, 971–977. [Google Scholar] [CrossRef]

- Rinck-Pfeiffer, S.; Ragusa, S.; Sztajnbok, P.; Vandevelde, T. Interrelationships between biological chemical and physical processes as an analog to clogging in aquifer storage and recovery (ASR) wells. Water Res. 2000, 34, 2110–2118. [Google Scholar] [CrossRef]

- Sniegocki, R.T.; Brown, R.F. Clogging in Recharge Wells, Causes and Cures. In Proceedings of Artificial GRoundwater Recharge Conference, University of Reading, Reading, England, 21–24 September 1970; pp. 337–352.

- Frycklund, C. Artificial Groundwater Recharge State of the Art. Report 1992-04; Svenska vatten- och avloppsverksföreningen: Stockholm, Sweden, 1998. [Google Scholar]

- Custodio, E.; Isamat, J.; Miralles, J. Twenty-five years of groundwater recharge in Barcelona (Spain). Artif. Groundw. Recharg. 1982, 11, 171–192. [Google Scholar]

- Iwasaki, T. Some notes on sand filtration. J. Am. Water Works Assoc. 1937, 29, 1591. [Google Scholar]

- Phipps, D.; Lyon, S.; Hutchinson, A. Development of a percolation decay model to guide future optimization of surface water recharge basins. In Proceedings of the 6th International Symposium on Managed Aquifer Recharge, ISMAR 6, Phoenix, AZ, USA, 27 October–2 November 2007.

- McDowell-Boyer, L.M.; Hunt, J.R.; Sitar, N. Particle transport through porous media. Water Resour. Res. 1986, 22, 1901–1921. [Google Scholar] [CrossRef]

- Pavelic, P.; Dillon, P.J.; Barry, K.E.; Herczeg, A.L.; Rattray, K.J.; Hekmeijer, P.; Gerges, N.Z. Well clogging effects determined from mass balances and hydraulic response at a stormwater ASR site. In Proceedings of the 3rd International Symposium on the Artificial Recharge of Ground Water, Amsterdam, Netherlands, 21–25 September 1998; Peters, J.H., Karsten, H.J., Eds.; Balkema: Amsterdam, the Netherlands; pp. 61–66.

- Schippers, J.C.; Verdouw, J. The modified fouling index, a method of determining the fouling characteristics of water. Desalination 1980, 32, 137–148. [Google Scholar] [CrossRef]

- Hauser, V.L.; Lotspeich, F.B. Artificial groundwater recharge through wells. J. Soil Water Conserv. 1967, 22, 11–15. [Google Scholar]

- Vecchioli, J. Experimental injection of tertiary treated sewage in a deep well at Bay Park, Long Island, NY. New England. Water Works Assoc. 1972, 86, 87–103. [Google Scholar]

- Siriwardene, N.R.; Deletic, A.; Fletcher, T.D. Clogging of stormwater gravel infiltration systems and filters-Insights from a laboratory study. Water Res. 2007, 41, 1433–1440. [Google Scholar] [CrossRef]

- Okubo, T.; Matsumoto, J. Biological clogging of sand and changes of organic constituents during artificial recharge. Water Res. 1983, 17, 813–821. [Google Scholar] [CrossRef]

- Winter, K.J.; Goetz, D. The impact of sewage composition on the soil clogging phenomena of vertical flow constructed wetlands. Water Sci. Technol. 2003, 48, 9–14. [Google Scholar]

- Glover, P.W.J.; Walker, E. Grain-size to effective pore-size transformation derived from electrokinetic theory. Geophysics 2009, 74, 17–29. [Google Scholar] [CrossRef]

- Lachenbruch, P A. Discriminant Analysis. Macmillan Pub Co.: New York, NY, USA, 1975. [Google Scholar]

- Wang, Z.; Du, X.; Yang, Y.; Ye, X. Surface clogging process modeling of suspended solids during urban stormwater aquifer recharge. J. Environ. Sci. 2012, 24, 1418–1424. [Google Scholar] [CrossRef]

- Aldenderfer, M.S.; Blashfield, R.K. Cluster Analysis, 3rd ed.SAGE Publications Inc.: New York, NY, USA, 1984. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Du, X.; Fang, Y.; Wang, Z.; Hou, J.; Ye, X. The Prediction Methods for Potential Suspended Solids Clogging Types during Managed Aquifer Recharge. Water 2014, 6, 961-975. https://doi.org/10.3390/w6040961

Du X, Fang Y, Wang Z, Hou J, Ye X. The Prediction Methods for Potential Suspended Solids Clogging Types during Managed Aquifer Recharge. Water. 2014; 6(4):961-975. https://doi.org/10.3390/w6040961

Chicago/Turabian StyleDu, Xinqiang, Yunqing Fang, Zijia Wang, Jiawei Hou, and Xueyan Ye. 2014. "The Prediction Methods for Potential Suspended Solids Clogging Types during Managed Aquifer Recharge" Water 6, no. 4: 961-975. https://doi.org/10.3390/w6040961

APA StyleDu, X., Fang, Y., Wang, Z., Hou, J., & Ye, X. (2014). The Prediction Methods for Potential Suspended Solids Clogging Types during Managed Aquifer Recharge. Water, 6(4), 961-975. https://doi.org/10.3390/w6040961